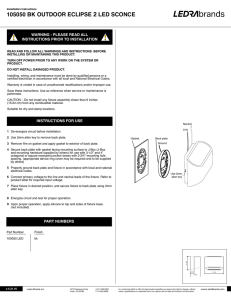

+ THERM H-I/H-V Planning Timber curtain wall THERM+ H-I/H-V Integration elements Integration elements FRAME+ Integration elements WING THERM+ H-I/H-V Thermal insulation Basics Uf values THERM+ curtain wall systems THERM+ H-I System sections THERM+ H-V Assembly options Connector technology Glazing/Sealing technology Accessories Connection profiles Statics THERM+ H-I Add-ons Burglar resistant curtain wall WK2 Burglar resistant curtain wall WK3 Structural Glazing SG2 THERM+ H-I Assembly options THERM+ H-V Add-ons THERM+ H-V System sections THERM+ H-V System sections System benefits System sections 50/56/76 mm Assembly options Polygon glazing system Cover/Pressure profile options Building connections THERM+ H-V Add-ons THERM+ H-I Assembly options Connector technology Glazing/Sealing technology Accessories Connection profiles Statics THERM+ H-V Assembly options Burglar resistant curtain wall WK2 Burglar resistant curtain wall WK3 Fire resistant curtain wall F30 (EI30) Structural Glazing SG2 THERM+ H-I/H-V Integration elements THERM+ H-I Add-ons THERM+ H-I/H-V Thermal insulation THERM+ H-I System sections System benefits System sections 50/56/76/96 mm Assembly options Polygon glazing system Cover/Pressure profile options Building connections 2016 3 4 2016 THERM+ H-I System sections Content System benefits Technology in detail Tests Variants TC timber connector Ventilation Sealing system 7 9 10 12 14 18 System sections System width 50 mm System width 56 mm System width 76 mm System width 96 mm Building connections 50/56/76 mm 19 44 68 87 92 2016 5 6 2016 THERM+ H-I Timber curtain wall 50/56/76/96 mm Technology in detail ■ Excellent product properties – System widths 50, 56, 76 and 96 mm. – Infill thickness from 6 to 64 mm. – Maximal energy saving by variable thermal insulation with insulating block options up to Uf= 0.80 W/(m²K) including screw influence. – All profiles can be used as well for mullions as for transoms. ■ Optimum planning – Glass load transmission for very high glass weights up to 600 kg. – Vertical curtain wall. – Construction as polygon curtain wall up to 45° with system accessories. – No components lasting from the outside to the timber construction. – Entire imposed load and load transmission tested. – Extensive system accessories. ■ Efficient installation – Two types of aluminium base profiles for screw connection: With or without positioning foot in the area of the timber structural profile. – Solid timber connector technology in the options SOLO and KOMBI, tested according to The European Technical Approval (ETA). – Integrated drainage at the continuous gasket in three levels. – Safe fixation of all construction elements in the continuous aluminium screw channel. – Easy and quick screwing of base profiles also with magazine screw driver possible. THERM+ Timber H-I with insulating block P 19 SH-0005 2016 7 THERM+ H-I System sections System benefits THERM+ H-I System benefits Timber curtain wall 50/56/76/96 mm Technology in detail ■ Pressure and cover profiles for curtain wall and roof light applications – Wide selection of various types as well as system widths. – Individual solutions for objects in a short time available. – Visually especially attractive flat pressure profile with an offset of only 4 mm above the glass surface. – Ideal cross point sealing by special accessories. – Timber cover profiles to clip available. ■ Base profiles – Suitable for all system variations. – Improved screw channel for optimum thermal break. – Specific gasket holding fixture for easy fixing of the silicon-free EPDM gasket. – Slottet holes for integrated expansion compensation. – With or without foot. ■ Connector system for timber curtain wall – Highly efficient and time-saving. – All machining is in transoms. – Few special screws required for maximum load-bearing capacity. – Stable connection for high glass loads. – Extremely fast construction site assembly: Push in transoms and screw together. – Transoms can be dismantled at any time. – No adjustment needed thanks to the automatically flush stop. – Tested with infill thicknesses of up to 64 mm. – Seven installation depths for transom depths from 60 to 300 mm. – Tested according to ETA-13/0765. 8 2016 THERM+ H-I Timber curtain wall 50/56/76 mm THERM+ – Certified quality, CE-conform and tested THERM+ quality you can rely upon. Extensive product tests with excellent results confirm the high quality in practical applications of the THERM+ curtain wall system. ■ Product standard for curtain walling EN 13830: Features and classification for the CE-Labelling. No. Test type/Standard Classification/Result Testing institute/Test no. 4.1 Wind resistance (EN 13116) Permissible load 2.5 KN/m2 Increased load 3.75 KN/m2 ift Rosenheim No. 10-000502 4.3 Resistance against impact (if specially requested) (EN 14019) Interior I5 Exterior E5 ift Rosenheim No. 10-000502 4.4 Air permeability (EN 12152) AE (>600) ift Rosenheim No. 10-000502 4.5 Water penetration (EN 12154) RE 2100 ift Rosenheim No. 10-000502 4.6 Airborne sound insulation (if specially requested) (EN ISO 140-3) RW(C;Ctr) = 36 (-1;-3) dB RW(C;Ctr) = 41 (-2;-5) dB RW(C;Ctr) = 41 (-3;-7) dB RW(C;Ctr) = 46 (-1;-5) dB RW(C;Ctr) = 49 (-2;-4) dB ift Rosenheim No. 10-000502 4.7 Thermal transmittance (UCW-value) (EN 13947) Calculation with data from RAICO Uf-value tables EN 13947 (calculation) ■ Notice – All features can be used for CE-Labelling by the manufactures of curtain walls. It is mandatory that only RAICO products has to be used and the production process has to be monitored by an in-house production control system. The whole production process has to be compliant to the RAICO assembly instructions. – Depending on the panel dimensions of the curtain wall and the structural connections the sound insulation value has to be calculated separately. The system testimonial can only be used for an overview. – Depending on the different systems options and the glass thickness the Uf-value can be adapted step-by-step. The exacts values based on DIN EN ISO 10077-2 are documented in the thermal protection documentations by RAICO. ■ Additional approvals and certifications Test Result Description German general approval: clamping joint for the curtain wall system - Fixing of base profile - Screw channel of mullion-transom profiles - Pressure profiles - Screws German general approval for the DIBt, Berlin fixing system THERM+ H-I Timber No. Z-14.4-455 curtain wall European Technical Approval: Connector types with max. vertical SOLO/KOMBI timber mullion- loads (characteristic resistance) transom connectors Glass roof with 2° inclination: Air permeability Water penetration Wind resistance Burglar prevention European Technical Approval for timber mullion-transom connection system THERM+ Class AE including accessories Criteria for glass roofs until 2° inclination fulfilled for all system (e. g. sun protection fixation) Class RE 2550 including accessories widths (e. g. sun protection fixation) test load 2600 Pa, safety 3900 Pa (e. g. sun protection fixation) Resistance class WK 2 for system Test THERM+ H-I Testing institute/Test no. ETA-Denmark No. ETA-13/0765 ift Rosenheim No. 13-002240-PR01 widhts 50, 56 and 76 mm according to DIN EN 1627 ff. ift Rosenheim No. 21121747 Burglar prevention Resistance class WK 3 for system widhts 50, 56 and 76 mm Test THERM+ H-I according to DIN EN 1627 ff. ift Rosenheim No. 21122229 Fall protection Criteria of DIN 18008-4 (technical rules for fall proof glazing) fulfilled Criteria fulfilled Passive house curtain wall Ucw ≤ 0.8 W/m2K of system THERM+ H-I 50, 56, 76 with insulating block P Fulfilment all criteria for components suitable for passive houses passive house institute Dr. Feist certificate 2016 9 THERM+ H-I System sections System benefits THERM+ H-I System benefits Timber curtain wall 50/56/76/96 mm Curtain wall options/drainage system ■ Structural Glazing SG2 – System widths 50 or 56 mm. – Glazing system for optical exclusive SG curtain wall. – Maximum thermal insulation by special insulating block SG. – Simple and economic processing. – Without visible physcial protections up to an assembly height of 8 m. ■ Burglar proof curtain wall WK2/WK3 – System widths 50, 56 and 76 mm. – Resistance class WK2 and WK3 permitted. – Simple processing. – Identical technology to the basic system. ■ Fire protection F30 (EI30) – System widths 50 or 56 mm. – Fire protection curtain walls F30 (EI30). – Glass dimension up to 1,500 mm x 3,000 mm horizontal and vertical. – Simple processing. – Identical technology to the basic system. ■ Drainage system – The drainage groove of the mullion and transom gasket is arranged in various levels. – In all THERM+ systems the ventilation and drainage principle is so designed that a controlled condensate removal from transom to the mullion rebate is secured via interior gaskets. 10 2016 HSG-0001, HWK-0001, H-EI30-0001, SH-0001 THERM+ H-I Timber curtain wall 50/56/76/96 mm Gasket options ■ Exterior gasket – Various exterior gaskets and insulating block options available. Standard exterior gasket – Gradual adaptation of the insulation value. – Maximum thermal insulation up to Uf= 0.80 W/(m²K) including screw influence. Insulating block 9 – Certified passive house curtain wall. – Economic solution. Insulating block 21 Insulating block P ■ Transom and mullion gaskets – Optimised shape for maximum thermal insulation and efficient fabrication. – Complete covering and sealing of the base prof ile. Mullion gasket Transom gasket – Perfect and easy fitting on the structural profile (without silicone). – Two options of gaskets with flaps for transom and base drainage as well as draining within the continuous gasket at the structural connections. Base transom gasket, flap Gasket for transom, flap – Reliable drainage in two or three levels by simply notching. – Proved up to 2° roof inclination. – Special accessories for all applications, e. g. transom and mullion sealing elements. Polygon gasket Mullion gasket Single glazing Expansion mullion gasket HI-0084 2016 11 THERM+ H-I System sections System benefits THERM+ H-I System benefits Timber curtain wall 50/56/76/96 mm Variants TC Timber connector ■ SOLO – Tensioned with nail screws. – Safe and tested dispersal of glass weights. – Inserted invisibly between mullion and transom. – Tested according to ETA-13/0765. – Safe dispersal of the glass loads and resulting torsion forces via the timber structure. – Seven installation depths for transom depths from 60 to 300 mm. – Installation in a few simple steps and minimum processing. – Integrated longitudinal stop and transom contact pressure over the entire depth for a perfect T-connection. ■ KOMBI – Tensioned with nail screws through the transom base profile. – Safe and tested dispersal of glass weights. – Inserted invisibly between mullion and transom. – Tested according to ETA-13/0765. – Safe dispersal of the glass loads and resulting torsion forces via the timber structure. – Seven installation depths for transom depths from 60 to 300 mm. – Installation in a few simple steps and minimum processing. – Integrated longitudinal stop and transom contact pressure over the entire depth for a perfect T-connection. ■ Super-simple installation – Highly efficient and time-saving. – All machining is in transoms. – Few special screws required for maximum load-bearing capacity. – Stable connection for high glass loads. – Extremely fast construction site assembly: Push in transoms and screw together. – Transoms can be dismantled at any time. – No adjustment needed thanks to the automatically flush stop. 12 2016 THERM+ H-I Timber curtain wall 50/56/76/96 mm Variants TC Timber connector ■ High loading capacity on european standard The new timber connector is tested according to the current guideline ETAG 015 and certified with the european technical approval ETA-13/0765. In comparison to the previous timber connector now the infill thickness of 64 mm is tested and also part of the aforementioned approval. Due to detail improvements the new timber connector which is available in the versions SOLO and KOMBI characterises a much more rational and technical superior assembly. – Static calculation possible on the base of the Eurocodes. – The denoted loads of the connector are based on a minimum apparent density of 350 kg/m³, with the use of timber or derived timber products with a higher apparent density the loads can be increase up to an apparent density of 500 kg/m³. Admissible loads in consideration of the apparent density TC SOLO Apparent density 350 kg/m3 400 kg/m3 450 kg/m3 500 kg/m3 Maximum glass load* per transom in kg Type of connector TC 60 SOLO 380 kg/m3 *it is imperative to respect the ETA-13/0765 116 119 120 124 126 TC 80 SOLO 138 141 143 147 151 TC 100 SOLO 162 167 170 176 182 TC 120 SOLO 182 188 191 198 205 TC 160 SOLO 218 225 229 239 248 TC 200 SOLO 250 258 263 274 286 TC 240 SOLO 276 285 291 305 317 450 kg/m3 500 kg/m3 Admissible loads in consideration of the apparent density TC KOMBI Apparent density 350 kg/m3 380 kg/m3 400 kg/m3 Maximum glass load* per transom in kg Type of connector *it is imperative to respect the ETA-13/0765 TC 60 KOMBI 253 256 257 260 263 TC 80 KOMBI 274 278 279 284 288 387 TC 100 KOMBI 367 372 375 381 TC 120 KOMBI 388 393 396 403 410 TC 160 KOMBI 423 430 434 444 453 TC 200 KOMBI 455 463 468 480 491 TC 240 KOMBI 481 490 496 510 523 KH-0520 2016 13 THERM+ H-I System sections System benefits THERM+ H-I System benefits Timber curtain wall 50/56/76/96 mm Isothermal lines Especially for aluminium curtain walls and conservatories it is essential for long term function and maximum satisfaction of the clients to offer a well-performing thermal insulation and an optimized isothermal line. Only high quality systems which correspond to both requirements can avoid the formation of condensate. ■ Isothermal lines – Double glazing with Ug=1.1 W/(m2K) and acrylic spacer. – Already with standard exterior gaskets the 10°C- isothermal line remains completely within the system. – Condensate is avoided efficiently. – Individual adaption at higher risk of condensation is possible (e. g. conservatories and swimming pools). THERM+ 50 H-I with acrylic spacer ■ Formation of condensate – The humidity in the room can no longer be absorbed by the air. Due to the outstanding thermal insulation already with standard gaskets as well as the insulating effect of acrylic spacers the isothermal line does not touch the surface of the structure. – The humidity builds up drops on building compoments with low surface temperatures. – Movement of the drop formation of insulating glass towards the area of the spacer an the frame of the curtain wall system. – Appearing of condensate at standardized conditions of 50% humidity and 20°C temperature on surfaces with a temperaure of 10°C. ■ Influence of the curtain wall system – The surface temperature on the inside of the curtain wall system does not decrease below 10°C even when the exterior temperature is 10°C below zero. – 10°C-isothermal line of the THERM+ system remains completely within the system and condensate is efficiently avoided. THERM+ 50 H-I with aluminium spacer ■ Influence of the glass spacer – Besides the thermal insulation of the curtain wall system the type of spacer and glass edge is another important factor. Here the isothermal line is less advantageous due to the influence of the aluminium spacer. – The spacer which is a thermal bridge transfers temperatures deep into the frame of the curtain wall system. – Use of glass spacers which offer a maximum thermal insulation (e. g. acrylic or steel). 14 2016 HI-0001 THERM+ H-I Timber curtain wall 50/56/76/96 mm Ventilation options Option I a: Pressure compensation via mullion – connection below/on top The ventilation and the condensate removal of the glazing rebate is effected via the four corners of every infill unit in the mullion profiles and across an on-site adapter construction. ■ Technical information – T44 = Foil connection behind drainage level – T45 = Collateral pressure compensation – T48 = Ventilation – T49 = Ventilation – T138 = Maximum 8 m resp. maximum 8 panels – T139 = All other 8 m resp. 8 panels KH-0100 2016 15 THERM+ H-I System sections System benefits THERM+ H-I System benefits Timber curtain wall 50/56 mm Ventilation options Option I b: Pressure compensation via mullion and synthetic sealing piece The ventilation and the condensate removal of the glazing rebate is effected via the four corners of every infill unit in the mullion profiles and addtional with a sealing piece via an opening of pressure profiles in the mullion area. Synthetic sealing piece: System widths 50 mm: No. 167140 PU = 10 pieces System widths 56 mm: No. 167145 PU = 10 pieces ■ Technical information – T44 = Foil connection behind drainage level – T45 = Collateral pressure compensation – T48 = Ventilation – T49 = Ventilation – T138 = Maximum 8 m resp. maximum 8 panels – T139 = All other 8 m resp. 8 panels 16 2016 KH-0102 THERM+ H-I Timber curtain wall 50/56/76/96 mm Ventilation options Option II: Pressure compensation of extra large transoms via pressure and cover profiles An additional opening result from a transom width of 1200 mm, two additional openings result from a transom width of 1800 mm in the pressure and cover profiles (options II a and II b). The number of openings depends on the transom length, the individual project and glazing requirements and must be determined in accordance with the glass supplier. to ■ Technical information – T121 = Option II a – T122 = Option II b KH-0101 2016 17 THERM+ H-I System sections System benefits THERM+ H-I System benefits Timber curtain wall 50/56/76 mm Interior sealing system 3 drainage levels ■ Technical information – T38 = Level 2. – T39 = Level 3. – T40 = Level 1. – T151 = Interior gasket E3. – T152 = Interior gasket E2. – T153 = Interior gasket E1. 7.5 – T159 = Interior gasket E2 with flap. 18 2016 K-0011 THERM+ H-I Timber curtain wall Certified passive house curtain wall with insulating block P 50/39 Mullion section/transom section ■ Technical information ■ Profiles – Certified by passive house institute Dr. Feist. Article No. PU – Uf-values see chapter Thermal insulation. Cover profile 50/15 013003 6m – T1 = Depths from 50 mm. Cover profile 50/12 013004 6m Pressure profile 47 punched 118005 6m Base profile 41 punched 145005 6m ■ Gaskets Article No. PU Gasket for pressure profile 5 011073 100 m Gasket for mullion 50 150005 20 m Gasket for transom 50 150010 20 m Insulating block P 50/39 168514 50 m No. PU 012029 100 pc(s) 012124 100 pc(s) 016050 10 pc(s) 152010 100 pc(s) 152401 10 pc(s) Glass carrier 43 to 44 162080 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x62 Crosspoint sealing plate 50 Sealing piece for transom 50 Sealing piece for pressure profile 50/5 HI-0084 2016 19 THERM+ H-I System sections System sections 50 mm THERM+ H-I System sections 50 mm Timber curtain wall Certified passive house curtain wall, insulating block P 50/39, base profile for groove installation Mullion section/transom section ■ Technical information ■ Profiles – Certified by passive house institute Dr. Feist. Article No. PU – Uf-values see chapter Thermal insulation. Cover profile 50/15 013003 6m Cover profile 50/12 013004 6m 118005 6m 145021 6m – T1 = Depths from 50 mm. Pressure profile 47 punched Base profile 41 with foot punched ■ Gaskets Article No. PU Gasket for pressure profile 5 011073 100 m Gasket for mullion 50 150005 20 m Gasket for transom 50 150010 20 m Insulating block P 50/39 168514 50 m No. PU 012029 100 pc(s) 012124 100 pc(s) 016050 10 pc(s) 152010 100 pc(s) 152401 10 pc(s) Glass carrier 43 to 44 162080 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x62 Crosspoint sealing plate 50 Sealing piece for transom 50 Sealing piece for pressure profile 50/5 20 2016 HI-0171 THERM+ H-I Timber curtain wall Insulating block P 50/19 Mullion section/transom section ■ Technical information ■ Profiles – The type of insulating block P depends on the infill thickness: - 24 to 29 mm: insulating block P 50/19, No. 168509 - 30 to 43 mm: insulating block P 50/25, No. 168510 - 44 to 64 mm: insulating block P 50/39, No. 168514. Article – Uf-values see chapter Thermal insulation. – T1 = Depths from 50 mm. No. PU Cover profile 50/15 013003 6m Cover profile 50/12 013004 6m Pressure profile 47 punched 118005 6m Base profile 41 punched 145005 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 50 150005 20 m Gasket for transom 50 150010 20 m Insulating block P 50/19 168509 50 m No. PU 012029 100 pc(s) 012114 100 pc(s) 014035 10 pc(s) 016050 10 pc(s) 152010 100 pc(s) Glass carrier 25 to 26 162035 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x42 Sealing piece for pressure profile 50 Crosspoint sealing plate 50 Sealing piece for transom 50 HI-0088 2016 21 THERM+ H-I System sections System sections 50 mm THERM+ H-I System sections 50 mm Timber curtain wall Insulating block 21 Mullion section/transom section ■ Technical information ■ Profiles – Uf-values see chapter Thermal insulation. Article – T1 = Depths from 50 mm. No. PU Cover profile 50/15 013003 6m Cover profile 50/12 013004 6m Pressure profile 47 punched 118005 6m Base profile 41 punched 145005 6m ■ Gaskets Article No. PU Gasket for mullion 50 150005 20 m Gasket for transom 50 150010 20 m Insulating block 50/21 150605 50 m No. PU 012029 100 pc(s) 012115 100 pc(s) 014035 10 pc(s) 016050 10 pc(s) 152010 100 pc(s) Glass carrier 27 to 28 162040 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x45 Sealing piece for pressure profile 50 Crosspoint sealing plate 50 Sealing piece for transom 50 22 2016 HI-0014 THERM+ H-I Timber curtain wall Insulating block 9 Mullion section/transom section ■ Technical information ■ Profiles – Uf -values see chapter Thermal insulation. Article – T1 = Depths from 50 mm. No. PU Cover profile 50/15 013003 6m Cover profile 50/12 013004 6m Pressure profile 47 punched 118005 6m Base profile 41 punched 145005 6m ■ Gaskets Article No. PU Gasket for mullion 50 150005 20 m Gasket for transom 50 150010 20 m Insulating block 50/9 151010 50 m No. PU 012029 100 pc(s) 012114 100 pc(s) 014035 10 pc(s) 016050 10 pc(s) 152010 100 pc(s) Glass carrier 25 to 26 162035 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x42 Sealing piece for pressure profile 50 Crosspoint sealing plate 50 Sealing piece for transom 50 HI-0010 2016 23 THERM+ H-I System sections System sections 50 mm THERM+ H-I System sections 50 mm Timber curtain wall Standard exterior gasket Mullion section/transom section ■ Technical information ■ Profiles – Uf -values see chapter Thermal insulation. Article – T1 = Depths from 50 mm. No. PU Cover profile 50/15 013003 6m Cover profile 50/12 013004 6m Pressure profile 47 punched 118005 6m Base profile 41 punched 145005 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 50 150005 20 m Gasket for transom 50 150010 20 m No. PU 012029 100 pc(s) 012114 100 pc(s) 014035 10 pc(s) 016050 10 pc(s) 152010 100 pc(s) Glass carrier 25 to 26 162035 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x42 Sealing piece for pressure profile 50 Crosspoint sealing plate 50 Sealing piece for transom 50 24 2016 HI-0001 THERM+ H-I 90° Timber curtain wall Corner mullion 90°, vertical Mullion section/transom section ■ Profiles Article No. PU Cover profile 50/15 013003 6m Pressure profile 47 punched 118005 6m Base profile 41 punched 145005 6m Connection profile 39/22 168021 6m No. PU 011070.LI 100 m 011070.RE 100 m ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for mullion 50 150005 20 m Compensation gasket 2 227010 100 m ■ Accessories Article Pan head tapping screw 5.5x42 Special timber screw 4.5x35 Special countersunk sheet metal screw 4.8x19 HI-0178 No. 012114 908020 908118 2016 PU 100 pc(s) 100 pc(s) 100 pc(s) 25 THERM+ H-I System sections System sections 50 mm THERM+ H-I System sections 50 mm 90° Timber curtain wall Corner mullion 90°, vertical Mullion section/transom section ■ Profiles Article No. PU Cover profile 50/15 013003 6m Pressure profile 47 punched 118005 6m Base profile 41 punched 145005 6m Connection profile 39/22 168021 6m No. PU 011070.LI 100 m 011070.RE 100 m ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for mullion 50 150005 20 m Compensation gasket 2 227010 100 m ■ Accessories Article Pan head tapping screw 5.5x42 Special timber screw 4.5x35 Special countersunk sheet metal screw 4.8x19 26 2016 HI-0177 No. 012114 908020 908118 PU 100 pc(s) 100 pc(s) 100 pc(s) THERM+ H-I Timber curtain wall Corner mullion for variable angles, vertical Mullion section/transom section ■ Profiles Article No. PU Cover profile 50/15 013003 6m Pressure profile 47 punched 118005 6m Base profile 41 punched 145005 6m Connection profile 39/22 168021 6m No. PU 011070.LI 100 m 011070.RE 100 m ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for mullion 50 150005 20 m Compensation gasket 2 227010 100 m ■ Accessories Article Special timber screw 4.5x35 Special countersunk sheet metal screw 4.8x19 HI-0179 No. 908020 908118 2016 PU 100 pc(s) 100 pc(s) 27 THERM+ H-I System sections System sections 50 mm THERM+ H-I System sections 50 mm Timber curtain wall Gasket for transom with flap between mullions Transom section ■ Technical information ■ Profiles – Available for all insulating blocks. Article – T1 = Depths from 50 mm. No. PU Cover profile 50/12 013004 6m Pressure profile 47 punched 118005 6m Base profile 41 punched 145005 6m No. PU 011070.LI 100 m 011070.RE 100 m 150015 20 m No. PU 012029 100 pc(s) 012114 100 pc(s) 014035 10 pc(s) 016050 10 pc(s) 152010 100 pc(s) Glass carrier 25 to 26 162035 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for transom 50 with flap ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x42 Sealing piece for pressure profile 50 Crosspoint sealing plate 50 Sealing piece for transom 50 28 2016 HI-0002a THERM+ H-I Timber curtain wall Continuous base gasket with flap Transom section 50 mm ■ Technical information ■ Profiles – Available for all insulating blocks. Article – Base gasket available up to an infill thickness of 64 mm. – T1 = Depths from 50 mm. No. PU Cover profile 50/12 013004 6m Pressure profile 47 punched 118005 6m Base profile 41 punched 145005 6m Connection profile 36/22 168005 6m No. PU 011070.LI 100 m 011070.RE 100 m 150020 20 m No. PU 012029 100 pc(s) 012114 100 pc(s) 014035 10 pc(s) 016050 10 pc(s) 152010 100 pc(s) 152070 10 pc(s) Glass carrier 25 to 26 162035 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Base gasket for transom 50 with flap ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x42 Sealing piece for pressure profile 50 Crosspoint sealing plate 50 Sealing piece for transom 50 Sealing piece for base transom HI-0002b 2016 29 THERM+ H-I System sections System sections 50 mm THERM+ H-I System sections 50 mm Timber curtain wall Timber cover profile clipped Mullion section/transom section ■ Technical information ■ Profiles – Timber cover profiles are products complementary to the RAICO system components, supplied by the fabricator. It must be assured that the function of the glazing system remains guaranteed by adaptation of the constructional and material characteristics of the timber cover profile. Article – The norms and regulations concerning the use of timber in exterior building areas must be respected. No. PU Pressure profile 44 punched 118505 6m Base profile 41 punched 145005 6m No. PU Gasket for mullion 50 150005 20 m Gasket for transom 50 150010 20 m Gasket for pressure profile 7 H 150510 100 m No. PU 012029 100 pc(s) 012114 100 pc(s) 014035 10 pc(s) 016050 10 pc(s) 152010 100 pc(s) Glass carrier 25 to 26 162035 10 pc(s) Cover profile fixation 80 167005 Special timber screw 4.5x35 908020 ■ Gaskets – Timber cover profiles must be secured mechanically after their installation. Article – For further information see Processing. – T1 = Depths from 50 mm. ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x42 Sealing piece for pressure profile 50 Crosspoint sealing plate 50 Sealing piece for transom 50 30 2016 HI-0107 100 pc(s) 100 pc(s) THERM+ H-I Timber curtain wall Connection of ventilated/non-ventilated curtain wall Transom section ■ Technical information ■ Profiles – For the alternative solution (direct screw connection) attention shall be paid to observing a sufficient tolerance compensation (see Processing). Article No. PU Cover profile 50/12 013004 6m Pressure profile 47 punched 118005 6m Base profile 41 punched 145005 6m Connection profile 45/42 168060 6m No. PU 011070.LI 100 m 011070.RE 100 m 011074 100 m 150015 20 m No. PU 012029 100 pc(s) 012114 100 pc(s) 014035 10 pc(s) Crosspoint sealing plate 50 016050 10 pc(s) Sealing piece for transom 50 152010 100 pc(s) Glass carrier 25 to 26 162035 10 pc(s) Spec. timber screw 4.5x35 908020 100 pc(s) Terminal clamp 47/22 915501 100 pc(s) 2016 31 ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for pressure profile 7 Gasket for transom 50 with flap ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x42 Sealing piece for pressure profile 50 HI-0158 THERM+ H-I System sections System sections 50 mm THERM+ H-I System sections 50 mm Timber curtain wall Interior compensation of varying infill thicknesses Mullion section/transom section ■ Technical information ■ Profiles – Difference between the glass thicknesses from 10 to 24 mm can be compensated without exterior glass offset. Article – T1 = Depths from 50 mm. No. PU Cover profile 50/15 013003 6m Cover profile 50/12 013004 6m 116005 6m 118005 6m 145005 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 50 150005 20 m Gasket for transom 50 150010 20 m Interior gasket 5 220321 100 m No. PU 012029 100 pc(s) 012103 100 pc(s) 012118 100 pc(s) 014035 10 pc(s) Crosspoint sealing plate 50 016050 10 pc(s) Sealing piece for transom 50 152010 100 pc(s) Glass carrier 33 to 34 162055 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) Fixture spring 26/25/10 915015 50 pc(s) Compensation profile 7/23 Pressure profile 47 punched Base profile 41 punched ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Flat fillister head screw 5.5x19 Pan head tapping screw 5.5x52 Sealing piece for pressure profile 50 32 2016 HI-0005a THERM+ H-I Timber curtain wall Single glazing Mullion section/transom section ■ Technical information ■ Profiles – Depending on the infill thickness the following gaskets for pressure profile must be used: - Infill thickness 10 to 11 mm: gaskets for pressure profile 5 mm - Infill thickness from 12 mm: gaskets for pressure profile 3 mm. – T1 = Depths from 50 mm. Article No. PU Cover profile 50/15 013003 6m Cover profile 50/12 013004 6m Pressure profile 47 punched 118005 6m Base profile 41 punched 145005 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 50 150005 20 m Gasket for transom 50 150010 20 m No. PU 012029 100 pc(s) 012109 100 pc(s) 014035 10 pc(s) 016050 10 pc(s) 152010 100 pc(s) Glass carrier 10 to 14 162005 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x30 Sealing piece for pressure profile 50 Crosspoint sealing plate 50 Sealing piece for transom 50 HI-0005 2016 33 THERM+ H-I System sections System sections 50 mm THERM+ H-I System sections 50 mm Timber curtain wall Single glazing and interior gasket 26 mm Mullion section/transom section ■ Technical information ■ Profiles – Infill thickness from 4 to 20 mm. Article – T1 = Depths from 50 mm. No. PU Cover profile 50/15 013003 6m Cover profile 50/12 013004 6m Pressure profile 47 punched 118005 6m Base profile 41 punched 145005 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 50/26 150461 20 m Interior gasket 50/26 E3 150462 20 m Interior gasket 50/26 E2 150463 20 m ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article Pan head tapping screw 5.5x32 Sealing piece for pressure profile 50 Crosspoint sealing plate 50 Sealing piece for transom 50/26 Sealing piece for transom 50/26 E2 Glass carrier 10/13 Special timber screw 4.5x35 Special flat fillister head screw 5.5x19 34 2016 HI-0133 No. PU 012110 100 pc(s) 014035 10 pc(s) 016050 10 pc(s) 152007 152011 167556 908020 908308 100 pc(s) 100 pc(s) 10 pc(s) 100 pc(s) 100 pc(s) THERM+ H-I Timber curtain wall Expansion mullion Mullion section ■ Technical information ■ Profiles – T11 = Depths from 100 mm. Article Cover profile 50/15 Pressure profile 47 punched Expansion base profile 41 left punched Expansion base profile 41 right punched Insertion profile 18/14 I No. PU 013003 6m 118005 6m 145105 6m 145106 6m 168201 6m No. PU 011070.LI 100 m 011070.RE 100 m 150305 40 m ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for mullion 50 H ■ Accessories Article Pan head tapping screw 5.5x42 Pan Head timber screw 4.5x20 PU sealing strip 10/7 No. 012114 907550 951990 PU 100 pc(s) 100 pc(s) 10 m offset arrangement HI-0110 2016 35 THERM+ H-I System sections System sections 50 mm THERM+ H-I System sections 50 mm Timber curtain wall Polygon glazing system with standard interior gasket 1° to 7° Mullion section exterior angle/interior angle ■ Technical information ■ Profiles – With exterior gasket for pressure profile 5 mm and standard interior gasket up to max. 7°. Article No. PU Cover profile 50/15 013003 6m Pressure profile 47 punched 118005 6m Base profile 41 punched 145005 6m ■ Gaskets Article No. PU Gasket for pressure profile 5 011073 100 m Gasket for mullion 50 150005 20 m ■ Accessories Article Pan head tapping screw 5.5x45 Special timber screw 4.5x35 36 2016 HI-0018 No. 012115 908020 PU 100 pc(s) 100 pc(s) THERM+ H-I Timber curtain wall Polygon glazing system 8° to 15° Mullion section exterior angle ■ Technical information ■ Profiles – Face width of cover profile depends on angle and infill thickness. Article No. PU – Glass bite (A and B) must be min. 12 mm. The distance between glass edge and gasket cap (C) has to be min. 3 mm. Please note the glass tolerances! Cover profile 56/15 013023 6m Pressure profile 53 punched 118010 6m Base profile 41 punched 145005 6m No. PU 011810 100 m 150040 20 m No. PU ■ Gaskets Article Gasket for pressure profile 8° to 15° Gasket for mullion 50 polygonal 8° to 20° ■ Accessories Article Pan head tapping screw 5.5x45 Special timber screw 4.5x35 HI-0135 012115 908020 2016 100 pc(s) 100 pc(s) 37 THERM+ H-I System sections System sections 50 mm THERM+ H-I System sections 50 mm Timber curtain wall Polygon glazing system 8° to 20° and 21° to 33° with polygon interior and exterior gasket Mullion section exterior angle ■ Technical information ■ Profiles – Insulating strips available on demand. Article Cover profile 50/15 Profile polygonal 8° to 20° Profile polygonal 21° to 33° Pressure profile 47 punched Base profile 41 punched No. PU 013003 6m 013800 6m 013801 6m 118005 6m 145005 6m No. PU 011805 100 m 150040 20 m 150045 20 m ■ Gaskets Article Gasket for pressure profile 5 polygonal Gasket for mullion 50 polygonal 8° to 20° Gasket for mullion 50 polygonal 21° to 33° ■ Accessories Article Pan head tapping screw 5.5x52 Pan head tapping screw 5.5x55 Special timber screw 4.5x35 38 2016 HI-0019 No. 012118 012119 908020 PU 100 pc(s) 100 pc(s) 100 pc(s) THERM+ H-I Timber curtain wall Polygon glazing system 34° to 45° with polygon interior and exterior gasket Mullion section exterior angle ■ Technical information ■ Profiles – Insulating strips available on demand. Article Cover profile 50/15 Profile polygonal 34° to 45° Pressure profile 47 punched Base profile 41 punched No. PU 013003 6m 013802 6m 118005 6m 145005 6m No. PU 011805 100 m 150050 20 m ■ Gaskets Article Gasket for pressure profile 5 polygonal Gasket for mullion 50 polygonal 34° to 45° ■ Accessories Article Pan head tapping screw 5.5x62 Special timber screw 4.5x35 HI-0020 No. 012124 908020 2016 PU 100 pc(s) 100 pc(s) 39 THERM+ H-I System sections System sections 50 mm THERM+ H-I System sections 50 mm Timber curtain wall Cover profile options clipped Mullion section ■ Technical information 40 ■ Profiles – Slipping down of the cover profiles must be prevented. Article No. PU – For more cover profiles, end caps and belay sheet see Product range. Cover profile 50/15 013003 6m Cover profile 50/12 013004 6m Cover profile 50/25 013005 6m Cover profile 50/25 013201 6m Cover profile 50/20 013210 6m Pressure profile 47 punched 118005 6m Cover profile 50/30 141106 6m 2016 HI-0024 THERM+ H-I Timber curtain wall Pressure profile options visible screw connection Mullion section ■ Technical information ■ Profiles – For more pressure profiles see Product range. Article Pressure profile 50/12 HI-0025 No. PU 013007 6m Pressure profile 50/9 013008 6m Pressure profile 50/25 013014 6m 2016 41 THERM+ H-I System sections System sections 50 mm THERM+ H-I System sections 50 mm Timber curtain wall Flat pressure profile options Mullion section with three options ■ Technical information ■ Profiles – Minimum infill thickness 22 mm. Article Pressure profile 50/3 No. PU 013300 6m No. PU 220205 100 m No. PU ■ Gaskets Article Gasket for pressure profile 2/16 ■ Accessories Article Flat fillister head screw 5.5x35 with sealing ring Pan head tapping screw 5.5x35 Pan head tapping screw 5.5x38 with sealing ring Cover 11 S 42 2016 HI-0026 012011 012111 012175 014110 100 pc(s) 100 pc(s) 100 pc(s) 100 pc(s) THERM+ H-I Timber curtain wall Flat pressure profile options for polygon glazing system 3° to 7° with standard interior gasket Mullion section exterior angle ■ Technical information ■ Profiles – Minimum infill thickness 22 mm. Article – Selection of pressure profiles according to infill thickness and angle. Pressure profile 50/3 No. PU 013300 6m No. PU 011850 200 m No. PU ■ Gaskets Article Gasket for pressure profile 3 polygonal 3° to 7° ■ Accessories Article Flat fillister head screw 5.5x35 with sealing ring Pan head tapping screw 5.5x35 Pan head tapping screw 5.5x35 with sealing ring Cover 11 S HI-0162 012011 012111 012174 014110 2016 100 pc(s) 100 pc(s) 100 pc(s) 100 pc(s) 43 THERM+ H-I System sections System sections 50 mm THERM+ H-I System sections 56 mm Timber curtain wall Certified passive house curtain wall with insulating block P 56/39 Mullion section/transom section ■ Technical information ■ Profiles – Certified by passive house institute Dr. Feist. Article No. PU – Uf -values see chapter Thermal insulation. Cover profile 56/15 013023 6m Cover profile 56/12 013024 6m Pressure profile 53 punched 118010 6m Base profile 47 punched 145010 6m – T1 = Depths from 50 mm. ■ Gaskets Article No. PU Gasket for pressure profile 5 011073 100 m Gasket for mullion 56 150105 20 m Gasket for transom 56 150110 20 m Insulating block P 56/39 168520 50 m No. PU 012029 100 pc(s) 012124 100 pc(s) 016051 10 pc(s) 152015 100 pc(s) 152411 10 pc(s) Glass carrier 43 to 44 162080 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x62 Crosspoint sealing plate 56 Sealing piece for transom 56 Sealing piece for pressure profile 56/5 44 2016 HI-0093 THERM+ H-I Timber curtain wall Certified passive house curtain wall, insulating block P 56/39, base profile for groove installation Mullion section/transom section ■ Technical information ■ Profiles – Certified by passive house institute Dr. Feist. Article No. PU – Uf -values see chapter Thermal insulation. Cover profile 56/15 013023 6m Cover profile 56/12 013024 6m 118010 6m 145026 6m – T1 = Depths from 50 mm. Pressure profile 53 punched Base profile 47 with foot punched ■ Gaskets Article No. PU Gasket for pressure profile 5 011073 100 m Gasket for mullion 56 150105 20 m Gasket for transom 56 150110 20 m Insulating block P 56/39 168520 50 m No. PU 012029 100 pc(s) 012124 100 pc(s) 016051 10 pc(s) 152015 100 pc(s) 152411 10 pc(s) Glass carrier 43 to 44 162080 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x62 Crosspoint sealing plate 56 Sealing piece for transom 56 Sealing piece for pressure profile 56/5 HI-0156 2016 45 THERM+ H-I System sections System sections 56 mm THERM+ H-I System sections 56 mm Timber curtain wall Insulating block P 56/19 Mullion section/transom section ■ Technical information ■ Profiles – The type of insulating block P depends on the infill thickness: - 24 to 29 mm: insulating block P 56/19, No. 168515 - 30 to 43 mm: insulating block P 56/25, No. 168516 - 44 to 64 mm: insulating block P 56/39, No. 168520. Article No. PU Cover profile 56/15 013023 6m Cover profile 56/12 013024 6m – Uf -values see chapter Thermal insulation. Pressure profile 53 punched 118010 6m – T1 = Depths from 50 mm. Base profile 47 punched 145010 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 56 150105 20 m Gasket for transom 56 150110 20 m Insulating block P 56/19 168515 50 m No. PU 012029 100 pc(s) 012114 100 pc(s) 014036 10 pc(s) 016051 10 pc(s) 152015 100 pc(s) Glass carrier 25 to 26 162035 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x42 Sealing piece for pressure profile 56 Crosspoint sealing plate 56 Sealing piece for transom 56 46 2016 HI-0091 THERM+ H-I Timber curtain wall Insulating block 21 Mullion section/transom section ■ Technical information ■ Profiles – Uf -values see chapter Thermal insulation. Article – T1 = Depths from 50 mm. No. PU Cover profile 56/15 013023 6m Cover profile 56/12 013024 6m Pressure profile 53 punched 118010 6m Base profile 47 punched 145010 6m ■ Gaskets Article Gasket for mullion 56 No. PU 150105 20 m Gasket for transom 56 150110 20 m Insulating block 56/21 150610 50 m No. PU 012029 100 pc(s) 012115 100 pc(s) 014036 10 pc(s) 016051 10 pc(s) 152015 100 pc(s) Glass carrier 27 to 28 162040 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x45 Sealing piece for pressure profile 56 Crosspoint sealing plate 56 Sealing piece for transom 56 HI-0043 2016 47 THERM+ H-I System sections System sections 56 mm THERM+ H-I System sections 56 mm Timber curtain wall Insulating block 9 Mullion section/transom section ■ Technical information ■ Profiles – Uf -values see chapter Thermal insulation. Article – T1 = Depths from 50 mm. No. PU Cover profile 56/15 013023 6m Cover profile 56/12 013024 6m Pressure profile 53 punched 118010 6m Base profile 47 punched 145010 6m ■ Gaskets Article Gasket for mullion 56 No. PU 150105 20 m Gasket for transom 56 150110 20 m Insulating block 56/9 151020 50 m No. PU 012029 100 pc(s) 012114 100 pc(s) 014036 10 pc(s) 016051 10 pc(s) 152015 100 pc(s) Glass carrier 25 to 26 162035 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x42 Sealing piece for pressure profile 56 Crosspoint sealing plate 56 Sealing piece for transom 56 48 2016 HI-0039 THERM+ H-I Timber curtain wall Standard exterior gasket Mullion section/transom section ■ Technical information ■ Profiles – Uf -values see chapter Thermal insulation. Article – T1 = Depths from 50 mm. No. PU Cover profile 56/15 013023 6m Cover profile 56/12 013024 6m Pressure profile 53 punched 118010 6m Base profile 47 punched 145010 6m No. PU 011070.LI 100 m 011070.RE 100 m ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for mullion 56 150105 20 m Gasket for transom 56 150110 20 m No. PU 012029 100 pc(s) 012114 100 pc(s) 014036 10 pc(s) 016051 10 pc(s) 152015 100 pc(s) Glass carrier 25 to 26 162035 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x42 Sealing piece for pressure profile 56 Crosspoint sealing plate 56 Sealing piece for transom 56 HI-0030 2016 49 THERM+ H-I System sections System sections 56 mm THERM+ H-I System sections 56 mm 90° Timber curtain wall Corner mullion 90°, vertical Mullion section/transom section ■ Profiles Article No. PU Cover profile 56/15 013023 6m Pressure profile 53 punched 118010 6m Base profile 47 punched 145010 6m Connection profile 39/22 168021 6m No. PU 011070.LI 100 m 011070.RE 100 m ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for mullion 56 150105 20 m Compensation gasket 2 227010 100 m ■ Accessories Article Pan head tapping screw 5.5x42 Special timber screw 4.5x35 Special countersunk sheet metal screw 4.8x19 50 2016 HI-0182 No. 012114 908020 908118 PU 100 pc(s) 100 pc(s) 100 pc(s) THERM+ H-I 90° Timber curtain wall Corner mullion 90°, vertical Mullion section/transom section ■ Profiles Article No. PU Cover profile 56/15 013023 6m Pressure profile 53 punched 118010 6m Base profile 47 punched 145010 6m Connection profile 39/22 168021 6m No. PU 011070.LI 100 m 011070.RE 100 m ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for mullion 56 150105 20 m Compensation gasket 2 227010 100 m ■ Accessories Article Pan head tapping screw 5.5x42 Special timber screw 4.5x35 Special countersunk sheet metal screw 4.8x19 HI-0181 No. 012114 908020 908118 2016 PU 100 pc(s) 100 pc(s) 100 pc(s) 51 THERM+ H-I System sections System sections 56 mm THERM+ H-I System sections 56 mm Timber curtain wall Corner mullion for variable angles, vertical Mullion section/transom section ■ Profiles Article No. PU Cover profile 56/15 013023 6m Pressure profile 53 punched 118010 6m Base profile 47 punched 145010 6m Connection profile 39/22 168021 6m No. PU 011070.LI 100 m 011070.RE 100 m ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for mullion 56 150105 20 m Compensation gasket 2 227010 100 m ■ Accessories Article Special timber screw 4.5x35 Special countersunk sheet metal screw 4.8x19 52 2016 HI-0183 No. PU 908020 100 pc(s) 908118 100 pc(s) THERM+ H-I Timber curtain wall Gasket for transom with flap between mullions Transom section ■ Technical information ■ Profiles – Available for all insulating blocks. Article – T1 = Depths from 50 mm. No. PU Cover profile 56/12 013024 6m Pressure profile 53 punched 118010 6m Base profile 47 punched 145010 6m No. PU 011070.LI 100 m 011070.RE 100 m 150115 20 m No. PU 012029 100 pc(s) 012114 100 pc(s) 014036 10 pc(s) 016051 10 pc(s) 152015 100 pc(s) Glass carrier 25 to 26 162035 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for transom 56 with flap ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x42 Sealing piece for pressure profile 56 Crosspoint sealing plate 56 Sealing piece for transom 56 HI-0031a 2016 53 THERM+ H-I System sections System sections 56 mm THERM+ H-I System sections 56 mm Timber curtain wall Continuous base gasket with flap Transom section ■ Technical information ■ Profiles – Available for all insulating blocks. Article No. PU – Base gasket available up to an infill thickness of 64 mm. Cover profile 56/12 013024 6m Pressure profile 53 punched 118010 6m Base profile 47 punched 145010 6m Connection profile 36/22 168005 6m No. PU 011070.LI 100 m 011070.RE 100 m 150120 20 m No. PU 012029 100 pc(s) 012114 100 pc(s) 014036 10 pc(s) 016051 10 pc(s) 152015 100 pc(s) 152070 10 pc(s) Glass carrier 25 to 26 162035 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) – T1 = Depths from 50 mm. ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Base gasket for transom 56 with flap ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x42 Sealing piece for pressure profile 56 Crosspoint sealing plate 56 Sealing piece for transom 56 Sealing piece for base transom 54 2016 HI-0031b THERM+ H-I Timber curtain wall Timber cover profile clipped Mullion section/transom section ■ Technical information ■ Profiles – Timber cover profiles are products complementary to the RAICO system components, supplied by the fabricator. It must be assured that the function of the glazing system remains guaranteed by adaptation of the constructional and material characteristics of the timber cover profile. – The norms and regulations concerning the use of timber in exterior building areas must be respected. Article No. PU Pressure profile 50 punched 118510 6m Base profile 47 punched 145010 6m No. PU Gasket for mullion 56 150105 20 m Gasket for transom 56 150110 20 m Gasket for pressure profile 7 H 150510 100 m No. PU 012029 100 pc(s) 012114 100 pc(s) 014036 10 pc(s) 016051 10 pc(s) 152015 100 pc(s) Glass carrier 25 to 26 162035 10 pc(s) Cover profile fixation 80 167005 Special timber screw 4.5x35 908020 ■ Gaskets – Timber cover profiles must be secured mechanically after their installation. Article – For further information see Processing. – T1 = Depths from 50 mm. ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x42 Sealing piece for pressure profile 56 Crosspoint sealing plate 56 Sealing piece for transom 56 HI-0108 2016 100 pc(s) 100 pc(s) 55 THERM+ H-I System sections System sections 56 mm THERM+ H-I System sections 56 mm Timber curtain wall Connection of ventilated/non-ventilated curtain wall Transom section ■ Technical information ■ Profiles – For the alternative solution (direct screw connection) attention shall be paid to observing a sufficient tolerance compensation (see Processing). Article No. PU Cover profile 56/12 013024 6m Pressure profile 53 punched 118010 6m Base profile 47 punched 145010 6m Connection profile 45/42 168060 6m No. PU 011070.LI 100 m 011070.RE 100 m 011074 100 m 150115 20 m No. PU 012029 100 pc(s) 012114 100 pc(s) Glass carrier 25 to 26 162035 10 pc(s) Special timber screw 4.5x35 908020 Terminal clamp 47/22 915501 ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for pressure profile 7 Gasket for transom 56 with flap ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x42 56 2016 HI-0189 100 pc(s) 100 pc(s) THERM+ H-I Timber curtain wall Interior compensation of varying infill thicknesses Mullion section/transom section ■ Technical information ■ Profiles – Difference between the glass thicknesses from 10 to 24 mm can be compensated without exterior glass offset. Article – T1 = Depths from 50 mm. No. PU Cover profile 56/15 013023 6m Cover profile 56/12 013024 6m Compensation profile 7/23 116005 6m Pressure profile 53 punched 118010 6m Base profile 47 punched 145010 6m No. PU 011070.LI 100 m 011070.RE 100 m ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for mullion 56 150105 20 m Gasket for transom 56 150110 20 m Interior gasket 5 220321 100 m No. PU 012029 100 pc(s) 012103 100 pc(s) 012118 100 pc(s) 014036 10 pc(s) Crosspoint sealing plate 56 016051 10 pc(s) Sealing piece for transom 56 152015 100 pc(s) Glass carrier 25 to 26 162035 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) Fixture spring 26/25/10 915015 50 pc(s) ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Flat fillister head screw 5.5x19 Pan head tapping screw 5.5x52 Sealing piece for pressure profile 56 HI-0034a 2016 57 THERM+ H-I System sections System sections 56 mm THERM+ H-I System sections 56 mm Timber curtain wall Single glazing Mullion section/transom section ■ Technical information ■ Profiles – Depending on the infill thickness the following gaskets for pressure profile must be used: - Infill thickness 10 to 11 mm: gaskets for pressure profile 5 mm - Infill thickness from 12 mm: gaskets for pressure profile 3 mm. Article – T1 = Depths from 50 mm. No. PU Cover profile 56/15 013023 6m Cover profile 56/12 013024 6m Pressure profile 53 punched 118010 6m Base profile 47 punched 145010 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 56 150105 20 m Gasket for transom 56 150110 20 m No. PU 012029 100 pc(s) 012108 100 pc(s) 014036 10 pc(s) 016051 10 pc(s) 152015 100 pc(s) Glass carrier 10 to 14 162005 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x28 Sealing piece for pressure profile 56 Crosspoint sealing plate 56 Sealing piece for transom 56 58 2016 HI-0034 THERM+ H-I Timber curtain wall Expansion mullion Mullion section ■ Technical information ■ Profiles – T11 = Depths from 100 mm. Article Cover profile 56/15 No. PU 013023 6m Pressure profile 53 punched Expansion base profile 47 left punched Expansion base profile 47 right punched 118010 6m 145110 6m 145111 6m Insertion profile 18/14 I 168201 6m No. PU 011070.LI 100 m 011070.RE 100 m 150335 40 m ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for mullion 56 H ■ Accessories Article Pan head tapping screw 5.5x42 Pan Head timber screw 4.5x20 PU sealing strip 10/7 No. 012114 907550 951990 PU 100 pc(s) 100 pc(s) 10 m offset arrangement HI-011 2016 59 THERM+ H-I System sections System sections 56 mm THERM+ H-I System sections 56 mm Timber curtain wall Polygon glazing system with standard interior gasket 1° to 7° Mullion section exterior angle/interior angle ■ Technical information ■ Profiles – With exterior gasket for pressure profile 5 mm and standard interior gasket to max. 7°. Article No. PU Cover profile 56/15 013023 6m Pressure profile 53 punched 118010 6m Base profile 47 punched 145010 6m ■ Gaskets Article No. PU Gasket for pressure profile 5 011073 100 m Gasket for mullion 56 150105 20 m ■ Accessories Article Pan head tapping screw 5.5x45 Special timber screw 4.5x35 60 2016 HI-0047 No. 012115 908020 PU 100 pc(s) 100 pc(s) THERM+ H-I Timber curtain wall Polygon glazing system 8° to 15° Mullion section exterior angle ■ Technical information ■ Profiles – Face width of cover profile depends on angle and infill thickness. Article No. PU – Glass bite (A and B) must be min. 13 mm. The distance between glass edge and gasket cap (C) has to be min. 3 mm. Cover profile 76/15 013050 6m Pressure profile 73 punched 118015 6m – Please note the glass tolerances! Base profile 47 punched 145010 6m No. PU 011810 100 m 150140 20 m No. PU ■ Gaskets Article Gasket for pressure profile 8° to 15° Gasket for mullion 56 polygonal 8° to 20° ■ Accessories Article Pan head tapping screw 5.5x45 Special timber screw 4.5x35 HI-0136 012115 908020 2016 100 pc(s) 100 pc(s) 61 THERM+ H-I System sections System sections 56 mm THERM+ H-I System sections 56 mm Timber curtain wall Polygon glazing system 8° to 20° and 21° to 33° with polygon interior and exterior gasket Mullion section exterior angle ■ Technical information ■ Profiles – Insulating strips available on demand. Article Cover profile 56/15 No. PU 013023 6m Profile polygonal 8° to 20° Profile polygonal 21° to 33° Pressure profile 53 punched 013800 6m 013801 6m 118010 6m Base profile 47 punched 145010 6m No. PU 011805 100 m 150140 20 m 150145 20 m ■ Gaskets Article Gasket for pressure profile 5 polygonal Gasket for mullion 56 polygonal 8° to 20° Gasket for mullion 56 polygonal 21° to 33° ■ Accessories Article Pan head tapping screw 5.5x52 Special timber screw 4.5x35 62 2016 HI-0048 No. 012118 908020 PU 100 pc(s) 100 pc(s) THERM+ H-I Timber curtain wall Polygon glazing system 34° to 45° with polygon interior and exterior gasket Mullion section exterior angle ■ Technical information ■ Profiles – Insulating strips available on demand. Article Cover profile 56/15 Profile polygonal 34° to 45° Pressure profile 53 punched Base profile 47 punched No. PU 013023 6m 013802 6m 118010 6m 145010 6m No. PU 011805 100 m 150150 20 m ■ Gaskets Article Gasket for pressure profile 5 polygonal Gasket for mullion 56 polygonal 34° to 45° ■ Accessories Article Pan head tapping screw 5.5x60 Special timber screw 4.5x35 HI-0049 No. 012123 908020 2016 PU 100 pc(s) 100 pc(s) 63 THERM+ H-I System sections System sections 56 mm THERM+ H-I System sections 56 mm Timber curtain wall Cover profile options clipped Mullion section ■ Technical information ■ Profiles – Slipping down of the cover profiles must be prevented. Article Cover profile 56/15 – For more cover profiles, end caps and belay sheet see Product range. 64 2016 HI-0054 No. PU 013023 6m Cover profile 56/12 013024 6m Cover profile 56/25 013025 6m Cover profile 56/25 013400 6m Cover profile 56/20 013410 6m Pressure profile 53 punched 118010 6m Cover profile 56/32 141307 6m THERM+ H-I Timber curtain wall Pressure profile options visible screwed Mullion section ■ Technical information ■ Profiles – For more pressure profiles see Product range. Article HI-0055 No. PU Pressure profile 56/12 013027 6m Pressure profile 56/9 013028 6m 2016 65 THERM+ H-I System sections System sections 56 mm THERM+ H-I System sections 56 mm Timber curtain wall Flat pressure profile options Mullion section with three options ■ Technical information ■ Profiles – Minimum infill thickness 22 mm. Article Pressure profile 56/3 No. PU 013310 6m No. PU 220205 100 m No. PU ■ Gaskets Article Gasket for pressure profile 2/16 ■ Accessories Article Flat fillister head screw 5.5x35 with sealing ring Pan head tapping screw 5.5x35 Pan head tapping screw 5.5x38 with sealing ring Cover 11 S 66 2016 HI-0056 012011 012111 012175 014110 100 pc(s) 100 pc(s) 100 pc(s) 100 pc(s) THERM+ H-I Timber curtain wall Flat pressure profile options for polygon glazing system 3° to 7° with standard interior gasket Mullion section exterior angle ■ Technical information ■ Profiles – Minimum infill thickness 22 mm. Article – Selection of pressure profiles according to infill thickness and angle. Pressure profile 56/3 No. PU 013310 6m No. PU 011850 200 m No. PU ■ Gaskets Article Gasket for pressure profile 3 polygonal 3° to 7° ■ Accessories Article Flat fillister head screw 5.5x35 with sealing ring Pan head tapping screw 5.5x35 Pan head tapping screw 5.5x38 with sealing ring Cover 11 S HI-0163 012011 012111 012175 014110 2016 100 pc(s) 100 pc(s) 100 pc(s) 100 pc(s) 67 THERM+ H-I System sections System sections 56 mm THERM+ H-I System sections 76 mm Timber curtain wall Certified passive house curtain wall with insulating block P 76/39 Mullion section/transom section ■ Technical information ■ Profiles – Certified by passive house institute Dr. Feist. Article No. PU – Uf -values see chapter Thermal insulation. Cover profile 76/15 013050 6m Cover profile 76/12 013051 6m Pressure profile 73 punched 118015 6m Base profile 67 punched 145015 6m – T1 = Depths from 50 mm. ■ Gaskets Article No. PU Gasket for pressure profile 5 011073 100 m Gasket for mullion 76 150205 20 m Gasket for transom 76 150210 20 m Insulating block P 76/39 168526 50 m No. PU 012029 100 pc(s) 012124 100 pc(s) 016056 10 pc(s) 152020 100 pc(s) 152421 10 pc(s) Glass carrier 43 to 44 162080 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x62 Cross point sealing plate 76 P Sealing piece for transom 76 Sealing piece for pressure profile 76/5 68 2016 HI-0144 THERM+ H-I ■ Technical information ■ Profiles – Certified by passive house institute Dr. Feist. Article No. PU – Uf -values see chapter Thermal insulation. Cover profile 76/15 013050 6m Cover profile 76/12 013051 6m 118015 6m 145031 6m – T1 = Depths from 50 mm. Pressure profile 73 punched Base profile 67 with foot punched ■ Gaskets Article No. PU Gasket for pressure profile 5 011073 100 m Gasket for mullion 76 150205 20 m Gasket for transom 76 150210 20 m Insulating block P 76/39 168526 50 m No. PU 012029 100 pc(s) 012124 100 pc(s) 014037 10 pc(s) 016056 10 pc(s) 152020 100 pc(s) Glass carrier 43 to 44 162080 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x62 Sealing piece for pressure profile 76 Cross point sealing plate 76 P Sealing piece for transom 76 HI-0157 2016 69 System sections Timber curtain wall Certified passive house curtain wall, insulating block P 76/39, base profile for groove installation Mullion section/transom section THERM+ H-I System sections 76 mm THERM+ H-I System sections 76 mm Timber curtain wall Insulating block P 76/19 Mullion section/transom section ■ Technical information ■ Profiles – The type of insulating block P depends on the infill thickness: - 24 to 29 mm: insulating block P 76/19, No. 168521 - 30 to 64 mm: insulating block P 76/25, No. 168522. Article – Uf -values see chapter Thermal insulation. – T1 = Depths from 50 mm. No. PU Cover profile 76/15 013050 6m Cover profile 76/12 013051 6m Pressure profile 73 punched 118015 6m Base profile 67 punched 145015 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 76 150205 20 m Gasket for transom 76 150210 20 m Insulating block P 76/19 168521 50 m No. PU 012029 100 pc(s) 012114 100 pc(s) 014037 10 pc(s) 016052 10 pc(s) 152020 100 pc(s) Glass carrier 25 to 26 162035 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x42 Sealing piece for pressure profile 76 Crosspoint sealing plate 76 Sealing piece for transom 76 70 2016 HI-0101 THERM+ H-I ■ Technical information ■ Profiles – Uf -values see chapter Thermal insulation. Article – T1 = Depths from 50 mm. No. PU Cover profile 76/15 013050 6m Cover profile 76/12 013051 6m Pressure profile 73 punched 118015 6m Base profile 67 punched 145015 6m ■ Gaskets Article No. PU Gasket for mullion 76 150205 20 m Gasket for transom 76 150210 20 m Insulating block 76/17 151035 50 m No. PU 012029 100 pc(s) 012114 100 pc(s) 014037 10 pc(s) 016052 10 pc(s) 152020 100 pc(s) Glass carrier 25 to 26 162035 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x42 Sealing piece for pressure profile 76 Crosspoint sealing plate 76 Sealing piece for transom 76 HI-0068 2016 71 System sections Timber curtain wall Insulating block 17 Mullion section/transom section THERM+ H-I System sections 76 mm THERM+ H-I System sections 76 mm Timber curtain wall Insulating block 9 Mullion section/transom section ■ Technical information ■ Profiles – Uf -values see chapter Thermal insulation. Article – T1 = Depths from 50 mm. No. PU Cover profile 76/15 013050 6m Cover profile 76/12 013051 6m Pressure profile 73 punched 118015 6m Base profile 67 punched 145015 6m ■ Gaskets Article No. PU Gasket for mullion 76 150205 20 m Gasket for transom 76 150210 20 m Insulating block 76/9 151030 50 m No. PU 012029 100 pc(s) 012114 100 pc(s) 014037 10 pc(s) 016052 10 pc(s) 152020 100 pc(s) Glass carrier 25 to 26 162035 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x42 Sealing piece for pressure profile 76 Crosspoint sealing plate 76 Sealing piece for transom 76 72 2016 HI-0065 THERM+ H-I ■ Technical information ■ Profiles – Uf -values see chapter Thermal insulation. Article – T1 = Depths from 50 mm. No. PU Cover profile 76/15 013050 6m Cover profile 76/12 013051 6m Pressure profile 73 punched 118015 6m Base profile 67 punched 145015 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 76 150205 20 m Gasket for transom 76 150210 20 m No. PU 012029 100 pc(s) 012114 100 pc(s) 014037 10 pc(s) 016052 10 pc(s) 152020 100 pc(s) Glass carrier 25 to 26 162035 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x42 Sealing piece for pressure profile 76 Crosspoint sealing plate 76 Sealing piece for transom 76 HI-0060 2016 73 System sections Timber curtain wall Standard exterior gasket Mullion section/transom section THERM+ H-I System sections 76 mm THERM+ H-I System sections 76 mm 90° Timber curtain wall Corner mullion 90°, vertical Mullion section/transom section ■ Profiles Article No. PU Cover profile 56/15 013023 6m Pressure profile 53 punched 118010 6m Base profile 47 punched 145010 6m Connection profile 39/22 168021 6m No. PU 011070.LI 100 m 011070.RE 100 m ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for mullion 56 150105 20 m Compensation gasket 2 227010 100 m ■ Accessories Article Pan head tapping screw 5.5x42 Special timber screw 4.5x35 Special countersunk sheet metal screw 4.8x19 74 2016 HI-0186 No. 012114 908020 908118 PU 100 pc(s) 100 pc(s) 100 pc(s) THERM+ H-I ■ Profiles Article No. PU Cover profile 56/15 013023 6m Pressure profile 53 punched 118010 6m Base profile 47 punched 145010 6m Connection profile 39/22 168021 6m ■ Gaskets Article No. Gasket for pressure prof. 3 011070.LI PU 100 m Gasket for pressure prof. 3 011070.RE 100 m Gasket for mullion 56 150105 20 m Compensation gasket 2 227010 100 m ■ Accessories Article Special timber screw 4.5x35 Special countersunk sheet metal screw 4.8x19 HI-0187 No. PU 908020 100 pc(s) 908118 100 pc(s) 2016 75 System sections Timber curtain wall Corner mullion for variable angles, vertical Mullion section/transom section THERM+ H-I System sections 76 mm THERM+ H-I System sections 76 mm Timber curtain wall Gasket for transom with flap between mullions Transom section ■ Technical information ■ Profiles – Available for all insulating blocks. Article – T1 = Depths from 50 mm. No. PU Cover profile 76/12 013051 6m Pressure profile 73 punched 118015 6m Base profile 67 punched 145015 6m No. PU 011070.LI 100 m 011070.RE 100 m 150215 20 m No. PU 012029 100 pc(s) 012114 100 pc(s) 014037 10 pc(s) Crosspoint sealing plate 76 016052 10 pc(s) Sealing piece for transom 76 152020 100 pc(s) Glass carrier 25 to 26 162035 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for transom 76 with flap ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x42 Sealing piece for pressure profile 76 76 2016 HI-0061 THERM+ H-I ■ Technical information ■ Profiles – Available for all insulating blocks. Article – Base gasket available up to an infill thickness of 64 mm. – T1 = Depths from 50 mm. No. PU Cover profile 76/12 013051 6m Pressure profile 73 punched 118015 6m Base profile 67 punched 145015 6m Connection profile 36/22 168005 6m ■ Gaskets Article No. PU Gasket for pressure prof. 3 011070.LI 100 m Gasket for pressure prof. 3 011070.RE 100 m Base gasket for transom 76 with flap 150220 20 m No. PU 012029 100 pc(s) 012114 100 pc(s) 014037 10 pc(s) 016052 10 pc(s) 152020 100 pc(s) 152070 10 pc(s) Glass carrier 25 to 26 162035 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x42 Sealing piece for pressure profile 76 Crosspoint sealing plate 76 Sealing piece for transom 76 Sealing piece for base transom HI-0062 2016 77 System sections Timber curtain wall Continuous base gasket with flap Transom section THERM+ H-I System sections 76 mm THERM+ H-I System sections 76 mm Timber curtain wall Timber cover profile clipped Mullion section/transom section ■ Technical information ■ Profiles – Timber cover profiles are products complementary to the RAICO system components, supplied by the fabricator. It must be assured that the function of the glazing system remains guaranteed by adaptation of the constructional and material characteristics of the timber cover profile. – The norms and regulations concerning the use of timber in exterior building areas must be respected. Article No. PU Pressure profile 70 punched 118515 6m Base profile 67 punched 145015 6m No. PU Gasket for mullion 76 150205 20 m Gasket for transom 76 150210 20 m Gasket for pressure profile 7 H 150510 100 m ■ Gaskets – Timber cover profiles must be secured mechanically after their installation. Article – For further information see Processing. – T1 = Depths from 50 mm. ■ Accessories Article Pan head tapping screw 5.5x42 Sealing piece for pressure profile 76 Crosspoint sealing plate 76 Sealing piece for transom 76 78 2016 HI-0109 No. PU 012114 100 pc(s) 014037 10 pc(s) 016052 10 pc(s) 152020 Cover profile fixation 80 167005 Special timber screw 4.5x35 908020 100 pc(s) 100 pc(s) 100 pc(s) THERM+ H-I ■ Technical information ■ Profiles – For the alternative solution (direct screw connection) attention shall be paid to observing a sufficient tolerance compensation (see Processing). Article No. PU Cover profile 76/12 013051 6m Pressure profile 73 punched 118015 6m Base profile 67 punched 145015 6m Connection profile 45/42 168060 6m ■ Gaskets Article No. Gasket for pressure prof. 3 011070.LI PU 100 m Gasket for pressure prof. 3 011070.RE 100 m Gasket for pressure prof. 7 011074 100 m Gasket for transom 76 with flap 150215 20 m No. PU 012029 100 pc(s) 012113 100 pc(s) Glass carrier 25 to 26 162035 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) Terminal clamp 47/22 915501 100 pc(s) 2016 79 ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x40 HI-0190 System sections Timber curtain wall Connection of ventilated/non-ventilated curtain wall Transom section THERM+ H-I System sections 76 mm THERM+ H-I System sections 76 mm Timber curtain wall Interior compensation of varying infill thicknesses Mullion section/transom section ■ Technical information ■ Profiles – Difference between the glass thicknesses from 10 to 24 mm can be compensated without exterior glass offset. Article Cover profile 76/15 Compensation profile 7/23 Pressure profile 73 punched – T1 = Depths from 50 mm. Base profile 67 punched No. PU 013050 6m 116005 6m 118015 6m 145015 6m ■ Gaskets Article No. PU Gasket for pressure prof. 3 011070.LI 100 m Gasket for pressure prof. 3 011070.RE 100 m Gasket for mullion 76 150205 20 m Gasket for transom 76 150210 20 m Interior gasket 5 220321 100 m No. PU 012029 100 pc(s) 012103 100 pc(s) 012118 100 pc(s) 014037 10 pc(s) Crosspoint sealing plate 76 016052 10 pc(s) Sealing piece for transom 76 152020 100 pc(s) Glass carrier 33 to 34 162055 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) Fixture spring 39/25/10 915020 50 pc(s) ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Flat fillister head screw 5.5x19 Pan head tapping screw 5.5x52 Sealing piece for pressure profile 76 80 2016 HI-0064 THERM+ H-I ■ Technical information ■ Profiles – Depending on the infill thickness the following gaskets for pressure profile must be used: - Infill thickness 10 to 11 mm: gaskets for pressure profile 5 mm - Infill thickness 12 mm: gaskets for pressure profile 3 mm. – T1 = Depths from 50 mm. Article No. PU Cover profile 76/15 013050 6m Cover profile 76/12 013051 6m Pressure profile 73 punched 118015 6m Base profile 67 punched 145015 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 76 150205 20 m Gasket for transom 76 150210 20 m No. PU 012029 100 pc(s) 012108 100 pc(s) 014037 10 pc(s) 016052 10 pc(s) 152020 100 pc(s) Glass carrier 10 to 14 162005 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x28 Sealing piece for pressure profile 76 Crosspoint sealing plate 76 Sealing piece for transom 76 HI-0063 2016 81 System sections Timber curtain wall Single glazing Mullion section/transom section THERM+ H-I System sections 76 mm THERM+ H-I System sections 76 mm Timber curtain wall Polygon glazing system with standard interior gasket 1° to 7° Mullion section exterior angle/interior angle ■ Technical information ■ Profiles – With exterior gasket for pressure profile 5 mm and standard interior gasket to max. 7°. Article No. PU Cover profile 76/15 013050 6m Pressure profile 73 punched 118015 6m Base profile 67 punched 145015 6m ■ Gaskets Article No. PU Gasket for pressure profile 5 011073 100 m Gasket for mullion 76 150205 20 m ■ Accessories Article Pan head tapping screw 5.5x45 Special timber screw 4.5x35 82 2016 HI-0069 No. 012115 908020 PU 100 pc(s) 100 pc(s) THERM+ H-I ■ Technical information ■ Profiles – Face width of cover profile depends on angle and infill thickness. Article – Glass bite (A and B) must be min. 15 mm. The distance between glass edge and gasket cap (C) has to be min 3 mm. – Please note the glass tolerances! No. PU Pressure profile 93 punched 118020 6m Cover profile 96/15 141710 6m Base profile 67 punched 145015 6m No. PU 011810 100 m 150240 20 m No. PU ■ Gaskets Article Gasket for pressure profile 8° to 15° Gasket for mullion 76 polygonal 8° to 20° ■ Accessories Article Pan head tapping screw 5.5x42 Special timber screw 4.5x35 HI-0205 012114 908020 2016 100 pc(s) 100 pc(s) 83 System sections Timber curtain wall Polygon glazing system 8° to 15° Mullion section exterior angle THERM+ H-I System sections 76 mm THERM+ H-I System sections 76 mm Timber curtain wall Cover profile options clipped Mullion section ■ Technical information 84 ■ Profiles – Slipping down of the cover profiles must be prevented. Article No. PU – For more cover profiles, end caps and belay sheet see Product range. Cover profile 76/15 013050 6m Cover profile 76/12 013051 6m Cover profile 76/20 013610 6m Cover profile 76/25 013615 6m Pressure profile 73 punched 118015 6m Cover profile 76/25 141505 6m 2016 HI-0071 THERM+ H-I ■ Technical information ■ Profiles – Minimum infill thickness 22 mm. Article Pressure profile 76/3 No. PU 013313 6m No. PU 220205 100 m No. PU ■ Gaskets Article Gasket for pressure profile 2/16 ■ Accessories Article Flat fillister head screw 5.5x32 with sealing ring Pan head tapping screw 5.5x35 Pan head tapping screw 5.5x35 with sealing ring Cover 11 S HI-0116 012010 012111 012174 014110 2016 100 pc(s) 100 pc(s) 100 pc(s) 100 pc(s) 85 System sections Timber curtain wall Flat pressure profile options Mullion section with three options THERM+ H-I System sections 76 mm THERM+ H-I System sections 76 mm Timber curtain wall Flat pressure profile options for polygon glazing system 3° to 7° with standard interior gasket Mullion section exterior angle ■ Technical information ■ Profiles – Minimum infill thickness 22 mm. Article – Selection of pressure profiles according to infill thickness and angle. Pressure profile 76/3 No. PU 013313 6m No. PU 011850 200 m No. PU ■ Gaskets Article Gasket for pressure profile 3 polygonal 3° to 7° ■ Accessories Article Flat fillister head screw 5.5x32 with sealing ring Pan head tapping screw 5.5x35 Pan head tapping screw 5.5x35 with sealing ring Cover 11 S 86 2016 HI-0164 012010 012111 012174 014110 100 pc(s) 100 pc(s) 100 pc(s) 100 pc(s) THERM+ H-I ■ Technical information ■ Profiles – Uf -values see chapter Thermal insulation. Article No. PU – T1 = Depths from 50 mm. Pressure profile 93 punched 118020 6m Cover profile 96/15 141710 6m Base profile 87 punched 145050 6m No. PU 011070.LI 100 m 011070.RE 100 m 150705 20 m ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for mullion 96 ■ Accessories Article Pan head tapping screw 5.5x42 Special timber screw 4.5x35 HI-0137 No. 012114 908020 2016 PU 100 pc(s) 100 pc(s) 87 System sections Timber curtain wall Standard exterior gasket Mullion section THERM+ H-I System sections 96 mm THERM+ H-I System sections 96 mm Timber curtain wall Standard exterior gasket Transom section ■ Technical information ■ Profiles – Uf-values see chapter Thermal insulation. Article No. PU – T1 = Depths from 50 mm. Pressure profile 93 punched 118020 6m Cover profile 96/15 141710 6m No. PU 011070.LI 100 m 011070.RE 100 m 150710 20 m No. PU ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for transom 96 ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x42 Sealing piece for pressure profile 96 Cross point sealing plate 96 88 2016 HI-0138 012029 012114 100 pc(s) 100 pc(s) 152425 10 pc(s) 167480 10 pc(s) THERM+ H-I ■ Technical information ■ Profiles – Depending on the infill thickness the following gaskets for pressure profile must be used: - Infill thickness 10 to 11 mm: gaskets for pressure profile 5 mm - Infill thickness from 12 mm: gaskets for pressure profile 3 mm. – T1 = Depths from 50 mm. Article No. PU Pressure profile 93 punched 118020 6m Cover profile 96/15 141710 6m Base profile 87 punched 145050 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 96 150705 20 m Gasket for transom 96 150710 20 m No. PU 012029 100 pc(s) 012108 100 pc(s) 152425 10 pc(s) 162005 10 pc(s) 167480 10 pc(s) 908020 100 pc(s) ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Pan head tapping screw 5.5x28 Sealing piece for pressure profile 96 T1 Glass carrier 10 to 14 Cross point sealing plate 96 Special timber screw 4.5x35 HI-0159 2016 89 System sections Timber curtain wall Single glazing Mullion section/transom section THERM+ H-I System sections 96 mm THERM+ H-I System sections 96 mm Timber curtain wall Polygon glazing system with standard interior gasket 1° to 7° Mullion section exterior angle/interior angle ■ Technical information ■ Profiles – With exterior gasket for pressure profile 5 mm and standard interior gasket to max. 7°. Article No. PU Pressure profile 93 punched 118020 6m Cover profile 96/15 141710 6m Base profile 87 punched 145050 6m ■ Gaskets Article No. PU Gasket for pressure profile 5 011073 100 m Gasket for mullion 96 150705 20 m No. PU ■ Accessories Article Pan head tapping screw 5.5x45 Special timber screw 4.5x35 90 2016 HI-0160 012115 908020 100 pc(s) 100 pc(s) THERM+ H-I ■ Technical information ■ Profiles – Slipping down of the cover profiles must be prevented. Article – For more cover profiles, end caps and belay sheet see Product range. HI-0161 No. PU Pressure profile 93 punched 118020 6m Cover profile 96/15 141710 6m 2016 91 System sections Timber curtain wall Cover profile options clipped Mullion section THERM+ H-I System sections 96 mm THERM+ H-I Building connections 50/56/76 mm Timber curtain wall Wall connection with thermal insulation system ■ Technical information – T255 = Vapour-tight membrane no. 951015. 92 2016 HI-1030 THERM+ H-I ■ Technical information – T128 = Breather membrane no. 951029. – T251 = Make provision for insect screen. – T255 = Vapour-tight membrane no. 951015. HI-1031 2016 93 System sections Timber curtain wall Wall connection with ventilated façade panelling THERM+ H-I Building connections 50/56/76 mm THERM+ H-I Building connections 50/56 mm Timber curtain wall Wall connection structural glazing SG2 with thermal insulation system ■ Technical information – Approval required in individual cases. – T129 = Vapour-tight membrane no. 951019. 94 2016 HI-1032 THERM+ H-I ■ Technical information – *Mask joint of mullion-transom or carry out vapour-tight. – T126 = Vapour-tight membrane no. 951021. – T249 = Execution vapour-tight or as breather membrane depending on installation-site. – T250 = Insulation with mineral cotton when required. HI-1033 2016 95 System sections Timber curtain wall Base connection with drainage to the front THERM+ H-I Building connections 50/56/76 mm THERM+ H-I Building connections 50/56/76 mm Timber curtain wall Base connection with drainage to the bottom ■ Technical information – *Mask joint of mullion-transom or carry out vapour-tight. – T126 = Vapour-tight membrane no. 951021. – T249 = Execution vapour-tight or as breather membrane depending on installation-site. – T250 = Insulation with mineral cotton when required. – T251 = Make provision for insect screen. 96 2016 HI-1034 THERM+ H-I ■ Technical information – Connection profile no. 168080: - Continuous insertion for bottom and top connection. - Cut out in mullion area for drainage/ventilation. – *Mask joint of mullion-transom or carry out vapour-tight. – Observe the different rates of thermal expansion for the screw connection of the aluminium window sill with the synthetic connection profile. – T129 = Vapour-tight membrane no. 951019. – T251 = Make provision for insect screen. – T252 = Breather membrane no. 951031. HI-1035 2016 97 System sections Timber curtain wall Base connection with frame profile THERM+ H-I Building connections 50/56/76 mm THERM+ H-I Building connections 50/56/76 mm Timber curtain wall Ceiling connection as non-locating bearing with thermal insulation system ■ Technical information – T126 = Vapour-tight membrane no. 951021. 98 2016 HI-1036 THERM+ H-I ■ Technical information – T126 = Vapour-tight membrane no. 951021. – T251 = Make provision for insect screen. – T252 = Breather membrane no. 951031. HI-1037 2016 99 System sections Timber curtain wall Ceiling connection as non-locating bearing with ventilated façade panelling THERM+ H-I Building connections 50/56/76 mm THERM+ H-I Building connections 50/56/76 mm Timber curtain wall Intermediate ceiling with curtain wall and panel joint ■ Technical information – *Mask joint of mullion-transom or carry out vapour-tight. – Pressure relief of the region behind the panel by cuttings in the mullion gasket. – T30 = Notching. – T124 = Breather membrane. – T129 = Vapour-tight membrane no. 951019. – T253 = Insulation with non-flammable mineral-cotton. – T254 = Seal joints. 100 2016 HI-1038 THERM+ H-I ■ Technical information – *Mask joint of mullion-transom or carry out vapour-tight. – Pressure relief of the region behind the panel by cuttings in the mullion gasket. – Stabilisation of the panel in the upper region when required. – T30 = Notching. – T124 = Breather membrane. – T129 = Vapour-tight membrane no. 951019. – T253 = Insulation with non-flammable mineral-cotton. – T254 = Seal joints. HI-1039 2016 101 System sections Timber curtain wall Intermediate ceiling with inserted construction and panel joint THERM+ H-I Building connections 50/56/76 mm THERM+ H-I Building connections 50/56/76 mm Timber curtain wall Attic with exposed curtain wall ■ Technical information – T126 = Vapour-tight membrane no. 951021. – T251 = Make provision for insect screen. – T252 = Breather membrane no. 951031. 102 2016 HI-1040 THERM+ H-I ■ Technical information – T124 = Breather membrane. – T126 = Vapour-tight membrane no. 951021. – T251 = Make provision for insect screen. – T252 = Breather membrane no. 951031. HI-1041 2016 103 System sections Timber curtain wall Attic with inserted curtain wall with ventilated façade panelling THERM+ H-I Building connections 50/56/76 mm 104 2016 Content Burglar prevention System benefits Sections resistance class WK2 Sections resistance class WK3 Screw selection WK2/WK3 107 109 123 137 Fire protection System benefits Sections fire protection F30 (EI30) Screw selection Selection glass carriers 141 143 146 147 Structural Glazing System benefits Sections Structural Glazing SG2 Exterior sealing Screw selection Selection insulating block Selection glass carriers Suction discs Indications for the execution of silicone joints 149 151 154 157 158 159 160 162 2016 105 THERM+ H-I Add-ons Add-ons 106 2016 THERM+ H-I System benefits Timber curtain wall 50/56/76 mm Burglar-resistant curtain walls – Technology in detail ■ Features burglar-resistant curtain wall THERM+ H-I Add-ons – Resistance classes WK2 and WK3. - WK2: - Additional shimming with glass carriers. - Balls in the screw heads. WK3: - Additional shimming with glass carriers. - Balls in the screw heads. - Pressure profile reinforcement. - Reinforced screwing in the screw channel. – Only few additional components. – No visual difference between the variations. – A huge selection of pressure and cover profiles. – System widths and infill thicknesses identical to the basic system. – For skylight glazing. – Simple and efficient assembly. – Extension by the use of insertion elements of FRAME+ and WING. Resistance class WK2 Resistance class WK3 SH-0002 2016 107 108 2016 THERM+ H-I Burglar-resistant curtain wall WK2 Timber curtain wall Standard exterior gasket Mullion section/transom section 50 mm ■ Profiles – Burglar-resistant curtain wall WK2 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article – Glazing class WK2-P4A (old A3). – For blocking of the glass unit see Processing. – T1 = Depths from 50 mm. – T17 = Depths from 80 mm. No. PU Cover profile 50/15 013003 6m Cover profile 50/20 013210 6m Pressure profile 47 punched 118005 6m Base profile 41 punched 145005 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 50 150005 20 m Gasket for transom 50 150010 20 m No. PU 012029 100 pc(s) 012153 100 pc(s) 014035 10 pc(s) 014060 100 pc(s) 016050 10 pc(s) 152010 100 pc(s) Glass carrier 25 to 26 162035 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories 22 - 64 mm Article Special countersunk sheet metal screw 5.5x24 Flat fillister head screw 5.5x42 Sealing piece for pressure profile 50 Bullet for screw heads Crosspoint sealing plate 50 Sealing piece for transom 50 22 - 64 mm HWK-0001 2016 109 THERM+ H-I Add-ons ■ Technical information THERM+ H-I Burglar-resistant curtain wall WK2 Timber curtain wall Gasket for transom with flap between mullions Transom section 50 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK2 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article – Glazing class WK2-P4A (old A3). – For blocking of the glass unit see Processing. – T1 = Depths from 50 mm. No. PU Cover profile 50/12 013004 6m Pressure profile 47 punched 118005 6m Base profile 41 punched 145005 6m No. PU 011070.LI 100 m 011070.RE 100 m 150015 20 m No. PU 012029 100 pc(s) 012153 100 pc(s) 014035 10 pc(s) 014060 100 pc(s) 016050 10 pc(s) 152010 100 pc(s) Glass carrier 25 to 26 162035 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for transom 50 with flap ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Flat fillister head screw 5.5x42 Sealing piece for pressure profile 50 Bullet for screw heads Crosspoint sealing plate 50 Sealing piece for transom 50 22 - 64 mm 110 2016 HWK-0056 THERM+ H-I Burglar-resistant curtain wall WK2 Timber curtain wall Continuous base gasket with flap Transom section 50 mm ■ Profiles – Burglar-resistant curtain wall WK2 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article – Glazing class WK2-P4A (old A3). No. PU Cover profile 50/15 013003 6m Pressure profile 47 punched 118005 6m – For blocking of the glass unit see Processing. Base profile 41 punched 145005 6m – T1 = Depths from 50 mm. Connection profile 36/22 168005 6m ■ Gaskets Article No. Gasket for pressure prof. 3 011070.LI PU 100 m Gasket for pressure prof. 3 011070.RE 100 m Compensation gasket 2 011080 100 m Base gasket for transom 50 with flap 150020 20 m No. PU 012029 100 pc(s) 012153 100 pc(s) 014035 10 pc(s) 014060 100 pc(s) 016050 10 pc(s) 152010 100 pc(s) 152070 10 pc(s) Glass carrier 25 to 26 162035 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) 2016 111 ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Flat fillister head screw 5.5x42 Sealing piece for pressure profile 50 Bullet for screw heads Crosspoint sealing plate 50 Sealing piece for transom 50 Sealing piece for base transom 22 - 64 mm HWK-0002 THERM+ H-I Add-ons ■ Technical information THERM+ H-I Burglar-resistant curtain wall WK2 Timber curtain wall Cover profile options clipped Mullion section 50 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK2 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article – Glazing class WK2-P4A (old A3). – Slipping down of the cover profiles must be prevented. – For more cover profiles, end caps and belay sheet see Product range. 112 2016 HWK-0003 No. PU Cover profile 50/15 013003 6m Cover profile 50/12 013004 6m Cover profile 50/25 013005 6m Cover profile 50/25 013201 6m Cover profile 50/20 013210 6m Pressure profile 47 punched 118005 6m Cover profile 50/30 141106 6m THERM+ H-I Burglar-resistant curtain wall WK2 Timber curtain wall Pressure profile options visible screwed Mullion section 50 mm ■ Profiles – Burglar-resistant curtain wall WK2 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article Pressure profile 50/12 – Glazing class WK2-P4A (old A3). – For more pressure profiles see Product range. HWK-0004 No. PU 013007 6m Pressure profile 50/9 013008 6m Pressure profile 50/25 013014 6m Pressure profile 50/3 013300 6m 2016 113 THERM+ H-I Add-ons ■ Technical information THERM+ H-I Burglar-resistant curtain wall WK2 Timber curtain wall Standard exterior gasket Mullion section/transom section 56 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK2 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article – Glazing class WK2-P4A (old A3). – For blocking of the glass unit see Processing. – T1 = Depths from 50 mm. – T17 = Depths from 80 mm. No. PU Cover profile 56/15 013023 6m Cover profile 56/20 013410 6m Pressure profile 53 punched 118010 6m Base profile 47 punched 145010 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 56 150105 20 m Gasket for transom 56 150110 20 m No. PU 012029 100 pc(s) 012153 100 pc(s) 014036 10 pc(s) 014060 100 pc(s) 016051 10 pc(s) 152015 100 pc(s) Glass carrier 25 to 26 162035 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Flat fillister head screw 5.5x42 Sealing piece for pressure profile 56 Bullet for screw heads Crosspoint sealing plate 56 Sealing piece for transom 56 114 2016 HWK-0011 THERM+ H-I Burglar-resistant curtain wall WK2 Timber curtain wall Gasket for transom with flap between mullions Transom section 56 mm ■ Profiles – Burglar-resistant curtain wall WK2 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article – Glazing class WK2-P4A (old A3). – For blocking of the glass unit see Processing. – T1 = Depths from 50 mm. No. PU Cover profile 56/12 013024 6m Pressure profile 53 punched 118010 6m Base profile 47 punched 145010 6m No. PU 011070.LI 100 m 011070.RE 100 m 150115 20 m No. PU 012029 100 pc(s) 012153 100 pc(s) 014036 10 pc(s) 014060 100 pc(s) 016051 10 pc(s) 152015 100 pc(s) Glass carrier 25 to 26 162035 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) THERM+ H-I Add-ons ■ Technical information ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for transom 56 with flap ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Flat fillister head screw 5.5x42 Sealing piece for pressure profile 56 Bullet for screw heads Crosspoint sealing plate 56 Sealing piece for transom 56 22 - 64 mm HWK-0057 2016 115 THERM+ H-I Burglar-resistant curtain wall WK2 Timber curtain wall Continuous base gasket with flap Transom section 56 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK2 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article No. PU Cover profile 56/15 013023 6m – For blocking of the glass unit see Processing. Pressure profile 53 punched 118010 6m Base profile 47 punched 145010 6m – T1 = Depths from 50 mm. Connection profile 36/22 168005 6m – Glazing class WK2-P4A (old A3). ■ Gaskets Article No. PU Gasket for pressure prof. 3 011070.LI 100 m Gasket for pressure prof. 3 011070.RE 100 m Compensation gasket 2 011080 100 m Base gasket for transom 56 with flap 150120 20 m No. PU 012029 100 pc(s) 012153 100 pc(s) 014036 10 pc(s) 014060 100 pc(s) 016051 10 pc(s) 152015 100 pc(s) 152070 10 pc(s) Glass carrier 25 to 26 162035 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Flat fillister head screw 5.5x42 Sealing piece for pressure profile 56 Bullet for screw heads Crosspoint sealing plate 56 Sealing piece for transom 56 Sealing piece for base transom 22 - 64 mm 116 2016 HWK-0012 THERM+ H-I Burglar-resistant curtain wall WK2 Timber curtain wall Cover profile options clipped Mullion section 56 mm ■ Profiles – Burglar-resistant curtain wall WK2 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article Cover profile 56/15 – Glazing class WK2-P4A (old A3). – Slipping down of the cover profiles must be prevented. – For more cover profiles, end caps and belay sheet see Product range. HWK-0013 No. PU 013023 6m Cover profile 56/12 013024 6m Cover profile 56/25 013025 6m Cover profile 56/25 013400 6m Cover profile 56/20 013410 6m Pressure profile 53 punched 118010 6m Cover profile 56/32 141307 6m 2016 117 THERM+ H-I Add-ons ■ Technical information THERM+ H-I Burglar-resistant curtain wall WK2 Timber curtain wall Pressure profile options visible screwed Mullion section 56 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK2 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article – Glazing class WK2-P4A (old A3). – For more pressure profiles see Product range. 118 2016 HWK-0014 No. PU Pressure profile 56/12 013027 6m Pressure profile 56/9 013028 6m Pressure profile 56/3 013310 6m THERM+ H-I Burglar-resistant curtain wall WK2 Timber curtain wall Standard exterior gasket Mullion section/transom section 76 mm ■ Profiles – Burglar-resistant curtain wall WK2 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article – Glazing class WK2-P4A (old A3). – For blocking of the glass unit see Processing. – T1 = Depths from 50 mm. – T17 = Depths from 80 mm. No. PU Cover profile 76/15 013050 6m Cover profile 76/20 013610 6m Pressure profile 73 punched 118015 6m Base profile 67 punched 145015 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 76 150205 20 m Gasket for transom 76 150210 20 m No. PU 012029 100 pc(s) 012153 100 pc(s) 014037 10 pc(s) 014060 100 pc(s) 016052 10 pc(s) ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Flat fillister head screw 5.5x42 Sealing piece for pressure profile 76 Bullet for screw heads Crosspoint sealing plate 76 Sealing piece for transom 76 Special timber screw 4.5x35 HWK-0021 152020 908020 2016 100 pc(s) 100 pc(s) 119 THERM+ H-I Add-ons ■ Technical information THERM+ H-I Burglar-resistant curtain wall WK2 Timber curtain wall Gasket for transom with flap between mullions Transom section 76 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK2 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article No. PU Cover profile 76/15 013050 6m – For blocking of the glass unit see Processing. Pressure profile 73 punched 118015 6m – T1 = Depths from 50 mm. Base profile 67 punched 145015 6m No. PU 011070.LI 100 m 011070.RE 100 m 150215 20 m – Glazing class WK2-P4A (old A3). ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for transom 76 with flap ■ Accessories Article Pan head tapping screw 5.5x58 Flat fillister head screw 5.5x42 Sealing piece for pressure profile 76 Bullet for screw heads Crosspoint sealing plate 76 Sealing piece for transom 76 Glass carrier 25 to 26 120 2016 HWK-0058 No. 012129 012153 PU 100 pc(s) 100 pc(s) 014037 10 pc(s) 014060 100 pc(s) 016052 10 pc(s) 152020 100 pc(s) 162035 10 pc(s) THERM+ H-I Burglar-resistant curtain wall WK2 Timber curtain wall Continuous base gasket with flap Transom section 76 mm ■ Profiles – Burglar-resistant curtain wall WK2 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article – Glazing class WK2-P4A (old A3). No. PU Cover profile 76/15 013050 6m Pressure profile 73 punched 118015 6m – For blocking of the glass unit see Processing. Base profile 67 punched 145015 6m – T1 = Depths from 50 mm. Connection profile 36/22 168005 6m ■ Gaskets Article No. Gasket for pressure prof. 3 011070.LI PU 100 m Gasket for pressure prof. 3 011070.RE 100 m Compensation gasket 2 011080 100 m Base gasket for transom 76 with flap 150220 20 m No. PU 012029 100 pc(s) 012153 100 pc(s) 014037 10 pc(s) Bullet for screw heads 014060 100 pc(s) Crosspoint sealing plate 76 016052 10 pc(s) 152020 100 pc(s) 152070 10 pc(s) Glass carrier 25 to 26 162035 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) 2016 121 ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Flat fillister head screw 5.5x42 Sealing piece for pressure profile 76 Sealing piece for transom 76 Sealing piece for base transom 22 - 64 mm HWK-0022 THERM+ H-I Add-ons ■ Technical information THERM+ H-I Burglar-resistant curtain wall WK2 Timber curtain wall Cover profile options clipped Mullion section 76 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK2 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article – Glazing class WK2-P4A (old A3). – Slipping down of the cover profiles must be prevented. – For more cover profiles, end caps and belay sheet see Product range. 122 2016 HWK-0023 No. PU Cover profile 76/15 013050 6m Cover profile 76/20 013610 6m Cover profile 76/25 013615 6m Pressure profile 73 punched 118015 6m Cover profile 76/25 141505 6m THERM+ H-I Burglar-resistant curtain wall WK3 Timber curtain wall Standard exterior gasket Mullion section/transom section 50 mm ■ Profiles – Burglar-resistant curtain wall WK3 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article No. PU Cover profile 50/15 013003 6m Reinforcement for pressure profile 40 013111 6m – T17 = Depths from 80 mm. Cover profile 50/20 013210 6m – T19 = Depths from 60 mm. Pressure profile 47 punched 118005 6m Base profile 41 punched 145005 6m No. PU 011070.LI 100 m 011070.RE 100 m 150005 20 m No. PU 012029 100 pc(s) 012161 100 pc(s) 014035 10 pc(s) 014060 100 pc(s) 016050 10 pc(s) 152010 100 pc(s) Glass carrier 31 to 32 162050 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) – Glazing class WK3-P6B (old B1). – For blocking of the glass unit see Processing. ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for mullion 50 ■ Accessories Article 26 - 64 mm Special countersunk sheet metal screw 5.5x24 Flat fillister head screw 5.5x62 Sealing piece for pressure profile 50 Bullet for screw heads Crosspoint sealing plate 50 Sealing piece for transom 50 26 - 64 mm HWK-0031 2016 123 THERM+ H-I Add-ons ■ Technical information THERM+ H-I Burglar-resistant curtain wall WK3 Timber curtain wall Gasket for transom with flap between mullions Transom section 50 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK3 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article No. PU 013003 6m 013111 6m 118005 6m 145005 6m No. PU 011070.LI 100 m 011070.RE 100 m 150015 20 m No. PU 012029 100 pc(s) 012161 100 pc(s) 014035 10 pc(s) 014060 100 pc(s) 016050 10 pc(s) 152010 100 pc(s) 152070 10 pc(s) Glass carrier 31 to 32 162050 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) Cover profile 50/15 – Glazing class WK3-P6B (old B1). Reinforcement for pressure profile 40 Pressure profile 47 punched – For blocking of the glass unit see Processing. – T19 = Depths from 60 mm. Base profile 41 punched ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for transom 50 with flap ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Flat fillister head screw 5.5x62 Sealing piece for pressure profile 50 Bullet for screw heads Crosspoint sealing plate 50 Sealing piece for transom 50 Sealing piece for base transom 26 - 64 mm 124 2016 HWK-0063 THERM+ H-I Burglar-resistant curtain wall WK3 Timber curtain wall Continuous base gasket with flap Transom section 50 mm ■ Profiles – Burglar-resistant curtain wall WK3 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article No. PU 013003 6m 013111 6m 118005 6m Base profile 41 punched 145005 6m Connection profile 36/22 168005 6m Cover profile 50/15 – Glazing class WK3-P6B (old B1). Reinforcement for pressure profile 40 Pressure profile 47 punched – For blocking of the glass unit see Processing. – T19 = Depths from 60 mm. ■ Gaskets Article No. PU Gasket for pressure prof. 3 011070.LI 100 m Gasket for pressure prof. 3 011070.RE 100 m Gasket for pressure profile 8 Base gasket for transom 50 with flap 011071 100 m 150020 20 m No. PU 012029 100 pc(s) 012161 100 pc(s) 014035 10 pc(s) Bullet for screw heads 014060 100 pc(s) Crosspoint sealing plate 50 016050 10 pc(s) 152010 100 pc(s) 152070 10 pc(s) Glass carrier 31 to 32 162050 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) 2016 125 ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Flat fillister head screw 5.5x62 Sealing piece for pressure profile 50 Sealing piece for transom 50 Sealing piece for base transom 26 - 64 mm HWK-0032 THERM+ H-I Add-ons ■ Technical information THERM+ H-I Burglar-resistant curtain wall WK3 Timber curtain wall Cover profile options clipped Mullion section 50 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK3 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article – Glazing class WK3-P6B (old B1). – Slipping down of the cover profiles must be prevented. – For more cover profiles, end caps and belay sheet see Product range. 126 2016 HWK-0033 No. PU Cover profile 50/15 013003 6m Cover profile 50/25 013005 6m Reinforcement for pressure profile 40 013111 6m Cover profile 50/25 013201 6m Cover profile 50/20 013210 6m Pressure profile 47 punched 118005 6m Cover profile 50/30 141106 6m THERM+ H-I Burglar-resistant curtain wall WK3 Timber curtain wall Pressure profile options visible screwed Mullion section 50 mm ■ Profiles – Burglar-resistant curtain wall WK3 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article Pressure profile 50/12 – Glazing class WK3-P6B (old B1). – T195 = Stainless steel flat (t = 2 mm) own production. HWK-0034 No. PU 013007 6m Pressure profile 50/9 013008 6m Pressure profile 50/25 013014 6m 2016 127 THERM+ H-I Add-ons ■ Technical information THERM+ H-I Burglar-resistant curtain wall WK3 Timber curtain wall Standard exterior gasket Mullion section/transom section 56 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK3 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article – Glazing class WK3-P6B (old B1). – For blocking of the glass unit see Processing. – T17 = Depths from 80 mm. – T19 = Depths from 60 mm. No. PU Cover profile 56/15 013023 6m Reinforcement for pressure profile 40 013111 6m Cover profile 56/20 013410 6m Pressure profile 53 punched 118010 6m Base profile 47 punched 145010 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 56 150105 20 m Gasket for transom 56 150110 20 m No. PU 012029 100 pc(s) 012161 100 pc(s) 014036 10 pc(s) 014060 100 pc(s) 016051 10 pc(s) 152015 100 pc(s) Glass carrier 31 to 32 162050 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article 26 - 64 mm Special countersunk sheet metal screw 5.5x24 Flat fillister head screw 5.5x62 Sealing piece for pressure profile 56 Bullet for screw heads Crosspoint sealing plate 56 Sealing piece for transom 56 26 - 64 mm 128 2016 HWK-0041 THERM+ H-I Burglar-resistant curtain wall WK3 Timber curtain wall Gasket for transom with flap between mullions Transom section 56 mm ■ Profiles – Burglar-resistant curtain wall WK3 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article No. PU 013023 6m 013111 6m 118010 6m 145010 6m No. PU 011070.LI 100 m 011070.RE 100 m 150115 20 m No. PU 012029 100 pc(s) 012161 100 pc(s) 014036 10 pc(s) 014060 100 pc(s) 016051 10 pc(s) 152015 100 pc(s) Glass carrier 31 to 32 162050 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) Cover profile 56/15 – Glazing class WK3-P6B (old B1). Reinforcement for pressure profile 40 Pressure profile 53 punched – For blocking of the glass unit see Processing. – T19 = Depths from 60 mm. Base profile 47 punched ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for transom 56 with flap ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Flat fillister head screw 5.5x62 Sealing piece for pressure profile 56 Bullet for screw heads Crosspoint sealing plate 56 Sealing piece for transom 56 26 - 64 mm HWK-0064 2016 129 THERM+ H-I Add-ons ■ Technical information THERM+ H-I Burglar-resistant curtain wall WK3 Timber curtain wall Continuous base gasket with flap Transom section 56 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK3 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article No. PU 013023 6m 013111 6m 118010 6m Base profile 47 punched 145010 6m Connection profile 36/22 168005 6m Cover profile 56/15 – Glazing class WK3-P6B (old B1). Reinforcement for pressure profile 40 Pressure profile 53 punched – For blocking of the glass unit see Processing. – T19 = Depths from 60 mm. ■ Gaskets Article No. PU Gasket for pressure prof. 3 011070.LI 100 m Gasket for pressure prof. 3 011070.RE 100 m Gasket for pressure prof. 8 011071 100 m Base gasket for transom 56 with flap 150120 20 m No. PU 012029 100 pc(s) 012161 100 pc(s) 014036 10 pc(s) 014060 100 pc(s) 016051 10 pc(s) 152070 10 pc(s) Glass carrier 31 to 32 162050 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Flat fillister head screw 5.5x62 Sealing piece for pressure profile 56 Bullet for screw heads Crosspoint sealing plate 56 Sealing piece for base transom 26 - 64 mm 130 2016 HWK-0042 THERM+ H-I Burglar-resistant curtain wall WK3 Timber curtain wall Cover profile options clipable Mullion section 56 mm ■ Profiles – Burglar-resistant curtain wall WK3 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article – Glazing class WK3-P6B (old B1). – Slipping down of the cover profiles must be prevented. – For more cover profiles, end caps and belay sheet see Product range. No. PU Cover profile 56/15 013023 6m Cover profile 56/25 013025 6m Reinforcement for pressure profile 40 013111 6m Cover profile 56/25 013400 6m Cover profile 56/20 013410 6m Pressure profile 53 punched 118010 6m Cover profile 56/32 141307 6m 013111 HWK-0043 2016 131 THERM+ H-I Add-ons ■ Technical information THERM+ H-I Burglar-resistant curtain wall WK3 Timber curtain wall Pressure profile options visible screwed Mullion section 56 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK3 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article – Glazing class WK3-P6B (old B1). – T195 = Stainless steel flat (t = 2 mm) own production. T195 132 2016 HWK-0044 No. PU Pressure profile 56/12 013027 6m Pressure profile 56/9 013028 6m THERM+ H-I Burglar-resistant curtain wall WK3 Timber curtain wall Standard exterior gasket Mullion section/transom section 76 mm ■ Profiles – Burglar-resistant curtain wall WK3 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article – Glazing class WK3-P6B (old B1). – For blocking of the glass unit see Processing. – T17 = Depths from 80 mm. – T19 = Depths from 60 mm. – T195 = Stainless steel flat (t = 2 mm) own production. No. PU Cover profile 76/15 013050 6m Cover profile 76/20 013610 6m Pressure profile 73 punched 118015 6m Base profile 67 punched 145015 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 76 150205 20 m Gasket for transom 76 150210 20 m No. PU 012029 100 pc(s) 012161 100 pc(s) 014037 10 pc(s) 014060 100 pc(s) 016052 10 pc(s) 152020 100 pc(s) Glass carrier 31 to 32 162050 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article 26 - 64 mm Special countersunk sheet metal screw 5.5x24 Flat fillister head screw 5.5x62 Sealing piece for pressure profile 76 Bullet for screw heads Crosspoint sealing plate 76 Sealing piece for transom 76 26 - 64 mm HWK-0051 2016 133 THERM+ H-I Add-ons ■ Technical information THERM+ H-I Burglar-resistant curtain wall WK3 Timber curtain wall Gasket for transom with flap between mullions Transom section 76 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK3 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article – Glazing class WK3-P6B (old B1). – For blocking of the glass unit see Processing. – T19 = Depths from 60 mm. – T195 = Stainless steel flat (t = 2 mm) own production. No. PU Cover profile 76/15 013050 6m Pressure profile 73 punched 118015 6m Base profile 67 punched 145015 6m No. PU 011070.LI 100 m 011070.RE 100 m 150215 20 m No. PU 012129 100 pc(s) 012161 100 pc(s) 014037 10 pc(s) 014060 100 pc(s) 016052 10 pc(s) 152020 100 pc(s) Glass carrier 31 to 32 162050 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for transom 76 with flap ■ Accessories Article Pan head tapping screw 5.5x58 Flat fillister head screw 5.5x62 Sealing piece for pressure profile 76 Bullet for screw heads Crosspoint sealing plate 76 Sealing piece for transom 76 26 - 64 mm 134 2016 HWK-0065 THERM+ H-I Burglar-resistant curtain wall WK3 Timber curtain wall Continuous base gasket with flap Transom section 76 mm ■ Profiles – Burglar-resistant curtain wall WK3 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article – Glazing class WK3-P6B (old B1). No. PU Cover profile 76/15 013050 6m Pressure profile 73 punched 118015 6m – For blocking of the glass unit see Processing. Base profile 67 punched 145015 6m – T19 = Depths from 60 mm. Connection profile 36/22 168005 6m – T195 = Stainless steel flat (t = 2 mm) own production. ■ Gaskets Article No. Gasket for pressure prof. 3 011070.LI PU 100 m Gasket for pressure prof. 3 011070.RE 100 m Gasket for pressure prof. 8 011071 100 m Base gasket for transom 76 with flap 150220 20 m No. PU 012029 100 pc(s) 012161 100 pc(s) 014037 10 pc(s) 014060 100 pc(s) 016052 10 pc(s) 152070 10 pc(s) Glass carrier 31 to 32 162050 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) 2016 135 ■ Accessories Article Special countersunk sheet metal screw 5.5x24 Flat fillister head screw 5.5x62 Sealing piece for pressure profile 76 Bullet for screw heads Crosspoint sealing plate 76 Sealing piece for base transom HWK-0052 THERM+ H-I Add-ons ■ Technical information THERM+ H-I Burglar-resistant curtain wall WK3 Timber curtain wall Cover profile options clipable Mullion section 76 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK3 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article No. PU Cover profile 76/15 013050 6m Cover profile 76/20 013610 6m Cover profile 76/25 013615 6m – For more cover profiles, end caps and belay sheet see Product range. Pressure profile 73 punched 118015 6m – T195 = Stainless steel flat (t = 2 mm) own production. Cover profile 76/25 141505 6m – Glazing class WK3-P6B (old B1). – Slipping down of the cover profiles must be prevented. 136 2016 HWK-0053 THERM+ H-I Burglar-resistant curtain wall WK2 THERM+ H-I Add-ons Timber curtain wall 50/56/76 mm Screw selection Pressure/cover profiles with exterior gasket 3 mm – For pressure profile no. 118005, 118010, 118015. – For pressure profile no. 013007, 013027. – For pressure profile no. 013014, 013008, 013028. – Accessories: Bullet for screw heads no. 014060. – Accessories: Bullet for screw heads no. 014060. – Accessories: Bullet for screw heads no. 014060. Infill thickness mm 12 13 to 14 15 to 16 17 to 19 20 to 22 23 to 24 25 to 26 27 to 29 30 to 32 33 to 34 35 to 36 37 to 39 40 to 42 43 to 44 45 to 46 47 to 49 50 to 52 53 to 54 55 to 56 57 to 59 60 to 62 63 to 64 Infill thickness mm 12 to 14 15 to 17 18 to 19 20 to 21 22 to 24 25 to 27 28 to 29 30 to 31 32 to 34 35 to 37 38 to 39 40 to 41 42 to 44 45 to 47 48 to 49 50 to 51 52 to 54 55 to 57 58 to 59 60 to 61 62 to 64 Infill thickness mm 12 13 to 14 15 to 17 18 to 20 21 to 22 23 to 24 25 to 27 28 to 30 31 to 32 33 to 34 35 to 37 38 to 40 41 to 42 43 to 44 45 to 47 48 to 50 51 to 52 53 to 54 55 to 57 58 to 60 61 to 62 63 to 64 No. 012098 012168 012150 012151 012152 012090 012153 012154 012155 012156 012157 012158 012159 012160 012161 012162 012163 012164 012165 012166 012145 012167 Length mm 28 30 32 35 38 40 42 45 48 50 52 55 58 60 62 65 68 70 72 75 78 80 No. 012011 012012 012139 012013 012014 012140 012015 012141 012016 012142 012017 012143 012018 012020 012146 012147 012148 012260 012149 012261 012262 KH-0060 Length mm 35 38 40 42 45 48 50 52 55 58 60 62 65 68 70 72 75 78 80 82 85 No. 012138 012010 012111 012112 012139 012013 012014 012140 012015 012141 012016 012142 012017 012143 012018 012020 012146 012147 012148 012260 012149 012261 2016 Length mm 30 32 35 38 40 42 45 48 50 52 55 58 60 62 65 68 70 72 75 78 80 82 137 THERM+ H-I Burglar-resistant curtain wall WK2 Timber curtain wall 50/56 mm Screw selection Flat pressure profile with exterior gasket 2 mm – For pressure profile no. 013300, 013310. – Accessories: Bullet for screw heads no. 014060. Infill thickness mm 22 to 23 24 to 26 27 to 29 30 to 31 32 to 33 34 to 36 37 to 39 40 to 41 42 to 43 44 to 46 47 to 49 50 to 51 52 to 53 54 to 56 57 to 59 60 to 61 62 to 63 64 138 2016 No. 012010 012011 012012 012139 012013 012014 012140 012015 012141 012016 012142 012017 012143 012018 012020 012146 012147 012148 Length mm 32 35 38 40 42 45 48 50 52 55 58 60 62 65 68 70 72 75 KH-0061 THERM+ H-I Burglar-resistant curtain wall WK3 THERM+ H-I Add-ons Timber curtain wall 50/56/76 mm Screw selection Pressure/cover profiles with exterior gasket 3 mm – For pressure profile no. 118005, 118010, 118015. – For pressure profile no. 013007, 013027. – For pressure profile no. 013014, 013008, 013028. – Accessories: Bullet for screw heads no. 014060. – Accessories: Bullet for screw heads no. 014060. – Accessories: Bullet for screw heads no. 014060. Infill thickness mm 12 to 13 14 to 16 17 to 19 20 to 21 22 to 23 24 to 26 27 to 29 30 to 31 32 to 33 34 to 36 37 to 39 40 to 41 42 to 43 44 to 46 47 to 49 50 to 51 52 to 53 54 to 56 57 to 59 60 to 63 64 Infill thickness mm 12 to 13 14 to 15 16 to 17 18 to 20 21 to 23 24 to 25 26 to 27 28 to 30 31 to 33 34 to 35 36 to 37 38 to 40 41 to 43 44 to 45 46 to 47 48 to 50 51 to 53 54 to 55 56 to 57 58 to 60 61 to 64 Infill thickness mm 12 to 13 14 to 16 17 to 18 19 to 20 21 to 23 24 to 26 27 to 28 29 to 30 31 to 33 34 to 36 37 to 38 39 to 40 41 to 43 44 to 46 47 to 48 49 to 50 51 to 53 54 to 56 57 to 58 59 to 60 61 to 63 64 No. 012153 012154 012155 012156 012157 012158 012159 012160 012161 012162 012163 012164 012165 012166 012145 012167 012275 012276 012277 012279 012280 Length mm 42 45 48 50 52 55 58 60 62 65 68 70 72 75 78 80 82 85 88 92 95 No. 012140 012015 012141 012016 012142 012017 012143 012018 012020 012146 012147 012148 012260 012149 012261 012262 012265 012266 012267 012268 012270 KH-0058 Length mm 48 50 52 55 58 60 62 65 68 70 72 75 78 80 82 85 88 90 92 95 100 No. 012014 012140 012015 012141 012016 012142 012017 012143 012018 012020 012146 012147 012148 012260 012149 012261 012262 012265 012266 012267 012268 012270 2016 Length mm 45 48 50 52 55 58 60 62 65 68 70 72 75 78 80 82 85 88 90 92 95 100 139 140 2016 THERM+ H-I Fire-resistant curtain wall F30 (EI30) Only minor additions to the THERM+ base systems are required to execute THERM+ as a fire resistant curtain wall in various protection classes. The maximum size of 1,500 x 3,000 mm of the panes provides a new dimension in fire protection. The THERM+ basic system can be upgraded to a fire protection curtain wall in various classes with a few additions and minimum additional costs and work. Maximum glass formats of 1500 x 3000 mm offer the greatest possible freedom of design in this case, too. The construction is approved in Germany, Austria and Switzerland. All specifications contained in the building authority approval Z-70.4-166 (Germany), the classification report 06042412-Rev-B (Austria), the VKF fire protection application 25135 (Switzerland) and our technical specifications must be adhered to. RAICO must be consulted for country-specific verifications. Features fire protection – Additions to the base system: Aluminium glass carrier, stainless steel reinforcement for pressure profile. – System width: 50 or 56 mm. – Structural profile width: min. 60 mm. – Mullion depth: min. 120 mm. – Transom depth: min. 100 mm. – Unlimited width and height of the fire-resistant curtain wall. – Fire exposure from the inside and outside permissible. – Assembly of the TC timber connector „KOMBI“ permissible. – Maximum mullion length 5000 mm. – Maximum height distance between the glass carriers 5000 mm. 2016 141 THERM+ H-I Add-ons Timber curtain wall 50/56 mm Fire-resistant curtain wall F30 (EI30) – Technology in detail THERM+ H-I Fire-resistant curtain wall F30 (EI30) Timber curtain wall Fire-resistant curtain wall F30 (EI30) Mullion section/transom section 50 mm ■ Technical information ■ Profiles – Maximum glass dimensions: 1500x3000 mm, horizontal and vertical. Article No. PU – Fire protection according to german general approval no. Z-70.4-166. Cover profile 50/15 013003 6m Cover profile 50/12 013004 6m Pressure profile 47 punched 118005 6m Base profile 41 punched 145005 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 50 150005 20 m Gasket for transom 50 150010 20 m – Further information see Processing. – T11 = Depths from 100 mm. – T27 = Depths from 120 mm. ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article 12 - 52 mm Flat fillister head screw 5.5x22 Pan head tapping screw 5.5x50 12 - 52 mm 142 2016 H-EI30-0001 No. 012100 012117 PU 100 pc(s) 100 pc(s) Sheet 40 167050 10 pc(s) Glass carrier 31 to 32 167351 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) THERM+ H-I Fire-resistant curtain wall F30 (EI30) Timber curtain wall Cover profile options clipped Mullion section 50 mm ■ Profiles – Maximum glass dimensions: 1500x3000 mm, horizontal and vertical. Article Cover profile 50/15 – Fire protection according to german general approval no. Z-70.4-166. PU 6m Cover profile 50/12 013004 6m Cover profile 50/25 013005 6m Cover profile 50/25 013201 6m Cover profile 50/20 013210 6m 118005 6m 118505 6m 141106 6m Pressure profile 47 punched Pressure profile 44 punched Cover profile 50/30 H-EI30-0003 No. 013003 2016 143 THERM+ H-I Add-ons ■ Technical information THERM+ H-I Fire-resistant curtain wall F30 (EI30) Timber curtain wall Fire-resistant curtain wall F30 (EI30) Mullion section/transom section 56 mm ■ Technical information ■ Profiles – Maximum glass dimensions: 1500x3000 mm, horizontal and vertical. Article No. PU – Fire protection according to german general approval no. Z-70.4-166. Cover profile 56/15 013023 6m Cover profile 56/12 013024 6m Pressure profile 53 punched 118010 6m Base profile 47 punched 145010 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 56 150105 20 m Gasket for transom 56 150110 20 m – Further information see Processing. – T11 = Depths from 100 mm. – T27 = Depths from 120 mm. ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article 12 - 52 mm Flat fillister head screw 5.5x22 Pan head tapping screw 5.5x50 12 - 52 mm 144 2016 H-EI30-0002 No. 012100 012117 PU 100 pc(s) 100 pc(s) Sheet 40 167050 10 pc(s) Glass carrier 31 to 32 167351 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) THERM+ H-I Fire-resistant curtain wall F30 (EI30) Timber curtain wall Cover profile options clipped Mullion section 56 mm ■ Profiles – Maximum glass dimensions: 1500x3000 mm, horizontal and vertical. Article Cover profile 56/15 – Fire protection according to german general approval no. Z-70.4-166. PU 6m Cover profile 56/12 013024 6m Cover profile 56/25 013025 6m Cover profile 56/25 013400 6m Cover profile 56/20 013410 6m 118010 6m 118510 6m 141307 6m Pressure profile 53 punched Pressure profile 50 punched Cover profile 56/32 H-EI30-0004 No. 013023 2016 145 THERM+ H-I Add-ons ■ Technical information THERM+ H-I Fire-resistant curtain wall F30 (EI30) Timber curtain wall 50/56 mm Screw selection Pressure/cover profiles with exterior gasket 3 mm – For pressure profile no. 118005, 118010. Infill thickness mm 12 to 13 14 to 15 16 to 18 19 to 21 22 to 23 24 to 25 26 to 28 29 to 31 32 to 33 34 to 35 36 to 38 39 to 41 42 to 43 44 to 45 46 to 48 49 to 51 52 146 2016 No. 012109 012110 012111 012112 012113 012114 012115 012116 012117 012118 012119 012129 012123 012124 012125 012106 012126 Length mm 30 32 35 38 40 42 45 48 50 52 55 58 60 62 65 68 70 KH-0056 THERM+ H-I Fire-resistant curtain wall F30 (EI30) THERM+ H-I Add-ons Timber curtain wall 50/56 mm Selection glass carriers – Max. load transmisson with 1 or 2 glass carriers per support point: see chapter Assembly options. – Screw connection with - 3 countersunk sheet metal screws no. 012028 each for no. 167306 to 167341. - 3 flat fillister head screws no. 012100 each for no. 167346 to 167931. Infill thickness mm 12 to 14 15 to 16 17 to 18 19 to 20 21 to 22 23 to 24 25 to 26 27 to 28 29 to 30 31 to 32 33 to 34 35 to 36 37 to 38 39 to 40 41 to 42 43 to 44 45 to 46 47 to 48 49 to 50 51 to 52 No. Article PU 167306 167311 167316 167321 167326 167331 167336 167341 167346 167351 167356 167361 167366 167371 167376 167381 167386 167391 167396 167401 Al. glass carrier 10 to 14 Al. glass carrier 15 to 16 Al. glass carrier 17 to 18 Al. glass carrier 19 to 20 Al. glass carrier 21 to 22 Al. glass carrier 23 to 24 Al. glass carrier 25 to 26 Al. glass carrier 27 to 28 Al. glass carrier 29 to 30 Al. glass carrier 31 to 32 Al. glass carrier 33 to 34 Al. glass carrier 35 to 36 Al. glass carrier 37 to 38 Al. glass carrier 39 to 40 Al. glass carrier 41 to 42 Al. glass carrier 43 to 44 Al. glass carrier 45 to 46 Al. glass carrier 47 to 48 Al. glass carrier 49 to 50 Al. glass carrier 51 to 52 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) KH-0019 2016 147 148 2016 THERM+ H-I Stuctural Glazing SG2 Timber curtain wall 50/56 mm SG2 curtain wall – Technology in detail ■ Features SG2-system THERM+ H-I Add-ons – Free choise of support construction made of aluminium, steel or timber. – System widths 50 and 56 mm. – Combination possible with THERM+ basic system. – Support- and basic construction as well as the interior gasket system are identical to the THERM+ basic system. – Variable capabilities. – Slim elevation widths. – Homogeneous, building enveloping glass area. – Maximum possible transparency. – Many application possibilities. – Approved curtain wall system. – Infill thicknesses of 32 up to 64 mm. – Simple and efficient assembly. SH-0004 2016 149 150 2016 THERM+ H-I Structural glazing SG2 Timber curtain wall Structural glazing curtain wall SG2 Mullion section/transom section 50 mm ■ Profiles – The indications in chapter Technical execution and installation must be respected. Article No. PU U-profile 034052 3m – Glass bite 13 mm. Base profile 41 punched 145005 6m – T1 = Depths from 50 mm. ■ Gaskets Article No. PU Gasket for mullion 50 150005 20 m Gasket for transom 50 150010 20 m Insulating block SG 25/14 168550 50 m No. PU 012100 100 pc(s) 012108 100 pc(s) 152010 100 pc(s) Toggle 20/58 SG 164610 10 pc(s) Glass carrier 29 to 30 167346 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) 2016 151 ■ Accessories Article Flat fillister head screw 5.5x22 Pan head tapping screw 5.5x28 Sealing piece for transom 50 HSG-0001 THERM+ H-I Add-ons ■ Technical information THERM+ H-I Structural glazing SG2 Timber curtain wall Structural glazing curtain wall SG2 Mullion section/transom section 56 mm ■ Technical information ■ Profiles – The indications in chapter Technical execution and installation must be respected. Article No. PU U-profile 034052 3m – Glass bite 16 mm. Base profile 47 punched 145010 6m – T1 = Depths from 50 mm. ■ Gaskets Article No. PU Gasket for mullion 56 150105 20 m Gasket for transom 56 150110 20 m Insulating block SG 25/14 168550 50 m No. PU ■ Accessories Article 152 2016 HSG-0002 Flat fillister head screw 5.5x22 Pan head tapping screw 5.5x28 Sealing piece for transom 56 012100 100 pc(s) 012108 100 pc(s) 152015 100 pc(s) Toggle 20/58 SG 164610 10 pc(s) Glass carrier 29 to 30 167346 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) THERM+ H-I Structural glazing SG2 Timber curtain wall 50/56 mm Wall connection structural glazing SG2 with thermal insulation system ■ Technical information THERM+ H-I Add-ons – Approval required in individual cases. – T129 = Vapour-tight membrane no. 951019. HI-0032 2016 153 THERM+ H-I Structural glazing SG2 Timber curtain wall 50/56 mm Exterior sealing system ■ Technical information – T30 = Notching. – T31 = Width of glass joint 24 mm. – T142 = Screwing in of the SG toggle with tool no. 170750. 154 2016 KH-0204 THERM+ H-I Structural glazing SG2 Timber curtain wall Exterior sealing system – Cutting and draw off dimensions System width 50 mm ■ Technical information T67 THERM+ H-I Add-ons – RB = Grid width RH = Grid height. – T58 = Length of the gasket for transom = RB - 28 + 0.5% add-on. – T66 = Length of the base profile = RB - 56. – T67 = Glass dimension = RB or RH - 24. T58 T66 KH-0804 2016 155 THERM+ H-I Structural glazing SG2 Timber curtain wall Exterior sealing system – Cutting and draw off dimensions System width 56 mm ■ Technical information T67 – RB = Grid width RH = Grid height. – T65 = Length of the gasket for transom = RB - 34 + 0.5%. – T67 = Glass dimension = RB or RH - 24. – T91 = Length of the base profile = RB - 62. T65 T91 156 2016 KH-0805 THERM+ H-I Structural glazing SG2 THERM+ H-I Add-ons Timber curtain wall 50/56 mm Screw selection Glazing with silicone joint and glazing shim and SG toggle – Screw selection tables apply only for a cavity of 18 mm between the glass panes (glass edge) and a centric position of the aluminium U profile no. 034052 in the glass edge. Interior pane thickness mm 6 to 8 No. Length mm 012108 28 9 to 10 012109 30 11 to 12 012110 32 13 to 15 012111 35 16 to 18 012112 38 19 to 20 012113 40 21 to 22 012114 42 23 to 25 012115 45 26 to 28 012116 48 29 to 30 012117 50 31 to 32 012118 52 33 to 35 012119 55 36 to 38 012129 58 KH-0071 2016 157 THERM+ H-I Structural glazing SG2 Timber curtain wall 50/56 mm Selection insulating block – The outer pane must be in tempered glass with min. 8 mm thickness. – A silicone joint width of 8 to 9 mm results by using this table, exept for an infill thickness of 25 mm. In that case the silicone joint width is 10 mm. – From an infill thickness of 32 mm with aluminium U profile no. 034052 possible. Infill thickness mm 23 to 25 26 to 27 28 to 29 30 to 31 32 to 33 34 to 35 36 to 37 38 to 39 40 to 41 42 to 43 44 to 45 46 to 47 48 to 49 50 to 51 52 to 53 54 to 55 56 to 57 58 to 59 60 to 61 62 to 63 64 158 2016 No. 168541 168544 168546 168548 168550 168552 168554 168556 168558 168560 168562 168564 168566 168568 168570 168572 168564 + 168546 2x 168556 168568 + 168546 2x 168558 168572 + 168546 KH-0205 THERM+ H-I Structural glazing SG2 THERM+ H-I Add-ons Timber curtain wall 50/56 mm Selection glass carriers – The outer pane must be in tempered glass with min. 8 mm thickness. – Bearing surface of the outer pane on the glass carrier: min. 50 % of the glass thickness + 1 mm. – Screw connection with - 3 countersunk sheet metal screws no. 012028 each for no. 167306 to 167341. - 3 flat fillister head screws no. 012100 each for no. 167346 to 167931. Infill thickness mm 20 to 21 22 to 23 24 to 25 26 to 27 28 to 29 30 to 31 32 to 33 34 to 35 36 to 37 38 to 39 40 to 41 42 to 43 44 to 45 46 to 47 48 to 49 50 to 51 52 to 53 54 to 55 56 to 57 58 to 59 60 to 61 62 to 63 64 No. Article PU 167316 167321 167326 167331 167336 167341 167346 167351 167356 167361 167366 167371 167376 167381 167386 167391 167396 167401 167906 167911 167916 167921 167926 Glass carrier 17 to 18 Glass carrier 19 to 20 Glass carrier 21 to 22 Glass carrier 23 to 24 Glass carrier 25 to 26 Glass carrier 27 to 28 Glass carrier 29 to 30 Glass carrier 31 to 32 Glass carrier 33 to 34 Glass carrier 35 to 36 Glass carrier 37 to 38 Glass carrier 39 to 40 Glass carrier 41 to 42 Glass carrier 43 to 44 Glass carrier 45 to 46 Glass carrier 47 to 48 Glass carrier 49 to 50 Glass carrier 51 to 52 Glass carrier 53 to 54 Glass carrier 55 to 56 Glass carrier 57 to 58 Glass carrier 59 to 60 Glass carrier 61 to 62 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) KH-0016 2016 159 THERM+ H-I Structural glazing SG2 Timber curtain wall 50/56 mm Glazing with suction discs ■ Technical information – For additional mechanical saving for all heights larger than 8 m. Suction disc set 75 No. 163807 160 2016 Suction disc set 50/90 No. 163810 Suction disc set 56/90 No. 163812 HSG-0003 THERM+ H-I Structural glazing SG2 Timber curtain wall 50/56 mm Assembly interior gasket and suction disc ■ Technical information THERM+ H-I Add-ons – T164 = Built-in conditions. – T170 = Assembly suction disc. – T171 = Suction disc variants. – T172 = Suction disc set. – T201 = Assembly aid no. 015230. T172 50/90 No. 163810 T172 56/90 No. 163812 T172 75 No. 163807 Z.-Nr. KH-0023 2016 161 THERM+ H-I Structural glazing SG2 Timber curtain wall 50/56 mm Technical execution and installation Indications for the execution of silicone joints SG-curtain walls with silicone joint on four sides SG-curtain walls with silicone joint on two sides and pressure profile on two sides ■ Technical information ■ Technical information – In the curtain wall THERM+ SG2 the glass units are fixed by means of aluminium toggles SG no. 164610. The quantity of the toggles and the structural values of the bonding must be determined by an approved specialist, taking into consideration the maximum distance of 500 mm between two toggles. – The national building regulations and codes must be applied. A permit may be required for the particular project. If an additional mechanical fuxture is required, RAICO suction discs can be applied (see Product range) – For assembly and installation the RAICO assembly instructions must be followed. For the silicone joint the indications of the manufacturer of the sealant must be respected in terms of adhesion on the glass edge and chemical interaction with the glass edge sealant. Insulated glass units must feature a UV-resistant glass edge sealant. The necessary glass quality and thickness must be coordinated with the glass supplier. – The silicone joint must be at least 8 mm. The exterior glass pane must be made of tempered glass with heat soak test with a minimum thickness of 8 mm. The cavity between the glass panes (glass edge) must be min. 18 mm, the interior glass pane min. 6 mm. – Glass tolerances: – The total tolerances of the glass units must be limited to +/- 2 mm. The panes must be produced on the standing edge. 162 2016 – In case of silicone joints on two sides of a glass unit, this must be fixed additionally with suction discs (see Product range) with at least one screw (diameter 5.5) in distances of max. 500 mm. The bearing surface of the suction discs must be min. 1,000 mm2 per glass unit. The aluminium disc must be underlaid with a weatherproof silicone disc (60 to 70 shore). As an alternative the glass unit can be fixed with special toggles in the glass edge, see system THERM+ SG2. – The backing for the exerior silicone joint must be executed with the insulation block SG (height according to the infill thickness). The silicone joint must be at least 8 mm. The material must be suitable for weatherproof sealing between glass units. Possible chemical interactions with the sealant of the glass edge and, in case of laminated glass, with the interlayer must be coordinated with the suppliers. The instructions of the manufacturers of these materials must be applied. If exterior silicone joints get in contact with pressure profiles, a RAICO silicone pressure profile gasket (see product range), must be used. Penetrations in the silicone joint must be sealed with the same material. If screws without washer are used for the suctions discs, the screw heads must be sealed with the material of the silicone joints. – Introduction: – Seam the exterior glass verge. Content Connector technology TC timber connector SOLO TC timber connector KOMBI TC timber connector with expansion mullion Statics 164 170 176 178 Glazing/Sealing technology Load transmission Assembly and installation cross point glass carriers Interior sealing system Exterior sealing system Screw selection 191 195 197 209 220 Accessories Fixation for sun protection systems Installation scaffolding anchor Installation fixture unit Connection profiles Suction discs Belay sheet Statical values 225 244 245 246 257 258 259 2016 163 THERM+ H-I Assembly options Assembly options THERM+ H-I Connector technology Timber curtain wall 50/56/76/96 mm TC timber connector SOLO Two-sided connection ■ Technical information – Technical information and selection tables, see next page. – T77 = Base profile length – T78 = Transom length – T79 = Machined recess 17.5 pc(s) 30 mm – T80 = Special nail screw – T82 = Mullion element – T84 = Special end grain screw – T85 = Longitudinal stop – T86 = Transom element – T225 = Threaded sleeve no. 160406 – T226 = Screw sleeve no. 160405 – T227 = Cylinder screw 164 2016 KH-0620 THERM+ H-I Connector technology Timber curtain wall 50/56/76/96 mm TC timber connector SOLO Two-sided connection ■ Technical information – The transom dimensions should be calculated according to the DIN EN 13830 product standard to max. 3 mm deflection in the direction of the glass load. – The finished connection is suitable only for F1, F23 and F45 loads (see chapter Dimensioning). The connector should be appropriately protected against distortion. THERM+ H-I Assembly options – The glass load specifications refer to theoretical maximum glass loads without taking into consideration wind loads, stanchion loads or additional loads. In the case of load case combinations, this load is reduced depending on the size and influence surface. The basis for determining these glass loads is the characteristic load-bearing capacity of the connector see ETA-13/0765 taking into account the following factors: - Gross density timber/timber-based materials б > 350 kg/m³ - Modification coefficient for load effect duration and moisture content kmod = 0.6 - Partial safety factor laminated timber уM = 1.30 - Partial safety factor for effect уG = 1.35 These factors can vary. The connection must be dimensioned based on the Eurocodes as well as the ETA-13/0765. – Connector set consists of: - Mullion element - Transom element - Longitudinal stop Screws, screw sleeves and threaded sleeves must be ordered separately. ■ SOLO two-sided connection selection and accessories Transom depth mm Max. glass weight* in kg 60 to 79 80 to 99 100 to 119 120 to 159 160 to 199 200 to 239 240 to 300 116 138 162 182 218 250 276 TC timber connector PU: 10 pc(s) No. 161302 161307 161312 161317 161322 161327 161332 Set 60 80 100 120 160 200 240 Qty. 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) Nail screw PU: 100 pc(s) No. 908554 908555 908556 908557 908558 908559 908560 Qty. 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) End grain Screw sleeve Threaded screw sleeve no. 908550 no. 160405 no. 160406 PU: 100 pc(s) PU: 100 pc(s) PU: 100 pc(s) Qty. Qty. Qty. 4 pc(s) 2 pc(s) 2 pc(s) 6 pc(s) 3 pc(s) 3 pc(s) 6 pc(s) 3 pc(s) 3 pc(s) 8 pc(s) 3 pc(s) 3 pc(s) 8 pc(s) 3 pc(s) 3 pc(s) 10 pc(s) 4 pc(s) 4 pc(s) 10 pc(s) 4 pc(s) 4 pc(s) ■ Cylinder head screw selection Cylinder head Timber screw mullion width PU: 100 pc(s) mm No. 50 to 58 905552 59 to 68 905562 69 to 78 905572 79 to 88 905582 89 to 98 905592 Screw quantity depends on the transom depth mm 60 to 79 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 80 to 99 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 100 to 119 120 to 159 160 to 199 200 to 239 240 to 300 3 pc(s) 3 pc(s) 3 pc(s) 4 pc(s) 4 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 4 pc(s) 4 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 4 pc(s) 4 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 4 pc(s) 4 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 4 pc(s) 4 pc(s) 2016 165 THERM+ H-I Connector technology Timber curtain wall 50/56/76/96 mm TC timber connector SOLO One-sided connection variant 1 ■ Technical information – Technical information and selection tables, see next page. – T77 = Base profile length – T78 = Transom length – T79 = Machined recess 17.5 pc(s) 30 mm – T80 = Special nail screw – T82 = Mullion element – T84 = Special end grain screw – T85 = Longitudinal stop – T86 = Transom element – T226 = Screw sleeve no. 160405 – T228 = Special timber screw no. 908545 166 2016 KH-0621 THERM+ H-I Connector technology Timber curtain wall 50/56/76/96 mm TC timber connector SOLO One-sided connection variant 1 ■ Technical information – The transom dimensions should be calculated according to the DIN EN 13830 product standard to max. 3 mm deflection in the direction of the glass load. – The finished connection is suitable only for F1, F23 and F45 loads (see chapter Dimensioning). The connector should be appropriately protected against distortion. THERM+ H-I Assembly options – The glass load specifications refer to theoretical maximum glass loads without taking into consideration wind loads, stanchion loads or additional loads. In the case of load case combinations, this load is reduced depending on the size and influence surface. The basis for determining these glass loads is the characteristic load-bearing capacity of the connector see ETA-13/0765 taking into account the following factors: - Gross density timber/timber-based materials б > 350 kg/m³ - Modification coefficient for load effect duration and moisture content kmod = 0.6 - Partial safety factor laminated timber уM = 1.30 - Partial safety factor for effect уG = 1.35 These factors can vary. The connection must be dimensioned based on the Eurocodes as well as the ETA-13/0765. – Connector set consists of: - Mullion element - Transom element - Longitudinal stop Screws, screw sleeves and threaded sleeves must be ordered separately. ■ SOLO one-sided connection variant 1 selection and accessories Transom depth mm Max. glass weight kg 60 to 79 80 to 99 100 to 119 120 to 159 160 to 199 200 to 239 240 to 300 116 138 162 182 218 250 276 TC timber connector PU: 10 pc(s) No. 161302 161307 161312 161317 161322 161327 161332 Set 60 80 100 120 160 200 240 Qty. 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) Nail screw PU: 100 pc(s) No. 908554 908555 908556 908557 908558 908559 908560 Qty. 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) End grain Screw sleeve Special timber screw screw no. 908550 no. 160405 no. 908545 PU: 100 pc(s) PU: 100 pc(s) PU: 100 pc(s) Qty. Qty. Qty. 2 pc(s) 2 pc(s) 2 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 4 pc(s) 3 pc(s) 3 pc(s) 4 pc(s) 3 pc(s) 3 pc(s) 5 pc(s) 4 pc(s) 4 pc(s) 5 pc(s) 4 pc(s) 4 pc(s) 2016 167 THERM+ H-I Connector technology Timber curtain wall 50/56/76/96 mm TC timber connector SOLO One-sided connection variant 2 ■ Technical information – Technical information and selection tables, see next page. – T77 = Base profile length – T78 = Transom length – T79 = Machined recess 17.5 pc(s) 30 mm – T80 = Special nail screw – T82 = Mullion element – T84 = Special end grain screw – T85 = Longitudinal stop – T86 = Transom element – T226 = Screw sleeve no. 160405 – T227 = Cylinder screw – T229 = M6 nut (customer provision) – T230 = Counter plate (self-made) 168 2016 KH-0622 THERM+ H-I Connector technology Timber curtain wall 50/56/76/96 mm TC timber connector SOLO One-sided connection variant 2 ■ Technical information – The transom dimensions should be calculated according to the DIN EN 13830 product standard to max. 3 mm deflection in the direction of the glass load. – The finished connection is suitable only for F1, F23 and F45 loads (see chapter Dimensioning). The connector should be appropriately protected against distortion. THERM+ H-I Assembly options – The glass load specifications refer to theoretical maximum glass loads without taking into consideration wind loads, stanchion loads or additional loads. In the case of load case combinations, this load is reduced depending on the size and influence surface. The basis for determining these glass loads is the characteristic load-bearing capacity of the connector see ETA-13/0765 taking into account the following factors: - Gross density timber/timber-based materials б > 350 kg/m³ - Modification coefficient for load effect duration and moisture content kmod = 0.6 - Partial safety factor laminated timber уM = 1.30 - Partial safety factor for effect уG = 1.35 These factors can vary. The connection must be dimensioned based on the Eurocodes as well as the ETA-13/0765. – Connector set consists of: - Mullion element - Transom element - Longitudinal stop Screws, screw sleeves and threaded sleeves must be ordered separately. ■ SOLO one-sided connection variant 2, selection and accessories Transom depth mm Max. glass weight kg 60 to 79 80 to 99 100 to 119 120 to 159 160 to 199 200 to 239 240 to 300 116 138 162 182 218 250 276 TC timber connector PU: 10 pc(s) No. 161302 161307 161312 161317 161322 161327 161332 Set 60 80 100 120 160 200 240 Qty. 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) Nail screw PU: 100 pc(s) No. 908554 908555 908556 908557 908558 908559 908560 Qty. 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) End grain Screw sleeve screw Length of no. 908550 no. 160405 counter plate PU: 100 pc(s) PU: 100 pc(s) mm Qty. Qty. 2 pc(s) 2 pc(s) 45 3 pc(s) 3 pc(s) 63 3 pc(s) 3 pc(s) 83 4 pc(s) 3 pc(s) 103 4 pc(s) 3 pc(s) 143 5 pc(s) 4 pc(s) 183 5 pc(s) 4 pc(s) 223 ■ Cylinder head screw selection Cylinder head Timber screw mullion width PU: 100 pc(s) mm No. 50 to 58 905572 59 to 68 905582 69 to 78 905592 79 to 88 905602 89 to 98 905612 Screw quantity depends on the transom depth mm 60 to 79 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 80 to 99 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 100 to 119 120 to 159 160 to 199 200 to 239 240 to 300 3 pc(s) 3 pc(s) 3 pc(s) 4 pc(s) 4 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 4 pc(s) 4 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 4 pc(s) 4 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 4 pc(s) 4 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 4 pc(s) 4 pc(s) 2016 169 THERM+ H-I Connector technology Timber curtain wall 50/56/76 mm TC timber connector KOMBI Two-sided connection ■ Technical information – Technical information and selection tables, see next page. – T78 = Transom length – T79 = Machined recess 17.5 pc(s) 30 mm – T80 = Special nail screw – T82 = Mullion element – T84 = Special end grain screw – T85 = Longitudinal stop – T86 = Transom element – T87 = "KOMBI" base profile – T225 = Threaded sleeve no. 160406 – T226 = Screw sleeve no. 160405 – T227 = Cylinder screw 170 2016 KH-0623 THERM+ H-I Connector technology Timber curtain wall 50/56/76 mm TC timber connector KOMBI Two-sided connection ■ Technical information – The transom dimensions should be calculated according to the DIN EN 13830 product standard to max. 3 mm deflection in the direction of the glass load. – The finished connection is suitable only for F1, F23 and F45 loads (see chapter Dimensioning). The connector should be appropriately protected against distortion. THERM+ H-I Assembly options – The glass load specifications refer to theoretical maximum glass loads without taking into consideration wind loads, stanchion loads or additional loads. In the case of load case combinations, this load is reduced depending on the size and influence surface. The basis for determining these glass loads is the characteristic load-bearing capacity of the connector see ETA-13/0765 taking into account the following factors: - Gross density timber/timber-based materials б > 350 kg/m³ - Modification coefficient for load effect duration and moisture content kmod = 0.6 - Partial safety factor laminated timber уM = 1.30 - Partial safety factor for effect уG = 1.35 These factors can vary. The connection must be dimensioned based on the Eurocodes as well as the ETA-13/0765. – Connector set consists of: - Mullion element - Transom element - Longitudinal stop Screws, screw sleeves and threaded sleeves must be ordered separately. ■ KOMBI two-sided connection selection and accessories Transom depth mm Max. glass weight kg 60 to 79 80 to 99 100 to 119 120 to 159 160 to 199 200 to 239 240 to 300 253 274 367 387 423 455 481 TC timber connector PU: 10 pc(s) No. 161302 161307 161312 161317 161322 161327 161332 Set 60 80 100 120 160 200 240 Nail screw PU: 100 pc(s) Qty. 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) No. 908554 908555 908556 908557 908558 908559 908560 Qty. 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) End grain Screw sleeve Threaded screw sleeve no. 908550 no. 160405 no. 160406 PU: 100 pc(s) PU: 100 pc(s) PU: 100 pc(s) Qty. Qty. Qty. 4 pc(s) 2 pc(s) 2 pc(s) 6 pc(s) 3 pc(s) 3 pc(s) 6 pc(s) 3 pc(s) 3 pc(s) 8 pc(s) 3 pc(s) 3 pc(s) 8 pc(s) 3 pc(s) 3 pc(s) 10 pc(s) 4 pc(s) 4 pc(s) 10 pc(s) 4 pc(s) 4 pc(s) ■ Selection of transom base profile System width mm No. 50 56 76 160550 160552 160554 KOMBI transom base Qty. profile PU: 10 pc(s) KOMBI 50 2 pc(s) KOMBI 56 2 pc(s) KOMBI 76 2 pc(s) Length mm 300 300 300 ■ Cylinder head screw selection Cylinder head Timber screw mullion width PU: 100 pc(s) mm No. 50 to 58 905552 59 to 68 905562 69 to 78 905572 79 to 88 905582 89 to 98 905592 Screw quantity depends on the transom depth mm 60 to 79 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 80 to 99 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 100 to 119 120 to 159 160 to 199 200 to 239 240 to 300 3 pc(s) 3 pc(s) 3 pc(s) 4 pc(s) 4 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 4 pc(s) 4 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 4 pc(s) 4 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 4 pc(s) 4 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 4 pc(s) 4 pc(s) 2016 171 THERM+ H-I Connector technology Timber curtain wall 50/56/76 mm TC timber connector KOMBI One-sided connection variant 1 Technical information – Technical information and selection tables, see next page. – T78 = Transom length – T79 = Machined recess 17.5 pc(s) 30 mm – T80 = Special nail screw – T82 = Mullion element – T84 = Special end grain screw – T85 = Longitudinal stop – T86 = Transom element – T87 = "KOMBI" base profile – T226 = Screw sleeve no. 160405 – T228 = Special timber screw no. 908545 172 2016 KH-0624 THERM+ H-I Connector technology Timber curtain wall 50/56/76 mm TC timber connector KOMBI One-sided connection variant 1 ■ Technical information – The transom dimensions should be calculated according to the DIN EN 13830 product standard to max. 3 mm deflection in the direction of the glass load. – The finished connection is suitable only for F1, F23 and F45 loads (see chapter Dimensioning). The connector should be appropriately protected against distortion. THERM+ H-I Assembly options – The glass load specifications refer to theoretical maximum glass loads without taking into consideration wind loads, stanchion loads or additional loads. In the case of load case combinations, this load is reduced depending on the size and influence surface. The basis for determining these glass loads is the characteristic load-bearing capacity of the connector see ETA-13/0765 taking into account the following factors: - Gross density timber/timber-based materials б > 350 kg/m³ - Modification coefficient for load effect duration and moisture content kmod = 0.6 - Partial safety factor laminated timber уM = 1.30 - Partial safety factor for effect уG = 1.35 These factors can vary. The connection must be dimensioned based on the Eurocodes as well as the ETA-13/0765. – Connector set consists of: - Mullion element - Transom element - Longitudinal stop Screws, screw sleeves and threaded sleeves must be ordered separately. ■ KOMBI one-sided connection variant 1, selection and accessories Transom depth mm Max. glass weight kg 60 to 79 80 to 99 100 to 119 120 to 159 160 to 199 200 to 239 240 to 300 253 274 367 387 426 455 481 TC timber connector PU: 10 pc(s) No. 161302 161307 161312 161317 161322 161327 161332 Set 60 80 100 120 160 200 240 Nail screw PU: 100 pc(s) Qty. 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) No. 908554 908555 908556 908557 908558 908559 908560 Qty. 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) End grain Special timber Screw sleeve screw screw no. 160405 no. 908550 no. 908545 PU: 100 pc(s) PU: 100 pc(s) PU: 100 pc(s) Qty. Qty. Qty. 2 pc(s) 2 pc(s) 2 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 4 pc(s) 3 pc(s) 3 pc(s) 4 pc(s) 3 pc(s) 3 pc(s) 5 pc(s) 4 pc(s) 4 pc(s) 5 pc(s) 4 pc(s) 4 pc(s) ■ Selection of transom base profile System width mm No. 50 56 76 160550 160552 160554 KOMBI transom base Qty. profile PU: 10 pc(s) KOMBI 50 1 pc(s) KOMBI 56 1 pc(s) KOMBI 76 1 pc(s) Length mm 300 300 300 2016 173 THERM+ H-I Connector technology Timber curtain wall 50/56/76 mm TC timber connector KOMBI One-sided connection variant 2 ■ Technical information – Technical information and selection tables, see next page. – T78 = Transom length – T79 = Machined recess 17.5 pc(s) 30 mm – T80 = Special nail screw – T82 = Mullion element – T84 = Special end grain screw – T85 = Longitudinal stop – T86 = Transom element – T87 = "KOMBI" base profile – T226 = Screw sleeve no. 160405 – T227 = Cylinder screw – T229 = M6 nut (customer provision) – T230 = Counter plate (self-made) 174 2016 KH-0625 THERM+ H-I Connector technology Timber curtain wall 50/56/76 mm TC timber connector KOMBI One-sided connection variant 2 ■ Technical information – The transom dimensions should be calculated according to the DIN EN 13830 product standard to max. 3 mm deflection in the direction of the glass load. – The finished connection is suitable only for F1, F23 and F45 loads (see chapter Dimensioning). The connector should be appropriately protected against distortion. THERM+ H-I Assembly options – The glass load specifications refer to theoretical maximum glass loads without taking into consideration wind loads, stanchion loads or additional loads. In the case of load case combinations, this load is reduced depending on the size and influence surface. The basis for determining these glass loads is the characteristic load-bearing capacity of the connector see ETA-13/0765 taking into account the following factors: - Gross density timber/timber-based materials б > 350 kg/m³ - Modification coefficient for load effect duration and moisture content kmod = 0.6 - Partial safety factor laminated timber уM = 1.30 - Partial safety factor for effect уG = 1.35 These factors can vary. The connection must be dimensioned based on the Eurocodes as well as the ETA-13/0765. – Connector set consists of: - Mullion element - Transom element - Longitudinal stop Screws, screw sleeves and threaded sleeves must be ordered separately. ■ KOMBI one-sided connection variant 2, selection and accessories Transom depth mm Max. glass weight kg 60 to 79 80 to 99 100 to 119 120 to 159 160 to 199 200 to 239 240 to 300 253 274 367 387 423 455 481 TC timber connector PU: 10 pc(s) No. 161302 161307 161312 161317 161322 161327 161332 Set 60 80 100 120 160 200 240 Nail screw PU: 100 pc(s) Qty. 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) No. 908554 908555 908556 908557 908558 908559 908560 Qty. 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) End grain Screw sleeve screw Length of no. 160405 no. 908550 PU: 100 pc(s) counter plate PU: 100 pc(s) mm Qty. Qty. 2 pc(s) 2 pc(s) 45 3 pc(s) 3 pc(s) 63 3 pc(s) 3 pc(s) 83 4 pc(s) 3 pc(s) 103 4 pc(s) 3 pc(s) 143 5 pc(s) 4 pc(s) 183 5 pc(s) 4 pc(s) 223 ■ Selection of transom base profile System width mm No. 50 56 76 160550 160552 160554 KOMBI transom base Qty. profile PU: 10 pc(s) KOMBI 50 1 pc(s) KOMBI 56 1 pc(s) KOMBI 76 1 pc(s) Length mm 300 300 300 ■ Cylinder head screw selection Cylinder head Timber screw mullion width PU: 100 pc(s) mm No. 50 to 58 905572 59 to 68 905582 69 to 78 905592 79 to 88 905602 89 to 98 905612 Screw quantity depends on the transom depth mm 60 to 79 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 80 to 99 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 100 to 119 120 to 159 160 to 199 200 to 239 240 to 300 3 pc(s) 3 pc(s) 3 pc(s) 4 pc(s) 4 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 4 pc(s) 4 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 4 pc(s) 4 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 4 pc(s) 4 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 4 pc(s) 4 pc(s) 2016 175 THERM+ H-I Connector technology Timber curtain wall 50/56 mm TC timber connector with expansion mullion Expansion mullion connection ■ Technical information – Technical information and selection tables, see next page. – T77 = Base profile length – T78 = Transom length – T79 = Machined recess 17.5 pc(s) 30 mm – T80 = Special nail screw – T82 = Mullion element – T84 = Special end grain screw – T85 = Longitudinal stop – T86 = Transom element – T231 = Threaded sleeve no. 160407 – T232 = Sealing tape no. 951990 – T233 = Screw no. 907550 – T234 = Screw no. 908225 176 2016 KH-0629 THERM+ H-I Connector technology Timber curtain wall 50/56 mm TC timber connector with expansion mullion Expansion mullion connection ■ Technical information – The transom dimensions should be calculated according to the DIN EN 13830 product standard to max. 3 mm deflection in the direction of the glass load. – The finished connection is suitable only for F1, F23 and F45 loads (see chapter Dimensioning). The connector should be appropriately protected against distortion. THERM+ H-I Assembly options – The glass load specifications refer to theoretical maximum glass loads without taking into consideration wind loads, stanchion loads or additional loads. In the case of load case combinations, this load is reduced depending on the size and influence surface. The basis for determining these glass loads is the characteristic load-bearing capacity of the connector see ETA-13/0765 taking into account the following factors: - Gross density timber/timber-based materials б > 350 kg/m³ - Modification coefficient for load effect duration and moisture content kmod = 0.6 - Partial safety factor laminated timber уM = 1.30 - Partial safety factor for effect уG = 1.35 These factors can vary. The connection must be dimensioned based on the Eurocodes as well as the ETA-13/0765. – Connector set consists of: - Mullion element - Transom element - Longitudinal stop Screws, screw sleeves and threaded sleeves must be ordered separately. ■ Expansion mullion connection selection and accessories Transom depth mm Max. glass weight kg 60 to 79 80 to 99 100 to 119 120 to 159 160 to 199 200 to 239 240 to 300 * * * * * * * TC timber connector PU: 10 pc(s) No. 161302 161307 161312 161317 161322 161327 161332 Set 60 80 100 120 160 200 240 Qty. 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) Nail screw PU: 100 pc(s) No. 908554 908555 908556 908557 908558 908559 908560 Qty. 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) End grain Flat head Screw sleeve screw screw no. 160407 no. 908550 no. 908225 PU: 100 pc(s) PU: 100 pc(s) PU: 100 pc(s) Qty. Qty. Qty. 4 pc(s) 4 pc(s) 4 pc(s) 6 pc(s) 6 pc(s) 6 pc(s) 6 pc(s) 6 pc(s) 6 pc(s) 8 pc(s) 6 pc(s) 6 pc(s) 8 pc(s) 6 pc(s) 6 pc(s) 10 pc(s) 8 pc(s) 8 pc(s) 10 pc(s) 8 pc(s) 8 pc(s) * Note: Design values for the extending mullion connection are available on request. 2016 177 THERM+ H-I Connector technology Timber curtain wall 50/56/76/96 mm TC timber connector Static dimensioning ■ Scope The use of the TC timber connector is regulated in ETA-13/0765 which sets out the basis for the static dimensioning and processing of the connector. The key elements of ETA-13/0765 are listed below. ■ Types of timber The following types of timber and timber-based materials are covered by the ETA: – Solid softwood according to EN 14081 – Solid hardwood according to EN 14081 – Glued laminated timber made of softwood according to EN 14081 – Glued laminated timber made of hardwood according to EN 14081 oak, beech or meranti (alternatives with building authority approval) – Laminated veneer lumber (LVL) as EN 14374 – Intrallam and Porallam with building authority approval – Plywood according to EN 636 The calculation is based on a gross density of 350 kg/m³. Materials with a higher gross density of up to 500 kg/m³ can be used. Gross densities over 500 kg/m³ are calculated with a value of 500 kg/m³. Minimum softwood requirements are grades S 10 / C 24. The conversion factors can be found in the ETA and/or the following example for static dimensioning. 178 2016 THERM+ H-I Connector technology Timber curtain wall 50/56/76/96 mm TC timber connector Static dimensioning ■ Service classes The RAICO TC timber connector can only be used in buildings in the service classes 1 + 2 according to Eurocode 5. These categories are differentiated as follows: Table NA.6 – equilibrium moisture content of timber structural materials Extract from DIN-EN 1995-1-1/NA:2010-12 1 2 3 (5 to 15) %a (10 to 20) %b (12 to 24) % c a In most softwoods in service class 1 the average equilibrium moisture content does not exceed 12 %. b In most softwoods in service class 2 the average equilibrium moisture content does not exceed 20 %. c Service class 3 also includes structures in which higher equilibrium moisture contents are permitted. THERM+ H-I Assembly options Service class Equilibrium moisture content Table 1-15 Service classes (NKL) according to DIN 1052: 2008-12, 7.1.1.1) Extract from DIN 1052 Service class 1 2 3 Moisture content in timber construction materials, corresponds to an ambient climate of T = 20° C φ = 65 % 2) T = 20° C φ = 85 % 2) Climatic conditions which lead to greater timber moistures than service class 2 Timber moisture w in timber construction materials after a period of acclimatisation Examples of ambient climate Up to around 12 % 3) all-round enclosed and heated structures Up to around 20 % 3) roofed, open structures around > 20 % Outdoor structures exposed to the weather 1) Equilibrium moisture content of timber construction materials, see Tables 1 – 18. 2) Relative humidities which are exceeded for only a few weeks per year. 3) In most softwoods in this service class, the specified timber moistures as average equilibrium moistures are not exceeded. 2016 179 THERM+ H-I Connector technology Timber curtain wall 50/56/76/96 mm TC timber connector Static dimensioning ■ Dimensioning concept according to EUROCODE Mullion and transom façades are dimensioned according to – EUROCODE 0 – Basis of structural design – EUROCODE 1 – Effect on structures – EUROCODE 5 – Design, calculation and dimensioning of timber buildings – EN 13830 – Product standard for curtain wall façades (This standard regulates the deflection limits for mullion and transom components of façades) Dimensioning is carried out according to the semi-probabilistic safety concept which substitutes admissible values with characteristic values and specifies different partial safety factors as fixed values. The mullion and transom components are dimensioned in accordance with the EUROCODES in this concept. The TC timber connectors from RAICO Bautechnik, have – reduced edge distances – end-grain screw fasteners – custom components and so fall into the standard category of "non-regulated components". Regulation is according to ETA-13/0765 dated 25.06.2013. This ETA rules the usability and load-bearing capacity of the T-connector in the following loading directions: ■ Description of the loads / direction of the load F45 = inherent weight load caused by a filling element such as glass or metal panel. With average force transmission the tested clamping thickness is max. 65 mm. In the case of asymmetric force transmission this clamping thickness should be reduced. Please get in contact with us to discuss F1 = centric tensile load on the transom. This can result from – wind load in the region of corner glazing – replacement of mullions and continuous transoms. In this case the corresponding proportion of the glass load of the adjacent fields is considered. F2, F3 = right-angled load on mullion- and transom axis. Loads in this direction can be e.g. – Wind suction loads – Wind pressure loads – Balustrade loads ETA-13/0765 breaks down the directions of loads as follows: F2 = load in the wind pressure direction F3 = load in the wind suction direction 180 2016 THERM+ H-I Connector technology Timber curtain wall 50/56/76/96 mm TC timber connector Static dimensioning Please note: The basis for structural dimensioning is always the European Technical Approval. – ETA-13/0765 – EUROCODES 0, 1, 5 as well as national appendices – Product standard EN 13830 for curtain wall façades – Requirements from the structure THERM+ H-I Assembly options – the national appendices the Eurocodes and/or national regulations must be observed. The T-connections of façades may only be exposed to loads and deformations listed in the ETA and in the above documents. Avoid distortions in the façades or prevent with suitable measures. Construction specifications e.g. final distances in the region of the connection points are not regulated in this permission. The specifications of EUROCODE 5 – Dimensioning and construction of timber buildings (DIN EN 1995) apply. 2016 181 THERM+ H-I Connector technology Timber curtain wall 50/56/76/96 mm TC timber connector Static dimensioning ■ Dimensioning connections of the T-connector When dimensioning according to the semi-probabilistic safety concept, there is a differentiation between effects/loads and the stress-bearing capacity. Effects are loads such as – Snow loads – Wind loads – Stanchion loads on the T-connections. The level and type of these loads are regulated in EUROCODE 1 – Effects (EN 1991). The partial safety factors γF of the loads must be considered. These are, – for independent constant loads e.g. inherent weight loads (glass loads), γG = 1.35 – independent variable loads e.g. wind load and stanchion load, γQ = 1.50 See the following extract from the standard. The most unfavourable values shall be used in all cases. Table NA.A.1.2(B) – partial safety coefficients for effects: (STR/GEO) (Group B) Extract from DIN EN 19990:2010-12 Effect Symbol Situations P/T A/E γG, sup 1.35 1.00 γG, inf 1.00 1.00 Independent variable loads: Unfavourable case b, c γQ 1.50 1.00 Extraordinary loads: γA – 1.00 Independent constant loads: Unfavourable case a, b Favourable case a, b a The limit state for the failure of the load-bearing structure is verified by multiplying all the characteristic values of an independent constant load (i.e. the characteristic values of all constant loads from the same origin) by the factor γG, sup if the total resulting effect on the observed stress is unfavourable, or by the factor γG, inf if the total resulting effect is favourable. b To choose the partial safety coefficients for the verification of geotechnical limit values, see DIN 1054-101:2009-02, Tables A 2-1, A 2-2 and A 2-3 c In the case of a favourable effect γQ = 0 d The values γG and γQ may only be divided in individual cases and only with the consent of the responsible building authorities into factors γg and γq for the uncertainties of the representative values of the loads and into a factor γEd for the model uncertainty of the loads and stresses. 182 2016 THERM+ H-I Connector technology Timber curtain wall 50/56/76/96 mm TC timber connector Static dimensioning The probability that all simultaneously occurring effects are at their maximum in one stress direction is extremely slim. In this case, so-called combination rules are applied, in which a variable load is taken into account with its maximum value and all other variable loads are reduced by so-called combination factors. The relevant load case combination is the one with the higher value which is used in mullion and transom façades, e.g. in the case of wind load (wind pressure, wind suction) and stanchion load. The combination factors can be taken from EUROCODE 0. An extract is given below: Effect Ψ0 Ψ1 Ψ2 – Category A: Living rooms and staff rooms 0.7 0.5 0.3 – Category B: Offices 0.7 0.5 0.3 – Category C: Conference rooms 0.7 0.7 0.6 – Category D: Sales rooms 0.7 0.7 0.6 1 0.9 0.8 – Category F: Thoroughfares, vehicle load ≤ 30 kN 0.7 0.7 0.6 – Category G: Thoroughfares, 30 kN ≤ vehicle load ≤ 160 kN 0.7 0.5 0.3 0 0 0 THERM+ H-I Assembly options Table NA.A.1.1 – Numerical values for combination coefficients in civil engineering Extract from DIN EN 1990:NA2010-12 – Germany Payloads in civil engineering (categories see EN 1991-1-1) a – Category E: Storage rooms – Category H: Roofs Snow and ice loads, see DIN EN 1991-1-3 – Locations up to sea level + 1000 m 0.5 0.2 0 Locations above sea level + 1000 m 0.7 0.5 0.2 Wind loads, see DIN EN 1991-1-4 0.6 0.2 0 Temperature effects (not fire), see DIN EN 1991-1-5 0.5 0.5 0 Construction site settlement, see DIN EN 1997 Other effects: b, c 1 1 1 0.8 0.7 0.5 a Reduction coefficients for payloads in multi-storey buildings see DIN EN 1991-1-1. b Fluid pressure is generally treated as a variable load for which the Ψ-coefficients are defined site-specifically. Fluid pressure whose value is limited by geometrical constraints may be treated as a constant load wherein all Ψ-coefficients should be set to 1.0. c Ψ coefficients for machine loads should be defined with respect to the operation. 2016 183 THERM+ H-I Connector technology Timber curtain wall 50/56/76/96 mm TC timber connector Static dimensioning ■ The stress-bearing capacity/resistance of the T-connection The stress-bearing capacity/resistance of the T-connection is regulated in ETA-13/0765. The characteristic strength of the connection at a gross density (gross density of mullions and transoms must be lower) of ρL = 350 kg/m³ can be taken from the following table. Table C.1 – Effective quantity nj, nef, 1, nef, 45 and characteristic values F1, RK, F2, RK, F3, RK, F45, RK for a characteristic gross density of 350 kg/m³ RAICO T-connector nef, 1 F1, RK [kN] nJ F2, RK [kN] Wind pressure F3, RK [kN] Wind suction nef, 45 F45, RK [kN] F45, in, RK [kN] SOLO 60 1.60 3.1 2 3.4 3.4 0.42 1.7 1.0 SOLO 80 2.41 4.7 3 5.1 5.1 0.60 2.0 1.0 SOLO 100 2.97 5.8 3 5.1 5.1 0.82 2.4 1.0 SOLO 120 2.63 5.2 4 6.8 5.8 0.99 2.7 1.0 SOLO 160 2.36 4.6 4 6.8 5.8 1.30 3.2 1.0 SOLO 200 3.85 7.5 5 7.0 5.8 1.57 3.7 1.0 SOLO 240 3.30 6.5 5 7.0 5.8 1.80 4.0 1.0 KOMBI 60 1.60 3.1 2 3.4 3.4 0.42 3.7 3.0 KOMBI 80 2.41 4.7 3 5.1 5.1 0.60 4.0 3.0 KOMBI 100 2.97 5.8 3 5.1 5.1 0.82 5.4 4.0 KOMBI 120 2.63 5.2 4 6.8 5.8 0.99 5.7 4.0 KOMBI 160 2.36 4.6 4 6.8 5.8 1.30 6.2 4.0 KOMBI 200 3.85 7.5 5 7.0 5.8 1.57 6.7 4.0 KOMBI 240 3.30 6.5 5 7.0 5.8 1.80 7.0 4.0 At higher gross densities the characteristic strengths are calculated according to the following equations. The forces F1, F2 and F3 always act in the centre of the connector. The force F45 has an eccentricity which corresponds to a maximum infill thickness of 65 mm (based on a symmetrical glass construction; the infill thickness should be reduced for asymmetrical glass constructions). The maximum gross density may not exceed 500 kg/m³. The minimum gross density may not be less than 350 kg/m³. F45, RK – characteristic value for inherent weight stress F45, RK = 1693 x nef45 x (ρK/350)0.5 + F45,in,RK [N] F1, RK – characteristics value for tensile stress on the transom F1, RK = nef1 x 1958 x (ρK/350)0.8 [N] F2, RK – characteristic value in the wind pressure direction F2, RK = min. s nj x 1693 x (ρK/350)0.5 [N] 7000 N F3, RK – the characteristic value in the wind suction direction F3, RK = min. nef, 1 s nj x 1693 x (ρK/350)0.5 [N] 5800 N = effective no. of screws for stress direction F1 nef, 45 = effective no. of screws for stress direction F45 nj = no. of screws in the transom PK = gross density in the mullion/transom in kg/m³. The lower value should be used for the dimensioning. F45,in,RK = additional load-bearing capacity in the loading direction These characteristic values apply only for connectors in pairs for load directions F1, F2, F3 and F45 The specified values apply per connection. 184 2016 THERM+ H-I Connector technology Timber curtain wall 50/56/76/96 mm TC timber connector Static dimensioning The following should be considered when determining the stress-bearing capacity/resistance of the connection: – Partial safety value for individual materials in timber constructions γM = 1.30 (Germany – national requirements must be taken into account) Building material γM Solid wood, chipboards, hard fibreboards, medium hard fibreboards, MDF fibreboards, soft fibreboards, laminated veneer lumber, plywood, OSB, laminated timber 1.3 THERM+ H-I Assembly options Table NA.2 – Partial safety coefficients γM for strength- and stiffness properties in constant and temporary dimensioning situations Extract from DIN EN 1995-1-1/NA:2010-12 – Germany Steel in connections – for bending-stressed dowel-type fasteners 1.3 – for tension or shear-stressed parts in verification of resistance to yield stress in the net cross section 1.3 – Board proof of load-bearing capacity for nail boards 1.25 Modification coefficient kmod according to EUROCODE 5 Load effect duration class Order of magnitude of the accumulated duration of the characteristic load effect medium 1 week to 6 months short shorter than a week very short shorter than a minute Note: Examples for assignment to duration of load effect classes can be found in Table 2.2. Climate-related load effects (snow, wind) vary in magnitude in different countries so the national appendix is used for assignment to load effect duration classes. 2016 185 THERM+ H-I Connector technology Timber curtain wall 50/56/76/96 mm TC timber connector Static dimensioning Table NA.1 – Breakdown of loads according to DIN 1055-1, DIN 1055-3, DIN 1055-4, DIN 1055-5, DIN 1055-9, DIN 1055-10 and DIN 1055-100 in load effect duration classes (KLED) Extract from DIN EN 1995-1-1-2010-12 – Germany Effect KLED Specific weights and surface loads according to DIN 1055-1 constant Perpendicular payloads DIN 1055-3 A Top ground, living- and staff rooms medium B Office surfaces, working surfaces, corridors medium C Rooms, conference rooms and surfaces which may be used for gatherings (with exception of categories defined under A, short B, D and E) D Sales rooms medium E Factories and workshops, sheds, storage surfaces and accesses, surfaces with considerable footfall long F Roads and parking surfaces for lightweight vehicles (total load ≤ kN), access ramps to these surfaces medium short G Surfaces for operation with counterweight stackers medium H Non weight-bearing roofs, except for typical maintenance or repair short K Helicopter normal loads short T Staircases and stair landings short Z Accesses, balconies and similar short Horizontal payloads according to DIN 1055-3 Horizontal payloads from persons on balustrades, landings and the constructions used as barriers Horizontal payloads for achieving adequate longitudinal and transverse rigidity Horizontal loads for helicopter landing pads on flat roofs – for horizontal payloads – for rollover protection Wind loads according to DIN 1055-4 short a short very short short/very short b Snow load and ice load according to DIN 1055-5 Height of construction site above sea level < 1000 m short Height of construction site above sea level > 1000 m medium Impact loads according to DIN 1055-9 very short Horizontal loads from crane and machine operation according to DIN 1055-10 short a Corresponding to the associated loads. wind, kmod the average of short and very short can be used. b For 186 2016 THERM+ H-I Connector technology Timber curtain wall 50/56/76/96 mm TC timber connector Static dimensioning Table NA.4 – Calculated values for modification coefficients kmod for timber, timber- and plaster materials Extract from DIN EN 1995-1-1/NA:2010-12 – Germany Load effect duration class Standard Laminated beams, cross-laminated timber, solid timber boards Gypsum boards (types GKB, GKF, GKBI and GKFI), gypsum fibre boards Cement bonded chipboards DIN 18180, DIN EN 15283-2 Service class long effect medium effect short effect very short effect 1 0.60 0.70 0.80 0.90 1.10 2 0.60 0.70 0.80 0.90 1.10 1 0.20 0.40 0.60 0.80 1.10 2 0.15 0.30 0.45 0.60 0.80 1 0.30 0.45 0.65 0.85 1.10 2 0.20 0.30 0.45 0.60 0.80 THERM+ H-I Assembly options Building material constant effect Please note that the table is taken from the national appendix (D) of the Eurocode. If used in other countries the correspondingly applicable values must be used. Example: Glass loads = inherent weight load = constant effect, kmod = 0.6 Wind loads = average value of short and very short effect kmod = 1.0 Impact loads = very short effect, kmod = 1.10 To dimension the connector, the effects are compared with the load-bearing capacity of the connector. In this case the following applies: FED / FRD ≤ 1 wherein FED = design value of force resulting from the stress FRD = design value of the load-bearing capacity of the fastener resulting from the admissible values, taking into account coefficients. In the event of load case combinations these are superimposed according to the calculation formula (B1.5), see ETA-13/0765 as follows: (F1,ED / F1,RD)² + (F23,ED / F23,RD)² + (F45,ED / F45,RD)² ≤ 1 2016 187 THERM+ H-I Connector technology Timber curtain wall 50/56/76/96 mm TC timber connector Static dimensioning ■ Example of calculation on the basis of the façade element shown Field width = 2.3 m Field height upper = 2.6 m Field height lower = 0.9 m Total glass thickness = 16 mm Stanchion load = 1.0 kN/m (cat B) Wind load suction + pressure = 0.5 KN/m² The inherent weight of the transom is not taken into account in this calculation. Gross density of laminated timber = 350 kg/m³ Use: Hotel AW type 1: Triangular load Field height > field width Effects Inherent weight load = glass load on the transom Field height Feldhöhe oben above Field width Feldbreite AW type 2: Trapezoidal load Field height < field width F45,ED = 2.12 KN x 1.35 = 2.86 KN Load surfaces for wind load/stanchion load: The wind suction load case is relevant in this case because it acts in the same direction as the stanchion load. In the case of type 1: Aw = Field width x field width 4 In the case of type 2: Aw = Field width x field height lower Field height lower x field height lower – 2 4 = = 2.3 m x 2.3 m = 1.32 m2 4 2.3 m x 0.9 m 0.9 m x 0.9 m – = 0.83 m2 2 4 Total stress surface = 1.32 m² + 0.83 m² = 2.15 m² Calculating of wind load on the transom: Total wind load = 2.15 m² x 0.5 kN/m² = 1.08 KN Partial safety factor of the effect γQ = 1.50 FW,ED = 1.08 x 1.50 = 1.62 KN Stanchion load FH = transom length x stanchion load = 2.3 m x 1.0 KN/m = 2.3 KN FH,ED = 2.30 x 1.50 = 3.45 KN Superimposition of the wind load and stanchion load: ψO = 0.6 for wind loads / 0.8 for other loads (Germany) LFK1: F3,ED = FW,ED + FH,ED x 0.8 = 1.62 + 3.45 x 0.8 = 4.38 KN LFK2: F3,ED = FH,ED + FW,ED x 0.6 = 3.45 + 1.62 x 0.6 = 4.42 KN Load case combination 2 is relevant. 188 2016 unten below Partial safety factor of the effect ϒG = 1.35 for independent constant loads Field height Feldhöhe Glass weight = 2.3 x 2.6 x 16 x 2.5 ≈ 212 kg = 2.12 KN THERM+ H-I Connector technology Timber curtain wall 50/56/76/96 mm TC timber connector Static dimensioning Resistance of the connector: SOLO 143 connector is used. On the basis of the gross density, the values from Table C1 – ETA-13/0765 can be used. These are: THERM+ H-I Assembly options F1,RK = 4.6 KN F3,RK (wind suction) = 5.8 KN F45,RK = 3.2 KN Please note that these values apply per connection and in the following calculation for a transom they are multiplied by a factor of 2. Resistance of the T-connectors in direction F45 – glass load Kmod for BSH service class 2 = 0.6 Safety factor γM for BSH = 1.30 F45,RD+ = F45,RK x (2 x 0.6 / 1.30) = 2.95 KN Resistance of the T-connection in direction F3 – wind suction Kmod for BSH service class 1 + 2 = 1.0 for wind loads = 1.10 for stanchion loads Because of the different Kmod the lower value of 1.0 is used for the calculation. Safety factor γM for BSH = 1.30 F3,RD = F3,RK x 2 x 1.0 = 8.92 KN 1.3 The load F1 is not taken into account. Proof for F45 F45,ED F45,RD = 2,86 2.86 2,95 2.95 = 0,97 4,42 4.42 8,92 8.92 = 0,5 Proof for F3 F3,ED F3,RD = Proof for combined load: (F1,ED / F1,RD)² + (F3,ED / F3,RD)² + (F45,ED / F45,RD)² < 1 (0 / 0)² + 0.5² + 0.97² = 0 + 0.24 + 0.94 = 1.19 2016 189 THERM+ H-I Connector technology Timber curtain wall 50/56/76/96 mm TC timber connector Static dimensioning ■ Result The connector cannot sustain the loads imposed. A lower connector or a KOMBI type connector must be used. In the case of the KOMBI 143, while maintaining the values, the following load-bearing capacities are obtained on the basis of the following values: F1,RK = 4.6 KN F3,RK (wind suction) = 5.8 KN F45,RK = 6.2 KN F45,RD = 6.2 x 2 x 0.6 1.3 F3,RD = 5.8 x 2 x 1.0 = 8.92 KN 1.3 = 5.72 KN Verification for combined loads with the KOMBI type connector: (F1,ED / F1,RD)² + (F3,ED / F3,RD)² + (F45,ED / F45,RD)² = (0 / 0)² + (4.42 / 8.92)² + (2.86 / 5.72)² = 0 + 0.5² + 0.52 = 0.5 This verification is satisfied; the load-bearing capacity of the connector is adequate. The following table provides orientation for the design width of the SOLO and KOMBI T-connectors taking into account the following factors: Gross density timber = 350 kg/m³ Kmod = 0.6 for load type F45 Kmod = 1.0 for load type F2.3 Kmod = 0.6 for load type F1 Partial safety factor of material γM= 1.30 Partial safety factor of constant load γG = 1.35 Partial safety factor of variable load γQ = 1.50 Design value for maximum glass load in direction F45 per transom (load case combinations shall be superimposed) SOLO 116 kg 138 kg 162 kg 182 kg 218 kg 250 kg 276 kg TC60 TC80 TC100 TC120 TC160 TC200 TC240 KOMBI 253 kg 274 kg 367 kg 388 kg 423 kg 455 kg 481 kg Design value for maximum wind pressure-/suction load in direction F2,3 per transom (load case combinations shall be superimposed) TC SOLO/KOMBI 60 TC SOLO/KOMBI 80 TC SOLO/KOMBI 100 TC SOLO/KOMBI 120 TC SOLO/KOMBI 160 TC SOLO/KOMBI 200 TC SOLO/KOMBI 240 190 2016 F2 – wind pressure F3 – wind suction 3.47 KN 5.21 KN 5.21 KN 6.95 KN 6.95 KN 7.18 KN 7.18 KN 3.47 KN 5.21 KN 5.21 KN 5.95 KN 5.95 KN 5.95 KN 5.95 KN THERM+ H-I Glazing/Sealing technology Timber curtain wall 50/56/76/96 mm Glass load transmission up to 200 kg – For glass loads up to 200 kg the load transmission needs one glass carrier per side. - Synthetic glass carrier: Infill thicknesses from 10 up to 64 mm: Fixation with 3 countersunk screws no. 012029 each. - Aluminium glass carrier: Infill thickness up to 28 mm fixed by 3 countersunk screws no. 012028 each. Infill thickness from 29 mm fixed by 3 flat fillister head screws no. 012100 each. – Two special timber screws no. 908020 additionally on top of the glass carrier. – Max. load per glass carrier: 100 kg. Selection of the glass carriers Infill Synthetic thickness glass carrier mm no. 10 to 14 162005 15 to 16 17 to 18 19 to 20 21 to 22 23 to 24 25 to 26 27 to 28 29 to 30 31 to 32 33 to 34 35 to 36 37 to 38 39 to 40 41 to 42 43 to 44 45 to 46 47 to 48 49 to 50 51 to 52 53 to 54 55 to 56 57 to 58 59 to 60 61 to 62 63 to 64 KH-0500 162010 162015 162020 162025 162030 162035 162040 162045 162050 162055 162060 162065 162070 162075 162080 162085 162090 162095 162100 162105 162110 162115 162120 162125 162130 Aluminium glass carrier no. 167306 167311 167316 167321 167326 167331 167336 167341 167346 167351 167356 167361 167366 167371 167376 167381 167386 167391 167396 167401 167906 167911 167916 167921 167926 167931 Article PU Glass carrier 10 to 14 10 pc(s) Glass carrier 15 to 16 Glass carrier 17 to 18 Glass carrier 19 to 20 Glass carrier 21 to 22 Glass carrier 23 to 24 Glass carrier 25 to 26 Glass carrier 27 to 28 Glass carrier 29 to 30 Glass carrier 31 to 32 Glass carrier 33 to 34 Glass carrier 35 to 36 Glass carrier 37 to 38 Glass carrier 39 to 40 Glass carrier 41 to 42 Glass carrier 43 to 44 Glass carrier 45 to 46 Glass carrier 47 to 48 Glass carrier 49 to 50 Glass carrier 51 to 52 Glass carrier 53 to 54 Glass carrier 55 to 56 Glass carrier 57 to 58 Glass carrier 59 to 60 Glass carrier 61 to 62 Glass carrier 63 to 64 2016 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 191 THERM+ H-I Assembly options ■ Technical information THERM+ H-I Glazing/Sealing technology Timber curtain wall 50/56/76/96 mm Glass load transmission up to 300 kg ■ Technical information – For glass loads up to 300 kg the load transmission needs one glass carrier per side. - Synthetic glass carrier: Infill thicknesses from 10 up to 64 mm: Fixation with 3 countersunk screws no. 012029 each. - Aluminium glass carrier: Infill thickness up to 28 mm fixed by 3 countersunk screws no. 012028 each. Infill thickness from 29 mm fixed by 3 flat fillister head screws no. 012100 each. – Three special timber screws no. 908020 additionally on top of the glass carrier. – Max. load per glass carrier: 150 kg. 192 2016 Selection of the glass carriers Infill Synthetic thickness glass carrier mm no. 10 to 14 162005 15 to 16 17 to 18 19 to 20 21 to 22 23 to 24 25 to 26 27 to 28 29 to 30 31 to 32 33 to 34 35 to 36 37 to 38 39 to 40 41 to 42 43 to 44 45 to 46 47 to 48 49 to 50 51 to 52 53 to 54 55 to 56 57 to 58 59 to 60 61 to 62 63 to 64 KH-0502 162010 162015 162020 162025 162030 162035 162040 162045 162050 162055 162060 162065 162070 162075 162080 162085 162090 162095 162100 162105 162110 162115 162120 162125 162130 Aluminium glass carrier no. 167306 167311 167316 167321 167326 167331 167336 167341 167346 167351 167356 167361 167366 167371 167376 167381 167386 167391 167396 167401 167906 167911 167916 167921 167926 167931 Article PU Glass carrier 10 to 14 10 pc(s) Glass carrier 15 to 16 Glass carrier 17 to 18 Glass carrier 19 to 20 Glass carrier 21 to 22 Glass carrier 23 to 24 Glass carrier 25 to 26 Glass carrier 27 to 28 Glass carrier 29 to 30 Glass carrier 31 to 32 Glass carrier 33 to 34 Glass carrier 35 to 36 Glass carrier 37 to 38 Glass carrier 39 to 40 Glass carrier 41 to 42 Glass carrier 43 to 44 Glass carrier 45 to 46 Glass carrier 47 to 48 Glass carrier 49 to 50 Glass carrier 51 to 52 Glass carrier 53 to 54 Glass carrier 55 to 56 Glass carrier 57 to 58 Glass carrier 59 to 60 Glass carrier 61 to 62 Glass carrier 63 to 64 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) THERM+ H-I Glazing/Sealing technology Timber curtain wall 50/56/76/96 mm Glass load transmission up to 450 kg – For glass loads up to 450 kg the load transmission needs two glass carrier per side. - Synthetic glass carrier: Infill thicknesses from 10 up to 64 mm: Fixation with 3 countersunk screws no. 012029 each. - Aluminium glass carrier: Infill thickness up to 28 mm fixed by 3 countersunk screws no. 012028 each. Infill thickness from 29 mm fixed by 3 flat fillister head screws no. 012100 each. – Eight special timber screws no. 908020 additionally on top and at the bottom of the glass carrier. – Max. load per glass carrier: 225 kg. Selection of the glass carriers Infill Synthetic thickness glass carrier mm no. 10 to 14 162005 15 to 16 17 to 18 19 to 20 21 to 22 23 to 24 25 to 26 27 to 28 29 to 30 31 to 32 33 to 34 35 to 36 37 to 38 39 to 40 41 to 42 43 to 44 45 to 46 47 to 48 49 to 50 51 to 52 53 to 54 55 to 56 57 to 58 59 to 60 61 to 62 63 to 64 KH-0501 162010 162015 162020 162025 162030 162035 162040 162045 162050 162055 162060 162065 162070 162075 162080 162085 162090 162095 162100 162105 162110 162115 162120 162125 162130 Aluminium glass carrier no. 167306 167311 167316 167321 167326 167331 167336 167341 167346 167351 167356 167361 167366 167371 167376 167381 167386 167391 167396 167401 167906 167911 167916 167921 167926 167931 Article PU Glass carrier 10 to 14 10 pc(s) Glass carrier 15 to 16 Glass carrier 17 to 18 Glass carrier 19 to 20 Glass carrier 21 to 22 Glass carrier 23 to 24 Glass carrier 25 to 26 Glass carrier 27 to 28 Glass carrier 29 to 30 Glass carrier 31 to 32 Glass carrier 33 to 34 Glass carrier 35 to 36 Glass carrier 37 to 38 Glass carrier 39 to 40 Glass carrier 41 to 42 Glass carrier 43 to 44 Glass carrier 45 to 46 Glass carrier 47 to 48 Glass carrier 49 to 50 Glass carrier 51 to 52 Glass carrier 53 to 54 Glass carrier 55 to 56 Glass carrier 57 to 58 Glass carrier 59 to 60 Glass carrier 61 to 62 Glass carrier 63 to 64 2016 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 193 THERM+ H-I Assembly options ■ Technical information THERM+ H-I Glazing/Sealing technology Timber curtain wall 50/56/76/96 mm Glass load transmission up to 200 kg Interior gaskets 26 mm ■ Technical information – For glass loads up to 200 kg the load transmission needs one glass carrier each side. - Aluminium glass carrier: Fixation with 3 special flat fillister head screws no. 908308 each. – Two special timber screws no. 908020 additionally on top of the glass carrier. – 2 additional screws for the base profile in the area of the glass carrier. – Max. load per glass carrier: 100 kg. 194 2016 Selection of the glass carriers Infill Aluminium thickness glass carrier mm no. 4 to 5 167555 6 to 7 167556 8 to 9 167557 10 to 11 167558 12 to 13 167559 14 to 15 167560 16 to 17 167561 18 to 19 167562 20 167563 KH-0563 Article Nominal size PU Glass carrier 8/13 Glass carrier 10/13 Glass carrier 12/13 Glass carrier 14/13 Glass carrier 16/13 Glass carrier 18/13 Glass carrier 20/13 Glass carrier 22/13 Glass carrier 24/13 8 10 12 14 16 18 20 22 24 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) THERM+ H-I Glazing/Sealing technology Timber curtain wall 50/56/76 mm Assembly cross point glass carrier ■ Technical information – Admissable glass loads: Infill thicknesses 35 mm to 52 mm: 450 kg to 600 kg Infill thicknesses 53 mm to 64 mm: 450 kg to 500 kg. T145 – Max. load per support point = max. glass load : 2. – Do not use the cross point glass carrier with specific flat pressure profiles. THERM+ H-I Assembly options – Please contact your glass vendor for clarifying the reduced distance of the setting block to axis of the mullion (50 mm). – The load transmission across the cross point glass carrier must be taken by the structural construction. – The base profile must be screwed down additionally (see Processing). – T144 = Glass shim. – T145 = Cross point glass carriers set (selection see table). – T149 = External view. KH-0015 2016 195 THERM+ H-I Glazing/Sealing technology Timber curtain wall 50/56/76 mm Assembly and installation cross point glass carriers ■ Technical information Selection of the cross point glass carriers – T82 = Mullion element. Infill thickness mm 35 to 36 37 to 38 39 to 40 41 to 42 43 to 44 45 to 46 47 to 48 49 to 50 51 to 52 53 to 54 55 to 56 57 to 58 59 to 60 61 to 62 63 to 64 – T86 = Transom element. 35 to - 64 mm T82 T86 No. Article PU 163750 163752 163754 163756 163758 163760 163762 163764 163766 163768 163770 163772 163774 163776 163778 Cross point glass carrier set 35 to 36 Cross point glass carrier set 37 to 38 Cross point glass carrier set 39 to 40 Cross point glass carrier set 41 to 42 Cross point glass carrier set 43 to 44 Cross point glass carrier set 45 to 46 Cross point glass carrier set 47 to 48 Cross point glass carrier set 49 to 50 Cross point glass carrier set 51 to 52 Cross point glass carrier set 53 to 54 Cross point glass carrier set 55 to 56 Cross point glass carrier set 57 to 58 Cross point glass carrier set 59 to 60 Cross point glass carrier set 61 to 62 Cross point glass carrier set 63 to 64 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) Content per set: 2 cross point glass carriers each (1 set per transom). Selection of screws Alternative: individual order (number of screws per cross point glass carrier) Screw set no. or 163790 Connection mullion with transom piece Screw connection in mullion Screw connection in transom Double-sided Unilateral No. No. No. No. 2x 012101 3x 012153 6x 012101 3x 012101 Content per set: screws for 2 cross point glass carriers (1 set per transom needed). Assembly cross point glass carrier set Assembly cross point glass carrier set – Assembly double-sided (e. g. in cross point). – Unilateral assembly (e. g. im the edge region). The transom piece has to be shortened accordingly. – Screws have to be ordered separately (see table). – Screws have to be ordered separately (see table). 196 2016 KH-0015 THERM+ H-I Glazing/Sealing technology Timber curtain wall 50/56/76/96 mm Interior sealing system Curtain wall, standard ■ Technical information The timber construction must be flush on the glazing side. Max. misalignment between mullion and transom = ± 0.5 mm. – Applicable gaskets THERM+ H-I Assembly options - Gasket for mullion with notching by special tool (see Processing) No. 150005 Gasket for mullion 50 No. 150105 Gasket for mullion 56 No. 150205 Gasket for mullion 76 No. 150705 Gasket for mullion 96 No. 150040 to 150050 Gasket for mullion 50 polygon No. 150140 to 150150 Gasket for mullion 56 polygon – - Gasket for transom with notching by special tool (see Processing) No. 150010 Gasket for transom 50 No. 150110 Gasket for transom 56 No. 150210 Gasket for transom 76 No. 150710 Gasket for transom 96 Sealing piece for transom gasket No. 152010 Transom sealing piece 50 No. 152015 Transom sealing piece 56 No. 152020 Transom sealing piece 76 - PU = 100 pc(s) - Assembly without sealing material. Transom sealing piece 96 P No. 152086 Transom sealing piece 96 P - PU = 100 pc(s) - Assembly with sealing material D2, no. 952015 or with Special Silicon B1, no. 952020. KH-0001 2016 197 THERM+ H-I Glazing/Sealing technology Timber curtain wall 50/56 mm Interior sealing system Curtain wall, expansion mullion for assembling elements ■ Technical information The timber construction must be flush on the glazing side. Max. misalignment between mullion and transom = ± 0.5 mm. – Pre-Assembly of complete and ready-for-glazing elements with specific base profiles and half gaskets as well as parts of accessories: – Applicable gaskets - Gasket for mullion with notching by special tool (see Processing) No. 150305 Gasket for mullion 50 H No. 150335 Gasket for mullion 56 H No. 168201 Insertion profile 18/14 I - Gasket for transom with notching by special tool (see Processing) No. 150010 Gasket for transom 50 No. 150110 Gasket for transom 56 Sealing piece for transom gasket No. 152010 Transom sealing piece 50 No. 152015 Transom sealing piece 56 - PU = 100 pc(s) - Assembly without sealing material. 198 2016 KH-0001.2 THERM+ H-I Glazing/Sealing technology Timber curtain wall 50/56/76 mm Interior sealing system Curtain wall, gasket for transom with flap ■ Technical information The timber construction must be flush on the glazing side. Max. misalignment between mullion and transom = ± 0.5 mm. – Applicable gaskets THERM+ H-I Assembly options - Gasket for mullion with notching by special tool (see Processing) No. 150005 Gasket for mullion 50 No. 150105 Gasket for mullion 56 No. 150205 Gasket for mullion 76 No. 150040 to 150050 Gasket for mullion 50 polygon No. 150140 to 150150 Gasket for mullion 56 polygon - Gasket for transom with notching by special tool (see Processing) No. 150015 Gasket for transom 50, flap No. 150115 Gasket for transom 56, flap No. 150215 Gasket for transom 76, flap Sealing piece for transom gasket No. 152010 Transom sealing piece 50 No. 152015 Transom sealing piece 56 No. 152020 Transom sealing piece 76 - PU = 100 pc(s) - Assembly without sealing material. – T196 = Belay sheet no. 167007. – T198 = Screw no. 908118. KH-0002 2016 199 THERM+ H-I Glazing/Sealing technology Timber curtain wall 50/56/76 mm Interior sealing system Curtain wall, base gasket with flap ■ Technical information The timber construction must be flush on the glazing side. Max. misalignment between mullion and transom = ± 0.5 mm. – Applicable gaskets - Base gasket with notching by special tool (see Processing) No. 150020 Base gasket 50, flap No. 150120 Base gasket 56, flap No. 150220 Base gasket 76, flap Sealing piece for transom gasket No. 152070 Transom sealing piece, applicable for all system widths. - PU = 10 pc(s) - Assembly with sealing material D2, no. 952015. – T196 = Sealing piece no. 167007. – T198 = Screw no. 908118. – T199 = Sealing piece. 200 2016 KH-0003 THERM+ H-I Glazing/Sealing technology Timber curtain wall 50/56/76 mm Interior sealing system Curtain wall, base gasket with flap, version center mullion ■ Technical information The timber construction must be flush on the glazing side. Max. misalignment between mullion and transom = ± 0.5 mm. – Applicable gaskets (PU = 20 m) THERM+ H-I Assembly options - Base gasket with notching by special tool (see Processing) No. 150020 Base gasket 50, flap No. 150120 Base gasket 56, flap No. 150220 Base gasket 76, flap - PU = 10 pcs. - Assembly with sealing material D2, no. 952015. KH-0004 2016 201 THERM+ H-I Glazing/Sealing technology Timber curtain wall 50/56/76 mm Interior sealing system 3 drainage levels ■ Technical information Interior gaskets for drainage level 1 – T38 = Level 2. Article Gasket for transom 50 Gasket for transom 56 Gasket for transom 76 – T39 = Level 3. – T40 = Level 1. – T151 = Interior gasket E3. No. 150010 150110 150210 PU 20 m 20 m 20 m – T152 = Interior gasket E2. – T153 = Interior gasket E1. – T159 = Interior gasket E2 with flap. Interior gaskets for drainage level 2 Article Interior gasket 50 E2 Interior gasket 50 E2, flap Interior gasket 56 E2 Interior gasket 56 E2, flap Interior gasket 76 E2 No. 150013 150018 150113 150118 150213 PU 20 m 20 m 20 m 20 m 20 m Interior gaskets for drainage level 3 Article Interior gasket 50 E3 Interior gasket 56 E3 Interior gasket 76 E3 No. 150008 150108 150208 PU 20 m 20 m 20 m Transom sealing pieces for drainage level 1 Article Transom sealing piece 50 Transom sealing piece 56 Transom sealing piece 76 No. 152010 152015 152020 PU 100 pc(s) 100 pc(s) 100 pc(s) Transom sealing pieces for drainage level 2 Article Transom sealing piece 50 E2 Transom sealing piece 56 E2 Transom sealing piece 76 E2 202 2016 K-0011 No. 152009 152014 152019 PU 100 pc(s) 100 pc(s) 100 pc(s) THERM+ H-I Glazing/Sealing technology Timber curtain wall 50/56/76 mm Interior sealing system Curtain wall, drainage level 1 to level 2 ■ Technical information The timber construction must be flush on the glazing side. Max. misalignment between mullion and transom = ± 0.5 mm. – Applicable gaskets THERM+ H-I Assembly options - Gasket for transom with notching by special tool (see Processing) No. 150010 Gasket for transom 50 No. 150110 Gasket for transom 56 No. 150210 Gasket for transom 76 – - Gasket for transom with notching by special tool (see Processing) No. 150013 Interior gasket 50 E2 No. 150113 Interior gasket 56 E2 No. 150213 Interior gasket 76 E2 Sealing piece for transom gasket No. 152010 Transom sealing piece 50 No. 152015 Transom sealing piece 56 No. 152020 Transom sealing piece 76 - PU = 100 pc(s) - Assembly without sealing material. – T38 = Level 2. – T40 = Level 1. KH-0012 2016 203 THERM+ H-I Glazing/Sealing technology Timber curtain wall 50/56/76 mm Interior sealing system Curtain wall, drainage level 2 to level 3 ■ Technical information The timber construction must be flush on the glazing side. Max. misalignment between mullion and transom = ± 0.5 mm. – Applicable gaskets - Gasket for transom with notching by special tool (see Processing) No. 150010 Interior gasket 50 No. 150110 Interior gasket 56 No. 150210 Interior gasket 76 – - Gasket for transom with notching by special tool (see Processing) No. 150013 Interior gasket 50 E2 No. 150113 Interior gasket 56 E2 No. 150213 Interior gasket 76 E2 Sealing piece for transom gasket No. 152009 Transom sealing piece 50 E2 No. 152014 Transom sealing piece 56 E2 No. 152019 Transom sealing piece 76 E2 - PU = 100 pc(s) - Assembly without sealing material. – T38 = Level 2. – T39 = Level 3. – T188 = Transom sealing piece. 204 2016 KH-0001.1 THERM+ H-I Glazing/Sealing technology Timber curtain wall 50/56 mm Interior sealing system Curtain wall, drainage level 2 to level 3 with flaps ■ Technical information – Applicable gaskets – - Gasket for mullion with notching by special tool (see Processing) No. 150008 Interior gasket 50 E3 No. 150108 Interior gasket 56 E3 THERM+ H-I Assembly options - Gasket for transom with notching by special tool (see Processing) No. 150018 Interior gasket 50 E2 flap No. 150118 Interior gasket 56 E2 flap Sealing piece for transom gasket No. 152009 Transom sealing piece 50 E2 No. 152014 Transom sealing piece 56 E2 - PU = 100 pc(s) - Assembly without sealing material. – T38 = Level 2. – T39 = Level 3. – T197 = Sealing piece no. 167008. – T198 = Screw no. 908118. KH-0009 2016 205 THERM+ H-I Glazing/Sealing technology Timber curtain wall 50 mm Interior sealing system Curtain wall, interior gasket with a height of 26 mm ■ Technical information The timber construction must be flush on the glazing side. Max. misalignment between mullion and transom = ± 0.5 mm. – Applicable gaskets - Gasket for transom with notching by special tool (see Processing). No. 150461 Transom gasket 50/26 No. 150462 Interior gasket 50/26 E3 No. 150463 Interior gasket 50/26 E2 Sealing piece for transom gasket No. 152007 Transom sealing piece 50/26 E1 No. 152011 Transom sealing piece 50/26 E2 - PU = 100 pc(s) - Assembly without sealing material. – T188 = Transom sealing piece. 206 2016 KH-0017 THERM+ H-I Glazing/Sealing technology Timber curtain wall 50/56/76 mm Interior sealing system Gasket joint with stainless steel sealing piece A ■ Technical information – The joint areas must be sealed carefully with sealing material. The stainless steel sealing pieces must be fixed with two screws no. 908118 each. – For more information see Processing. – T199 = Sealing piece. A Straight extension Stainless steel sealing piece System width for mullion for transom for level E3 mm no. no. no. 50 B B T199 C C PU 167105 167131 167103 10 pc(s) 56 167115 – – 10 pc(s) 76 167125 – – 10 pc(s) Exterior angle 90° to 180° Stainless steel sealing piece System width mm for mullion no. for level E3 no. PU 50 167106 167098 10 pc(s) 56 167116 167112 10 pc(s) 76 167126 – 10 pc(s) Interior angle 180° to 270° Stainless steel sealing piece System width mm for mullion no. for level E3 no. PU 50 167107 167099 10 pc(s) 56 167117 – 10 pc(s) 76 167127 – 10 pc(s) T199 D D Exterior angle 0° to 90° System width mm Stainless steel sealing piece 50 167130 10 pc(s) 56 167132 10 pc(s) 76 167134 10 pc(s) for transom no. PU T199 KH-0006, KH-0007, KH-0008; KH-0018 2016 207 THERM+ H-I Assembly options T199 THERM+ H-I Glazing/Sealing technology Timber curtain wall 50/56 mm Interior sealing system Pressure compensation via mullion rebate ■ Technical information Measure x for the shortening of the sealing piece – The synthetic sealing piece supports the ventilation as well as the condensate drainage. – The flaps of the gasket for mullions must be notched in the area of the sealing pieces. – Shorten the sealing piece according to the infill thickness (see table) and fix it with a pan head tapping screw no. 012103. – Assembly with sealing material D2, no. 952015. 118005 118010 2016 013007 013027 013008 013028 013014 24 28 – 28 30 26 30 26 28 27 to 28 24 28 24 26 29 to 30 22 26 22 24 31 to 32 20 24 20 22 33 to 34 18 22 18 20 35 to 36 16 20 16 18 37 to 38 14 18 14 16 39 to 40 12 16 12 14 41 to 42 10 14 10 12 43 to 44 8 12 8 10 45 to 46 6 10 6 8 47 to 48 4 8 4 6 49 to 50 2 6 2 4 51 to 52 0 4 0 2 50/56 208 013018 013038 25 to 26 to measure x – For more information see Processing. Pressure profile no. Infill thickness mm K-0005 THERM+ H-I Glazing/Sealing technology Timber curtain wall 50/56/76/96 mm Exterior sealing system Pressure profiles and snap-in cover profiles ■ Technical information Stainless steel cross point sealing plates self-adhesive, assembly at the glass edge No. – T163 = Sealing piece for pressure profile. Application area PU 016050 Pressure profiles 50 mm 10 pc(s) 016051 Pressure profiles 56 mm 10 pc(s) 016052 Pressure profiles 76 mm 10 pc(s) 167480 Pressure profiles 96 mm 10 pc(s) EPDM sealing pieces for pressure profiles self-adhesive, assembly at the interior side of the pressure profile No. KH-0200 Application area PU 014035 Pressure profiles 50 mm 10 pc(s) 014036 Pressure profiles 56 mm 10 pc(s) 014037 Pressure profiles 76 mm 10 pc(s) 152425 Pressure profiles 96 mm 10 pc(s) 2016 209 THERM+ H-I Assembly options – T162 = Cross point sealing plate. THERM+ H-I Glazing/Sealing technology Timber curtain wall 50/56/76/96 mm Exterior sealing system Pressure profiles with visible screw connection ■ Technical information Stainless steel cross point sealing plates self-adhesive, assembly at the glass edge – T162 = Cross point sealing plate. No. – T163 = Sealing piece for pressure profile. Application area PU 016050 Pressure profiles 50 mm 10 pc(s) 016051 Pressure profiles 56 mm 10 pc(s) 016052 Pressure profiles 76 mm 10 pc(s) 167480 Pressure profiles 96 mm 10 pc(s) EPDM sealing pieces for pressure profiles self-adhesive, assembly at the interior side of the pressure profile No. 210 2016 KH-0202 Application area PU 014035 Pressure profiles 50 mm 10 pc(s) 014036 Pressure profiles 56 mm 10 pc(s) 014037 Pressure profiles 76 mm 10 pc(s) 152425 Pressure profiles 96 mm 10 pc(s) THERM+ H-I Glazing/Sealing technology Timber curtain wall 50/56/76 mm Exterior sealing system Flat pressure profiles ■ Technical information Stainless steel cross point sealing plates self-adhesive, assembly at the glass edge No. – T41 = Notch. 016053 – T162 = Cross point sealing plate. – T163 = Sealing piece for pressure profile. 016054 016055 Application area PU Flat pressure profile 50 no. 013300 Flat pressure profile 56 no. 013310 Flat pressure profile 76 no. 013313 10 pc(s) 10 pc(s) 10 pc(s) EPDM sealing pieces for pressure profiles self-adhesive, assembly at the interior side of the pressure profile No. 014038 014039 014041 Application area PU Flat pressure profile 50 no. 013300 Flat pressure profile 56 no. 013310 Flat pressure profile 76 no. 013313 10 pc(s) 10 pc(s) 10 pc(s) T41 KH-0201 2016 211 THERM+ H-I Assembly options Notch the end of the flat pressure profiles for transom (see Processing). THERM+ H-I Glazing/Sealing technology Timber curtain wall 50/56/76 mm Exterior sealing system Assembly of insulating blocks ■ Technical information – All insulating blocks must be notched with a special tool at the end of the transom gasket (A) for assembling the sealing piece for pressure profile (see Processing). – The version with insulating blocks 21 and P must be notched (B) additionally with a special tool in the area of the glass support (see Processing). – PU of the insulating blocks: 50 m. – T50 = Notching A. – T51 = Notching B. – T162 = Cross point sealing plate. – T163 = Sealing piece for pressure profile. 212 2016 KH-0203 THERM+ H-I Glazing/Sealing technology Timber curtain wall 50/56/76 mm Exterior sealing system Cover profile joint curtain wall A B ■ Technical information Selection of interior joint plate and profile joint sealing plate – Do not joint the pressure profile at the cross point. Sealing piece for pressure profile no. Interior joint plate no. Profile joint sealing plate no. 013003 (50x15) 014035 167230 016070 013210 (50x20) 014035 167232 016070 141106 (50x30) 014035 167236 016070 – T176 = Pressure profile gasket. 013023 (56x15) 014036 167250 016071 – T177 = Interior joint plate. 013410 (56x20) 014036 167252 016071 – T178 = Profile joint sealing plate. 141307 (56x32) 014036 167257 016071 013610 (76x20) 014037 167272 016072 013050 (76x15) 014037 167270 016072 013615 (76x25) 014037 167274 016072 013620 (76x30) 014037 167276 016072 – T160 = Joint at intermediate range. – T161 = Joint at the cross point. – T163 = Sealing piece for pressure profile. – T174 = Pressure profile. – T175 = Cover profile. K-0016 2016 THERM+ H-I Assembly options Cover profile no. – Length exterior gasket = length pressure profile + 0.5 %. 213 THERM+ H-I Glazing/Sealing technology Timber curtain wall 50/56/76 mm Exterior sealing system Pressure profile joint curtain wall ■ Technical information Selection of profile joint sealing plate – Do not joint the pressure profile at the cross point. – Length exterior gasket = length pressure profile + 0.5 %. – T41 = Notch. – T163 = Sealing piece for pressure profile. – T174 = Pressure profile. – T176 = Pressure profiles gasket. – T178 = Profile joint sealing plate. 214 2016 K-0017, K-0018 Pressure profile no. Profile joint sealing plate no. Sealing piece for pressure profile no. 013300 (50x3) 014038 016073 013310 (56x3) 014039 016074 013313 (76x3) 014041 016075 013008 (50x9) 014035 016070 013007 (50x12) 014035 016070 013028 (56x9) 014036 016071 013027 (56x12) 014036 016071 THERM+ H-I Glazing/Sealing technology Timber curtain wall 50/56/76 mm Exterior sealing system Cross point sealing plates and transom sealing pieces sloping connection ■ Technical information – Pressure profiles sealing pieces No. 014080 to 014085, 152402 to 152422 for self-cutting acc. to angle (90°– α). Angle α – Cross point sealing plates No. 016080 to 016085 for self-cutting acc. to angle (90°– α). Cutted pieces have to be plane and burr-free. 90° to 84° 83° to 74° to 59° to 44° to – T41 = Notch. – T155 = Transom gasket. 75° 60° 45° 35° Left Right Left E2 Right E2 no. no. no. no. 152010 (50) 152010 (50) 152009 (50) 152009 (50) 152015 (56) 152015 (56) 152014 (56) 152014 (56) 152020 (76) 152020 (76) 152019 (76) 152019 (76) 152020 152020 152019 152019 152021 152024 152027 152030 152022 152025 152028 152031 152023 152026 152029 152032 – T186 = Self-cutting. – T188 = Transom sealing piece. Selection cross-point sealing plate and pressure profile sealing piece (self-cutting acc. to angle) Exterior gasket 5 mm System width mm Pressure and cover profile Pressure Pressure Cross point profile sealing profile sealing sealing plate Width x piece piece no. mm no. no. PU = 10 pc(s) PU = 5 pc(s) PU = 5 pc(s) For pressure and cover profile 50 016080 36 014080 56 016081 37 014081 152402 152412 76 016082 39 014082 152422 For flat pressure profile 50 016083 28 014083 56 016084 29 014084 76 016085 31 014085 Flat pressure profile K-0004 2016 215 THERM+ H-I Assembly options Selection of transom sealing piece THERM+ H-I Glazing/Sealing technology Timber curtain wall 50 mm Cutting and draw off dimensions ■ Technical information – RB = Grid width RH = Grid height. – T53 = Length flatpressure profile = RB - 51. – T54 = Length pressure profile with visible screwed connection = RB - 51. – T55 = Length cover profile clipped = RB - 51. – T56 = Length pressure profile = RB - 55. – T57 = Glass dimensions = RB or RH - 26. – T58 = Length transom gasket = RB - 28 + 0.5% add-on. – T66 = Length of the base profile = RB - 56. 216 2016 KH-0800 THERM+ H-I Glazing/Sealing technology Timber curtain wall 56 mm Cutting and draw off dimensions ■ Technical information – RB = Grid width RH = Grid height. – T60 = Length flat pressure profile = RB - 57. – T61 = Length pressure profile with visible screwed connection = RB - 57. – T62 = Length cover profile clipped = RB - 57. THERM+ H-I Assembly options – T63 = Length pressure profile = RB - 61. – T64 = Glass dimensions = RB or RH - 30. – T65 = Length transom gasket = RB - 34 + 0.5 % add-on. – T91 = Length of the base profile = SW - 62. KH-0801 2016 217 THERM+ H-I Glazing/Sealing technology Timber curtain wall 76 mm Cutting and draw off dimensions ■ Technical information – RB = Grid width RH = Grid height. – T64 = Glass dimension = RB or RH - 30. – T92 = Length cover profile = RB - 77. – T93 = Length pressure profile = RB - 81. – T94 = Glass dimensions = RB or RH - 46. – T95 = Length transom gasket = RB - 54 + 0.5% add-on. – T96 = Length profile = RB - 86. Passive house with insulating block P no. 168526 218 2016 KH-0802_0803 THERM+ H-I Glazing/Sealing technology Timber curtain wall 96 mm Cutting and draw off dimensions ■ Technical information – RB = Grid width RH = Grid height. – T97 = Length cover profile = RB - 97. – T98 = Length pressure profile = RB - 101. – T99 = Glass dimensions = RB or RH - 66. THERM+ H-I Assembly options – T100 = Length transom gasket = RB - 74 + 0.5% add-on. – T101 = Length profile = RB - 106. KH-0806 2016 219 THERM+ H-I Glazing/Sealing technology Timber curtain wall 50/56/76/96 mm Screw selection Pressure profiles with exterior gasket 3 mm ■ Technical information – For the application of the pressure profile gaskets 4, 6, 7, 8, 9, 11 and 13 extended screws must be used. – For pressure profile no. 118505, 118510, 118515, 118005, 118010, 118015, 118020. Infill thickness mm 12 13 to 14 15 to 16 17 to 19 20 to 22 23 to 24 25 to 26 27 to 29 30 to 32 33 to 34 35 to 36 37 to 39 40 to 42 43 to 44 45 to 46 47 to 49 50 to 52 53 to 54 55 to 56 57 to 59 60 to 62 63 to 64 220 2016 No. Length mm 012108 012109 012110 012111 012112 012113 012114 012115 012116 012117 012118 012119 012129 012123 012124 012125 012106 012126 012144 012127 012200 012128 28 30 32 35 38 40 42 45 48 50 52 55 58 60 62 65 68 70 72 75 78 80 – For pressure profile no. 013007, 013027. Infill thickness mm 12 to 14 15 to 17 18 to 19 20 to 21 22 to 24 25 to 27 28 to 29 30 to 31 32 to 34 35 to 37 38 to 39 40 to 41 42 to 44 45 to 47 48 to 49 50 to 51 52 to 54 55 to 57 58 to 59 60 to 61 62 to 64 No. Length mm 012011 012012 012139 012013 012014 012140 012015 012141 012016 012142 012017 012143 012018 012020 012146 012147 012148 012260 012149 012261 012262 35 38 40 42 45 48 50 52 55 58 60 62 65 68 70 72 75 78 80 82 85 KH-0040 – For pressure profile no. 013014, 013008, 013028. Infill thickness mm 12 13 to 14 15 to 17 18 to 20 21 to 22 23 to 24 25 to 27 28 to 30 31 to 32 33 to 34 35 to 37 38 to 40 41 to 42 43 to 44 45 to 47 48 to 50 51 to 52 53 to 54 55 to 57 58 to 60 61 to 62 63 to 64 No. Length mm 012138 012010 012011 012012 012139 012013 012014 012140 012015 012141 012016 012142 012017 012143 012018 012020 012146 012147 012148 012260 012149 012261 30 32 35 38 40 42 45 48 50 52 55 58 60 62 65 68 70 72 75 78 80 82 THERM+ H-I Glazing/Sealing technology – For pressure profile no. 118005, 118010, 118015, 118020. Infill thickness mm 12 to 13 14 to 15 16 to 18 19 to 21 22 to 23 24 to 25 26 to 28 29 to 31 32 to 33 34 to 35 36 to 38 39 to 41 42 to 43 44 to 45 46 to 48 49 to 51 52 to 53 54 to 55 56 to 58 59 to 61 62 to 63 64 No. Length mm 012109 012110 012111 012112 012113 012114 012115 012116 012117 012118 012119 012129 012123 012124 012125 012106 012126 012144 012127 012200 012128 012201 30 32 35 38 40 42 45 48 50 52 55 58 60 62 65 68 70 72 75 78 80 82 – For pressure profile no. 013007, 013027. Infill thickness mm 12 to 13 14 to 16 17 to 18 19 to 20 21 to 23 24 to 26 27 to 28 29 to 30 31 to 33 34 to 36 37 to 38 39 to 40 41 to 43 44 to 46 47 to 48 49 to 50 51 to 53 54 to 56 57 to 58 59 to 60 61 to 63 64 No. Length mm 012011 012012 012139 012013 012014 012140 012015 012141 012016 012142 012017 012143 012018 012020 012146 012147 012148 012260 012149 012261 012262 012265 35 38 40 42 45 48 50 52 55 58 60 62 65 68 70 72 75 78 80 82 85 88 KH-0050 THERM+ H-I Assembly options Timber curtain wall 50/56/76/96 mm Screw selection Pressure profiles with exterior gasket 5 mm – For pressure profile no. 013014, 013008, 013028. Infill thickness mm 12 to 13 14 to 16 17 to 19 20 to 21 22 to 23 24 to 26 27 to 29 30 to 31 32 to 33 34 to 36 37 to 39 40 to 41 42 to 43 44 to 46 47 to 49 50 to 51 52 to 53 54 to 56 57 to 59 60 to 61 62 to 63 64 No. Length mm 012010 012011 012012 012139 012013 012014 012140 012015 012141 012016 012142 012017 012143 012018 012020 012146 012147 012148 012260 012149 012261 012262 32 35 38 40 42 45 48 50 52 55 58 60 62 65 68 70 72 75 78 80 82 85 2016 221 THERM+ H-I Glazing/Sealing technology Timber curtain wall 50/56/76 mm Screw selection Flat pressure profiles with exterior gasket 2 mm – For pressure profile no. 013300, 013310, 013313. Infill thickness mm 22 to 23 24 to 26 27 to 29 30 to 31 32 to 33 34 to 36 37 to 39 40 to 41 42 to 43 44 to 46 47 to 49 50 to 51 52 to 53 54 to 56 57 to 59 60 to 61 62 to 63 64 222 2016 No. Length mm 012010 012011 012012 012139 012013 012014 012140 012015 012141 012016 012142 012017 012143 012018 012020 012146 012147 012148 32 35 38 40 42 45 48 50 52 55 58 60 62 65 68 70 72 75 – For pressure profile no. 013300, 013310, 013313. Infill thickness mm 22 to 24 25 to 27 28 to 29 30 to 31 32 to 34 35 to 37 38 to 39 40 to 41 42 to 44 45 to 47 48 to 49 50 to 51 52 to 54 55 to 57 58 to 59 60 to 61 62 to 64 No. Length mm 012174 012175 012176 012177 012178 012179 012180 012181 012182 012183 012184 012185 012186 012190 012187 012192 012188 35 38 40 42 45 48 50 52 55 58 60 62 65 68 70 72 75 KH-0042 – For pressure profile no. 013300, 013310, 013313. Infill thickness mm 22 to 23 24 to 25 26 to 28 29 to 31 32 to 33 34 to 35 36 to 38 39 to 41 42 to 43 44 to 45 46 to 48 49 to 51 52 to 53 54 to 55 56 to 58 59 to 61 62 to 63 64 No. Length mm 012109 012110 012111 012112 012113 012114 012115 012116 012117 012118 012119 012129 012123 012124 012125 012106 012126 012144 30 32 35 38 40 42 45 48 50 52 55 58 60 62 65 68 70 72 THERM+ H-I Glazing/Sealing technology – For pressure profile no. 118505, 118510, 118515, 118005, 118010, 118015, 118020. Infill thickness mm 4 5 to 6 7 to 9 10 to 12 13 to 14 15 to 16 17 to 19 20 to 22 23 to 24 25 to 26 27 to 29 30 to 32 33 to 34 35 to 36 37 to 39 40 to 42 43 to 44 45 to 46 47 to 49 50 to 52 No. Length mm 012109 012110 012111 012112 012113 012114 012115 012116 012117 012118 012119 012129 012123 012124 012125 012106 012126 012144 012127 012200 30 32 35 38 40 42 45 48 50 52 55 58 60 62 65 68 70 72 75 78 – For pressure profile no. 013007, 013027. Infill thickness mm 4 5 to 7 8 to 9 10 to 11 12 to 14 15 to 17 18 to 19 20 to 21 22 to 24 25 to 27 28 to 29 30 to 31 32 to 34 35 to 37 38 to 39 40 to 41 42 to 44 45 to 47 48 to 49 50 to 51 52 No. Length mm 012011 012012 012139 012013 012014 012140 012015 012141 012016 012142 012017 012143 012018 012020 012146 012147 012148 012260 012149 012261 012262 35 38 40 42 45 48 50 52 55 58 60 62 65 68 70 72 75 78 80 82 85 KH-0064 THERM+ H-I Assembly options Timber curtain wall 50 mm Screw selection Pressure profiles with exterior gasket 26 mm – For pressure profile no. 013014, 013008, 013028. Infill thickness mm 4 5 to 7 8 to 10 11 to 12 13 to 14 15 to 17 18 to 20 21 to 22 23 to 24 25 to 27 28 to 30 31 to 32 33 to 34 35 to 37 38 to 40 41 to 42 43 to 44 45 to 47 48 to 50 51 to 52 No. Length mm 012010 012011 012012 012139 012013 012014 012140 012015 012141 012016 012142 012017 012143 012018 012020 012146 012147 012148 012260 012149 32 35 38 40 42 45 48 50 52 55 58 60 62 65 68 70 72 75 78 80 2016 223 THERM+ H-I Glazing/Sealing technology Timber curtain wall 50/56 mm Screw selection Glazing with silicone joint and suction discs – For suction disc no. 163807, 163810, 163812. Infill thickness mm 20 to 21 22 to 23 24 to 25 26 to 27 28 to 29 30 to 31 32 to 33 34 to 35 36 to 37 38 to 39 40 to 41 42 to 43 44 to 45 46 to 47 48 to 49 50 to 51 52 to 53 54 to 55 56 to 58 59 to 61 62 to 64 224 2016 RAL 9004 no. 907204 907206 907208 907210 907212 907214 907216 907218 907220 907222 907224 907226 907228 907230 907232 907234 907236 907238 907240 907242 907244 – For suction disc no. 163807, 163810, 163812. Stainless steel no. 907254 907256 907258 907260 907262 907264 907266 907268 907270 907272 907274 907276 907278 907280 907282 907284 907286 907288 907290 907292 907294 Length mm Infill thickness mm 10 to 13 13 to 14 15 to 16 17 to 18 19 to 20 21 to 22 23 to 24 39 41 43 45 47 49 51 53 55 57 59 61 63 65 67 69 71 73 75 78 81 KH-0062, KH-0066 RAL 9004 no. 907204 907206 907208 907210 907212 907214 907216 Stainless steel no. 907254 907256 907258 907260 907262 907264 907266 Length mm 39 41 43 45 47 49 51 THERM+ H-I Accessories Timber curtain wall 50/56/76/96 mm Fixation of sun protection Assembly and information Selection of sockets – The fixation of the sun protection can be used for all system widths and pressure and cover profiles. No. – Assembling at any time, even at existing curtain walls. – For the selection of stainless steel sockets see table. The length results from the selection of pressure and cover profiles as well as from the infill thickness (detailed information see handling manual). – Applied load figueres see following pages. – Max. usability force FH regarding to one pair of sockets. – Max. usability force FH is constant at every load distance → FH = 0.80 kN. – A force crosswise to the mullion cannot be taken → FQ = 0 kN. – The indicated loads are dimensioning loads. – A connection plate by the customer (min. 40 x 10 mm) is used for leading the forces into the the screws. – The screws 5.5 has to be bolted with a bolting torque of min. 8 Nm. – The fixation of sun protection can only be used by pairs. – For each assembling situation a statical calculation is mandatory. The influencing variables of EUROCODE 1 and DIN 1055 have to be considered. – T13 = Infill thickness. – T33 = Fixation of sun protection. 169942 169946 169950 169954 169958 169962 169966 169970 169974 169978 169982 169986 169990 169994 169998 169999 Length mm 42 46 50 54 58 62 66 70 74 78 82 86 90 94 98 102 Selection of sleeves No. 169900 169901 169902 169903 169904 169905 169906 169907 169908 169909 169910 169911 169912 169913 169914 169915 169917 169918 169919 Length mm 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 42 44 46 – T34 = Length of socket. – T35 = Offset point of application a. – T185 = Dimensioning example for connection plate provided by customer. – T224 = See table. to T224 T185 ZH-1021 2016 225 THERM+ H-I Assembly options ■ Technical information THERM+ H-I Accessories Timber curtain wall 50/56/76/96 mm Fixation of sun protection Screw distance 90 mm Vertical force in use F [kN] 1.15 1.10 ■ Technical information 1.05 Calculation basis: 1.00 0.95 – Horizontal force FH: 0.8 kN. 0.90 – Thickness of connection plate: 10 mm. 0.85 – Material connection plate: Aluminium. 0.80 – Assembling and additional information see previous page. 0.75 0.70 0.65 – a = Offset point of application. 0.60 0.55 0.50 0.45 0.40 0.35 0.30 Length of socket [mm] Screw distance 130 mm Screw distance 110 mm Vertical force in use F [kN] Vertical force in use F [kN] 1.15 1.15 1.10 1.10 1.05 1.05 1.00 1.00 0.95 0.95 0.90 0.90 0.85 0.85 0.80 0.80 0.75 0.75 0.70 0.70 0.65 0.65 0.60 0.60 0.55 0.55 0.50 0.50 0.45 0.45 0.40 0.40 0.35 0.35 0.30 Length of socket [mm] 0.30 Screw distance 150 mm Length of socket [mm] Screw distance 170 mm Vertical force in use F [kN] Vertical force in use F [kN] 1.15 1.15 1.10 1.10 1.05 1.05 1.00 1.00 0.95 0.95 0.90 0.90 0.85 0.85 0.80 0.80 0.75 0.75 0.70 0.70 0.65 0.65 0.60 0.60 0.55 0.55 0.50 0.50 0.45 0.45 0.40 0.40 0.35 0.35 0.30 0.30 Length of socket [mm] 226 2016 Length of socket [mm] ZH-1020 THERM+ H-I Accessories Timber curtain wall 50/56/76 mm Fixation of sun protection for cover profiles 12 mm Exterior gasket 3 mm ■ Technical information – Cover profiles: No. 013004 (50 mm) No. 013024 (56 mm) No. 013051 (76 mm) – T74 = Infill thickness. ■ Selection of sockets and sealing sleeves Infill thickness mm 20 21 to 22 23 to 24 25 to 26 27 to 28 29 to 30 31 to 32 33 to 34 35 to 36 37 to 38 39 to 40 41 to 42 43 to 44 45 to 46 47 to 48 49 to 50 51 to 52 53 to 54 55 to 56 57 to 58 59 to 60 61 to 62 63 to 64 ZH-1001 No. socket No. sealing sleeve 169942 169946 169946 169950 169950 169954 169954 169958 169958 169962 169962 169966 169966 169970 169970 169974 169974 169978 169978 169982 169982 169986 169986 169903 169904 169903 169904 169903 169904 169903 169904 169903 169904 169903 169904 169903 169904 169903 169904 169903 169904 169903 169904 169903 169904 169903 2016 227 THERM+ H-I Assembly options – Pressure profiles: No. 118005 (50 mm) No. 118010 (56 mm) No. 118015 (76 mm) THERM+ H-I Accessories Timber curtain wall 50/56/76 mm Fixation of sun protection for cover profiles 12 mm Exterior gasket 5 mm ■ Technical information – Pressure profiles: No. 118005 (50 mm) No. 118010 (56 mm) No. 118015 (76 mm) – Cover profiles: No. 013004 (50 mm) No. 013024 (56 mm) No. 013051 (76 mm) – T74 = Infill thickness. ■ Selection of sockets and sealing sleeves Infill thickness mm 20 to 21 22 to 23 24 to 25 26 to 27 28 to 29 30 to 31 32 to 33 34 to 35 36 to 37 38 to 39 40 to 41 42 to 43 44 to 45 46 to 47 48 to 49 50 to 51 52 to 53 54 to 55 56 to 57 58 to 59 60 to 61 62 to 63 64 228 2016 ZH-1001 No. socket No. sealing sleeve 169946 169946 169950 169950 169954 169954 169958 169958 169962 169962 169966 169966 169970 169970 169974 169974 169978 169978 169982 169982 169986 169986 169990 169904 169903 169904 169903 169904 169903 169904 169903 169904 169903 169904 169903 169904 169903 169904 169903 169904 169903 169904 169903 169904 169903 169904 THERM+ H-I Accessories Timber curtain wall 50/56/76/96 mm Fixation of sun protection for cover profiles 15 mm Exterior gasket 3 mm ■ Technical information – Cover profiles: No. 013003 (50 mm) No. 013023 (56 mm) No. 013050 (76 mm) No. 141710 (96 mm) – T74 = Infill thickness. T74 ■ Selection of sockets and sealing sleeves Infill thickness mm 20 21 22 23 to 24 25 26 27 to 28 29 30 31 to 32 33 34 35 to 36 37 38 39 to 40 41 42 43 to 44 45 46 47 to 48 49 50 51 to 52 53 54 55 to 56 57 58 59 to 60 61 62 63 to 64 ZH-1002 No. socket No. sealing sleeve 169946 169946 169950 169950 169950 169954 169954 169954 169958 169958 169958 169962 169962 169962 169966 169966 169966 169970 169970 169970 169974 169974 169974 169978 169978 169978 169982 169982 169982 169986 169986 169986 169990 169990 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 2016 229 THERM+ H-I Assembly options – Pressure profiles: No. 118005 (50 mm) No. 118010 (56 mm) No. 118015 (76 mm) No. 118020 (96 mm) THERM+ H-I Accessories Timber curtain wall 50/56/76/96 mm Fixation of sun protection for cover profiles 15 mm Exterior gasket 5 mm ■ Technical information – Pressure profiles: No. 118005 (50 mm) No. 118010 (56 mm) No. 118015 (76 mm) No. 118020 (96 mm) – Cover profiles: No. 013003 (50 mm) No. 013023 (56 mm) No. 013050 (76 mm) No. 141710 (96 mm) – T74 = Infill thickness. ■ Selection of sockets and sealing sleeves T74 Infill thickness mm 20 21 22 to 23 24 25 26 to 27 28 29 30 to 31 32 33 34 to 35 36 37 38 to 39 40 41 42 to 43 44 45 46 to 47 48 49 50 to 51 52 53 54 to 55 56 57 58 to 59 60 61 62 to 63 64 230 2016 ZH-1002 No. socket No. sealing sleeve 169946 169950 169950 169950 169954 169954 169954 169958 169958 169958 169962 169962 169962 169966 169966 169966 169970 169970 169970 169974 169974 169974 169978 169978 169978 169982 169982 169982 169986 169986 169986 169990 169990 169990 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 THERM+ H-I Accessories Timber curtain wall 50/56/76 mm Fixation of sun protection for cover profiles 20 mm Exterior gasket 3 mm ■ Technical information – Cover profiles: No. 013210 (50 mm) No. 013410 (56 mm) No. 013610 (76 mm) – T74 = Infill thickness. ■ Selection of sockets and sealing sleeves T74 Infill thickness mm 20 21 to 22 23 to 24 25 to 26 27 to 28 29 to 30 31 to 32 33 to 34 35 to 36 37 to 38 39 to 40 41 to 42 43 to 44 45 to 46 47 to 48 49 to 50 51 to 52 53 to 54 55 to 56 57 to 58 59 to 60 61 to 62 63 to 64 ZH-1004 No. socket No. sealing sleeve 169950 169954 169954 169958 169958 169962 169962 169966 169966 169970 169970 169974 169974 169978 169978 169982 169982 169986 169986 169990 169990 169994 169994 169907 169908 169907 169908 169907 169908 169907 169908 169907 169908 169907 169908 169907 169908 169907 169908 169907 169908 169907 169908 169907 169908 169907 2016 231 THERM+ H-I Assembly options – Pressure profiles: No. 118005 (50 mm) No. 118010 (56 mm) No. 118015 (76 mm) THERM+ H-I Accessories Timber curtain wall 50/56/76 mm Fixation of sun protection for cover profiles 20 mm Exterior gasket 5 mm ■ Technical information – Pressure profiles: No. 118005 (50 mm) No. 118010 (56 mm) No. 118015 (76 mm) – Cover profiles: No. 013210 (50 mm) No. 013410 (56 mm) No. 013610 (76 mm) – T74 = Infill thickness. ■ Selection of sockets and sealing sleeves T74 Infill thickness mm 20 to 21 22 to 23 24 to 25 26 to 27 28 to 29 30 to 31 32 to 33 34 to 35 36 to 37 38 to 39 40 to 41 42 to 43 44 to 45 46 to 47 48 to 49 50 to 51 52 to 53 54 to 55 56 to 57 58 to 59 60 to 61 62 to 63 64 232 2016 ZH-1004 No. socket No. sealing sleeve 169954 169954 169958 169958 169962 169962 169966 169966 169970 169970 169974 169974 169978 169978 169982 169982 169986 169986 169990 169990 169994 169994 169998 169908 169907 169908 169907 169908 169907 169908 169907 169908 169907 169908 169907 169908 169907 169908 169907 169908 169907 169908 169907 169908 169907 169908 THERM+ H-I Accessories Timber curtain wall 50/56/76 mm Fixation of sun protection for cover profiles 25 mm Exterior gasket 3 mm ■ Technical information – Cover profiles: No. 013005 (50 mm) No. 013025 (56 mm) No. 141505 (76 mm) No. 013201 (50 mm) No. 013400 (56 mm) – T74 = Infill thickness. T74 ■ Selection of sockets and sealing sleeves Infill thickness mm 20 21 to 22 23 24 25 to 26 27 28 29 to 30 31 32 33 to 34 35 36 37 to 38 39 40 41 to 42 43 44 45 to 46 47 48 49 to 50 51 52 53 to 54 55 56 57 to 58 59 60 61 to 62 63 64 ZH-1003 No. socket No. sealing sleeve 169954 169954 169954 169958 169958 169958 169962 169962 169962 169966 169966 169966 169970 169970 169970 169974 169974 169974 169978 169978 169978 169982 169982 169982 169986 169986 169986 169990 169990 169990 169994 169994 169994 169998 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 2016 233 THERM+ H-I Assembly options – Pressure profiles: No. 118005 (50 mm) No. 118010 (56 mm) No. 118015 (76 mm) THERM+ H-I Accessories Timber curtain wall 50/56/76 mm Fixation of sun protection for cover profiles 25 mm Exterior gasket 5 mm ■ Technical information – Pressure profiles: No. 118005 (50 mm) No. 118010 (56 mm) No. 118015 (76 mm) – Cover profiles: No. 013005 (50 mm) No. 013025 (56 mm) No. 141505 (76 mm) No. 013201 (50 mm) No. 013400 (56 mm) – T74 = Infill thickness. ■ Selection of sockets and sealing sleeves T74 Infill thickness mm 20 to 21 22 23 24 to 25 26 27 28 to 29 30 31 32 to 33 34 35 36 to 37 38 39 40 to 41 42 43 44 to 45 46 47 48 to 49 50 51 52 to 53 54 55 56 to 57 58 59 60 to 61 62 63 64 234 2016 ZH-1003 No. socket No. sealing sleeve 169954 169954 169958 169958 169958 169962 169962 169962 169966 169966 169966 169970 169970 169970 169974 169974 169974 169978 169978 169978 169982 169982 169982 169986 169986 169986 169990 169990 169990 169994 169994 169994 169998 169998 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 THERM+ H-I Accessories Timber curtain wall 50/56/76/96 mm Fixation of sun protection for pressure profiles 7 mm Exterior gasket 3 mm ■ Technical information – Pressure profiles: No. 013018 (50 mm) No. 013038 (56 mm) No. 013068 (76 mm) No. 142770 (96 mm) T74 50 / 56 / 76 / 96 ■ Selection of sockets and sealing sleeves Infill thickness mm 20 21 to 22 23 24 25 to 26 27 28 29 to 30 31 32 33 to 34 35 36 37 to 38 39 40 41 to 42 43 44 45 to 46 47 48 49 to 50 51 52 53 to 54 55 56 57 to 58 59 60 61 to 62 63 64 ZH-1005 No. socket No. sealing sleeve 169942 169946 169946 169946 169950 169950 169950 169954 169954 169954 169958 169958 169958 169962 169962 169962 169966 169966 169966 169970 169970 169970 169974 169974 169974 169978 169978 169978 169982 169982 169982 169986 169986 169986 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 2016 235 THERM+ H-I Assembly options – T74 = Infill thickness. THERM+ H-I Accessories Timber curtain wall 50/56/76/96 mm Fixation of sun protection for pressure profiles 7 mm Exterior gasket 5 mm ■ Technical information – Pressure profiles: No. 013018 (50 mm) No. 013038 (56 mm) No. 013068 (76 mm) No. 142770 (96 mm) – T74 = Infill thickness. 50 / 56 / 76 / 96 ■ Selection of sockets and sealing sleeves T74 Infill thickness mm 20 to 21 22 23 24 to 25 26 27 28 to 29 30 31 32 to 33 34 35 36 to 37 38 39 40 to 41 42 43 44 to 45 46 47 48 to 49 50 51 52 to 53 54 55 56 to 57 58 59 60 to 61 62 63 64 236 2016 ZH-1005 No. socket No. sealing sleeve 169946 169946 169946 169950 169950 169950 169954 169954 169954 169958 169958 169958 169962 169962 169962 169966 169966 169966 169970 169970 169970 169974 169974 169974 169978 169978 169978 169982 169982 169982 169986 169986 169986 169990 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 THERM+ H-I Accessories Timber curtain wall 50/56 mm Fixation of sun protection for pressure profiles 9 mm Exterior gasket 3 mm ■ Technical information – Pressure profiles: No. 013008 (50 mm) No. 013028 (56 mm) T74 ■ Selection of sockets and sealing sleeves Infill thickness mm 20 21 to 22 23 24 25 to 26 27 28 29 to 30 31 32 33 to 34 35 36 37 to 38 39 40 41 to 42 43 44 45 to 46 47 48 49 to 50 51 52 53 to 54 55 56 57 to 58 59 60 61 to 62 63 64 ZH-1006 No. socket No. sealing sleeve 169946 169946 169946 169950 169950 169950 169954 169954 169954 169958 169958 169958 169962 169962 169962 169966 169966 169966 169970 169970 169970 169974 169974 169974 169978 169978 169978 169982 169982 169982 169986 169986 169986 169990 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 2016 237 THERM+ H-I Assembly options – T74 = Infill thickness. THERM+ H-I Accessories Timber curtain wall 50/56 mm Fixation of sun protection for pressure profiles 9 mm Exterior gasket 5 mm ■ Technical information – Pressure profiles: No. 013008 (50 mm) No. 013028 (56 mm) – T74 = Infill thickness. ■ Selection of sockets and sealing sleeves T74 Infill thickness mm 20 to 21 22 23 24 to 25 26 27 28 to 29 30 31 32 to 33 34 35 36 to 37 38 39 40 to 41 42 43 44 to 45 46 47 48 to 49 50 51 52 to 53 54 55 56 to 57 58 59 60 to 61 62 63 64 238 2016 ZH-1006 No. socket No. sealing sleeve 169946 169946 169950 169950 169950 169954 169954 169954 169958 169958 169958 169962 169962 169962 169966 169966 169966 169970 169970 169970 169974 169974 169974 169978 169978 169978 169982 169982 169982 169986 169986 169986 169990 169990 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 THERM+ H-I Accessories Timber curtain wall 50/56 mm Fixation of sun protection for pressure profiles 12 mm Exterior gasket 3 mm ■ Technical information – Pressure profiles: No. 013007 (50 mm) No. 013027 (56 mm) T74 ■ Selection of sockets and sealing sleeves Infill thickness mm 20 21 22 to 23 24 25 26 to 27 28 29 30 to 31 32 33 34 to 35 36 37 38 to 39 40 41 42 to 43 44 45 46 to 47 48 49 50 to 51 52 53 54 -55 56 57 58 to 59 60 61 62 to 63 64 ZH-1007 No. socket No. sealing sleeve 169946 169950 169950 169950 169954 169954 169954 169958 169958 169958 169962 169962 169962 169966 169966 169966 169970 169970 169970 169974 169974 169974 169978 169978 169978 169982 169982 169982 169986 169986 169986 169990 169990 169990 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 2016 239 THERM+ H-I Assembly options – T74 = Infill thickness. THERM+ H-I Accessories Timber curtain wall 50/56 mm Fixation of sun protection for pressure profiles 12 mm Exterior gasket 5 mm ■ Technical information – Pressure profiles: No. 013007 (50 mm) No. 013027 (56 mm) – T74 = Infill thickness. ■ Selection of sockets and sealing sleeves T74 Infill thickness mm 20 21 to 22 23 24 25 to 26 27 28 29 to 30 31 32 33 to 34 35 36 37 to 38 39 40 41 to 42 43 44 45 to 46 47 48 49 to 50 51 52 53 to 54 55 56 57 to 58 59 60 61 to 62 63 64 240 2016 ZH-1007 No. socket No. sealing sleeve 169950 169950 169950 169954 169954 169954 169958 169958 169958 169962 169962 169962 169966 169966 169966 169970 169970 169970 169974 169974 169974 169978 169978 169978 169982 169982 169982 169986 169986 169986 169990 169990 169990 169994 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 THERM+ H-I Accessories Timber curtain wall 50 mm Fixation of sun protection for pressure profiles 25 mm Exterior gasket 3 mm ■ Technical information – Pressure profiles: No. 013014 (50 mm) T74 ■ Selection of sockets and sealing sleeves Infill thickness mm 20 21 to 22 23 24 to 25 26 27 28 29 to 30 31 32 33 to 34 35 36 37 to 38 39 40 41 to 42 43 44 45 to 46 47 48 49 to 50 51 52 53 to 54 55 56 57 to 58 59 60 61 to 62 63 64 ZH-1011 No. socket No. sealing sleeve 169954 169954 169954 169958 169958 169958 169962 169962 169962 169966 169966 169966 169970 169970 169970 169974 169974 169974 169978 169978 169978 169982 169982 169982 169986 169986 169986 169990 169990 169990 169994 169994 169994 169998 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 2016 241 THERM+ H-I Assembly options – T74 = Infill thickness. THERM+ H-I Accessories Timber curtain wall 50 mm Fixation of sun protection for pressure profiles 25 mm Exterior gasket 5 mm ■ Technical information – Pressure profiles: No. 013014 (50 mm) – T74 = Infill thickness. ■ Selection of sockets and sealing sleeves T74 Infill thickness mm 20 to 21 22 23 24 to 25 26 27 28 to 29 30 31 32 to 33 34 35 36 to 37 38 39 40 to 41 42 43 44 to 45 46 47 48 to 49 50 51 52 to 53 54 55 56 to 57 58 59 60 to 61 62 63 64 242 2016 ZH-1011 No. socket No. sealing sleeve 169954 169954 169958 169958 169958 169962 169962 169962 169966 169966 169966 169970 169970 169970 169974 169974 169974 169978 169978 169978 169982 169982 169982 169986 169986 169986 169990 169990 169990 169994 169994 169994 169998 169998 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 THERM+ H-I Accessories Timber curtain wall 50/56/76 mm Fixation of sun protection for flat pressure profiles 3 mm Exterior gasket 2 mm ■ Technical information – Pressure profiles: No. 013300 (50 mm) No. 013310 (56 mm) No. 013313 (76 mm) T74 ■ Selection of sockets and sealing sleeves Infill thickness mm 24 to 25 26 27 28 to 29 30 31 32 to 33 34 35 36 to 37 38 39 40 to 41 42 43 44 to 45 46 47 48 to 49 50 51 52 to 53 54 55 56 to 57 58 59 60 to 61 62 63 64 ZH-1010 No. socket No. sealing sleeve 169942 169942 169946 169946 169946 169950 169950 169950 169954 169954 169954 169958 169958 169958 169962 169962 169962 169966 169966 169966 169970 169970 169970 169974 169974 169974 169978 169978 169978 169982 169982 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 169900 169902 169901 2016 243 THERM+ H-I Assembly options – T74 = Infill thickness. THERM+ H-I Accessories Timber curtain wall 50/56/76/96 mm Assembly scaffolding anchors ■ Technical information Selection of fastening screws – The base profile ist screwed to the scaffolding anchors range in addition. – Scaffolding fixation no. 166235 with screw no. 012110. – Expansion structure profile cannot take forces right-angled to the structural profile (Frt). – Please order additionally: - 1 halfen screw no. 907605. - 1 cover 15 white no. 167075 or - 1 cover 15 black no. 167076. – Application of flat pressure profile possible from an infill thickness of 32 mm. – The number and position of the fixation points depends on the specific requirements of the scaffold. The max. load transmission into the curtain wall construction is system immanent and can be taken from the table Representative parameter. Representative parameter – T182 = Assembly scaffolding anchor. – T183 = Offset posts. – T184 = Height of scaffold. 244 2016 ZH-0022 Right-angled to structural profile Frt Parallel to structural profile Fpt Right-angled to curtain wall Frf 0.53 kN 4.58 kN 12.87 kN THERM+ H-I Accessories Timber curtain wall 50/56/76/96 mm Fixture unit – Assembling the fixture unit no. 166206 with: - 3 screws no. 908655 (PU = 100 pc(s)). - 4 screws no. 908020 (PU = 100 pc(s)). – Fixation in consideration of construction circumstances and statical requirements. – For each assembling situation a statical calculation is mandatory. The influencing variables of DIN 1055 has to be considered. – Please consider several international, national, regional and local laws and rules. – The common and accepted rules of technique have to be considered. – T68 = Offset action point a. Additional loads Vertical load Fv in combination with horizontal load Fh (offset action point a = 100) Fv [kN] 7.0 6.0 5.0 4.0 3.0 2.0 1.0 Fh [kN] 1.0 2.0 3.0 3.5 4.5 5.5 6.5 Vertical load Fv in combination with horizontal load Fh (offset action point a = 180) Fv [kN] 4.0 3.5 3.0 2.5 2.0 1.5 1.0 Fh [kN] 0.8 1.7 2.5 3.4 4.2 5.1 5.9 Diagonal pull Fd in consideration of angle α (offset action point a = 100) α [°] 50 45 40 35 30 Fd [kN] 5.5 5.5 5.5 5.6 5.7 – T69 = Fixation bracket. – T164 = Built-in conditions. – T165 = Presentation without glass and exterior gasket. ZH-0021 2016 245 THERM+ H-I Assembly options ■ Technical information THERM+ H-I Accessories Timber curtain wall 50/56/76 mm Connection profiles for transom and mullion gasket Connection with gasket without flap ■ Technical information – Bolted with no. 908118. – *Gasket easy to tear off to 3 / 7 / 9 mm. – ** With sheet t = 3 mm (self-production) instead of no. 051012 (t = 2.2 mm). – T13 = Infill thickness. 246 2016 Selection of gaskets and profiles Infill thickness mm 24 25** 26 27 28 29 30 31 32 33 34 35** 36 37 38 39 40 41 42 43 44 45** 46 47 48 49 50 51 52 53 54 55** 56 57 58 59 60 61 62 63 64 ZH-0009 Compensation gasket no. – – 227010 227032 227015 227032 227020 227032 227025 227032 227030 – 227010 227032 227015 227032 227020 227032 227025 227032 – – 227010 227032 227015 227032 227020 227032 227025 227032 227030 – 227010 227032 227015 227032 227020 227032 227025 227032 227030 Compensation profile no. – – – – – – – – – – – 227006 227006 227006 227006 227006 227006 227006 227006 227006 – – – – – – – – – – – 227006 227006 227006 227006 227006 227006 227006 227006 227006 227006 Connection profile no. 168021 (50/56) 168026 (76) 168031 (50/56) 168033 (76) THERM+ H-I Accessories Timber curtain wall 50/56/76 mm Connection profiles for transom and mullion gasket Base point connection with gasket and flap ■ Technical information – T248 = Compensation gasket. Connection profile no. 168005 with 3 mm sheet Selection compensation gasket Selection compensation gasket THERM+ H-I Assembly options Connection profile no. 168005 with 2 mm sheet Infill thickness mm 24 26 27 28 29 30 31 32 33 35 37 Gasket No. – 011080 011070 011077 011073 011076 011074 011071 011075 011072 011078 No. Infill thickness mm 25 27 28 29 30 31 32 33 34 36 38 PU – 100 m 100 m 100 m 100 m 100 m 100 m 100 m 100 m 100 m 50 m No. No. No. Gasket No. – 011080 011070 011077 011073 011076 011074 011071 011075 011072 011078 PU – 100 m 100 m 100 m 100 m 100 m 100 m 100 m 100 m 100 m 50 m No. No. 168005 No. No. No. No. ZH-0001 No. 2016 247 THERM+ H-I Accessories Timber curtain wall 50/56/76 mm Connection profiles for transom and mullion gasket Base point connection with compensation gasket Selection of compensation gaskets Infill thickness mm 22 24 25 26 27 28 29 30 31 33 35 248 2016 Compensation gasket mm – 011080 011070 011077 011073 011076 011074 011071 011075 011072 011078 No. No. No. No. No. No. No. No. No. No. ZH-0003 Height mm PU – 2 3 4 5 6 7 8 9 11 13 – 100 m 100 m 100 m 100 m 100 m 100 m 100 m 100 m 100 m 50 m THERM+ H-I Accessories Timber curtain wall 50/56/76 mm Connection profiles Connection frame profile ■ Technical information – Connection profile no. 168080: - Continuous insertion for bottom and top connection. - Cut out in mullion area for drainage/ventilation. Article – Observe the different rates of thermal expansion for the screw connection of the aluminium window sill with the synthetic connection profile. ZH-0008 No. PU Connection profile 55/15 168080 6m Connection profile 39/22 168021 6m Connection profile 48/22 168026 6m Connection profile 39/42 168031 6m Connection profile 48/42 168033 6m 2016 249 THERM+ H-I Assembly options Selection of articles THERM+ H-I Accessories Timber curtain wall 50/56/76 mm Connection profiles Ventilated/non-ventilated façade ■ Technical information List of glass thickness compensation – Max. weight of the pane at the connection profile: 50 kg. Difference allowed mm – For higher offsets between the two infill thicknesses (infill thickness 1 – infill thickness 2) the compensation profile 12 no. 013090, compensation height 12 mm, may be used. (PU = 6 m). 18 19 20 21 22 23 24 25 26 27 28 – IT = Infill thickness. – For more information see Processing. Compensation gasket No. 011070 011077 011073 011076 011074 011071 011075 – 011072 – 011078 Height mm 3 4 5 6 7 8 9 – 11 – 13 PU 100 m – 100 m – 50 m Difference D between the two glass infill thicknesses is necessary for the selection. (D = IT1 minus IT2; IT1 = 20 to 64 mm, IT2 = 2 to 46 mm). No. 168060 IT 2 IT 1 250 2016 ZH-0006 THERM+ H-I Accessories Timber curtain wall 50/56/76/96 mm Connection profiles Terminal clamp as assembly aid for sheets and profiles ■ Technical information – Applicable as an assembly aid or for the fixation of sheets and connection profiles at hard-toreach places. – Clamp thickness 1.5 to 3 mm. THERM+ H-I Assembly options – Fixation with a suitable screw for hole Ø 6 mm. ZH-0007 2016 251 THERM+ H-I Accessories Timber curtain wall 50/56/76 mm Connection profiles Fixture spring – interior compensation of different infill thicknesses ■ Technical information – Table for the selection of the compensation gasket see following page. – Reduced glass weights have to be obtained in individual cases. – T13 = Infill thickness (IT). and 252 2016 ZH-0010 6 8 64 62 60 58 56 54 52 50 48 46 44 42 40 38 36 34 32 30 18 20 22 24 26 30 32 34 36 38 40 42 44 46 48 50 52 54 THERM+ H-I Assembly options 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 28 IT 2 (mm) 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 28 220326 220325 220324 220323 220322 220321 220320 16 24 220325 220324 220323 220322 220321 220320 14 26 220324 220323 220322 220321 220320 12 20 10 22 220323 220322 220321 220320 4 18 2 220322 220321 220320 16 IT 1 (mm) Selection compensation gasket THERM+ H-I Accessories Timber curtain wall 50/56/76 mm Connection profiles Table for the selection of compensation gasket 2016 253 THERM+ H-I Accessories Timber curtain wall 50/56 mm Connection profiles Stainless steel retainer for panel fixing ■ Technical information Selection of retainer – For fixing the panel before assembling the pressure profile. Infill thickness mm 24 to 25 26 to 27 28 to 29 30 to 31 32 to 33 34 to 35 36 to 37 38 to 39 40 to 41 42 to 43 44 to 45 46 to 47 48 to 49 50 to 51 52 – Retainer may stay at glass rebate. – T13 = Infill thickness (IT). Art.-Nr. No. 167165 167165 –to167193 167193 No. 012103 254 2016 ZH-0030 No. 167165 167167 167169 167171 167173 167175 167177 167179 167181 167183 167185 167187 167189 167191 167193 THERM+ H-I Accessories Timber curtain wall 50/56/76 mm Connection profiles Selection of assembly angles for integration outer frame FRAME+ 75 WB ■ Technical information Gap dimensions x and y – For the positioning of assembly angles see Processing. – T13 = Infill thickness. System width mm Dim. x No. 207666 Dim. x Dim. y No. 207667 Profile width mm 50 9 5 14 10 50 56 8 4 13 7 60 76 – – 11 5 80 THERM+ H-I Assembly options – T141 = Selection of assembly angle and screws see table. Dim. y x y Assembly angle and screws 75 WB for THERM+ I 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 Screw Length / No. 22 mm – 22 mm 25 mm 25 mm 25 mm 28 mm 28 mm 30 mm 30 mm 32 mm – 32 mm 35 mm 35 mm 35 mm 38 mm 38 mm 40 mm 40 mm 42 mm 012105 – 012105 012107 012107 012107 012108 012108 012109 012109 012110 – 012110 012111 012111 012111 012112 012112 012113 012113 012114 Assembly angle for 50 mm 167604 – 167606 167607 167608 167609 167610 167611 167612 167613 167614 – 167616 167617 167618 167619 167620 167621 167622 167623 167624 Assembly angle for 56 mm 167654 – 167656 167657 167658 167659 167660 167661 167662 167663 167664 – 167666 167667 167668 167669 167670 167671 167672 167673 167674 Assembly angle for 76 mm Self-production IT mm KH-0014 EPDM compensation gasket without without – – 2 mm 227010 3 mm 227032 4 mm 227015 5 mm 227032 6 mm 227020 7 mm 227032 8 mm 227025 9 mm 227032 10 mm 227030 – – 2 mm 227010 3 mm 227032 4 mm 227015 5 mm 227032 6 mm 227020 7 mm 227032 8 mm 227025 9 mm 227032 10 mm 227030 Synthetic compensation profile without without – – without without without without without without without without without without without without without without without without without without – – 10 mm 227006 10 mm 227006 10 mm 227006 10 mm 227006 10 mm 227006 10 mm 227006 10 mm 227006 10 mm 227006 10 mm 227006 2016 255 THERM+ H-I Accessories Timber curtain wall 50/56 mm Connection profiles Selection of assembly angles for integration outer frame FRAME+ 75 WB ■ Technical information Gap dimensions x and y – For the positioning of assembly angles see Processing. – T13 = Infill thickness. – T141 = Selection of assembly angle and screws see table. System width mm Dim. x 50 9 5 50 56 8 4 60 x y Assembly angle and screws 75 WB for THERM+ I IT mm 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 256 Screw Length / No. 32 mm 35 mm 35 mm 35 mm 38 mm 38 mm 40 mm 40 mm 42 mm 42 mm 42 mm – 45 mm 45 mm 48 mm 48 mm 50 mm 50 mm 52 mm 52 mm 52 mm 2016 012110 012111 012111 012111 012112 012112 012113 012113 012114 012114 012114 – 012115 012115 012116 012116 012117 012117 012118 012118 012118 Assembly angle for 50 mm 167616 167617 167618 167619 167620 167621 167622 167623 167624 167625 167626 – 167628 167629 167630 167631 167632 167633 167634 167635 167636 Assembly angle for 56 mm 167666 167667 167668 167669 167670 167671 167672 167673 167674 167675 167676 – 167678 167679 167680 167681 167682 167683 167684 167685 167686 EPDM compensation gasket without without – – 2 mm 227010 3 mm 227032 4 mm 227015 5 mm 227032 6 mm 227020 7 mm 227032 8 mm 227025 9 mm 227032 10 mm 227030 – – 2 mm 227010 3 mm 227032 4 mm 227015 5 mm 227032 6 mm 227020 7 mm 227032 8 mm 227025 9 mm 227032 10 mm 227030 KH-0010 Synthetic compensation profile without without – – without without without without without without without without without without without without without without without without without without – – 10 mm 227006 10 mm 227006 10 mm 227006 10 mm 227006 10 mm 227006 10 mm 227006 10 mm 227006 10 mm 227006 10 mm 227006 Dim. y No. 207670 Profile width mm THERM+ H-I Accessories Timber curtain wall 50/56 mm Suction disc Mullion section with silicone joint ■ Technical information – Only insulated glass with UV resistance edge seal or optional with enameling/screen printing may be used. – The necessary infill thicknesses have to be coordinated with the glass supplier. THERM+ H-I Assembly options – The legal glazing instructions have to be taken into consideration and if necessary an approval in individual cases has to be obtained. – The suction discs can be also used as a mechanical saving in combination with the SG2 system for all heights larger than 8 m (min. infill thickness 32 mm). – From an infill thickness of 23 mm possible with insulating blocks SG. – Selection of screws see screw selection tables. – Please consider DIN EN 18008, TRLV and TRPV. - 64 mm 20to 907216 Suction disc set 75 No. 163807 Suction disc set 56/90 No. 163812 Suction disc set 50/90 No. 163810 HI-0191 2016 257 THERM+ H-I Accessories Timber curtain wall 50/56/76 mm Belay sheet Protection of vertical cover profile to prevent slipping ■ Technical information – Rotate drilling jig for pre-drilling the belay sheet 180° for pre-drilling the belay sheet. No. Art.-Nr. 127100 127100 258 2016 No. Art.-Nr. 902511 902511 ZH-0020 THERM+ H-I Accessories Timber curtain wall 50/56/76 mm Static table Vertical glazing – The shown list is only for pre-dimensioning of necessary cross sections for mullion and transom within the glass construction. This is no compensation for necessary tension and stabilty certification. – Please account for the factors by using other E-modules for the mullion material: –Timber-E-Module 5500: Conversion factor E-Module 2 Timber-E-Module 12000: Conversion factor E-Module 0.92 Timber-E-Module 13000: Conversion factor E-Module 0.85 Timber-E-Modul 14000: Conversion factor E-Module 0.79 – The following parameters are used for the determination of the table: wind load referred to DIN EN 1991-1-4: 0 m to 8 m assembly height 0.5 KN/m² > 8 m to 20 m assembly height 0.8 KN/m² (conversion factor 1.6) > 20 m to 100 m assembly height 1.1 KN/m² (conversion factor 2.2) Pressure cp: 0.8 Load increasing for singular items: 25 % max. deflection referred to. DIN EN 13830: - I/200, when L ≤ 3000 mm - L/300 + 5 mm, when 3000 mm < L < 7500 mm – The listed parameters are based on 1-fieldbearing. For 2-fields-bearing the deflections and the necessary torque of inertia will be reduced by a factor of 0.42. For 2-fieldsbearing a tension certification is always mandatory. Possible deviating max. deflections of the glass manufacturer’s technical specifications have to be respected. Balustrade loads are not taken into consideration. – T133 = 1-field-bearing – T134 = 2-fields-bearing Influencing parameter e [m] 0.50 0.75 1.00 1.25 1.50 1.75 2.00 2.25 2.50 2.75 3.00 6.00 1534 2301 3068 3835 4602 5369 6136 6903 7670 8438 9205 5.90 1454 2181 2907 3634 4361 5088 5815 6542 7269 7996 8722 5.80 1376 2064 2752 3441 4129 4817 5505 6193 6881 7569 8257 5.70 1302 1952 2603 3254 3905 4556 5206 5857 6508 7159 7810 5.60 1230 1845 2459 3074 3689 4304 4919 5534 6149 6763 7378 5.50 1161 1741 2321 2901 3482 4062 4642 5222 5803 6383 6963 5.40 1094 1641 2188 2735 3282 3829 4376 4923 5470 6017 6564 5.30 1030 1545 2060 2575 3090 3606 4121 4636 5151 5666 6181 5.20 969 1453 1938 2422 2906 3391 3875 4360 4844 5329 5813 5.10 910 1365 1820 2275 2730 3185 3640 4095 4550 5005 5460 5.00 854 1280 1707 2134 2561 2988 3415 3841 4268 4695 5122 4.90 800 1200 1599 1999 2399 2799 3199 3599 3998 4398 4798 4.80 748 4.70 699 1048 1397 1747 2096 2446 2795 3144 3494 3843 4192 4.60 652 977 1303 1629 1955 2281 2607 2932 3258 3584 3910 4.50 607 910 1213 1517 1820 2124 2427 2730 3034 3337 3640 4.40 564 846 4.30 523 785 1047 1308 1570 1832 2093 2355 2617 2878 3140 4.20 485 727 969 1212 1454 1696 1939 2181 2423 2666 2908 4.10 448 672 896 4.00 413 620 826 1033 1240 1446 1653 1860 2066 2273 2479 3.90 380 571 761 951 3.80 349 524 699 873 1048 1222 1397 1572 1746 1921 2096 3.70 320 480 640 800 960 3.60 292 439 585 731 877 1023 1170 1316 1462 1608 1754 3.50 266 400 533 666 799 933 1066 1199 1332 1465 1599 3.40 242 363 484 605 726 847 968 1090 1211 1332 1453 3.30 219 329 439 548 658 768 877 987 1097 1206 1316 3.20 198 297 396 495 594 693 792 891 990 1089 1188 3.10 178 267 356 446 535 624 713 802 891 980 1069 3.00 160 240 320 400 479 559 639 719 799 879 959 2.75 123 185 246 308 369 431 492 554 615 677 739 2.50 92.5 139 185 231 277 324 370 416 462 509 555 2.25 67.4 101 135 169 202 236 270 303 337 371 404 2.00 47.3 71.0 94.7 118 142 166 189 213 237 260 284 1.75 31.7 47.6 63.4 79.3 95.2 111 127 143 159 174 190 1.50 20.0 30.0 40.0 49.9 59.9 69.9 79.9 89.9 99.9 110 120 1122 1496 1870 2244 2618 2992 3366 3740 4114 4488 1128 1410 1692 1974 2256 2538 2820 3102 3384 1120 1344 1568 1792 2016 2240 2464 2688 1141 1331 1521 1712 1902 2092 2282 1120 1280 1440 1600 1760 1920 1.25 11.6 17.3 23.1 28.9 34.7 40.5 46.2 52.0 57.8 63.6 69.4 1.00 5.9 8.9 11.8 14.8 17.8 20.7 23.7 26.6 29.6 32.6 35.5 Caluclation example: Influencing parameter B: Height of mullion L: 1.25 m 2.5 m Solution for assembly heights 0 m to 8 m: Ix mullion = 231 cm4 (see list) Solution for assembly heights > 8 m to 20 m (conversion factor 1.6) Ix mullion = 231 cm4 x 1.6 = 370 cm4 Solution for assembly heights > 20 m to 100 m and timber with E-Module 13000: (Factor wind 2.2 and factor E-module 0.85) Ix mullion = 231 cm4 x 2.2 x 0.85 = 432 cm4 KH-0601 2016 259 THERM+ H-I Assembly options Pre-dimensioning list: Result Ix [cm4] at assembly height 0 m to 8 m, E-Module 11000 N/mm² (BS 11/BS 14 glued-laminated timber) Length of mullion L [m] / length of transom B [m] ■ Technical information THERM+ H-I Accessories Timber curtain wall 50/56/76 mm Static table Statical and technical parameters ■ Technical information – Caluclation example: Determined necessary statical parameter lx = 231 cm4. – Used timber profile: 50 x 90 or 60 x 80 mm List 1: Statical parameters lx Mullion width (mm) Mullion depth (mm) 50 60 70 80 90 100 50 52.08 62.50 72.92 83.33 93.75 104.17 60 90.00 108.00 126.00 144.00 162.00 180.00 70 142.92 171.50 200.08 228.67 257.25 285.83 80 213.33 256.00 298.67 341.33 384.00 426.67 90 303.75 364.50 425.25 486.00 546.75 607.50 100 416.67 500.00 583.33 666.67 750.00 833.33 120 720.00 864.00 1008.00 1152.00 1296.00 1440.00 140 1143.33 1372.00 1600.67 1829.33 2058.00 2286.67 160 1706.67 2048.00 2389.33 2730.67 3072.00 3413.33 180 2430.00 2916.00 3402.00 3888.00 4374.00 4860.00 200 3333.33 4000.00 4666.67 5333.33 6000.00 6666.67 220 4436.67 5324.00 6211.33 7098.67 7986.00 8873.33 240 5760.00 6912.00 8064.00 9216.00 10368.00 11520.00 260 7323.33 8788.00 10252.67 11717.33 13182.00 14646.67 280 9146.67 10976.00 12805.33 14634.67 16464.00 18293.33 300 11250.00 13500.00 15750.00 18000.00 20250.00 Result Ix [cm4] List 2: Statical parameters ly Mullion width (mm) Mullion depth (mm) 50 60 70 80 100 50 52.08 90.00 142.92 213.33 303.75 416.67 60 62.50 108.00 171.50 256.00 364.50 500.00 70 72.92 126.00 200.08 298.67 425.25 583.33 80 83.33 144.00 228.67 341.33 486.00 666.67 90 93.75 162.00 257.25 384.00 546.75 750.00 100 104.17 180.00 285.83 426.67 607.50 833.33 120 125.00 216.00 343.00 512.00 729.00 1000.00 140 145.83 252.00 400.17 597.33 850.50 1166.67 160 166.67 288.00 457.33 682.67 972.00 1333.33 180 187.50 324.00 514.50 768.00 1093.50 1500.00 200 208.33 360.00 571.67 853.33 1215.00 1666.67 220 229.17 396.00 628.83 938.67 1336.50 1833.33 240 250.00 432.00 686.00 1024.00 1458.00 2000.00 260 270.83 468.00 743.17 1109.33 1579.50 2166.67 280 291.67 504.00 800.33 1194.67 1701.00 2333.33 300 312.50 540.00 857.50 1280.00 1822.50 2500.00 Result Iy [cm4] 260 90 2016 + H-V THERM Content System benefits System benefits Technology in detail Tests Variants TC timber connector Ventilation Sealing system 263 265 266 268 270 274 System width 50 mm System width 56 mm System width 76 mm Building connections 50/56/76 mm 275 299 323 337 2016 261 THERM+ H-V System sections System sections 262 2016 THERM+ H-V System benefits Timber curtain wall 50/56/76 mm Technology in detail ■ Excellent product properties – System widths 50, 56 and 76 mm. – Infill thickness from 6 to 64 mm. – Maximal energy saving by variable thermal insulation with insulating block options up to Uf= 0.80 W/(m²K) including screw influence. – All profiles can be used as well for mullions as for transoms. ■ Optimum planning – Glass load transmission for very high glass weights up to 600 kg. – Vertical curtain walls. – Construction as polygon curtain wall up to 45° with system accessories. – No components lasting from the outside to the timber construction. – Extensive system accessories. ■ Efficient installation – Two types of aluminium base profiles for screw connection: With or without positioning foot in the area of the timber structural profile. – Solid timber connector technology in the options SOLO and KOMBI, tested according to The European Technical Approval (ETA). – Integrated drainage at the continuous gasket in three levels. – Safe fixation of all construction elements in the continuous aluminium screw channel. – Easy and quick screwing of base profiles also with magazine screw driver possible. THERM+ Timber H-V with insulating block P 19 SHV-0001 2016 263 THERM+ H-V System sections – Entire imposed load and load transmission tested. THERM+ H-V System benefits Timber curtain wall 50/56/76 mm Technology in detail ■ Pressure and cover profiles for curtain wall and roof light applications – Wide selection of various types as well as system widths. – Individual solutions for objects in a short time available. – Visually especially attractive flat pressure profile with an offset of only 4 mm above the glass surface. – Ideal cross point sealing by special accessories. – Timber cover profiles to clip available. ■ Base profiles – Suitable for all system variations. – Improved screw channel for optimum thermal break. – Specific gasket holding fixture for easy fixing of the silicon-free EPDM gasket. – Slottet holes for integrated expansion compensation. – With or without foot. ■ Connector system for timber curtain wall – Highly efficient and time-saving. – All machining is in transoms. – Few special screws required for maximum load-bearing capacity. – Stable connection for high glass loads. – Extremely fast construction site assembly: Push in transoms and screw together. – Transoms can be dismantled at any time. – No adjustment needed thanks to the automatically flush stop. – Tested at infill thicknesses of up to 64 mm. – Seven installation depths for transom depths from 60 to 300 mm. – Tested according to ETA-13/0765. 264 2016 THERM+ H-V System benefits Timber curtain wall 50/56/76 mm THERM+ – Certified quality, CE-conform and tested THERM+ – Quality you can rely upon. Extensive product tests with excellent results confirm the high quality in practical applications of the THERM+ curtain wall system. No. Test type/Standard Classification/Result Testing institute/Test no. 4.1 Wind resistance (EN 13116) Permissible load 2.5 KN/m2 Increased load 3.75 KN/m2 ift Rosenheim No. 10838884 4.3 Resistance against impact (if specially requested) (EN 14019) Interior I5 Exterior E5 ift Rosenheim No. 10838884 4.4 Air permeability (EN 12152) AE (>600) ift Rosenheim No. 10838884 4.5 Water penetration (EN 12154) RE 2100 ift Rosenheim No. 10838884 4.7 Thermal transmittance (UCW-value) (EN 13947) Calculation with data from RAICO Uf-value tables EN 13947 (calculation) ■ Notice – All features can be used for CE-Labelling by the manufactures of curtain walls. It is mandatory that only RAICO products has to be used and the production process has to be monitored by an in-house production control system. The whole production process has to be compliant to the RAICO assembly instructions. – Depending on the panel dimensions of the curtain wall and the structural connections the sound insulation value has to be calculated separately. The system testimonial can only be used for an overview. – Depending on the different systems options and the glass thickness the Uf-value can be adapted step-by-step. The exacts values based on DIN EN ISO 10077-2 are documented in the thermal protection documentations by RAICO. ■ Additional approvals and certifications Test Result Description Testing institute/test no. German general approval: clamping joint for the curtain wall system – Fixing of base profile – Screw channel of mullion-transom profiles – Pressure profiles – Screws German general approval for thefixing system THERM+ H-I timber curtain wall DIBt, Berlin No. Z-14.4-516 European Technical Approval for timber mullion-transom connection system THERM+ Test THERM+ H-V ETA-Denmark No. ETA-13/0765 European Technical Approval: Connector types with characteristic SOLO/KOMBI timber mullion resistance & transom connectors Burglar prevention Resistance class WK2 for system widhts 50, 56 and 76 mm according to DIN ENV 1627 ff. ift Rosenheim No. 25534211 Test THERM+ H-V according to DIN EN 1627 ff. ift Rosenheim No. 25534211 Burglar prevention Resistance class WK3 for system widhts 50, 56 and 76 mm Fall protection Criteria of DIN 18008-4 Criteria fulfilled (technical rules for fall proof glazing) fulfilled Passive house curtain wall Ucw ≤ 0.8 W/m2K of system THERM+ H-V 50, 56, 76 with insulating block P Fulfilment all criteria for components suitable for passive houses passive house institute Dr. Feist certificate 2016 265 THERM+ H-V System sections ■ Product standard for curtain walling EN 13830: Features and classification for the CE-Labelling. THERM+ H-V System benefits Timber curtain wall 50/56/76 mm Curtain wall options/drainage system ■ Structural Glazing SG2 – System widths 50 or 56 mm. – Glazing system for optical exclusive SG curtain wall. – Maximum thermal insulation by special insulating block SG. – Simple and economic processing. – Without visible physcial protections up to an assembly height of 8 m. ■ Burglar proof curtain wall WK2/WK3 – System widths 50, 56 and 76 mm. – Resistance class WK2 and WK3 permitted. – Simple processing. – Identical technology to the basic system. ■ Drainage system – The drainage groove of the mullion and transom gasket is arranged in various levels. – In all THERM+ systems the ventilation and drainage principle is so designed that a controlled condensate removal from transom to the mullion rebate is secured via interior gaskets. 266 2016 H-VSG-0001, HVWK-0001, SHV-0002 THERM+ H-V System benefits Timber curtain wall 50/56/76 mm Gasket options ■ Exterior gasket – Various exterior gaskets and insulating block options available. Standard exterior gasket – Gradual adaptation of the insulation value. – Maximum thermal insulation up to Uf= 0.80 W/(m²K) including screw influence. Insulating block 9 – Certified passive house curtain wall. – Economic solution. Insulating block 21 THERM+ H-V System sections Insulating block P ■ Transom and mullion gaskets – Optimised shape for maximum thermal insulation and efficient fabrication. – Complete covering and sealing of the base prof ile. Mullion gasket Transom gasket – Perfect and easy fitting on the structural profile (without silicone). – Two options of gaskets with flaps for transom and base drainage as well as draining within the continuous gasket at the structural connections. Base transom gasket, flap Gasket for transom, flap Polygon gasket Mullion gasket Compensation of infill thickness – Reliable drainage in two or three levels by simply notching. – Special accessories for all applications, e. g. transom and mullion sealing elements. Expansion mullion gasket 2016 267 THERM+ H-V System benefits Timber curtain wall 50/56/76 mm Timber-connector-options ■ SOLO – Tensioned with nail screws. – Safe and tested dispersal of glass weights. – Inserted invisibly between mullion and transom. – Tested according to ETA-13/0765. – Safe dispersal of the glass loads and resulting torsion forces via the timber structure. – Seven installation depths for transom depths from 60 to 300 mm. – Installation in a few simple steps and minimum processing. – Integrated longitudinal stop and transom contact pressure over the entire depth for a perfect T-connection. ■ KOMBI – Tensioned with nail screws through the transom base profile. – Safe and tested dispersal of glass weights. – Inserted invisibly between mullion and transom. – Tested according to ETA-13/0765. – Safe dispersal of the glass loads and resulting torsion forces via the timber structure. – Seven installation depths for transom depths from 60 to 300 mm. – Installation in a few simple steps and minimum processing. – Integrated longitudinal stop and transom contact pressure over the entire depth for a perfect T-connection. ■ Super-simple installation – Highly efficient and time-saving. – All machining is in transoms. – Few special screws required for maximum load-bearing capacity. – Stable connection for high glass loads. – Extremely fast construction site assembly: Push in transoms and screw together. – Transoms can be dismantled at any time. – No adjustment needed thanks to the automatically flush stop. 268 2016 THERM+ H-V System benefits Timber curtain wall 50/56/76 mm Timber-connector-options ■ High loading capacity on european standard The new timber connector is tested according to the current guideline ETAG 015 and certified with the european technical approval ETA-13/0765. In comparison to the previous timber connector now the infill thickness of 64 mm is tested and also part of the aforementioned approval. Due to detail improvements the new timber connector which is available in the versions SOLO and KOMBI characterises a much more rational and technical superior assembly. – Static calculation possible on the base of the Eurocodes. – The denoted loads of the connector are based on a minimum apparent density of 350 kg/m³, with the use of timber or derived timber products with a higher apparent density the loads can be increase up to an apparent density of 500 kg/m³. Admissible loads in consideration of the apparent density TC SOLO 350 kg/m3 400 kg/m3 450 kg/m3 500 kg/m3 Maximum glass load* per transom in kg Type of connector TC 60 SOLO 380 kg/m3 *it is imperative to respect the ETA-13/0765 116 119 120 124 126 TC 80 SOLO 138 141 143 147 151 TC 100 SOLO 162 167 170 176 182 TC 120 SOLO 182 188 191 198 205 TC 160 SOLO 218 225 229 239 248 TC 200 SOLO 250 258 263 274 286 TC 240 SOLO 276 285 291 305 317 450 kg/m3 500 kg/m3 THERM+ H-V System sections Apparent density Admissible loads in consideration of the apparent density TC KOMBI Apparent density 350 kg/m3 380 kg/m3 400 kg/m3 Maximum glass load* per transom in kg Type of connector *it is imperative to respect the ETA-13/0765 TC 60 KOMBI 253 256 257 260 263 TC 80 KOMBI 274 278 279 284 288 387 TC 100 KOMBI 367 372 375 381 TC 120 KOMBI 388 393 396 403 410 TC 160 KOMBI 423 430 434 444 453 TC 200 KOMBI 455 463 468 480 491 TC 240 KOMBI 481 490 496 510 523 KHV-0620 2016 269 THERM+ H-V System benefits Timber curtain wall 50/56/76 mm Isothermal lines Especially for aluminium curtain walls and conservatories it is essential for long term function and maximum satisfaction of the clients to offer a well-performing thermal insulation and an optimized isothermal line. Only high quality systems which correspond to both requirements can avoid the formation of condensate. ■ Isothermal lines – Double glazing with Ug=1.1 W/(m2K) and acrylic spacer. – Already with standard exterior gaskets the 10°C- isothermal line remains completely within the system. – Condensate is avoided efficiently. – Individual adaption at higher risk of condensation is possible (e. g. conservatories and swimming pools). ■ Formation of condensate – The humidity in the room can no longer be absorbed by the air. – The humidity builds up drops on building compoments with low surface temperatures. – Movement of the drop formation of insulating glass towards the area of the spacer an the frame of the curtain wall system. THERM+ 50 H-V with acrylic spacer Due to the outstanding thermal insulation already with standard gaskets as well as the insulating effect of acrylic spacers the isothermal line does not touch the surface of the structure. – Appearing of condensate at standardized conditions of 50% humidity and 20°C temperature on surfaces with a temperaure of 10°C. ■ Influence of the curtain wall system – The surface temperature on the inside of the curtain wall system does not decrease below 10°C even when the exterior temperature is 10°C below zero. – 10°C-isothermal line of the THERM+ system remains completely within the system and condensate is efficiently avoided. ■ Influence of the glass spacer – Besides the thermal insulation of the curtain wall system the type of spacer and glass edge is another important factor. – The spacer which is a thermal bridge transfers temperatures deep into the frame of the curtain wall system. – Use of glass spacers which offer a maximum thermal insulation (e. g. acrylic or steel). 270 2016 THERM+ 50 H-V with aluminium spacer Here the isothermal line is less advantageous due to the influence of the aluminium spacer. THERM+ H-V System benefits Timber curtain wall 50/56/76 mm Ventilation options Option I a: Pressure compensation via mullion – connection below/on top THERM+ H-V System sections The ventilation and the condensate removal of the glazing rebate is effected via the four corners of every infill unit in the mullion profiles and across an on-site adapter constructions. ■ Technical information – T44 = Foil connection behind drainage level – T45 = Collateral pressure compensation – T48 = Ventilation – T49 = Ventilation – T138 = Maximum 8 m resp. maximum 8 panels – T139 = All other 8 m resp. 8 panels KHV-0100 2016 271 THERM+ H-V System benefits Timber curtain wall 50/56 mm Ventilation options Option I b: Pressure compensation via mullion and synthetic sealing piece The ventilation and the condensate removal of the glazing rebate is effected via the four corners of every infill unit in the mullion profiles and addtional with a sealing piece via an opening of pressure profiles in the mullion area. Synthetic sealing piece: System widths 50 mm: No. 167142 PU = 10 pieces System widths 56 mm: No. 167147 PU = 10 pieces ■ Technical information – T44 = Foil connection behind drainage level. – T45 = Collateral pressure compensation. – T48 = Ventilation. – T49 = Ventilation. – T138 = Maximum 8 m resp. maximum 8 panels. – T139 = All other 8 m resp. 8 panels. 272 2016 KHV-0102 THERM+ H-V System benefits Timber curtain wall 50/56/76 mm Ventilation options Option II: Pressure compensation of extra large transoms via pressure and cover profiles THERM+ H-V System sections An additional opening result from a transom width of 1200 mm, two additional openings result from a transom width of 1800 mm in the pressure and cover profiles (options II a and II b). The number of openings depends on the transom length, the individual project and glazing requirements and must be determined in accordance with the glass supplier. to ■ Technical information – T121 = Option II a. – T122 = Option II b. KH-0101 2016 273 THERM+ H-V System benefits Timber curtain wall 50/56/76 mm Interior gasket design 3 drainage levels ■ Technical information – T38 = Level 2. – T39 = Level 3. – T40 = Level 1. – T151 = Interior gasket E3. – T152 = Interior gasket E2. – T153 = Interior gasket E1. – T159 = Interior gasket E2 with flap. 274 2016 KV-0011 THERM+ H-V System sections 50 mm Timber curtain wall Certified passive house curtain wall with insulating block P 50/39 Mullion section/transom section ■ Technical information ■ Profiles – Certified by passive house institute Dr. Feist. Article No. PU – Uf -values see chapter Thermal insulation. Cover profile 50/15 013003 6m Cover profile 50/12 013004 6m 118005 6m 144005 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 50 V 153005 40 m Gasket for transom 50 V 153010 40 m Insulating block P 50/39 168514 50 m No. PU – T1 = Depths from 50 mm. Pressure profile 47 punched Base profile 41 V punched Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article Special countersunk sheet metal screw 5.5x20 Pan head tapping screw 5.5x60 Sealing piece for pressure profile 50 Crosspoint sealing plate 50 Sealing piece for transom 50 V 012122 012123 100 pc(s) 100 pc(s) 014035 10 pc(s) 016050 10 pc(s) 152012 100 pc(s) Glass carrier 44 to 45 V 162087 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) 012122 HV-0082 2016 275 THERM+ H-V System sections ■ Gaskets THERM+ H-V System sections 50 mm Timber curtain wall Certified passive house curtain wall, insulating block P 50/39, base profile for groove installation Mullion section/transom section ■ Technical information ■ Profiles – Certified by passive house institute Dr. Feist. Article No. PU – Uf -values see chapter Thermal insulation. Cover profile 50/15 013003 6m Cover profile 50/12 013004 6m 118005 6m 144020 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 50 V 153005 40 m Gasket for transom 50 V 153010 40 m Insulating block P 50/39 168514 50 m No. PU – T1 = Depths from 50 mm. Pressure profile 47 punched Base profile 41 V with foot punched ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article Special countersunk sheet metal screw 5.5x20 Pan head tapping screw 5.5x60 Sealing piece for pressure profile 50 Crosspoint sealing plate 50 Sealing piece for transom 50 V 276 2016 HV-0144 012122 012123 100 pc(s) 100 pc(s) 014035 10 pc(s) 016050 10 pc(s) 152012 100 pc(s) Glass carrier 44 to 45 V 162087 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) THERM+ H-V System sections 50 mm Timber curtain wall Insulating block P 50/19 Mullion section/transom section ■ Technical information ■ Profiles – The type of insulating block P depends on the infill thickness: - 22 to 27 mm: insulating block P 50/19, no. 168509 - 28 to 41 mm: insulating block P 50/25, no. 168510 - 42 to 64 mm: insulating block P 50/39, no. 168514. Article No. PU Cover profile 50/15 013003 6m Cover profile 50/12 013004 6m 118005 6m 144005 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 50 V 153005 40 m Gasket for transom 50 V 153010 40 m Insulating block P 50/19 168509 50 m No. PU Pressure profile 47 punched Base profile 41 V punched – Uf-values see chapter Thermal insulation. – T1 = Depths from 50 mm. Article Gasket for pressure profile 3 Gasket for pressure profile 3 22 ■ Accessories Article Pan head tapping screw 5.5x42 Special countersunk sheet metal screw 5.5x20 Sealing piece for pressure profile 50 Crosspoint sealing plate 50 Sealing piece for transom 50 V 22 HV-0081 012114 012122 100 pc(s) 100 pc(s) 014035 10 pc(s) 016050 10 pc(s) 152012 100 pc(s) Glass carrier 26 to 27 V 162042 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) 2016 277 THERM+ H-V System sections ■ Gaskets THERM+ H-V System sections 50 mm Timber curtain wall Insulating block 21 Mullion section/transom section ■ Technical information ■ Profiles – Uf -values see chapter Thermal insulation. Article – T1 = Depths from 50 mm. No. PU Cover profile 50/15 013003 6m Cover profile 50/12 013004 6m 118005 6m 144005 6m No. PU Insulating block 50/21 150605 50 m Gasket for mullion 50 V 153005 40 m Gasket for transom 50 V 153010 40 m Pressure profile 47 punched Base profile 41 V punched ■ Gaskets Article ■ Accessories Article Pan head tapping screw 5.5x42 Special countersunk sheet metal screw 5.5x20 Sealing piece for pressure profile 50 Crosspoint sealing plate 50 Sealing piece for transom 50 V 278 2016 HV-0030 No. 012114 012122 PU 100 pc(s) 100 pc(s) 014035 10 pc(s) 016050 10 pc(s) 152012 100 pc(s) Glass carrier 26 to 27 V 162042 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) THERM+ H-V System sections 50 mm Timber curtain wall Insulating block 9 Mullion section/transom section ■ Technical information ■ Profiles – Uf -values see chapter Thermal insulation. Article – T1 = Depths from 50 mm. No. PU Cover profile 50/15 013003 6m Cover profile 50/12 013004 6m 118005 6m 144005 6m No. PU Pressure profile 47 punched Base profile 41 V punched Article Insulating block 50/9 151010 50 m Gasket for mullion 50 V 153005 40 m Gasket for transom 50 V 153010 40 m ■ Accessories Article Pan head tapping screw 5.5x42 Special countersunk sheet metal screw 5.5x20 Sealing piece for pressure profile 50 Crosspoint sealing plate 50 Sealing piece for transom 50 V HV-0008 No. 012114 012122 PU 100 pc(s) 100 pc(s) 014035 10 pc(s) 016050 10 pc(s) 152012 100 pc(s) Glass carrier 26 to 27 V 162042 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) 2016 279 THERM+ H-V System sections ■ Gaskets THERM+ H-V System sections 50 mm Timber curtain wall Standard exterior gasket Mullion section/transom section ■ Technical information ■ Profiles – Uf -values see chapter Thermal insulation. Article – T1 = Depths from 50 mm. No. PU Cover profile 50/15 013003 6m Cover profile 50/12 013004 6m 118005 6m 144005 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 50 V 153005 40 m Gasket for transom 50 V 153010 40 m Pressure profile 47 punched Base profile 41 V punched ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article Pan head tapping screw 5.5x42 Special countersunk sheet metal screw 5.5x20 Sealing piece for pressure profile 50 Crosspoint sealing plate 50 Sealing piece for transom 50 V 280 2016 HV-0001 No. 012114 012122 PU 100 pc(s) 100 pc(s) 014035 10 pc(s) 016050 10 pc(s) 152012 100 pc(s) Glass carrier 26 to 27 V 162042 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) THERM+ H-V System sections 50 mm 90° Timber curtain wall Corner mullion 90°, vertical Mullion section/transom section ■ Profiles Article No. PU 013003 6m 118005 6m 144005 6m 168023 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 50 V 153005 40 m Compensation gasket 2 227010 100 m Cover profile 50/15 Pressure profile 47 punched Base profile 41 V punched Connection profile 39/22 V Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article Pan head tapping screw 5.5x42 Special timber screw 4.5x35 Special countersunk sheet metal screw 4.8x19 HV-0164 No. 012114 908020 908118 2016 PU 100 pc(s) 100 pc(s) 100 pc(s) 281 THERM+ H-V System sections ■ Gaskets THERM+ H-V System sections 50 mm 90° Timber curtain wall Corner mullion 90°, vertical Mullion section/transom section ■ Profiles Article No. PU 013003 6m 118005 6m 144005 6m 168023 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 50 V 153005 40 m Compensation gasket 2 227010 100 m Cover profile 50/15 Pressure profile 47 punched Base profile 41 V punched Connection profile 39/22 V ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article Pan head tapping screw 5.5x42 Special timber screw 4.5x35 Special countersunk sheet metal screw 4.8x19 282 2016 HV-0163 No. 012114 908020 908118 PU 100 pc(s) 100 pc(s) 100 pc(s) THERM+ H-V System sections 50 mm Timber curtain wall Corner mullion for variable angles, vertical Mullion section/transom section ■ Profiles Article No. PU Cover profile 50/15 013003 6m Pressure prof. 47 punched 118005 6m Base profile 41 V punched 144005 6m Connection profile 39/22 V 168023 6m ■ Gaskets No. PU Gasket for pressure prof. 3 011070.LI 100 m Gasket for pressure prof. 3 011070.RE 100 m Gasket for mullion 50 V 153005 40 m Compensation gasket 2 227010 100 m ■ Accessories Article Pan head tapping screw 5.5x42 Special timber screw 4.5x35 Special countersunk sheet metal screw 4.8x19 HV-0165 No. 012114 908020 908118 2016 PU 100 pc(s) 100 pc(s) 100 pc(s) 283 THERM+ H-V System sections Article THERM+ H-V System sections 50 mm Timber curtain wall Gasket for transom with flap between mullions Transom section ■ Technical information ■ Profiles – Available for all insulating blocks. Article – T1 = Depths from 50 mm. Cover profile 50/12 Pressure profile 47 punched Base profile 41 V punched No. PU 013004 6m 118005 6m 144005 6m No. PU 011070.LI 100 m 011070.RE 100 m 153015 40 m No. PU ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for transom 50 V with flap ■ Accessories Article Pan head tapping screw 5.5x42 Special countersunk sheet metal screw 5.5x20 Sealing piece for pressure profile 50 Crosspoint sealing plate 50 Sealing piece for transom 50 V 284 2016 HV-0002a 012114 012122 100 pc(s) 100 pc(s) 014035 10 pc(s) 016050 10 pc(s) 152012 100 pc(s) Glass carrier 26 to 27 V 162042 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) THERM+ H-V System sections 50 mm Timber curtain wall Continuous base gasket with flap Transom section ■ Technical information ■ Profiles – Available for all insulating blocks. Article – Base gasket available up to an infill thickness of 64 mm. Cover profile 50/12 No. PU 013004 6m 118005 6m 144005 6m 168005 6m No. PU 011070.LI 100 m 011070.RE 100 m Compensation gasket 2 011080 100 m Base gasket for transom 50 V with flap 153020 40 m Pressure profile 47 punched Base profile 41 V punched – T1 = Depths from 50 mm. Connection profile 36/22 Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article Pan head tapping screw 5.5x42 Special countersunk sheet metal screw 5.5x20 Sealing piece for pressure profile 50 Crosspoint sealing plate 50 Sealing piece for base transom V HV-0002b No. 012114 012122 PU 100 pc(s) 100 pc(s) 014035 10 pc(s) 016050 10 pc(s) 152075 10 pc(s) Glass carrier 26 to 27 V 162042 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) 2016 285 THERM+ H-V System sections ■ Gaskets THERM+ H-V System sections 50 mm Timber curtain wall Timber cover profile clipped Mullion section/transom section ■ Technical information ■ Profiles – Timber cover profiles are products complementary to the RAICO system components, supplied by the fabricator. It must be assured that the function of the glazing system remains guaranteed by adaptation of the constructional and material characteristics of the timber cover profile. Article Pressure profile 44 punched Base profile 41 V punched – The norms and regulations concerning the use of timber in exterior building areas must be respected. No. PU 118505 6m 144005 6m ■ Gaskets – Timber cover profiles must be secured mechanically after their installation. Article – For further information see Processing. – T1 = Depths from 50 mm. No. PU Gasket for pressure profile 7 H 150510 100 m Gasket for mullion 50 V 153005 40 m Gasket for transom 50 V 153010 40 m No. PU ■ Accessories Article Pan head tapping screw 5.5x42 Special countersunk sheet metal screw 5.5x20 Sealing piece for pressure profile 50 Crosspoint sealing plate 50 Sealing piece for transom 50 V 286 2016 HV-0107 012114 012122 100 pc(s) 100 pc(s) 014035 10 pc(s) 016050 10 pc(s) 152012 100 pc(s) Glass carrier 26 to 27 V 162042 10 pc(s) Cover profile fixation 80 167005 Special timber screw 4.5x35 908020 100 pc(s) 100 pc(s) THERM+ H-V System sections 50 mm Timber curtain wall Connection of ventilated/non-ventilated curtain wall Transom section ■ Technical information ■ Profiles – For the alternative solution (direct screw connection) attention shall be paid to observing a sufficient tolerance compensation (see Processing). Article No. PU Cover profile 50/12 013004 6m Pressure prof. 47 punched 118005 6m Base profile 41 V punched 144005 6m Connection profile 45/42 168060 6m ■ Gaskets No. Gasket for pressure prof. 3 011070.LI PU 100 m Gasket for pressure prof. 3 011070.RE 100 m Gasket for pressure prof. 7 011074 100 m Gasket for transom 50 V with flap 153015 40 m ■ Accessories Article Pan head tapping screw 5.5x42 Special countersunk sheet metal screw 5.5x20 Sealing piece for pressure profile 50 Crosspoint sealing plate 50 Sealing piece for transom 50 V HV-0157 No. 012114 012122 PU 100 pc(s) 100 pc(s) 014035 10 pc(s) 016050 10 pc(s) 152012 100 pc(s) Glass carrier 26 to 27 V 162042 10 pc(s) Special timber screw 4.5x35 908020 Terminal clamp 47/22 915501 2016 100 pc(s) 100 pc(s) 287 THERM+ H-V System sections Article THERM+ H-V System sections 50 mm Timber curtain wall Interior compensation of varying infill thicknesses Mullion section/transom section ■ Technical information ■ Profiles – Possible compensation of infill thickness: - 2 mm: compensation gasket 2, 154505 - 4 mm: compensation gasket 4, 154507 - 6 mm: compensation gasket 6, 154509. Article – T1 = Depths from 50 mm. Pressure profile 47 punched Base profile 41 V punched No. PU Cover profile 50/15 013003 6m Cover profile 50/12 013004 6m 118005 6m 144005 6m No. PU 011070.LI 100 m 011070.RE 100 m Compensation gasket 4 154507 100 m Gasket for mullion 50 V 158005 40 m Gasket for transom 50 V 158010 40 m No. PU ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article Pan head tapping screw 5.5x42 Special countersunk sheet metal screw 5.5x20 Sealing piece for pressure profile 50 Crosspoint sealing plate 50 Sealing piece for transom 50 288 2016 HV-0119 012114 012122 100 pc(s) 100 pc(s) 014035 10 pc(s) 016050 10 pc(s) 152040 100 pc(s) Glass carrier 28 to 29 V 162047 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) THERM+ H-V System sections 50 mm Timber curtain wall Single glazing Mullion section/transom section ■ Technical information ■ Profiles – Depending on the infill thickness the following gaskets for pressure profile must be used: - Infill thickness 8 to 9 mm: gaskets for pressure profile 5 mm - Infill thickness from 10 mm: gaskets for pressure profile 3 mm. – T1 = Depths from 50 mm. Article No. PU Cover profile 50/15 013003 6m Cover profile 50/12 013004 6m 118005 6m 144005 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 50 V 153005 40 m Gasket for transom 50 V 153010 40 m Pressure profile 47 punched Base profile 41 V punched Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article Pan head tapping screw 5.5x25 Special countersunk sheet metal screw 5.5x20 Sealing piece for pressure profile 50 Crosspoint sealing plate 50 Sealing piece for transom 50 V HV-0007 No. 012107 012122 PU 100 pc(s) 100 pc(s) 014035 10 pc(s) 016050 10 pc(s) 152012 100 pc(s) Glass carrier 10 to 11 V 162002 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) 2016 289 THERM+ H-V System sections ■ Gaskets THERM+ H-V System sections 50 mm Timber curtain wall Expansion mullion Mullion section ■ Technical information ■ Profiles – T11 = Depths from 100 mm. Article Cover profile 50/15 No. PU 013003 6m Pressure profile 47 punched Expansion base profile 41 V left punched Expansion base profile 41 V right punched 118005 6m 144105 6m 144106 6m Insertion profile 16/10 V 168220 6m No. PU 011070.LI 100 m 011070.RE 100 m 153305 40 m ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for mullion 50 H V ■ Accessories Article Pan head tapping screw 5.5x42 Pan Head timber screw 4.5x20 PU sealing strip 10/7 offset arrangement 290 2016 HV-0117 No. 012114 907550 951990 PU 100 pc(s) 100 pc(s) 10 m THERM+ H-V System sections 50 mm Timber curtain wall Polygon glazing system with standard interior gasket 1° to 7° Mullion section exterior angle/interior angle ■ Technical information ■ Profiles – With exterior gasket for pressure profile 5 mm and standard interior gasket to max. 7°. Article Cover profile 50/15 Pressure profile 47 punched Base profile 41 V punched No. PU 013003 6m 118005 6m 144005 6m ■ Gaskets Article No. PU Gasket for pressure profile 5 011073 100 m Gasket for mullion 50 V 153005 40 m No. PU Article Pan head tapping screw 5.5x45 Special timber screw 4.5x35 HV-0027 012115 908020 2016 100 pc(s) 100 pc(s) 291 THERM+ H-V System sections ■ Accessories THERM+ H-V System sections 50 mm Timber curtain wall Polygon glazing system 8° to 15° Mullion section exterior angle ■ Technical information ■ Profiles – Face width of cover profile depends on angle and infill thickness. Article Cover profile 56/15 – Glass bite (A and B) must be min. 12 mm. The distance between glass edge and gasket cap (C) has to be min. 3 mm. Please note the glass tolerances! Pressure profile 53 punched Base profile 41 V punched No. PU 013023 6m 118010 6m 144005 6m No. PU 011810 100 m 153040 40 m ■ Gaskets Article Gasket for pressure profile 8° to 15° Gasket for transom 50 V polygonal 8° to 20° ■ Accessories Article Pan head tapping screw 5.5x45 Special timber screw 4.5x35 292 2016 HV-0044 No. 012115 908020 PU 100 pc(s) 100 pc(s) THERM+ H-V System sections 50 mm Timber curtain wall Polygon glazing system 8° to 20° and 21° to 33° with polygon interior and exterior gasket Mullion section exterior angle ■ Technical information ■ Profiles – Insulating strips available on demand. Article Cover profile 50/15 Profile polygonal 8° to 20° Profile polygonal 21° to 33° Pressure profile 47 punched Base profile 41 V punched No. PU 013003 6m 013800 6m 013801 6m 118005 6m 144005 6m No. PU 011805 100 m 153040 40 m 153045 40 m Article Gasket for pressure profile 5 polygonal Gasket for transom 50 V polygonal 8° to 20° Gasket for mullion 50 V polygonal 21° to 33° ■ Accessories Article Pan head tapping screw 5.5x50 Pan head tapping screw 5.5x52 Special timber screw 4.5x35 HV-0029 No. 012117 012118 908020 2016 PU 100 pc(s) 100 pc(s) 100 pc(s) 293 THERM+ H-V System sections ■ Gaskets THERM+ H-V System sections 50 mm Timber curtain wall Polygon glazing system 34° to 45° with polygon interior and exterior gasket Mullion section exterior angle ■ Technical information ■ Profiles – Insulating strips available on demand. Article Cover profile 50/15 Profile polygonal 34° to 45° Pressure profile 47 punched Base profile 41 V punched No. PU 013003 6m 013802 6m 118005 6m 144005 6m No. PU 011805 100 m 153050 40 m No. PU ■ Gaskets Article Gasket for pressure profile 5 polygonal Gasket for mullion 50 V polygonal 34° to 45° ■ Accessories Article Pan head tapping screw 5.5x55 Special timber screw 4.5x35 294 2016 HV-0033 012119 908020 100 pc(s) 100 pc(s) THERM+ H-V System sections 50 mm Timber curtain wall Cover profile options clipped Mullion section ■ Technical information ■ Profiles – Slipping down of the cover profiles must be prevented. Article Cover profile 50/15 PU 6m Cover profile 50/12 013004 6m Cover profile 50/25 013005 6m Cover profile 50/25 013201 6m Cover profile 50/20 013210 6m Pressure profile 47 punched 118005 6m Cover profile 50/30 141106 6m THERM+ H-V System sections – For more cover profiles, end caps and belay sheet see Product range. No. 013003 HV-0158 2016 295 THERM+ H-V System sections 50 mm Timber curtain wall Pressure profile options with visible screw connection Mullion section ■ Technical information ■ Profiles – For more pressure profiles see Product range. 296 2016 Article HV-0041 No. PU Pressure profile 50/12 013007 6m Pressure profile 50/9 013008 6m Pressure profile 50/25 013014 6m THERM+ H-V System sections 50 mm Timber curtain wall Flat pressure profile options Mullion section with three options ■ Technical information ■ Profiles – Minimum infill thickness 18 mm. Article Pressure profile 50/3 No. PU 013300 6m No. PU 220205 100 m No. PU ■ Gaskets Article Gasket for pressure profile 2/16 Article Flat fillister head screw 5.5x35 with sealing ring Pan head tapping screw 5.5x32 Pan head tapping screw 5.5x35 with sealing ring Cover 11 S HV-0043 012011 012110 012174 014110 2016 100 pc(s) 100 pc(s) 100 pc(s) 100 pc(s) 297 THERM+ H-V System sections ■ Accessories THERM+ H-V System sections 50 mm Timber curtain wall Flat pressure profile options for polygon glazing system 3° to 7° with standard interior gasket Mullion section exterior angle ■ Technical information ■ Profiles – Minimum infill thickness 18 mm. Article – Selection of pressure profiles according to infill thickness and angle. Pressure profile 50/3 No. PU 013300 6m No. PU 011850 200 m ■ Gaskets Article Gasket for pressure profile 3 polygonal 3° to 7° ■ Accessories Article Flat fillister head screw 5.5x35 with sealing ring Pan head tapping screw 5.5x32 Pan head tapping screw 5.5x35 with sealing ring Cover 11 S 298 2016 HV-0032 No. 012011 012110 012174 014110 PU 100 pc(s) 100 pc(s) 100 pc(s) 100 pc(s) THERM+ H-V System sections 56 mm Timber curtain wall Certified passive house curtain wall with insulating block P 56/39 Mullion section/transom section ■ Technical information ■ Profiles – Certified by passive house institute Dr. Feist. Article No. PU – Uf -values see chapter Thermal insulation. Cover profile 56/15 013023 6m Cover profile 56/12 013024 6m 118010 6m 144010 6m No. PU 011070.LI 100 m 011070.RE 100 m 153105 40 m – T1 = Depths from 50 mm. Pressure profile 53 punched Base profile 47 V punched Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for mullion 56 V Gasket for transom 56 V 153110 40 m Insulating block P 56/39 168520 50 m No. PU ■ Accessories Article Special countersunk sheet metal screw 5.5x20 Pan head tapping screw 5.5x60 Crosspoint sealing plate 56 Sealing piece for transom 56 V HV-0108 012122 012123 100 pc(s) 100 pc(s) 016051 10 pc(s) 152017 100 pc(s) Glass carrier 44 to 45 V 162087 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) 2016 299 THERM+ H-V System sections ■ Gaskets THERM+ H-V System sections 56 mm Timber curtain wall Certified passive house curtain wall, insulating block P 56/39, base profile for groove installation Mullion section/transom section ■ Technical information ■ Profiles – Certified by passive house institute Dr. Feist. Article No. PU – Uf -values see chapter Thermal insulation. Cover profile 56/15 013023 6m Cover profile 56/12 013024 6m 118010 6m 144025 6m No. PU 011070.LI 100 m 011070.RE 100 m 153105 40 m – T1 = Depths from 50 mm. Pressure profile 53 punched Base profile 47 V with foot punched ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for mullion 56 V Gasket for transom 56 V 153110 40 m Insulating block P 56/39 168520 50 m No. PU ■ Accessories Article Special countersunk sheet metal screw 5.5x20 Pan head tapping screw 5.5x60 Sealing piece for pressure profile 56 Crosspoint sealing plate 56 Sealing piece for transom 56 V 300 2016 HV-0145 012122 012123 100 pc(s) 100 pc(s) 014036 10 pc(s) 016051 10 pc(s) 152017 100 pc(s) Glass carrier 44 to 45 V 162087 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) THERM+ H-V System sections 56 mm Timber curtain wall Insulating block P 56/19 Mullion section/transom section ■ Technical information ■ Profiles – The type of insulating block P depends on the infill thickness: - 22 to 27 mm: insulating block P 56/19, No. 168515 - 28 to 41 mm: insulating block P 56/25, No. 168516 - 42 to 64 mm: insulating block P 56/39, No. 168520. Article No. PU 013023 6m 118010 6m 144010 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 56 V 153105 40 m Gasket for transom 56 V 153110 40 m Insulating block P 56/19 168515 50 m Cover profile 56/15 Pressure profile 53 punched Base profile 47 V punched – Uf -values see chapter Thermal insulation. – T1 = Depths from 50 mm. Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article Pan head tapping screw 5.5x42 Special countersunk sheet metal screw 5.5x20 Sealing piece for pressure profile 56 Crosspoint sealing plate 56 Sealing piece for transom 56 V HV-0103 No. 012114 012122 PU 100 pc(s) 100 pc(s) 014036 10 pc(s) 016051 10 pc(s) 152017 100 pc(s) Glass carrier 26 to 27 V 162042 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) 2016 301 THERM+ H-V System sections ■ Gaskets THERM+ H-V System sections 56 mm Timber curtain wall Insulating block 21 Mullion section/transom section ■ Technical information ■ Profiles – Uf -values see chapter Thermal insulation. Article – T1 = Depths from 50 mm. No. PU Cover profile 56/15 013023 6m Cover profile 56/12 013024 6m 118010 6m 144010 6m No. PU Insulating block 56/21 150610 50 m Gasket for mullion 56 V 153105 40 m Gasket for transom 56 V 153110 40 m Pressure profile 53 punched Base profile 47 V punched ■ Gaskets Article ■ Accessories Article Pan head tapping screw 5.5x42 Special countersunk sheet metal screw 5.5x20 Sealing piece for pressure profile 56 Crosspoint sealing plate 56 Sealing piece for transom 56 V 302 2016 HV-0115 No. 012114 012122 PU 100 pc(s) 100 pc(s) 014036 10 pc(s) 016051 10 pc(s) 152017 100 pc(s) Glass carrier 26 to 27 V 162042 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) THERM+ H-V System sections 56 mm Timber curtain wall Insulating block 9 Mullion section/transom section ■ Technical information ■ Profiles – Uf -values see chapter Thermal insulation. Article – T1 = Depths from 50 mm. No. PU Cover profile 56/15 013023 6m Cover profile 56/12 013024 6m 118010 6m 144010 6m No. PU Pressure profile 53 punched Base profile 47 V punched Article Insulating block 56/9 151020 50 m Gasket for mullion 56 V 153105 40 m Gasket for transom 56 V 153110 40 m ■ Accessories Article Pan head tapping screw 5.5x42 Special countersunk sheet metal screw 5.5x20 Sealing piece for pressure profile 56 Crosspoint sealing plate 56 Sealing piece for transom 56 V HV-0111 No. 012114 012122 PU 100 pc(s) 100 pc(s) 014036 10 pc(s) 016051 10 pc(s) 152017 100 pc(s) Glass carrier 26 to 27 V 162042 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) 2016 303 THERM+ H-V System sections ■ Gaskets THERM+ H-V System sections 56 mm Timber curtain wall Standard exterior gasket Mullion section/transom section ■ Technical information ■ Profiles – Uf -values see chapter Thermal insulation. Article – T1 = Depths from 50 mm. No. PU Cover profile 56/15 013023 6m Cover profile 56/12 013024 6m Pressure profile 53 punched 118010 6m Base profile 47 V punched 144010 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 56 V 153105 40 m Gasket for transom 56 V 153110 40 m ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article Pan head tapping screw 5.5x42 Special countersunk sheet metal screw 5.5x20 Sealing piece for pressure profile 56 Crosspoint sealing plate 56 Sealing piece for transom 56 V 304 2016 HV-0100 No. 012114 012122 PU 100 pc(s) 100 pc(s) 014036 10 pc(s) 016051 10 pc(s) 152017 100 pc(s) Glass carrier 26 to 27 V 162042 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) THERM+ H-V System sections 56 mm 90° Timber curtain wall Corner mullion 90°, vertical Mullion section/transom section ■ Profiles Article No. PU 013023 6m 118010 6m 144010 6m 168023 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 56 V 153105 40 m Compensation gasket 2 227010 100 m Cover profile 56/15 Pressure profile 53 punched Base profile 47 V punched Connection profile 39/22 V Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article Pan head tapping screw 5.5x42 Special timber screw 4.5x35 Special countersunk sheet metal screw 4.8x19 HV-0167 No. 012114 908020 908118 2016 PU 100 pc(s) 100 pc(s) 100 pc(s) 305 THERM+ H-V System sections ■ Gaskets THERM+ H-V System sections 56 mm 90° Timber curtain wall Corner mullion 90°, vertical Mullion section/transom section ■ Profiles Article No. PU 013023 6m 118010 6m 144010 6m 168023 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 56 V 153105 40 m Compensation gasket 2 227010 100 m Cover profile 56/15 Pressure profile 53 punched Base profile 47 V punched Connection profile 39/22 V ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article Pan head tapping screw 5.5x42 Special timber screw 4.5x35 Special countersunk sheet metal screw 4.8x19 306 2016 HV-0166 No. 012114 908020 908118 PU 100 pc(s) 100 pc(s) 100 pc(s) THERM+ H-V System sections 56 mm Timber curtain wall Corner mullion for variable angles, vertical Mullion section/transom section ■ Profiles Article No. PU Cover profile 56/15 013023 6m Pressure profile 53 punched 118010 6m Base profile 47 V punched 144010 6m Connection profile 39/22 V 168023 6m ■ Gaskets No. PU Gasket for pressure prof. 3 011070.LI 100 m Gasket for pressure prof. 3 011070.RE 100 m Gasket for mullion 56 V 153105 40 m Compensation gasket 2 227010 100 m ■ Accessories Article Pan head tapping screw 5.5x42 Special timber screw 4.5x35 Special countersunk sheet metal screw 4.8x19 HV-0168 No. 012114 908020 908118 2016 PU 100 pc(s) 100 pc(s) 100 pc(s) 307 THERM+ H-V System sections Article THERM+ H-V System sections 56 mm Timber curtain wall Gasket for transom with flap between mullions Transom section ■ Technical information ■ Profiles – Available for all insulating blocks. Article – T1 = Depths from 50 mm. Cover profile 56/12 Pressure profile 53 punched Base profile 47 V punched No. PU 013024 6m 118010 6m 144010 6m No. PU 011070.LI 100 m 011070.RE 100 m 153115 40 m No. PU ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for transom 56 V with flap ■ Accessories Article Pan head tapping screw 5.5x42 Special countersunk sheet metal screw 5.5x20 Sealing piece for pressure profile 56 Crosspoint sealing plate 56 Sealing piece for transom 56 V 308 2016 HV-0112a 012114 012122 100 pc(s) 100 pc(s) 014036 10 pc(s) 016051 10 pc(s) 152017 100 pc(s) Glass carrier 26 to 27 V 162042 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) THERM+ H-V System sections 56 mm Timber curtain wall Continuous base gasket with flap Transom section ■ Technical information ■ Profiles – Available for all insulating blocks. Article – Base gasket available up to an infill thickness of 64 mm. No. PU 013024 6m 118010 6m 144010 6m 168005 6m No. PU 011070.LI 100 m 011070.RE 100 m Compensation gasket 2 011080 100 m Base gasket for transom 56 V with flap 153120 40 m Cover profile 56/12 Pressure profile 53 punched Base profile 47 V punched – T1 = Depths from 50 mm. Connection profile 36/22 Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article Pan head tapping screw 5.5x42 Special countersunk sheet metal screw 5.5x20 Sealing piece for pressure profile 56 Crosspoint sealing plate 56 Sealing piece for base transom V 10 - 64 mm HV-0112b No. 012114 012122 PU 100 pc(s) 100 pc(s) 014036 10 pc(s) 016051 10 pc(s) 152075 10 pc(s) Glass carrier 26 to 27 V 162042 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) 2016 309 THERM+ H-V System sections ■ Gaskets THERM+ H-V System sections 56 mm Timber curtain wall Timber cover profile clipped Mullion section/transom section ■ Technical information ■ Profiles – Timber cover profiles are products complementary to the RAICO system components, supplied by the fabricator. It must be assured that the function of the glazing system remains guaranteed by adaptation of the constructional and material characteristics of the timber cover profile. Article Pressure profile 50 punched Base profile 47 V punched – The norms and regulations concerning the use of timber in exterior building areas must be respected. No. PU 118510 6m 144010 6m ■ Gaskets – Timber cover profiles must be secured mechanically after their installation. Article – For further information see Processing. – T1 = Depths from 50 mm. No. PU Gasket for pressure profile 7 H 150510 100 m Gasket for mullion 56 V 153105 40 m Gasket for transom 56 V 153110 40 m No. PU ■ Accessories Article Pan head tapping screw 5.5x42 Special countersunk sheet metal screw 5.5x20 Sealing piece for pressure profile 56 Crosspoint sealing plate 56 Sealing piece for transom 56 V 310 2016 HV-0023 012114 012122 100 pc(s) 100 pc(s) 014036 10 pc(s) 016051 10 pc(s) 152017 100 pc(s) Glass carrier 26 to 27 V 162042 10 pc(s) Cover profile fixation 80 167005 Special timber screw 4.5x35 908020 100 pc(s) 100 pc(s) THERM+ H-V System sections 56 mm Timber curtain wall Connection of ventilated/non-ventilated curtain wall Transom section ■ Technical information ■ Profiles – For the alternative solution (direct screw connection) attention shall be paid to observing a sufficient tolerance compensation (see Processing). Article No. PU Cover profile 56/12 013024 6m Pressure prof. 53 punched 118010 6m Base profile 47 V punched 144010 6m Connection profile 45/42 168060 6m ■ Gaskets No. Gasket for pressure prof. 3 011070.LI PU 100 m Gasket for pressure prof. 3 011070.RE 100 m Gasket for pressure prof. 7 011074 100 m Gasket for transom 56 V with flap 153115 40 m ■ Accessories Article HV-0171 No. PU 100 pc(s) 100 pc(s) Pan head tapping screw 5.5x42 Special countersunk sheet metal screw 5.5x20 Sealing piece for pressure profile 56 012122 014036 10 pc(s) Crosspoint sealing plate 56 016051 10 pc(s) Sealing piece for transom 56 V 152017 100 pc(s) Glass carrier 26 to 27 V 162042 10 pc(s) Special timber screw 4.5x35 908020 Terminal clamp 47/22 915501 012114 2016 100 pc(s) 100 pc(s) 311 THERM+ H-V System sections Article THERM+ H-V System sections 56 mm Timber curtain wall Interior compensation of varying infill thicknesses Mullion section/transom section ■ Technical information ■ Profiles – Possible compensation of infill thickness: - 2 mm: compensation gasket 2, 154505 - 4 mm: compensation gasket 4, 154507 - 6 mm: compensation gasket 6, 154509. Article – T1 = Depths from 50 mm. Pressure profile 53 punched Base profile 47 V punched No. PU Cover profile 56/15 013023 6m Cover profile 56/12 013024 6m 118010 6m 144010 6m No. PU 011070.LI 100 m 011070.RE 100 m Compensation gasket 4 154507 100 m Gasket for mullion 56 V 158105 40 m Gasket for transom 56 V 158110 40 m ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article Pan head tapping screw 5.5x42 Special countersunk sheet metal screw 5.5x20 Sealing piece for pressure profile 56 Crosspoint sealing plate 56 Sealing piece for transom 50 312 2016 HV-0016 No. 012114 012122 PU 100 pc(s) 100 pc(s) 014036 10 pc(s) 016051 10 pc(s) 152040 100 pc(s) Glass carrier 28 to 29 V 162047 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) THERM+ H-V System sections 56 mm Timber curtain wall Single glazing Mullion section/transom section ■ Technical information ■ Profiles – Depending on the infill thickness the following gaskets for pressure profile must be used: - Infill thickness 8 to 9 mm: gaskets for pressure profile 5 mm - Infill thickness from 10 mm: gaskets for pressure profile 3 mm. Article PU Cover profile 56/15 013023 6m Cover profile 56/12 013024 6m 118010 6m 144010 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 56 V 153105 40 m Gasket for transom 56 V 153110 40 m Pressure profile 53 punched Base profile 47 V punched – T1 = Depths from 50 mm. No. Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article Pan head tapping screw 5.5x25 Special countersunk sheet metal screw 5.5x20 Sealing piece for pressure profile 56 Crosspoint sealing plate 56 Sealing piece for transom 56 V HV-0101 No. 012107 012122 PU 100 pc(s) 100 pc(s) 014036 10 pc(s) 016051 10 pc(s) 152017 100 pc(s) Glass carrier 10 to 11 V 162002 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) 2016 313 THERM+ H-V System sections ■ Gaskets THERM+ H-V System sections 56 mm Timber curtain wall Expansion mullion Mullion section ■ Technical information ■ Profiles – T11 = Depths from 100 mm. Article No. PU Cover profile 56/15 013023 6m Pressure profile 53 punched 118010 6m Insertion profile 16/10 V 168220 6m No. PU 011070.LI 100 m 011070.RE 100 m 153335 40 m ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for mullion 56 H V ■ Accessories Article Pan head tapping screw 5.5x42 Pan Head timber screw 4.5x20 PU sealing strip 10/7 offset arrangement 314 2016 HV-0118 No. 012114 907550 951990 PU 100 pc(s) 100 pc(s) 10 m THERM+ H-V System sections 56 mm Timber curtain wall Polygon glazing system with standard interior gasket 1° to 7° Mullion section exterior angle/interior angle ■ Technical information ■ Profiles – With exterior gasket for pressure profile 5 mm and standard interior gasket to max. 7°. Article Cover profile 56/15 Pressure profile 53 punched Base profile 47 V punched No. PU 013023 6m 118010 6m 144010 6m ■ Gaskets Article No. PU Gasket for pressure profile 5 011073 100 m Gasket for mullion 56 V 153105 40 m No. PU Article Pan head tapping screw 5.5x45 Special timber screw 4.5x35 HV-0105 012115 908020 2016 100 pc(s) 100 pc(s) 315 THERM+ H-V System sections ■ Accessories THERM+ H-V System sections 56 mm Timber curtain wall Polygon glazing system 8° to 15° Mullion section exterior angle ■ Technical information ■ Profiles Article – Face width of cover profile depends on angle and infill thickness. Cover profile 76/15 – Glass bite (A and B) must be min. 13 mm. The distance between glass edge and gasket cap (C) has to be min. 3 mm. Please note the glass tolerances! Pressure profile 73 punched Base profile 47 V punched No. PU 013050 6m 118015 6m 144010 6m No. PU 011810 100 m 153140 40 m ■ Gaskets Article Gasket for pressure profile 8° to 15° Gasket for transom 56 V polygonal 8° to 20° ■ Accessories Article Pan head tapping screw 5.5x45 Special timber screw 4.5x35 316 2016 HV-0045 No. 012115 908020 PU 100 pc(s) 100 pc(s) THERM+ H-V System sections 56 mm Timber curtain wall Polygon glazing system 8° to 20° and 21° to 33° with polygon interior and exterior gasket Mullion section exterior angle ■ Technical information ■ Profiles – Insulating strips available on demand. Article Cover profile 56/15 Profile polygonal 8° to 20° Profile polygonal 21° to 33° Pressure profile 53 punched Base profile 47 V punched No. PU 013023 6m 013800 6m 013801 6m 118010 6m 144010 6m No. PU 011805 100 m 153140 40 m 153145 40 m Article Gasket for pressure profile 5 polygonal Gasket for transom 56 V polygonal 8° to 20° Gasket for mullion 56 V polygonal 21° to 33° ■ Accessories Article Pan head tapping screw 5.5x50 Pan head tapping screw 5.5x52 Special timber screw 4.5x35 HV-0106 No. 012117 012118 908020 2016 PU 100 pc(s) 100 pc(s) 100 pc(s) 317 THERM+ H-V System sections ■ Gaskets THERM+ H-V System sections 56 mm Timber curtain wall Polygon glazing system 34° to 45° with polygon interior and exterior gasket Mullion section exterior angle ■ Technical information ■ Profiles – Insulating strips available on demand. Article Cover profile 56/15 Profile polygonal 34° to 45° Pressure profile 53 punched Base profile 47 V punched No. PU 013023 6m 013802 6m 118010 6m 144010 6m No. PU 011805 100 m 153150 40 m No. PU ■ Gaskets Article Gasket for pressure profile 5 polygonal Gasket for mullion 56 V polygonal 34° to 45° ■ Accessories Article Pan head tapping screw 5.5x55 Special timber screw 4.5x35 318 2016 HV-0020 012119 908020 100 pc(s) 100 pc(s) THERM+ H-V System sections 56 mm Timber curtain wall Cover profile options clipped Mullion section ■ Technical information ■ Profiles – Slipping down of the cover profiles must be prevented. Article Cover profile 56/15 PU 6m Cover profile 56/12 013024 6m Cover profile 56/25 013025 6m Cover profile 56/25 013400 6m Cover profile 56/20 013410 6m Pressure profile 53 punched 118010 6m Cover profile 56/32 141307 6m THERM+ H-V System sections – For more cover profiles, end caps and belay sheet see Product range. No. 013023 HV-0024 2016 319 THERM+ H-V System sections 56 mm Timber curtain wall Pressure profile options visible screwed Mullion section ■ Technical information ■ Profiles – For more pressure profiles see Product range. 320 2016 Article HV-0025 No. PU Pressure profile 56/12 013027 6m Pressure profile 56/9 013028 6m THERM+ H-V System sections 56 mm Timber curtain wall Flat pressure profile options Mullion section with three options ■ Technical information ■ Profiles – Minimum infill thickness 18 mm. Article Pressure profile 56/3 No. PU 013310 6m No. PU 220205 100 m No. PU ■ Gaskets Article Gasket for pressure profile 2/16 Article Flat fillister head screw 5.5x35 with sealing ring Pan head tapping screw 5.5x32 Pan head tapping screw 5.5x35 with sealing ring Cover 11 S HV-0014 012011 012110 012174 014110 2016 100 pc(s) 100 pc(s) 100 pc(s) 100 pc(s) 321 THERM+ H-V System sections ■ Accessories THERM+ H-V System sections 56 mm Timber curtain wall Flat pressure profile options for polygon glazing system 3° to 7° with standard interior gasket Mullion section exterior angle ■ Technical information ■ Profiles – Minimum infill thickness 18 mm. Article – Selection of pressure profiles according to infill thickness and angle. Pressure profile 56/3 No. PU 013310 6m No. PU 011850 200 m ■ Gaskets Article Gasket for pressure profile 3 polygonal 3° to 7° ■ Accessories Article Flat fillister head screw 5.5x35 with sealing ring Pan head tapping screw 5.5x35 Pan head tapping screw 5.5x38 with sealing ring Cover 11 S 322 2016 HV-0015 No. 012011 012111 012175 014110 PU 100 pc(s) 100 pc(s) 100 pc(s) 100 pc(s) THERM+ H-V System sections 76 mm Timber curtain wall Certified passive house curtain wall with insulating block P 76/39 Mullion section/transom section ■ Technical information ■ Profiles – Certified by passive house institute Dr. Feist. Article No. PU – Uf -values see chapter Thermal insulation. Cover profile 76/15 013050 6m Cover profile 76/12 013051 6m 118015 6m 144015 6m – T1 = Depths from 50 mm. Pressure profile 73 punched Base profile 67 V punched Article No. PU Gasket for pressure profile 5 011073 100 m Gasket for mullion 76 V 153205 40 m Gasket for transom 76 V 153210 40 m Insulating block P 76/39 168526 50 m ■ Accessories Article Special countersunk sheet metal screw 5.5x20 Pan head tapping screw 5.5x60 Cross point sealing plate 76 P Sealing piece for transom 76 V Sealing piece for pressure profile 76/5 HV-0123 No. 012122 012123 PU 100 pc(s) 100 pc(s) 016056 10 pc(s) 152058 100 pc(s) 152421 10 pc(s) Glass carrier 44 to 45 V 162087 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) 2016 323 THERM+ H-V System sections ■ Gaskets THERM+ H-V System sections 76 mm Timber curtain wall Certified passive house curtain wall, insulating block P 76/39, base profile for groove installation Mullion section/transom section ■ Technical information ■ Profiles – Certified by passive house institute Dr. Feist. Article No. PU – Uf -values see chapter Thermal insulation. Cover profile 76/15 013050 6m Cover profile 76/12 013051 6m 118015 6m 144030 6m – T1 = Depths from 50 mm. Pressure profile 73 punched Base profile 67 V with foot punched ■ Gaskets Article No. PU Gasket for pressure profile 5 011073 100 m Gasket for mullion 76 V 153205 40 m Gasket for transom 76 V 153210 40 m Insulating block P 76/39 168526 50 m No. PU 012122 100 pc(s) 012123 100 pc(s) 016056 10 pc(s) 152058 100 pc(s) 152421 10 pc(s) Glass carrier 44 to 45 V 162087 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Accessories Article Special countersunk sheet metal screw 5.5x20 Pan head tapping screw 5.5x60 Cross point sealing plate 76 P Sealing piece for transom 76 V Sealing piece for pressure profile 76/5 324 2016 HV-0146 THERM+ H-V System sections 76 mm Timber curtain wall Insulating block P 76/19 Mullion section/transom section ■ Technical information ■ Profiles – The type of insulating block P depends on the infill thickness: - 22 to 27 mm: insulating block P 76/19, No. 168521 - 28 to 64 mm: insulating block P 76/25, No. 168522. Article No. PU Cover profile 76/15 013050 6m Cover profile 76/12 013051 6m 118015 6m 144015 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 76 V 153205 40 m Gasket for transom 76 V 153210 40 m Insulating block P 76/19 168521 50 m Pressure profile 73 punched Base profile 67 V punched – Uf -values see chapter Thermal insulation. – T1 = Depths from 50 mm. Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article Pan head tapping screw 5.5x42 Special countersunk sheet metal screw 5.5x20 Sealing piece for pressure profile 76 Crosspoint sealing plate 76 Sealing piece for transom 76 V HV-0129 No. 012114 012122 PU 100 pc(s) 100 pc(s) 014037 10 pc(s) 016052 10 pc(s) 152058 100 pc(s) Glass carrier 26 to 27 V 162042 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) 2016 325 THERM+ H-V System sections ■ Gaskets THERM+ H-V System sections 76 mm Timber curtain wall Insulating block 17 Mullion section/transom section ■ Technical information ■ Profiles – Uf -values see chapter Thermal insulation. Article – T1 = Depths from 50 mm. No. PU Cover profile 76/15 013050 6m Cover profile 76/12 013051 6m 118015 6m 144015 6m No. PU Insulating block 76/17 151035 50 m Gasket for mullion 76 V 153205 40 m Gasket for transom 76 V 153210 40 m Pressure profile 73 punched Base profile 67 V punched ■ Gaskets Article ■ Accessories Article 20 Pan head tapping screw 5.5x42 Special countersunk sheet metal screw 5.5x20 Sealing piece for pressure profile 76 Crosspoint sealing plate 76 Sealing piece for transom 76 V 20 326 2016 HV-0128 No. 012114 012122 PU 100 pc(s) 100 pc(s) 014037 10 pc(s) 016052 10 pc(s) 152058 100 pc(s) Glass carrier 26 to 27 V 162042 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) THERM+ H-V System sections 76 mm Timber curtain wall Insulating block 9 Mullion section/transom section ■ Technical information ■ Profiles – Uf -values see chapter Thermal insulation. Article – T1 = Depths from 50 mm. No. PU Cover profile 76/15 013050 6m Cover profile 76/12 013051 6m 118015 6m 144015 6m No. PU Pressure profile 73 punched Base profile 67 V punched Article Insulating block 76/9 151030 50 m Gasket for mullion 76 V 153205 40 m Gasket for transom 76 V 153210 40 m ■ Accessories Article Pan head tapping screw 5.5x42 Special countersunk sheet metal screw 5.5x20 Sealing piece for pressure profile 76 Crosspoint sealing plate 76 Sealing piece for transom 76 V HV-0127 No. 012114 012122 PU 100 pc(s) 100 pc(s) 014037 10 pc(s) 016052 10 pc(s) 152058 100 pc(s) Glass carrier 26 to 27 V 162042 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) 2016 327 THERM+ H-V System sections ■ Gaskets THERM+ H-V System sections 76 mm Timber curtain wall Standard exterior gasket Mullion section/transom section ■ Technical information ■ Profiles – Uf -values see chapter Thermal insulation. Article – T1 = Depths from 50 mm. No. PU Cover profile 76/15 013050 6m Cover profile 76/12 013051 6m 118015 6m 144015 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 76 V 153205 40 m Gasket for transom 76 V 153210 40 m Pressure profile 73 punched Base profile 67 V punched ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article Pan head tapping screw 5.5x42 Special countersunk sheet metal screw 5.5x20 Sealing piece for pressure profile 76 Crosspoint sealing plate 76 Sealing piece for transom 76 V 328 2016 HV-0121 No. 012114 012122 PU 100 pc(s) 100 pc(s) 014037 10 pc(s) 016052 10 pc(s) 152058 100 pc(s) Glass carrier 26 to 27 V 162042 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) THERM+ H-V System sections 76 mm 90° Timber curtain wall Corner mullion 90°, vertical Mullion section/transom section ■ Profiles Article No. PU Cover profile 76/15 013050 6m Pressure profile 73 punched 118015 6m Base profile 67 V punched 144015 6m Connection profile 48/22 V 168028 6m No. PU 011070.LI 100 m 011070.RE 100 m Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for mullion 76 V 153205 40 m Compensation gasket 2 227010 100 m ■ Accessories Article Pan head tapping screw 5.5x42 Special timber screw 4.5x35 Special countersunk sheet metal screw 4.8x19 HV-0169 No. 012114 908020 908118 2016 PU 100 pc(s) 100 pc(s) 100 pc(s) 329 THERM+ H-V System sections ■ Gaskets THERM+ H-V System sections 76 mm Timber curtain wall Corner mullion for variable angles, vertical Mullion section/transom section ■ Profiles Article Cover profile 76/15 Pressure prof. 73 punched Base profile 67 V punched Connection profile 48/22 V No. 013050 118015 144015 168028 PU 6m 6m 6m 6m ■ Gaskets Article No. Gasket for pressure prof. 3 011070.LI Gasket for pressure prof. 3 011070.RE Gasket for mullion 76 V 153205 Compensation gasket 2 227010 PU 100 m 100 m 40 m 100 m ■ Accessories Article Pan head tapping screw 5.5x42 Special timber screw 4.5x35 Special countersunk sheet metal screw 4.8x19 330 2016 HV-0170 No. 012114 908020 908118 PU 100 pc(s) 100 pc(s) 100 pc(s) THERM+ H-V System sections 76 mm Timber curtain wall Timber cover profile clipped Mullion section/transom section ■ Technical information ■ Profiles – Timber cover profiles are products complementary to the RAICO system components, supplied by the fabricator. It must be assured that the function of the glazing system remains guaranteed by adaptation of the constructional and material characteristics of the timber cover profile. – The norms and regulations concerning the use of timber in exterior building areas must be respected. – Timber cover profiles must be secured mechanically after their installation. – For further information see Processing. – T1 = Depths from 50 mm. Article Pressure profile 70 punched Base profile 67 V punched No. PU 118515 6m 144015 6m ■ Gaskets Article No. PU Gasket for pressure profile 7 H 150510 100 m Gasket for mullion 76 V 153205 40 m Gasket for transom 76 V 153210 40 m No. PU Article Pan head tapping screw 5.5x42 Special countersunk sheet metal screw 5.5x20 Sealing piece for pressure profile 76 Crosspoint sealing plate 76 Sealing piece for transom 76 V HV-0134 012114 012122 100 pc(s) 100 pc(s) 014037 10 pc(s) 016052 10 pc(s) 152058 100 pc(s) Glass carrier 26 to 27 V 162042 10 pc(s) Cover profile fixation 80 167005 Special timber screw 4.5x35 908020 2016 100 pc(s) 100 pc(s) 331 THERM+ H-V System sections ■ Accessories THERM+ H-V System sections 76 mm Timber curtain wall Single glazing Mullion section/transom section ■ Technical information ■ Profiles – Depending on the infill thickness the following gaskets for pressure profile must be used: - Infill thickness 8 to 9 mm: gaskets for pressure profile 5 mm - Infill thickness from 10 mm: gaskets for pressure profile 3 mm. Article – T1 = Depths from 50 mm. Pressure profile 73 punched Base profile 67 V punched No. PU Cover profile 76/15 013050 6m Cover profile 76/12 013051 6m 118015 6m 144015 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 76 V 153205 40 m Gasket for transom 76 V 153210 40 m ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article Pan head tapping screw 5.5x25 Special countersunk sheet metal screw 5.5x20 Sealing piece for pressure profile 76 Crosspoint sealing plate 76 Sealing piece for transom 76 V 332 2016 HV-0131 No. 012107 012122 PU 100 pc(s) 100 pc(s) 014037 10 pc(s) 016052 10 pc(s) 152058 100 pc(s) Glass carrier 10 to 11 V 162002 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) THERM+ H-V System sections 76 mm Timber curtain wall Polygon glazing system with standard interior gasket 1° to 7° Mullion section exterior angle/interior angle ■ Technical information ■ Profiles – With exterior gasket for pressure profile 5 mm and standard interior gasket to max. 7°. Article Cover profile 76/15 Pressure profile 73 punched Base profile 67 V punched No. PU 013050 6m 118015 6m 144015 6m ■ Gaskets Article No. PU Gasket for pressure profile 5 011073 100 m Gasket for mullion 76 V 153205 40 m No. PU Article Pan head tapping screw 5.5x42 Pan head tapping screw 5.5x45 Special timber screw 4.5x35 HV-0132 012114 012115 908020 2016 100 pc(s) 100 pc(s) 100 pc(s) 333 THERM+ H-V System sections ■ Accessories THERM+ H-V System sections 76 mm Timber curtain wall Cover profile options clipped Mullion section ■ Technical information ■ Profile Article – Slipping down of the cover profiles must be prevented. – For more cover profiles, end caps and belay sheet see Product range. 334 2016 HV-0159 No. PU Cover profile 76/15 013050 6m Cover profile 76/12 013051 6m Cover profile 76/20 013610 6m Cover profile 76/25 013615 6m Pressure profile 73 punched 118015 6m Cover profile 76/25 141505 6m THERM+ H-V System sections 76 mm Timber curtain wall Flat pressure profile options Mullion section with three options ■ Technical information ■ Profiles – Minimum infill thickness 18 mm. Article Pressure profile 76/3 No. PU 013313 6m No. PU 220205 100 m No. PU ■ Gaskets Article Gasket for pressure profile 2/16 Article Flat fillister head screw 5.5x35 with sealing ring Pan head tapping screw 5.5x32 Pan head tapping screw 5.5x35 with sealing ring Cover 11 S HV-0130 012011 012110 012174 014110 2016 100 pc(s) 100 pc(s) 100 pc(s) 100 pc(s) 335 THERM+ H-V System sections ■ Accessories THERM+ H-V System sections 76 mm Timber curtain wall Flat pressure profile options for polygon glazing system 3° to 7° with standard interior gasket Mullion section exterior angle ■ Technical information ■ Profiles – Minimum infill thickness 18 mm. Article – Selection of pressure profiles according to infill thickness and angle. Pressure profile 76/3 No. PU 013313 6m No. PU 011850 200 m ■ Gaskets Article Gasket for pressure profile 3 polygonal 3° to 7° ■ Accessories Article Flat fillister head screw 5.5x32 with sealing ring Pan head tapping screw 5.5x35 Pan head tapping screw 5.5x35 with sealing ring Cover 11 S 336 2016 HV-0160 No. 012010 012111 012174 014110 PU 100 pc(s) 100 pc(s) 100 pc(s) 100 pc(s) THERM+ H-V Building connections 50/56/76 mm Timber curtain wall Wall connection with thermal insulation system ■ Technical information THERM+ H-V System sections – T255 = Vapour-tight membrane no. 951015. HV-1030 2016 337 THERM+ H-V Building connections 50/56/76 mm Timber curtain wall Wall connection with ventilated façade panelling ■ Technical information – T128 = Breather membrane no. 951029. – T251 = Make provision for insect screen. – T255 = Vapour-tight membrane no. 951015. 338 2016 HV-1031 THERM+ H-V Building connections 50/56 mm Timber curtain wall Wall connection structural glazing SG2 with thermal insulation system ■ Technical information – Approval required in individual cases. THERM+ H-V System sections – T129 = Vapour-tight membrane no. 951019. HV-1032 2016 339 THERM+ H-V Building connections 50/56/76 mm Timber curtain wall Base connection with drainage to the front ■ Technical information – *Mask joint of mullion-transom or carry out vapour-tight. – T126 = Vapour-tight membrane no. 951021. – T249 = Execution vapour-tight or as breather membrane depending on installation-site. – T250 = Insulation with mineral cotton when required. 340 2016 HV-1033 THERM+ H-V Building connections 50/56/76 mm Timber curtain wall Base connection with drainage to the bottom ■ Technical information – *Mask joint of mullion-transom or carry out vapour-tight. – T126 = Vapour-tight membrane no. 951021. – T249 = Execution vapour-tight or as breather membrane depending on installation-site. – T250 = Insulation with mineral cotton when required. THERM+ H-V System sections – T251 = Make provision for insect screen. HV-1034 2016 341 THERM+ H-V Building connections 50/56/76 mm Timber curtain wall Base connection with frame profile ■ Technical information – Connection profile no. 168080: - Continuous insertion for bottom and top connection. - Cut out in mullion area for drainage/ventilation. – *Mask joint of mullion-transom or carry out vapour-tight. – Observe the different rates of thermal expansion for the screw connection of the aluminium window sill with the synthetic connection profile. – T129 = Vapour-tight membrane no. 951019. – T251 = Make provision for insect screen. – T252 = Breather membrane no. 951031. 342 2016 HV-1035 THERM+ H-V Building connections 50/56/76 mm Timber curtain wall Ceiling connection as non-locating bearing with thermal insulation system ■ Technical information THERM+ H-V System sections – T126 = Vapour-tight membrane no. 951021. HV-1036 2016 343 THERM+ H-V Building connections 50/56/76 mm Timber curtain wall Ceiling connection as non-locating bearing with ventilated façade panelling ■ Technical information – T126 = Vapour-tight membrane no. 951021. – T251 = Make provision for insect screen. – T252 = Breather membrane no. 951031. 344 2016 HV-1037 THERM+ H-V Building connections 50/56/76 mm Timber curtain wall Intermediate ceiling with curtain wall and panel joint ■ Technical information – *Mask joint of mullion-transom or carry out vapour-tight. – Pressure relief of the region behind the panel by cuttings in the mullion gasket. – T30 = Notching. – T124 = Breather membrane. – T129 = Vapour-tight membrane no. 951019. – T253 = Insulation with non-flammable mineral-cotton. THERM+ H-V System sections – T254 = Seal joints. HV-1038 2016 345 THERM+ H-V Building connections 50/56/76 mm Timber curtain wall Intermediate ceiling with inserted construction and panel joint ■ Technical information – *Mask joint of mullion-transom or carry out vapour-tight. – Pressure relief of the region behind the panel by cuttings in the mullion gasket. – Stabilisation of the panel in the upper region when required. – T30 = Notching. – T124 = Breather membrane. – T129 = Vapour-tight membrane no. 951019. – T253 = Insulation with non-flammable mineral-cotton. – T254 = Seal joints. 346 2016 HV-1039 THERM+ H-V Building connections 50/56/76 mm Timber curtain wall Connection of curtain wall and attic ■ Technical information – T126 = Vapour-tight membrane no. 951021. – T251 = Make provision for insect screen. THERM+ H-V System sections – T252 = Breather membrane no. 951031. HV-1040 2016 347 THERM+ H-V Building connections 50/56/76 mm Timber curtain wall Attic with inserted curtain wall with ventilated façade panelling ■ Technical information – T124 = Breather membrane. – T126 = Vapour-tight membrane no. 951021. – T251 = Make provision for insect screen. – T252 = Breather membrane no. 951031. 348 2016 HV-1041 Content Add-ons 351 353 365 377 Structural Glazing System benefits Sections Structural Glazing SG2 Exterior sealing Screw selection Selection insulating block Selection glass carriers Suction discs Indications for the execution of silicone joints 381 383 386 389 390 391 392 394 THERM+ H-V Add-ons Burglar prevention System benefits Sections resistance class WK2 Sections resistance class WK3 Screw selection WK2/WK3 2016 349 350 2016 THERM+ H-V System benefits Timber curtain wall 50/56/76 mm Burglar-resistant curtain walls – Technology in detail ■ Features burglar-resistant curtain wall – Resistance classes WK2 and WK3. - WK2: - Additional shimming with glass carriers. - Balls in the screw heads. WK3: - Additional shimming with glass carriers. - Balls in the screw heads. - Pressure profile reinforcement. - Reinforced screwing in the screw channel. – Only few additional components. – No visual difference between the variations. – A huge selection of pressure and cover profiles. – System widths and infill thicknesses identical to the basic system. – For skylight glazing. – Simple and efficient assembly. THERM+ H-V Add-ons – Extension by the use of insertion elements of FRAME+ and WING. Resistance class WK2 Resistance class WK3 SHV-0003 2016 351 352 2016 THERM+ H-V Burglar-resistant curtain wall WK2 Timber curtain wall Standard exterior gasket Mullion section/transom section 50 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK2 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article – Glazing class WK2-P4A (old A3). – For blocking of the glass unit see Processing. No. PU Cover profile 50/15 013003 6m Cover profile 50/20 013210 6m 118005 6m 144005 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 50 V 153005 40 m Gasket for transom 50 V 153010 40 m Pressure profile 47 punched Base profile 41 V punched – T1 = Depths from 50 mm. – T17 = Depths from 80 mm. ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Article Special countersunk sheet metal screw 5.5x20 Flat fillister head screw 5.5x42 Sealing piece for pressure profile 50 012153 10 pc(s) 014060 100 pc(s) 016050 10 pc(s) 152012 100 pc(s) Glass carrier 26 to 27 V 162042 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) Crosspoint sealing plate 50 Sealing piece for transom 50 V HVWK-0001 012122 PU 100 pc(s) 100 pc(s) 014035 Bullet for screw heads 22 - 64 mm No. 2016 353 THERM+ H-V Add-ons 22 - 64 mm ■ Accessories THERM+ H-V Burglar-resistant curtain wall WK2 Timber curtain wall Gasket for transom with flap between mullions Transom section 50 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK2 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article Cover profile 50/15 – Glazing class WK2-P4A (old A3). Pressure profile 47 punched Base profile 41 V punched – For blocking of the glass unit see Processing. – T1 = Depths from 50 mm. No. PU 013003 6m 118005 6m 144005 6m No. PU 011070.LI 100 m 011070.RE 100 m 153015 40 m No. PU ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for transom 50 V with flap ■ Accessories Article Special countersunk sheet metal screw 5.5x20 Flat fillister head screw 5.5x42 Sealing piece for pressure profile 50 10 pc(s) 014060 100 pc(s) 016050 10 pc(s) 152012 100 pc(s) Glass carrier 26 to 27 V 162042 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) Crosspoint sealing plate 50 Sealing piece for transom 50 V 354 2016 HVWK-0002a 012153 100 pc(s) 100 pc(s) 014035 Bullet for screw heads 22 - 64 mm 012122 THERM+ H-V Burglar-resistant curtain wall WK2 Timber curtain wall Continuous base gasket with flap Transom section 50 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK2 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article – Glazing class WK2-P4A (old A3). – For blocking of the glass unit see Processing. – T1 = Depths from 50 mm. No. PU Cover profile 50/15 013003 6m Pressure prof. 47 punched 118005 6m Base profile 41 V punched 144005 6m Connection profile 36/22 168005 6m ■ Gaskets Article No. Gasket for pressure prof. 3 011070.LI PU 100 m Gasket for pressure prof. 3 011070.RE 100 m Compensation gasket 2 011080 100 m Base gasket for transom 50 V with flap 153020 40 m ■ Accessories No. PU 100 pc(s) 100 pc(s) Special countersunk sheet metal screw 5.5x20 Flat fillister head screw 5.5x42 Sealing piece for pressure profile 50 012153 014035 10 pc(s) Bullet for screw heads 014060 100 pc(s) 016050 10 pc(s) 152010 100 pc(s) 152075 10 pc(s) Glass carrier 26 to 27 V 162042 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) Crosspoint sealing plate 50 Sealing piece for transom 50 Sealing piece for base transom V 012122 22 - 64 mm HVWK-0002b 2016 355 THERM+ H-V Add-ons Article THERM+ H-V Burglar-resistant curtain wall WK2 Timber curtain wall Cover profile options clipped Mullion section 50 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK2 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article – Glazing class WK2-P4A (old A3). – Slipping down of the cover profiles must be prevented. – For more cover profiles, end caps and belay sheet see Product range. 356 2016 HVWK-0003 No. PU Cover profile 50/15 013003 6m Cover profile 50/12 013004 6m Cover profile 50/25 013005 6m Cover profile 50/25 013201 6m Cover profile 50/20 013210 6m Pressure profile 47 punched 118005 6m Cover profile 50/30 141106 6m THERM+ H-V Burglar-resistant curtain wall WK2 Timber curtain wall Pressure profile options visible screwed Mullion section 50 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK2 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article Pressure profile 50/12 – Glazing class WK2-P4A (old A3). PU 6m Pressure profile 50/9 013008 6m Pressure profile 50/25 013014 6m Pressure profile 50/3 013300 6m THERM+ H-V Add-ons – For more pressure profiles see Product range. No. 013007 HVWK-0004 2016 357 THERM+ H-V Burglar-resistant curtain wall WK2 Timber curtain wall Standard exterior gasket Mullion section/transom section 56 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK2 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article – Glazing class WK2-P4A (old A3). – For blocking of the glass unit see Processing. No. PU Cover profile 56/15 013023 6m Cover profile 56/20 013410 6m 118010 6m 144010 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 56 V 153105 40 m Gasket for transom 56 V 153110 40 m Pressure profile 53 punched Base profile 47 V punched – T1 = Depths from 50 mm. – T17 = Depths from 80 mm. ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories Article Special countersunk sheet metal screw 5.5x20 Flat fillister head screw 5.5x42 Sealing piece for pressure profile 56 HVWK-0011 012153 10 pc(s) 014060 100 pc(s) 016051 10 pc(s) 152017 100 pc(s) Glass carrier 26 to 27 V 162042 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) Crosspoint sealing plate 56 Sealing piece for transom 56 V 2016 012122 PU 100 pc(s) 100 pc(s) 014036 Bullet for screw heads 358 No. THERM+ H-V Burglar-resistant curtain wall WK2 Timber curtain wall Gasket for transom with flap between mullions Transom section 56 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK2 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article Cover profile 56/15 – Glazing class WK2-P4A (old A3). Pressure profile 53 punched Base profile 47 V punched – For blocking of the glass unit see Processing. – T1 = Depths from 50 mm. No. PU 013023 6m 118010 6m 144010 6m No. PU 011070.LI 100 m 011070.RE 100 m 153115 40 m No. PU ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 Gasket for transom 56 V with flap ■ Accessories Special countersunk sheet metal screw 5.5x20 Flat fillister head screw 5.5x42 Sealing piece for pressure profile 56 012153 014036 10 pc(s) Bullet for screw heads 014060 100 pc(s) 016051 10 pc(s) 152017 100 pc(s) Glass carrier 26 to 27 V 162042 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) Crosspoint sealing plate 56 Sealing piece for transom 56 V HVWK-0012a 012122 2016 100 pc(s) 100 pc(s) 359 THERM+ H-V Add-ons Article THERM+ H-V Burglar-resistant curtain wall WK2 Timber curtain wall Continuous base gasket with flap Transom section 56 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK2 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article No. PU Cover profile 56/15 013023 6m – For blocking of the glass unit see Processing. Pressure profile 53 punched 118010 6m Base profile 47 V punched 144010 6m – T1 = Depths from 50 mm. Connection profile 36/22 168005 6m – Glazing class WK2-P4A (old A3). ■ Gaskets Article No. PU Gasket for pressure prof. 3 011070.LI 100 m Gasket for pressure prof. 3 011070.RE 100 m Compensation gasket 2 011080 100 m Base gasket for transom 56 V with flap 153120 40 m No. PU 012122 100 pc(s) 012153 100 pc(s) 014036 10 pc(s) 014060 100 pc(s) 016051 10 pc(s) 152015 100 pc(s) 152075 10 pc(s) Glass carrier 26 to 27 V 162042 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) ■ Accessories Article Special countersunk sheet metal screw 5.5x20 Flat fillister head screw 5.5x42 Sealing piece for pressure profile 56 Bullet for screw heads Crosspoint sealing plate 56 Sealing piece for transom 56 Sealing piece for base transom V 360 2016 HVWK-0012b THERM+ H-V Burglar-resistant curtain wall WK2 Timber curtain wall Cover profile options clipped Mullion section 56 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK2 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article Cover profile 56/15 – Glazing class WK2-P4A (old A3). – Slipping down of the cover profiles must be prevented. PU 6m Cover profile 56/12 013024 6m Cover profile 56/25 013025 6m Cover profile 56/25 013400 6m Cover profile 56/20 013410 6m Pressure profile 53 punched 118010 6m Cover profile 56/32 141307 6m THERM+ H-V Add-ons – For more cover profiles, end caps and belay sheet see Product range. No. 013023 HVWK-0013 2016 361 THERM+ H-V Burglar-resistant curtain wall WK2 Timber curtain wall Pressure profile options visible screwed Mullion section 56 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK2 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article – Glazing class WK2-P4A (old A3). – For more pressure profiles see Product range. 362 2016 HVWK-0014 No. PU Pressure profile 56/12 013027 6m Pressure profile 56/9 013028 6m Pressure profile 56/3 013310 6m THERM+ H-V Burglar-resistant curtain wall WK2 Timber curtain wall Standard exterior gasket Mullion section/transom section 76 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK2 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article – Glazing class WK2-P4A (old A3). – For blocking of the glass unit see Processing. – T1 = Depths from 50 mm. – T17 = Depths from 80 mm. No. PU Cover profile 76/15 013050 6m Cover profile 76/20 013610 6m Pressure profile 73 punched 118015 6m Base profile 67 V punched 144015 6m ■ Gaskets Article No. PU Gasket for pressure prof. 3 011070.LI 100 m Gasket for pressure prof. 3 011070.RE 100 m Gasket for mullion 76 V 153205 40 m Gasket for transom 76 V 153210 40 m ■ Accessories 22 - 64 mm Special countersunk sheet metal screw 5.5x20 Flat fillister head screw 5.5x42 Sealing piece for pressure profile 76 No. 012122 012153 PU 100 pc(s) 100 pc(s) 014037 10 pc(s) 014060 100 pc(s) 016052 10 pc(s) 152058 100 pc(s) Glass carrier 26 to 27 V 162042 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) Bullet for screw heads Crosspoint sealing plate 76 Sealing piece for transom 76 V 22 - 64 mm HVWK-0021 2016 363 THERM+ H-V Add-ons Article THERM+ H-V Burglar-resistant curtain wall WK2 Timber curtain wall Cover profile options clipped Mullion section 76 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK2 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article – Glazing class WK2-P4A (old A3). – Slipping down of the cover profiles must be prevented. – For more cover profiles, end caps and belay sheet see Product range. 364 2016 HVWK-0023 No. PU Cover profile 76/15 013050 6m Cover profile 76/20 013610 6m Cover profile 76/25 013615 6m Pressure profile 73 punched 118015 6m Cover profile 76/25 141505 6m THERM+ H-V Burglar-resistant curtain wall WK3 Timber curtain wall Standard exterior gasket Mullion section/transom section 50 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK3 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article – Glazing class WK3-P6B (old B1). – For blocking of the glass unit see Processing. – T1 = Depths from 50 mm. – T17 = Depths from 80 mm. No. PU Cover profile 50/15 013003 6m Reinforcement for pressure profile 40 013111 6m Cover profile 50/20 013210 6m Pressure profile 47 punched 118005 6m Base profile 41 V punched 144005 6m ■ Gaskets Article No. PU Gasket for pressure prof. 3 011070.LI 100 m Gasket for pressure prof. 3 011070.RE 100 m Gasket for mullion 50 V 153005 40 m Gasket for transom 50 V 153010 40 m ■ Accessories Special countersunk sheet metal screw 5.5x20 Flat fillister head screw 5.5x58 Sealing piece for pressure profile 50 012159 10 pc(s) 014060 100 pc(s) 016050 10 pc(s) 152012 100 pc(s) Glass carrier 32 to 33 V 162057 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) Crosspoint sealing plate 50 Sealing piece for transom 50 V HVWK-0031 012122 PU 100 pc(s) 100 pc(s) 014035 Bullet for screw heads 26 - 64 mm No. 2016 365 THERM+ H-V Add-ons 26 - 64 mm Article THERM+ H-V Burglar-resistant curtain wall WK3 Timber curtain wall Gasket for transom with flap between mullions Transom section 50 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK3 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article Cover profile 50/15 – Glazing class WK3-P6B (old B1). Reinforcement for pressure profile 40 Pressure profile 47 punched – For blocking of the glass unit see Processing. – T1 = Depths from 50 mm. Base profile 41 V punched No. PU 013003 6m 013111 6m 118005 6m 144005 6m No. PU ■ Gaskets Article Gasket for pressure prof. 3 011070.LI 100 m Gasket for pressure prof. 3 011070.RE 100 m Gasket for transom 50 V with flap 40 m 153015 ■ Accessories Article Special countersunk sheet metal screw 5.5x20 Flat fillister head screw 5.5x58 Sealing piece for pressure profile 50 Bullet for screw heads Crosspoint sealing plate 50 Sealing piece for transom 50 Sealing piece for transom 50 V 26 - 64 mm 366 2016 HVWK-0032a No. 012122 012159 PU 100 pc(s) 100 pc(s) 014035 10 pc(s) 014060 100 pc(s) 016050 10 pc(s) 152010 152012 100 pc(s) 100 pc(s) Glass carrier 32 to 33 V 162057 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) THERM+ H-V Burglar-resistant curtain wall WK3 Timber curtain wall Continuous base gasket with flap Transom section 50 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK3 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article No. PU 013003 6m 013111 6m 118005 6m Base profile 41 V punched 144005 6m Connection profile 36/22 168005 6m Cover profile 50/15 – Glazing class WK3-P6B (old B1). Reinforcement for pressure profile 40 Pressure profile 47 punched – For blocking of the glass unit see Processing. – T1 = Depths from 50 mm. ■ Gaskets Article No. Gasket for pressure prof. 3 011070.LI PU 100 m Gasket for pressure prof. 3 011070.RE 100 m Gasket for pressure prof. 8 011071 100 m Base gasket for transom 50 V with flap 153020 40 m ■ Accessories No. PU Special countersunk sheet metal screw 5.5x20 Flat fillister head screw 5.5x58 Sealing piece for pressure profile 50 012159 014035 10 pc(s) Bullet for screw heads 014060 100 pc(s) 016050 10 pc(s) 152075 10 pc(s) Glass carrier 32 to 33 V 162057 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) Crosspoint sealing plate 50 Sealing piece for base transom V 012122 100 pc(s) 100 pc(s) 26 - 64 mm HVWK-0032b 2016 367 THERM+ H-V Add-ons Article THERM+ H-V Burglar-resistant curtain wall WK3 Timber curtain wall Cover profile options clipped Mullion section 50 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK3 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article – Glazing class WK3-P6B (old B1). – Slipping down of the cover profiles must be prevented. – For more cover profiles, end caps and belay sheet see Product range. 368 2016 HVWK-0033 No. PU Cover profile 50/15 013003 6m Cover profile 50/25 013005 6m Reinforcement for pressure profile 40 013111 6m Cover profile 50/25 013201 6m Cover profile 50/20 013210 6m Pressure profile 47 punched 118005 6m Cover profile 50/30 141106 6m THERM+ H-V Burglar-resistant curtain wall WK3 Timber curtain wall Pressure profile options visible screwed Mullion section 50 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK3 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article Pressure profile 50/12 – Glazing class WK3-P6B (old B1). – For more pressure profiles see Product range. PU 6m Pressure profile 50/9 013008 6m Pressure profile 50/25 013014 6m THERM+ H-V Add-ons – T195 = Stainless steel flat (t = 2 mm) own production. No. 013007 HVWK-0034 2016 369 THERM+ H-V Burglar-resistant curtain wall WK3 Timber curtain wall Standard exterior gasket Mullion section/transom section 56 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK3 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article – Glazing class WK3-P6B (old B1). – For blocking of the glass unit see Processing. – T1 = Depths from 50 mm. – T17 = Depths from 80 mm. No. PU Cover profile 56/15 013023 6m Reinforcement for pressure profile 40 013111 6m Cover profile 56/20 013410 6m Pressure profile 53 punched 118010 6m Base profile 47 V punched 144010 6m ■ Gaskets Article No. PU Gasket for pressure prof. 3 011070.LI 100 m Gasket for pressure prof. 3 011070.RE 100 m Gasket for mullion 56 V 153105 40 m Gasket for transom 56 V 153110 40 m ■ Accessories 26 - 64 mm Article Special countersunk sheet metal screw 5.5x20 Flat fillister head screw 5.5x58 Sealing piece for pressure profile 56 2016 HVWK-0041 012159 10 pc(s) 014060 100 pc(s) 016051 10 pc(s) 152017 100 pc(s) Glass carrier 32 to 33 V 162057 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) Crosspoint sealing plate 56 Sealing piece for transom 56 V 370 012122 PU 100 pc(s) 100 pc(s) 014036 Bullet for screw heads 26 - 64 mm No. THERM+ H-V Burglar-resistant curtain wall WK3 Timber curtain wall Gasket for transom with flap between mullions Transom section 56 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK3 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article Cover profile 56/15 – Glazing class WK3-P6B (old B1). Reinforcement for pressure profile 40 Pressure profile 53 punched – For blocking of the glass unit see Processing. – T1 = Depths from 50 mm. Base profile 47 V punched No. PU 013023 6m 013111 6m 118010 6m 144010 6m No. PU ■ Gaskets Article Gasket for pressure prof. 3 011070.LI 100 m Gasket for pressure prof. 3 011070.RE 100 m Gasket for transom 56 V with flap 40 m 153115 ■ Accessories PU 012159 014036 10 pc(s) Bullet for screw heads 014060 100 pc(s) 016051 10 pc(s) 152017 100 pc(s) Glass carrier 32 to 33 V 162057 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) Crosspoint sealing plate 56 Sealing piece for transom 56 V HVWK-0042a No. Special countersunk sheet metal screw 5.5x20 Flat fillister head screw 5.5x58 Sealing piece for pressure profile 56 012122 2016 100 pc(s) 100 pc(s) 371 THERM+ H-V Add-ons Article THERM+ H-V Burglar-resistant curtain wall WK3 Timber curtain wall Continuous base gasket with flap Transom section 56 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK3 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article No. PU 013023 6m 013111 6m 118010 6m Base profile 47 V punched 144010 6m Connection profile 36/22 168005 6m Cover profile 56/15 – Glazing class WK3-P6B (old B1). Reinforcement for pressure profile 40 Pressure profile 53 punched – For blocking of the glass unit see Processing. – T1 = Depths from 50 mm. ■ Gaskets Article No. PU Gasket for pressure prof. 3 011070.LI 100 m Gasket for pressure prof. 3 011070.RE 100 m Gasket for pressure prof. 8 011071 100 m Base gasket for transom 56 V with flap 153120 40 m ■ Accessories Article Special countersunk sheet metal screw 5.5x20 Flat fillister head screw 5.5x58 Sealing piece for pressure profile 56 HVWK-0042b 012159 10 pc(s) 014060 100 pc(s) 016051 10 pc(s) 152075 10 pc(s) Glass carrier 32 to 33 V 162057 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) Crosspoint sealing plate 56 Sealing piece for base transom V 2016 012122 PU 100 pc(s) 100 pc(s) 014036 Bullet for screw heads 372 No. THERM+ H-V Burglar-resistant curtain wall WK3 Timber curtain wall Cover profile options clipable Mullion section 56 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK3 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article – Glazing class WK3-P6B (old B1). – Slipping down of the cover profiles must be prevented. PU 013023 6m Cover profile 56/25 013025 6m Reinforcement for pressure profile 40 013111 6m Cover profile 56/25 013400 6m Cover profile 56/20 013410 6m Pressure profile 53 punched 118010 6m Cover profile 56/32 141307 6m THERM+ H-V Add-ons – For more cover profiles, end caps and belay sheet see Product range. No. Cover profile 56/15 HVWK-0043 2016 373 THERM+ H-V Burglar-resistant curtain wall WK3 Timber curtain wall Pressure profile options visible screwed Mullion section 56 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK3 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article – Glazing class WK3-P6B (old B1). – T195 = Stainless steel flat (t = 2 mm) own production. 374 2016 HVWK-0044 No. PU Pressure profile 56/12 013027 6m Pressure profile 56/9 013028 6m THERM+ H-V Burglar-resistant curtain wall WK3 Timber curtain wall Standard exterior gasket Mullion section/transom section 76 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK3 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article – Glazing class WK3-P6B (old B1). – For blocking of the glass unit see Processing. – T17 = Depths from 80 mm. – T19 = Depths from 60 mm. – T195 = Stainless steel flat (t = 2 mm) own production. No. PU Cover profile 76/15 013050 6m Cover profile 76/20 013610 6m Pressure profile 73 punched 118015 6m Base profile 67 V punched 144015 6m No. PU 011070.LI 100 m 011070.RE 100 m Gasket for mullion 76 V 153205 40 m Gasket for transom 76 V 153210 40 m ■ Gaskets Article Gasket for pressure profile 3 Gasket for pressure profile 3 ■ Accessories 26 - 64 mm Special countersunk sheet metal screw 5.5x20 Flat fillister head screw 5.5x58 Sealing piece for pressure profile 76 No. 012122 012159 PU 100 pc(s) 100 pc(s) 014037 10 pc(s) 014060 100 pc(s) 016052 10 pc(s) 152058 100 pc(s) Glass carrier 32 to 33 V 162057 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) Bullet for screw heads Crosspoint sealing plate 76 Sealing piece for transom 76 V 26 - 64 mm HVWK-0051 2016 375 THERM+ H-V Add-ons Article THERM+ H-V Burglar-resistant curtain wall WK3 Timber curtain wall Cover profile options clipable Mullion section 76 mm ■ Technical information ■ Profiles – Burglar-resistant curtain wall WK3 (EF1) acc. to DIN EN 1627 (DIN V 18054). Article No. PU Cover profile 76/15 013050 6m Cover profile 76/20 013610 6m Cover profile 76/25 013615 6m – For more cover profiles, end caps and belay sheet see Product range. Pressure profile 73 punched 118015 6m – T195 = Stainless steel flat (t = 2 mm) own production. Cover profile 76/25 141505 6m – Glazing class WK3-P6B (old B1). – Slipping down of the cover profiles must be prevented. 376 2016 HVWK-0053 THERM+ H-V Burglar-resistant curtain-wall WK2 Timber curtain wall 50/56/76 mm Screw selection Pressure/cover profiles with exterior gasket 3 mm – For pressure profile no. 013007, 013027. – For pressure profile no. 013014, 013008, 013028. – Accessories: Bullet for screw heads no. 014060. – Accessories: Bullet for screw heads no. 014060. – Accessories: Bullet for screw heads no. 014060. THERM+ H-V Add-ons – For pressure profile no. 118005, 118010, 118015. Infill thickness mm 10 – 11 12 – 13 14 – 15 16 – 18 19 – 21 22 – 23 24 – 25 26 – 28 29 – 31 32 – 33 34 – 35 36 – 38 39 – 41 42 – 43 44 – 45 46 – 48 49 – 51 52 – 53 54 – 55 56 – 58 59 – 61 62 – 63 64 No. 012101 012098 012168 012150 012151 012152 012090 012153 012154 012155 012156 012157 012158 012159 012160 012161 012162 012163 012164 012165 012166 012145 012167 Length mm 25 28 30 32 35 38 40 42 45 48 50 52 55 58 60 62 65 68 70 72 75 78 80 Infill thickness mm 10 11 – 13 14 – 16 17 – 18 19 – 20 21 – 23 24 – 26 27 – 28 29 – 30 31 – 33 34 – 36 37 – 38 39 – 40 41 – 43 44 – 46 47 – 48 49 – 50 51 – 53 54 – 56 57 – 58 59 – 60 61 – 63 64 No. 012138 012010 012011 012012 012139 012013 012014 012140 012015 012141 012016 012142 012017 012143 012018 012020 012146 012147 012148 012260 012149 012261 012262 KHV-0043 Length mm 30 32 35 38 40 42 45 48 50 52 55 58 60 62 65 68 70 72 75 78 80 82 85 Infill thickness mm 10 – 11 12 – 13 14 – 15 16 – 18 19 – 21 22 – 23 24 – 25 26 – 28 29 – 31 32 – 33 34 – 35 36 – 38 39 – 41 42 – 43 44 – 45 46 – 48 49 – 51 52 – 53 54 – 55 56 – 58 59 – 61 62 – 63 64 No. 012137 012138 012010 012011 012012 012139 012013 012014 012140 012015 012141 012016 012142 012017 012143 012018 012020 012146 012147 012148 012260 012149 012261 2016 Length mm 28 30 32 35 38 40 42 45 48 50 52 55 58 60 62 65 68 70 72 75 78 80 82 377 THERM+ H-V Burglar-resistant curtain wall WK2 Timber curtain wall 50/56/76 mm Screw selection Flat pressure profile with exterior gasket 2 mm – For pressure profile no. 013300, 013310. – Accessories: Bullet for screw heads no. 014060. Infill thickness mm 22 23 – 25 26 – 28 29 – 30 31 – 32 33 – 35 36 – 38 39 – 40 41 – 42 43 – 45 46 – 48 49 – 50 51 – 52 53 – 55 56 – 58 59 – 60 61 – 62 63 – 64 378 2016 No. 012138 012010 012011 012012 012139 012013 012014 012140 012015 012141 012016 012142 012017 012143 012018 012020 012146 012147 Length mm 30 32 35 38 40 42 45 48 50 52 55 58 60 62 65 68 70 72 KHV-0061 THERM+ H-V Burglar-resistant curtain wall WK3 Timber curtain wall 50/56/76 mm Screw selection Pressure/cover profiles with exterior gasket 3 mm – For pressure profile no. 013007, 013027. – For pressure profile no. 013014, 013008, 013028. – Accessories: Bullet for screw heads no. 014060. – Accessories: Bullet for screw heads no. 014060. – Accessories: Bullet for screw heads no. 014060. THERM+ H-V Add-ons – For pressure profile no. 118005, 118010, 118015. Infill thickness mm 10 11 to 13 14 to 15 16 to 17 18 to 20 21 to 23 24 to 25 26 to 27 28 to 30 31 to 33 34 to 35 36 to 37 38 to 40 41 to 43 44 to 45 46 to 47 48 to 50 51 to 53 54 to 55 56 to 57 58 to 60 61 to 63 64 No. 012151 012152 012090 012153 012154 012155 012156 012157 012158 012159 012160 012161 012162 012163 012164 012165 012166 012145 012167 012275 012276 012277 012279 Length mm 35 38 40 42 45 48 50 52 55 58 60 62 65 68 70 72 75 78 80 82 85 88 92 Infill thickness mm 10 to 11 12 to 14 15 to 17 18 to 19 20 to 21 22 to 24 25 to 27 28 to 29 30 to 31 32 to 34 35 to 37 38 to 39 40 to 41 42 to 44 45 to 47 48 to 49 50 to 51 52 to 54 55 to 57 58 to 59 60 to 61 62 to 64 No. 012013 012014 012140 012050 012141 012016 012142 012017 012143 012018 012020 012146 012147 012148 012260 012149 012261 012262 012265 012266 012267 012268 KHV-0044 Length mm 42 45 48 50 52 55 58 60 62 65 68 70 72 75 78 80 82 85 88 90 92 95 Infill thickness mm 10 11 to 12 13 to 14 15 to 17 18 to 20 21 to 22 23 to 24 25 to 27 28 to 30 31 to 32 33 to 34 35 to 37 38 to 40 41 to 42 43 to 44 45 to 47 48 to 50 51 to 52 53 to 54 55 to 57 58 to 60 61 to 62 63 to 64 No. 012012 012139 012013 012014 012140 012015 012141 012016 012142 012017 012143 012018 012020 012146 012147 012148 012260 012149 012261 012262 012265 012266 012267 2016 Length mm 38 40 42 45 48 50 52 55 58 60 62 65 68 70 72 75 78 80 82 85 88 90 92 379 380 2016 THERM+ H-V Burglar-resistant curtain wall WK3 Timber curtain wall 50/56 mm SG2 curtain wall – Technology in detail ■ Features SG2-system – Free choise of support construction made of aluminium, steel or timber. – System widths 50 and 56 mm. – Combination possible with THERM+ basic system. – Support- and basic construction as well as the interior gasket system are identical to the THERM+ basic system. – Variable capabilities. – Slim elevation widths. – Homogeneous, building enveloping glass area. – Maximum possible transparency. – Many application possibilities. – Approved curtain wall system. – Infill thicknesses of 32 up to 64 mm. THERM+ H-V Add-ons – Simple and efficient assembly. SHV-0004 2016 381 382 2016 THERM+ H-V Structural glazing SG2 Timber curtain wall Structural glazing curtain wall SG2 Mullion section/transom section 50 mm ■ Technical information ■ Profiles – The indications in chapter Technical execution and installation must be respected. Article No. PU U-profile 034052 3m – Glass bite 13 mm. Base profile 41 V punched 144005 6m – T1 = Depths from 50 mm. ■ Gaskets Article No. PU Gasket for mullion 50 V 153005 40 m Gasket for transom 50 V 153010 40 m Insulating block SG 25/16 168552 50 m No. PU ■ Accessories Article Flat fillister head screw 5.5x20 Pan head tapping screw 5.5x25 Sealing piece for transom 50 V HVSG-0001 100 pc(s) 100 pc(s) 100 pc(s) 012099 012107 152012 164610 10 pc(s) Glass carrier 27 to 28 V 167342 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) 2016 THERM+ H-V Add-ons Toggle 20/58 SG 383 THERM+ H-V Structural glazing SG2 Timber curtain wall Structural glazing curtain wall SG2 Mullion section/transom section 56 mm ■ Technical information ■ Profiles – The indications in chapter Technical execution and installation must be respected. Article No. PU U-profile 034052 3m – Glass bite 16 mm. Base profile 47 V punched 144010 6m – T1 = Depths from 50 mm. ■ Gaskets Article No. PU Gasket for mullion 56 V 153105 40 m Gasket for transom 56 V 153110 40 m Insulating block SG 25/16 168552 50 m No. PU ■ Accessories Article Flat fillister head screw 5.5x20 Pan head tapping screw 5.5x25 Sealing piece for transom 56 384 2016 HSG-0002 012099 012107 152015 100 pc(s) 100 pc(s) 100 pc(s) Toggle 20/58 SG 164610 10 pc(s) Glass carrier 27 to 28 V 167342 10 pc(s) Special timber screw 4.5x35 908020 100 pc(s) THERM+ H-V Structural glazing SG2 Timber curtain wall 50/56 mm Wall connection structural glazing SG2 with thermal insulation system ■ Technical information – Approval required in individual cases. THERM+ H-V Add-ons – T129 = Vapour-tight membrane no. 951019. HI-0032 2016 385 THERM+ H-V Structural glazing SG2 Timber curtain wall 50/56 mm Exterior sealing system ■ Technical information – T30 = Notching. – T31 = Width of glass joint 24 mm. – T142 = Screwing in of the SG toggle with tool no. 170750. 386 2016 KHV-0204 THERM+ H-V Structural glazing SG2 Timber curtain wall Exterior sealing system – Cutting and draw off dimensions System width 50 mm ■ Technical information T67 – RB = Grid width RH = Grid height. – T58 = Length of the gasket for transom = RB - 28 + 0.5% add-on. – T66 = Length of the base profile = RB - 56. – T67 = Glass dimension = RB or RH - 24. T58 THERM+ H-V Add-ons T66 KHV-0803 2016 387 THERM+ H-V Structural glazing SG2 Timber curtain wall Exterior sealing system – Cutting and draw off dimensions System width 56 mm ■ Technical information T67 – RB = Grid width RH = Grid height. – T65 = Length of the gasket for transom = RB - 34 + 0.5%. – T67 = Glass dimension = RB or RH - 24. – T91 = Length of the base profile = RB - 62. T65 T91 388 2016 KHV-0804 THERM+ H-V Structural glazing SG2 Timber curtain wall 50/56 mm Screw selection Glazing with silicone joint and glazing shim and SG toggle THERM+ H-V Add-ons – Screw selection tables apply only for a cavity of 18 mm between the glass panes (glass edge) and a centric position of the aluminium U profile no. 034052 in the glass edge. Interior pane thickness mm 6 to 7 No. Length mm 012107 25 8 to 9 012108 28 10 to 11 012109 30 12 to 14 012110 32 15 to 17 012111 35 18 to 19 012112 38 20 to 21 012113 40 22 to 24 012114 42 25 to 27 012115 45 28 to 29 012116 48 30 to 31 012117 50 32 to 34 012118 52 35 to 37 012119 55 38 012129 58 KHV-0063 2016 389 THERM+ H-V Structural glazing SG2 Timber curtain wall 50/56 mm Selection insulating block – The outer pane must be in tempered glass with min. 8 mm thickness. – A silicone joint width of 8 to 9 mm results by using this table, exept for an infill thickness of 22 mm. In that case the silicone joint width is 10 mm. – From an infill thickness of 32 mm with aluminium U profile no. 034052 possible. Infill thickness mm 20 to 22 168541 23 to 24 168544 25 to 26 168546 27 to 28 168548 29 to 30 168550 31 to 32 168552 33 to 34 168554 35 to 36 168556 37 to 38 168558 39 to 40 168560 41 to 42 168562 43 to 44 168564 45 to 46 168566 47 to 48 168568 49 to 50 168570 51 to 52 168572 53 to 54 168564 + 168546 390 No. 55 to 56 2x 168556 57 to 58 168568 + 168546 59 to 60 2x 168558 61 to 62 168572 + 168546 63 to 64 2x 168560 2016 KHV-0205 THERM+ H-V Structural glazing SG2 Timber curtain wall 50/56 mm Selection glass carriers – The outer pane must be in tempered glass with min. 8 mm thickness. – Bearing surface of the outer pane on the glass carrier: min. 50 % of the glass thickness + 1 mm. THERM+ H-V Add-ons – Screw connection of the glass carrier (length 100 mm) with 3 flat fillister head screws no. 012099 each (PU = 100 pc(s). Infill thickness mm 20 21 to 22 23 to 24 25 to 26 27 to 28 29 to 30 31 to 32 33 to 34 35 to 36 37 to 38 39 to 40 41 to 42 43 to 44 45 to 46 47 to 48 49 to 50 51 to 52 53 to 54 55 to 56 57 to 58 59 to 60 61 to 62 63 to 64 No. Article PU 167312 167317 167322 167327 167332 167337 167342 167347 167352 167357 167362 167367 167372 167377 167382 167387 167392 167397 167402 167907 167912 167917 167922 Glass carrier 15 to 16 V Glass carrier 17 to 18 V Glass carrier 19 to 20 V Glass carrier 21 to 22 V Glass carrier 23 to 24 V Glass carrier 25 to 26 V Glass carrier 27 to 28 V Glass carrier 29 to 30 V Glass carrier 31 to 32 V Glass carrier 33 to 34 V Glass carrier 35 to 36 V Glass carrier 37 to 38 V Glass carrier 39 to 40 V Glass carrier 41 to 42 V Glass carrier 43 to 44 V Glass carrier 45 to 46 V Glass carrier 47 to 48 V Glass carrier 49 to 50 V Glass carrier 51 to 52 V Glass carrier 53 to 54 V Glass carrier 55 to 56 V Glass carrier 57 to 58 V Glass carrier 59 to 60 V 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) 10 pc(s) KHV-0011 2016 391 THERM+ H-V Structural glazing SG2 Timber curtain wall 50/56 mm Glazing with suction discs ■ Technical information – For additional mechanical saving for all heights larger than 8 m. Suction disc set 75 No. 163807 392 2016 Suction disc set 50/90 No. 163810 Suction disc set 56/90 No. 163812 HVSG-0003 THERM+ H-V Structural glazing SG2 Timber curtain wall 50/56 mm Assembly interior gasket and suction disc ■ Technical information – T164 = Built-in conditions. – T170 = Assembly suction disc. – T171 = Suction disc variants. – T172 = Suction disc set. THERM+ H-V Add-ons – T201 = Assembly aid no. 015230. T172 50/90 No. 163810 T172 56/90 No. 163812 T172 75 No. 163807 Z.-Nr. KHV-0014 2016 393 THERM+ H-V Structural glazing SG2 Timber curtain wall 50/56 mm Technical execution and installation Indications for the execution of silicone joints SG-curtain walls with silicone joint on four sides ■ Technical information – In the curtain wall THERM+ SG2 the glass units are fixed by means of aluminium toggles SG no. 164610. The quantity of the toggles and the structural values of the bonding must be determined by an approved specialist, taking into consideration the maximum distance of 500 mm between two toggles. – The national building regulations and codes must be applied. A permit may be required for the particular project. If an additional mechanical fuxture is required, RAICO suction discs can be applied (see Product range) – For assembly and installation the RAICO assembly instructions must be followed. For the silicone joint the indications of the manufacturer of the sealant must be respected in terms of adhesion on the glass edge and chemical interaction with the glass edge sealant. Insulated glass units must feature a UV-resistant glass edge sealant. The necessary glass quality and thickness must be coordinated with the glass supplier. – The silicone joint must be at least 8 mm. The exterior glass pane must be made of tempered glass with heat soak test with a minimum thickness of 8 mm. The cavity between the glass panes (glass edge) must be min. 18 mm, the interior glass pane min. 6 mm. – Glass tolerances: – The total tolerances of the glass units must be limited to +/- 2 mm. The panes must be produced on the standing edge. 394 2016 SG-curtain walls with silicone joint on two sides and pressure profile on two sides ■ Technical information – In case of silicone joints on two sides of a glass unit, this must be fixed additionally with suction discs (see Product range) with at least one screw (diameter 5.5) in distances of max. 500 mm. The bearing surface of the suction discs must be min. 1,000 mm2 per glass unit. The aluminium disc must be underlaid with a weatherproof silicone disc (60 to 70 shore). As an alternative the glass unit can be fixed with special toggles in the glass edge, see system THERM+ SG2. – The backing for the exerior silicone joint must be executed with the insulation block SG (height according to the infill thickness). The silicone joint must be at least 8 mm. The material must be suitable for weatherproof sealing between glass units. Possible chemical interactions with the sealant of the glass edge and, in case of laminated glass, with the interlayer must be coordinated with the suppliers. The instructions of the manufacturers of these materials must be applied. If exterior silicone joints get in contact with pressure profiles, a RAICO silicone pressure profile gasket (see product range), must be used. Penetrations in the silicone joint must be sealed with the same material. If screws without washer are used for the suctions discs, the screw heads must be sealed with the material of the silicone joints. – Introduction: – Seam the exterior glass verge. + H-V THERM Content Connector technology Assembly options 396 402 408 410 Glazing/Sealing technology Load transmission Assembly and installation cross point glass carriers Interior sealing system Exterior sealing system Screw selection 423 426 428 439 449 Accessories Fixation for sun protection systems Installation scaffolding anchor Installation fixture unit Connection profiles Suction discs Belay sheet Statics 453 470 471 472 482 483 484 THERM+ H-V Assembly options Connector technology TC timber connector SOLO TC timber connector KOMBI TC timber connector with expansion mullion Statics 2016 395 THERM+ H-V Connector technology Timber façade THERM+ H-V 50/56/76 mm TC timber connector SOLO Two-sided connection ■ Technical information – Technical information and options tables, see next page. – T77 = Base profile length – T78 = Transom length – T79 = Machined recess 17.5 x 30 mm – T80 = Special nail screw – T82 = Mullion element – T84 = Special end grain screw – T85 = Longitudinal stop – T86 = Transom element – T225 = Threaded sleeve no. 160406 – T226 = Screw sleeve no. 160405 – T227 = Cylinder screw 396 2016 KHV-0620 THERM+ H-V Connector technology Timber façade THERM+ H-V 50/56/76 mm TC timber connector SOLO Two-sided connection ■ Technical information – The transom dimensions should be calculated according to the DIN EN 13830 product standard to max. 3 mm deflection in the direction of the glass load. – The finished connection is suitable only for F1, F23 and F45 loads (see chapter Dimensioning). The connector should be appropriately protected against distortion. – The glass load specifications refer to theoretical maximum glass loads without taking into consideration wind loads, stanchion loads or additional loads. In the case of load case combinations, this load is reduced depending on the size and influence surface. The basis for determining these glass loads is the characteristic load-bearing capacity of the connector see ETA-13/0765 taking into account the following factors: - Gross density wood/wood-based materials б > 350 kg/m³ - Modification coefficient for load effect duration and moisture content kmod = 0.6 - Partial safety factor laminated timber уM = 1.30 - Partial safety factor for effect уG = 1.35 These factors can vary. The connection must be dimensioned based on the Eurocodes as well as the ETA-13/0765. – Connector set consists of: - Mullion element - Transom element - Longitudinal stop Screws, screw sleeves and threaded sleeves must be ordered separately. Transom depth mm Max. glass weight kg 60 to 79 80 to 99 100 to 119 120 to 159 160 to 199 200 to 239 240 to 300 116 138 162 182 218 250 276 TC timber connector PU: 10 pc(s) No. 161302 161307 161312 161317 161322 161327 161332 Set 60 80 100 120 160 200 240 Qty. 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) Nail screw PU: 100 pc(s) No. 908554 908555 908556 908557 908558 908559 908560 Qty. 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) End grain Screw sleeve screw no. 908550 no. 160405 PU: 100 pc(s) PU: 100 pc(s) Qty. Qty. 4 pc(s) 2 pc(s) 6 pc(s) 3 pc(s) 6 pc(s) 3 pc(s) 8 pc(s) 3 pc(s) 8 pc(s) 3 pc(s) 10 pc(s) 4 pc(s) 10 pc(s) 4 pc(s) Threaded sleeve no. 160406 PU: 100 pc(s) Qty. 2 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 4 pc(s) 4 pc(s) ■ Cylinder head screw selection Cylinder head Timber screw mullion width PU: 100 pc(s) mm No. 50 to 58 905552 59 to 68 905562 69 to 78 905572 79 to 88 905582 89 to 98 905592 Screw quantity depends on the transom depth mm 60 to 79 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 80 to 99 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 100 to 119 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 120 to 159 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 160 to 199 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 200 to 239 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 240 to 300 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 2016 397 THERM+ H-V Assembly options ■ SOLO two-sided connection selection and accessories THERM+ H-V Connector technology Timber façade THERM+ H-V 50/56/76 mm TC timber connector SOLO One-sided connection variant 1 ■ Technical information – Technical information and options tables, see next page. – T77 = Base profile length – T78 = Transom length – T79 = Machined recess 17.5 x 30 mm – T80 = Special nail screw – T82 = Mullion element – T84 = Special end grain screw – T85 = Longitudinal stop – T86 = Transom element – T226 = Screw sleeve no. 160405 – T228 = Special timber screw no. 908545 398 2016 KHV-0621 THERM+ H-V Connector technology Timber façade THERM+ H-V 50/56/76 mm TC timber connector SOLO One-sided connection variant 1 ■ Technical information – The transom dimensions should be calculated according to the DIN EN 13830 product standard to max. 3 mm deflection in the direction of the glass load. – The finished connection is suitable only for F1, F23 and F45 loads (see chapter Dimensioning). The connector should be appropriately protected against distortion. – The glass load specifications refer to theoretical maximum glass loads without taking into consideration wind loads, stanchion loads or additional loads. In the case of load case combinations, this load is reduced depending on the size and influence surface. The basis for determining these glass loads is the characteristic load-bearing capacity of the connector see ETA-13/0765 taking into account the following factors: - Gross density wood/wood-based materials б > 350 kg/m³ - Modification coefficient for load effect duration and moisture content kmod = 0.6 - Partial safety factor laminated timber уM = 1.30 - Partial safety factor for effect уG = 1.35 These factors can vary. The connection must be dimensioned based on the Eurocodes as well as the ETA-13/0765. – Connector set consists of: - Mullion element - Transom element - Longitudinal stop Screws, screw sleeves and threaded sleeves must be ordered separately. Transom depth mm Max. glass weight kg 60 to 79 80 to 99 100 to 119 120 to 159 160 to 199 200 to 239 240 to 300 116 138 162 182 218 250 276 TC timber connector PU: 10 pc(s) No. 161302 161307 161312 161317 161322 161327 161332 Set 60 80 100 120 160 200 240 Qty. 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) Nail screw PU: 100 pc(s) No. 908554 908555 908556 908557 908558 908559 908560 Qty. 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) End grain Screw sleeve Special timber screw screw no. 908550 no. 160405 no. 908545 PU: 100 pc(s) PU: 100 pc(s) PU: 100 pc(s) Qty. Qty. Qty. 2 pc(s) 2 pc(s) 2 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 4 pc(s) 3 pc(s) 3 pc(s) 4 pc(s) 3 pc(s) 3 pc(s) 5 pc(s) 4 pc(s) 4 pc(s) 5 pc(s) 4 pc(s) 4 pc(s) 2016 399 THERM+ H-V Assembly options ■ SOLO one-sided connection variant 1, selection and accessories THERM+ H-V Connector technology Timber façade THERM+ H-V 50/56/76 mm TC timber connector SOLO One-sided connection variant 2 ■ Technical information – Technical information and options tables, see next page. – T77 = Base profile length – T78 = Transom length – T79 = Machined recess 17.5 x 30 mm – T80 = Special nail screw – T82 = Mullion element – T84 = Special end grain screw – T85 = Longitudinal stop – T86 = Transom element – T226 = Screw sleeve no. 160405 – T227 = Cylinder screw – T229 = M6 nut (customer provision) – T230 = Counter plate (self-made) 400 2016 KHV-0622 THERM+ H-V Connector technology Timber façade THERM+ H-V 50/56/76 mm TC timber connector SOLO One-sided connection variant 2 ■ Technical information – The transom dimensions should be calculated according to the DIN EN 13830 product standard to max. 3 mm deflection in the direction of the glass load. – The finished connection is suitable only for F1, F23 and F45 loads (see chapter Dimensioning). The connector should be appropriately protected against distortion. – The glass load specifications refer to theoretical maximum glass loads without taking into consideration wind loads, stanchion loads or additional loads. In the case of load case combinations, this load is reduced depending on the size and influence surface. The basis for determining these glass loads is the characteristic load-bearing capacity of the connector see ETA-13/0765 taking into account the following factors: - Gross density wood/wood-based materials б > 350 kg/m³ - Modification coefficient for load effect duration and moisture content kmod = 0.6 - Partial safety factor laminated timber уM = 1.30 - Partial safety factor for effect уG = 1.35 These factors can vary. The connection must be dimensioned based on the Eurocodes as well as the ETA-13/0765. – Connector set consists of: - Mullion element - Transom element - Longitudinal stop Screws, screw sleeves and threaded sleeves must be ordered separately. ■ SOLO one-sided connection variant 2, selection and accessories Max. glass weight kg 60 to 79 80 to 99 100 to 119 120 to 159 160 to 199 200 to 239 240 to 300 116 138 162 182 218 250 276 TC timber connector PU: 10 pc(s) No. 161302 161307 161312 161317 161322 161327 161332 Set 60 80 100 120 160 200 240 Qty. 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) Nail screw PU: 100 pc(s) No. 908554 908555 908556 908557 908558 908559 908560 Qty. 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) End grain Screw sleeve screw no. 908550 no. 160405 PU: 100 pc(s) PU: 100 pc(s) Qty. Qty. 2 pc(s) 2 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 4 pc(s) 3 pc(s) 4 pc(s) 3 pc(s) 5 pc(s) 4 pc(s) 5 pc(s) 4 pc(s) Length of counter plate mm 45 63 83 103 143 183 223 THERM+ H-V Assembly options Transom depth mm ■ Cylinder head screw selection Cylinder Timber head screw mullion width PU: 100 pc(s) mm No. 50 to 58 905572 59 to 68 905582 69 to 78 905592 79 to 88 905602 89 to 98 905612 Screw quantity depends on the transom depth mm 60 to 79 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 80 to 99 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 100 to 119 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 120 to 159 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 160 to 199 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 200 to 239 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 240 to 300 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 2016 401 THERM+ H-V Connector technology Timber façade THERM+ H-V 50/56/76 mm TC timber connector KOMBI Two-sided connection ■ Technical information – Technical information and options tables, see next page. – T78 = Transom length – T79 = Machined recess 17.5 x 30 mm – T80 = Special nail screw – T82 = Mullion element – T84 = Special end grain screw – T85 = Longitudinal stop – T86 = Transom element – T87 = "KOMBI" base profile – T225 = Threaded sleeve no. 160406 – T227 = Cylinder screw 402 2016 KHV-0623 THERM+ H-V Connector technology Timber façade THERM+ H-V 50/56/76 mm TC timber connector KOMBI Two-sided connection ■ Technical information – The transom dimensions should be calculated according to the DIN EN 13830 product standard to max. 3 mm deflection in the direction of the glass load. – The finished connection is suitable only for F1, F23 and F45 loads (see chapter Dimensioning). The connector should be appropriately protected against distortion. – The glass load specifications refer to theoretical maximum glass loads without taking into consideration wind loads, stanchion loads or additional loads. In the case of load case combinations, this load is reduced depending on the size and influence surface. The basis for determining these glass loads is the characteristic load-bearing capacity of the connector see ETA-13/0765 taking into account the following factors: - Gross density wood/wood-based materials б > 350 kg/m³ - Modification coefficient for load effect duration and moisture content kmod = 0.6 - Partial safety factor laminated timber уM = 1.30 - Partial safety factor for effect уG = 1.35 These factors can vary. The connection must be dimensioned based on the Eurocodes as well as the ETA-13/0765. – Connector set consists of: - Mullion element - Transom element - Longitudinal stop Screws, screw sleeves and threaded sleeves must be ordered separately. Transom depth mm Max. glass weight kg 60 to 79 80 to 99 100 to 119 120 to 159 160 to 199 200 to 239 240 to 300 253 274 367 387 423 455 481 TC timber connector PU: 10 pc(s) No. 161302 161307 161312 161317 161322 161327 161332 Set 60 80 100 120 160 200 240 Nail screw PU: 100 pc(s) Qty. 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) No. 908554 908555 908556 908557 908558 908559 908560 Qty. 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) End grain Screw sleeve screw no. 908550 no. 160405 PU: 100 pc(s) PU: 100 pc(s) Qty. Qty. 4 pc(s) 2 pc(s) 6 pc(s) 3 pc(s) 6 pc(s) 3 pc(s) 8 pc(s) 3 pc(s) 8 pc(s) 3 pc(s) 10 pc(s) 4 pc(s) 10 pc(s) 4 pc(s) Threaded sleeve no. 160406 PU: 100 pc(s) Qty. 2 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 4 pc(s) 4 pc(s) ■ Selection, transom base profile System width mm No. 50 56 76 160551 160553 160555 KOMBI transom base Qty. profile PU: 10 pc(s) KOMBI 50 V 2 pc(s) KOMBI 56 V 2 pc(s) KOMBI 76 V 2 pc(s) Length mm 300 300 300 ■ Cylinder head screw selection Cylinder head Timber screw mullion width PU: 100 pc(s) mm No. 50 to 58 905552 59 to 68 905562 69 to 78 905572 79 to 88 905582 89 to 98 905592 Quantity screws depends on the transom depth mm 60 to 79 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 80 to 99 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 100 to 119 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 120 to 159 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 160 to 199 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 200 to 239 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 240 to 300 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 2016 403 THERM+ H-V Assembly options ■ KOMBI two-sided connection selection and accessories THERM+ H-V Connector technology Timber façade THERM+ H-V 50/56/76 mm TC timber connector KOMBI One-sided connection variant 1 ■ Technical information – Technical information and options tables, see next page. – T78 = Transom length – T79 = Machined recess 17.5 x 30 mm – T80 = Special nail screw – T82 = Mullion element – T84 = Special end grain screw – T85 = Longitudinal stop – T86 = Transom element – T87 = "KOMBI" base profile – T226 = Screw sleeve no. 160405 – T228 = Special timber screw no. 908545 404 2016 KHV-0624 THERM+ H-V Connector technology Timber façade THERM+ H-V 50/56/76 mm TC timber connector KOMBI One-sided connection variant 1 ■ Technical information – The transom dimensions should be calculated according to the DIN EN 13830 product standard to max. 3 mm deflection in the direction of the glass load. – The finished connection is suitable only for F1, F23 and F45 loads (see chapter Dimensioning). The connector should be appropriately protected against distortion. – The glass load specifications refer to theoretical maximum glass loads without taking into consideration wind loads, stanchion loads or additional loads. In the case of load case combinations, this load is reduced depending on the size and influence surface. The basis for determining these glass loads is the characteristic load-bearing capacity of the connector see ETA-13/0765 taking into account the following factors: - Gross density wood/wood-based materials б > 350 kg/m³ - Modification coefficient for load effect duration and moisture content kmod = 0.6 - Partial safety factor laminated timber уM = 1.30 - Partial safety factor for effect уG = 1.35 These factors can vary. The connection must be dimensioned based on the Eurocodes as well as the ETA-13/0765. – Connector set consists of: - Mullion element - Transom element - Longitudinal stop Screws, screw sleeves and threaded sleeves must be ordered separately. Transom depth mm Max. glass weight kg 60 to 79 80 to 99 100 to 119 120 to 159 160 to 199 200 to 239 240 to 300 253 274 367 387 426 455 481 TC timber connector PU: 10 pc(s) No. 161302 161307 161312 161317 161322 161327 161332 Set 60 80 100 120 160 200 240 Nail screw PU: 100 pc(s) Qty. 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) No. 908554 908555 908556 908557 908558 908559 908560 Qty. 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) End grain Screw sleeve Special timber screw screw no. 908550 no. 160405 no. 908545 PU: 100 pc(s) PU: 100 pc(s) PU: 100 pc(s) Qty. Qty. Qty. 2 pc(s) 2 pc(s) 2 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 4 pc(s) 3 pc(s) 3 pc(s) 4 pc(s) 3 pc(s) 3 pc(s) 5 pc(s) 4 pc(s) 4 pc(s) 5 pc(s) 4 pc(s) 4 pc(s) ■ Selection, transom base profile System width mm No. 50 56 76 160551 160553 160555 KOMBI transom base Qty. profile PU: 10 pc(s) KOMBI 50 V 1 pc(s) KOMBI 56 V 1 pc(s) KOMBI 76 V 1 pc(s) Length mm 300 300 300 2016 405 THERM+ H-V Assembly options ■ KOMBI one-sided connection variant 1, selection and accessories THERM+ H-V Connector technology Timber façade THERM+ H-V 50/56/76 mm TC timber connector KOMBI One-sided connection variant 2 ■ Technical information – Technical information and options tables, see next page. – T78 = Transom length – T79 = Machined recess 17.5 x 30 mm – T80 = Special nail screw – T82 = Mullion element – T84 = Special end grain screw – T85 = Longitudinal stop – T86 = Transom element – T87 = "KOMBI" base profile – T227 = Cylinder screw – T229 = M6 nut (customer provision) – T230 = Counter plate (self-made) 406 2016 KHV-0625 THERM+ H-V Connector technology Timber façade THERM+ H-V 50/56/76 mm TC timber connector KOMBI One-sided connection variant 2 ■ Technical information – The transom dimensions should be calculated according to the DIN EN 13830 product standard to max. 3 mm deflection in the direction of the glass load. – The finished connection is suitable only for F1, F23 and F45 loads (see chapter Dimensioning). The connector should be appropriately protected against distortion. – The glass load specifications refer to theoretical maximum glass loads without taking into consideration wind loads, stanchion loads or additional loads. In the case of load case combinations, this load is reduced depending on the size and influence surface. The basis for determining these glass loads is the characteristic load-bearing capacity of the connector see ETA-13/0765 taking into account the following factors: - Gross density wood/wood-based materials б > 350 kg/m³ - Modification coefficient for load effect duration and moisture content kmod = 0.6 - Partial safety factor laminated timber уM = 1.30 - Partial safety factor for effect уG = 1.35 These factors can vary. The connection must be dimensioned based on the Eurocodes as well as the ETA-13/0765. – Connector set consists of: - Mullion element - Transom element - Longitudinal stop Screws, screw sleeves and threaded sleeves must be ordered separately. ■ KOMBI one-sided connection variant 2, selection and accessories Max. glass weight kg 60 to 79 80 to 99 100 to 119 120 to 159 160 to 199 200 to 239 240 to 300 253 274 367 387 423 455 481 TC timber connector PU: 10 pc(s) No. 161302 161307 161312 161317 161322 161327 161332 Set 60 80 100 120 160 200 240 Nail screw PU: 100 pc(s) Qty. 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) No. 908554 908555 908556 908557 908558 908559 908560 Qty. 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) End grain Screw sleeve screw no. 908550 no. 160405 PU: 100 pc(s) PU: 100 pc(s) Qty. Qty. 2 pc(s) 2 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 4 pc(s) 3 pc(s) 4 pc(s) 3 pc(s) 5 pc(s) 4 pc(s) 5 pc(s) 4 pc(s) Length of counter plate mm 45 63 83 103 143 183 223 THERM+ H-V Assembly options Transom depth mm ■ Selection, transom base profile System width mm No. 50 56 76 160551 160553 160555 KOMBI transom base Qty. profile PU: 10 pc(s) KOMBI 50 V 1 pc(s) KOMBI 56 V 1 pc(s) KOMBI 76 V 1 pc(s) Length mm 300 300 300 ■ Cylinder head screw selection Cylinder head Timber screw mullion width PU: 100 pc(s) mm No. 50 to 58 905572 59 to 68 905582 69 to 78 905592 79 to 88 905602 89 to 98 905612 Quantity screws depends on the transom depth mm 60 to 79 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 80 to 99 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 100 to 119 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 120 to 159 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 160 to 199 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 3 pc(s) 200 to 239 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 240 to 300 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 2016 407 THERM+ H-V Connector technology Timber façade THERM+ H-V 50/56 mm TC timber connector with expansion mullion Expansion mullion connection ■ Technical information – Technical information and options tables, see next page. – T77 = Base profile length – T78 = Transom length – T79 = Machined recess 17.5 x 30 mm – T80 = Special nail screw – T82 = Mullion element – T84 = Special end grain screw – T85 = Longitudinal stop – T86 = Transom element – T231 = Threaded sleeve no. 160407 – T232 = Sealing tape no. 951990 – T233 = Screw no. 907550 – T234 = Screw no. 908225 408 2016 KHV-0629 THERM+ H-V Connector technology Timber façade THERM+ H-V 50/56 mm TC timber connector with expansion mullion Expansion mullion connection ■ Technical information – The transom dimensions should be calculated according to the DIN EN 13830 product standard– max. 3 mm deflection in the direction of the glass load. – The finished connection is suitable only for F1, F23 and F45 loads (see chapter Dimensioning). The connector should be appropriately protected against distortion. – The glass load specifications refer to theoretical maximum glass loads without taking into consideration wind loads, stanchion loads or additional loads. In the case of load case combinations, this load is reduced depending on the size and influence surface. The basis for determining these glass loads is the characteristic load-bearing capacity of the connector see ETA-13/0765 taking into account the following factors: - Gross density wood/wood-based materials б > 350 kg/m³ - Modification coefficient for load effect duration and moisture content kmod = 0.6 - Partial safety factor laminated timber уM = 1.30 - Partial safety factor for effect уG = 1.35 These factors can vary. The connection must be dimensioned based on the Eurocodes as well as the ETA-13/0765. – Connector set consists of: - Mullion element - Transom element - Longitudinal stop Screws, screw sleeves and threaded sleeves must be ordered separately. Transom depth mm Max. glass weight kg 60 to 79 80 to 99 100 to 119 120 to 159 160 to 199 200 to 239 240 to 300 * * * * * * * TC timber connector PU: 10 pc(s) No. 161302 161307 161312 161317 161322 161327 161332 Set 60 80 100 120 160 200 240 Qty. 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) 2 pc(s) Nail screw PU: 100 pc(s) No. 908554 908555 908556 908557 908558 908559 908560 Qty. 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) 4 pc(s) End grain Screw sleeve screw no. 908550 no. 160407 PU: 100 pc(s) PU: 100 pc(s) Qty. Qty. 4 pc(s) 4 pc(s) 6 pc(s) 6 pc(s) 6 pc(s) 6 pc(s) 8 pc(s) 6 pc(s) 8 pc(s) 6 pc(s) 10 pc(s) 8 pc(s) 10 pc(s) 8 pc(s) Flat head screw no. 908225 PU: 100 pc(s) Qty. 4 pc(s) 6 pc(s) 6 pc(s) 6 pc(s) 6 pc(s) 8 pc(s) 8 pc(s) * Note: Design values for the extending mullion connection are available on request. 2016 409 THERM+ H-V Assembly options ■ Extending mullion connection, selection and accessories THERM+ H-V Connector technology Timber curtain wall 50/56/76 mm TC timber connector Static dimensioning ■ Scope The use of the TC timber connector is regulated in ETA-13/0765 which sets out the basis for the static dimensioning and processing of the connector. The key elements of ETA-13/0765 are listed below. ■ Types of timber The following types of timber and timber-based materials are covered by the ETA: – Solid softwood according to EN 14081 – Solid hardwood according to EN 14081 – Glued laminated timber made of softwood according to EN 14081 – Glued laminated timber made of hardwood according to EN 14081 oak, beech or meranti (alternatives with building authority approval) – Laminated veneer lumber (LVL) as EN 14374 – Intrallam and Porallam with building authority approval – Plywood according to EN 636 The calculation is based on a gross density of 350 kg/m³. Materials with a higher gross density of up to 500 kg/m³ can be used. Gross densities over 500 kg/m³ are calculated with a value of 500 kg/m³. Minimum softwood requirements are grades S 10 / C 24. The conversion factors can be found in the ETA and/or the following example for static dimensioning. 410 2016 THERM+ H-V Connector technology Timber curtain wall 50/56/76 mm TC timber connector Static dimensioning ■ Service classes The RAICO TC timber connector can only be used in buildings in the service classes 1 + 2 according to Eurocode 5. These categories are differentiated as follows: Table NA.6 – equilibrium moisture content of timber structural materials Extract from DIN-EN 1995-1-1/NA:2010-12 Service class Equilibrium moisture content 1 2 3 (5 to 15) %a (10 to 20) %b (12 to 24) % c a In most softwoods in service class 1 the average equilibrium moisture content does not exceed 12 %. b In most softwoods in service class 2 the average equilibrium moisture content does not exceed 20 %. c Service class 3 also includes structures in which higher equilibrium moisture contents are permitted. Service class 1 2 3 Moisture content in timber construction materials, corresponds to an ambient climate of T = 20° C φ = 65 % 2) T = 20° C φ = 85 % 2) Climatic conditions which lead to greater timber moistures than service class 2 Timber moisture w in timber construction materials after a period of acclimatisation Examples of ambient climate Up to around 12 % 3) all-round enclosed and heated structures Up to around 20 % 3) roofed, open structures around > 20 % Outdoor structures exposed to the weather 1) Equilibrium moisture content of timber construction materials, see Tables 1 – 18. 2) Relative humidities which are exceeded for only a few weeks per year. 3) In most softwoods in this service class, the specified timber moistures as average equilibrium moistures are not exceeded. THERM+ H-V Assembly options Table 1-15 Service classes (NKL) according to DIN 1052: 2008-12, 7.1.1.1) Extract from DIN 1052 2016 411 THERM+ H-V Connector technology Timber curtain wall 50/56/76 mm TC timber connector Static dimensioning ■ Dimensioning concept according to EUROCODE Mullion and transom façades are dimensioned according to – EUROCODE 0 – Basis of structural design – EUROCODE 1 – Effect on structures – EUROCODE 5 – Design, calculation and dimensioning of timber buildings – EN 13830 – Product standard for curtain wall façades (This standard regulates the deflection limits for mullion and transom components of façades) Dimensioning is carried out according to the semi-probabilistic safety concept which substitutes admissible values with characteristic values and specifies different partial safety factors as fixed values. The mullion and transom components are dimensioned in accordance with the EUROCODES in this concept. The TC timber connectors from RAICO Bautechnik, have – reduced edge distances – end-grain screw fasteners – custom components and so fall into the standard category of "non-regulated components". Regulation is according to ETA-13/0765 dated 25.06.2013. This ETA rules the usability and load-bearing capacity of the T-connector in the following loading directions: ■ Description of the loads / direction of the load F45 = inherent weight load caused by a filling element such as glass or metal panel. With average force transmission the tested clamping thickness is max. 65 mm. In the case of asymmetric force transmission this clamping thickness should be reduced. Please get in contact with us to discuss F1 = centric tensile load on the transom. This can result from – wind load in the region of corner glazing – replacement of mullions and continuous transoms. In this case the corresponding proportion of the glass load of the adjacent fields is considered. F2, F3 = right-angled load on mullion- and transom axis. Loads in this direction can be e.g. – Wind suction loads – Wind pressure loads – Balustrade loads ETA-13/0765 breaks down the directions of loads as follows: F2 = load in the wind pressure direction F3 = load in the wind suction direction 412 2016 THERM+ H-V Connector technology Timber curtain wall 50/56/76 mm TC timber connector Static dimensioning Please note: The basis for structural dimensioning is always the European Technical Approval. – ETA-13/0765 – EUROCODES 0, 1, 5 as well as national appendices – Product standard EN 13830 for curtain wall façades – Requirements from the structure – the national appendices the Eurocodes and/or national regulations must be observed. The T-connections of façades may only be exposed to loads and deformations listed in the ETA and in the above documents. Avoid distortions in the façades or prevent with suitable measures. THERM+ H-V Assembly options Construction specifications e.g. final distances in the region of the connection points are not regulated in this permission. The specifications of EUROCODE 5 – Dimensioning and construction of timber buildings (DIN EN 1995) apply. 2016 413 THERM+ H-V Connector technology Timber curtain wall 50/56/76 mm TC timber connector Static dimensioning ■ Dimensioning connections of the T-connector When dimensioning according to the semi-probabilistic safety concept, there is a differentiation between effects/loads and the stress-bearing capacity. Effects are loads such as – Snow loads – Wind loads – Stanchion loads on the T-connections. The level and type of these loads are regulated in EUROCODE 1 – Effects (EN 1991). The partial safety factors γF of the loads must be considered. These are, – for independent constant loads e.g. inherent weight loads (glass loads), γG = 1.35 – independent variable loads e.g. wind load and stanchion load, γQ = 1.50 See the following extract from the standard. The most unfavourable values shall be used in all cases. Table NA.A.1.2(B) – partial safety coefficients for effects: (STR/GEO) (Group B) Extract from DIN EN 19990:2010-12 Effect Symbol Situations P/T A/E γG, sup 1.35 1.00 γG, inf 1.00 1.00 Independent variable loads: Unfavourable case b, c γQ 1.50 1.00 Extraordinary loads: γA – 1.00 Independent constant loads: Unfavourable case a, b Favourable case a, b a The limit state for the failure of the load-bearing structure is verified by multiplying all the characteristic values of an independent constant load (i.e. the characteristic values of all constant loads from the same origin) by the factor γG, sup if the total resulting effect on the observed stress is unfavourable, or by the factor γG, inf if the total resulting effect is favourable. b To choose the partial safety coefficients for the verification of geotechnical limit values, see DIN 1054-101:2009-02, Tables A 2-1, A 2-2 and A 2-3 c In the case of a favourable effect γQ = 0 d The values γG and γQ may only be divided in individual cases and only with the consent of the responsible building authorities into factors γg and γq for the uncertainties of the representative values of the loads and into a factor γEd for the model uncertainty of the loads and stresses. 414 2016 THERM+ H-V Connector technology Timber curtain wall 50/56/76 mm TC timber connector Static dimensioning The probability that all simultaneously occurring effects are at their maximum in one stress direction is extremely slim. In this case, so-called combination rules are applied, in which a variable load is taken into account with its maximum value and all other variable loads are reduced by so-called combination factors. The relevant load case combination is the one with the higher value which is used in mullion and transom façades, e.g. in the case of wind load (wind pressure, wind suction) and stanchion load. The combination factors can be taken from EUROCODE 0. An extract is given below: Table NA.A.1.1 – Numerical values for combination coefficients in civil engineering Extract from DIN EN 1990:NA2010-12 – Germany Effect Ψ0 Ψ1 Ψ2 – Category A: Living rooms and staff rooms 0.7 0.5 0.3 – Category B: Offices 0.7 0.5 0.3 – Category C: Conference rooms 0.7 0.7 0.6 – Category D: Sales rooms 0.7 0.7 0.6 1 0.9 0.8 – Category F: Thoroughfares, vehicle load ≤ 30 kN 0.7 0.7 0.6 – Category G: Thoroughfares, 30 kN ≤ vehicle load ≤ 160 kN 0.7 0.5 0.3 0 0 0 Payloads in civil engineering (categories see EN 1991-1-1) a – Category E: Storage rooms – Category H: Roofs Snow and ice loads, see DIN EN 1991-1-3 – Locations up to sea level + 1000 m 0.5 0.2 0 Locations above sea level + 1000 m 0.7 0.5 0.2 Wind loads, see DIN EN 1991-1-4 0.6 0.2 0 Temperature effects (not fire), see DIN EN 1991-1-5 0.5 0.5 0 Construction site settlement, see DIN EN 1997 Other effects: b, c 1 1 1 0.8 0.7 0.5 Reduction coefficients for payloads in multi-storey buildings see DIN EN 1991-1-1. b Fluid pressure is generally treated as a variable load for which the Ψ-coefficients are defined site-specifically. Fluid pressure whose value is limited by geometrical constraints may be treated as a constant load wherein all Ψ-coefficients should be set to 1.0. c Ψ coefficients for machine loads should be defined with respect to the operation. THERM+ H-V Assembly options a 2016 415 THERM+ H-V Connector technology Timber curtain wall 50/56/76 mm TC timber connector Static dimensioning ■ The stress-bearing capacity/resistance of the T-connection The stress-bearing capacity/resistance of the T-connection is regulated in ETA-13/0765. The characteristic strength of the connection at a gross density (gross density of mullions and transoms must be lower) of ρL = 350 kg/m³ can be taken from the following table. Table C.1 – Effective quantity nj, nef, 1, nef, 45 and characteristic values F1, RK, F2, RK, F3, RK, F45, RK for a characteristic gross density of 350 kg/m³ RAICO T-connector nef, 1 F1, RK [kN] nJ F2, RK [kN] Wind pressure F3, RK [kN] Wind suction nef, 45 F45, RK [kN] F45, in, RK [kN] SOLO 60 1.60 3.1 2 3.4 3.4 0.42 1.7 1.0 SOLO 80 2.41 4.7 3 5.1 5.1 0.60 2.0 1.0 SOLO 100 2.97 5.8 3 5.1 5.1 0.82 2.4 1.0 SOLO 120 2.63 5.2 4 6.8 5.8 0.99 2.7 1.0 SOLO 160 2.36 4.6 4 6.8 5.8 1.30 3.2 1.0 SOLO 200 3.85 7.5 5 7.0 5.8 1.57 3.7 1.0 SOLO 240 3.30 6.5 5 7.0 5.8 1.80 4.0 1.0 KOMBI 60 1.60 3.1 2 3.4 3.4 0.42 3.7 3.0 KOMBI 80 2.41 4.7 3 5.1 5.1 0.60 4.0 3.0 KOMBI 100 2.97 5.8 3 5.1 5.1 0.82 5.4 4.0 KOMBI 120 2.63 5.2 4 6.8 5.8 0.99 5.7 4.0 KOMBI 160 2.36 4.6 4 6.8 5.8 1.30 6.2 4.0 KOMBI 200 3.85 7.5 5 7.0 5.8 1.57 6.7 4.0 KOMBI 240 3.30 6.5 5 7.0 5.8 1.80 7.0 4.0 At higher gross densities the characteristic strengths are calculated according to the following equations. The forces F1, F2 and F3 always act in the centre of the connector. The force F45 has an eccentricity which corresponds to a maximum infill thickness of 65 mm (based on a symmetrical glass construction; the infill thickness should be reduced for asymmetrical glass constructions). The maximum gross density may not exceed 500 kg/m³. The minimum gross density may not be less than 350 kg/m³. F45, RK – characteristic value for inherent weight stress F45, RK = 1693 x nef45 x (ρK/350)0.5 + F45,in,RK [N] F1, RK – characteristics value for tensile stress on the transom F1, RK = nef1 x 1958 x (ρK/350)0.8 [N] F2, RK – characteristic value in the wind pressure direction F2, RK = min. s nj x 1693 x (ρK/350)0.5 [N] 7000 N F3, RK – the characteristic value in the wind suction direction F3, RK = min. nef, 1 s nj x 1693 x (ρK/350)0.5 [N] 5800 N = effective no. of screws for stress direction F1 nef, 45 = effective no. of screws for stress direction F45 nj = no. of screws in the transom PK = gross density in the mullion/transom in kg/m³. The lower value should be used for the dimensioning. F45,in,RK = additional load-bearing capacity in the loading direction These characteristic values apply only for connectors in pairs for load directions F1, F2, F3 and F45 The specified values apply per connection. 416 2016 THERM+ H-V Connector technology Timber curtain wall 50/56/76 mm TC timber connector Static dimensioning The following should be considered when determining the stress-bearing capacity/resistance of the connection: – Partial safety value for individual materials in timber constructions γM = 1.30 (Germany – national requirements must be taken into account) Table NA.2 – Partial safety coefficients γM for strength- and stiffness properties in constant and temporary dimensioning situations Extract from DIN EN 1995-1-1/NA:2010-12 – Germany Building material γM Solid wood, chipboards, hard fibreboards, medium hard fibreboards, MDF fibreboards, soft fibreboards, laminated veneer lumber, plywood, OSB, laminated timber 1.3 Steel in connections – for bending-stressed dowel-type fasteners 1.3 – for tension or shear-stressed parts in verification of resistance to yield stress in the net cross section 1.3 – Board proof of load-bearing capacity for nail boards 1.25 Modification coefficient kmod according to EUROCODE 5 Load effect duration class Order of magnitude of the accumulated duration of the characteristic load effect medium 1 week to 6 months short shorter than a week very short shorter than a minute THERM+ H-V Assembly options Note: Examples for assignment to duration of load effect classes can be found in Table 2.2. Climate-related load effects (snow, wind) vary in magnitude in different countries so the national appendix is used for assignment to load effect duration classes. 2016 417 THERM+ H-V Connector technology Timber curtain wall 50/56/76 mm TC timber connector Static dimensioning Table NA.1 – Breakdown of loads according to DIN 1055-1, DIN 1055-3, DIN 1055-4, DIN 1055-5, DIN 1055-9, DIN 1055-10 and DIN 1055-100 in load effect duration classes (KLED) Extract from DIN EN 1995-1-1-2010-12 – Germany Effect KLED Specific weights and surface loads according to DIN 1055-1 constant Perpendicular payloads DIN 1055-3 A Top ground, living- and staff rooms medium B Office surfaces, working surfaces, corridors medium C Rooms, conference rooms and surfaces which may be used for gatherings (with exception of categories defined under A, short B, D and E) D Sales rooms medium E Factories and workshops, sheds, storage surfaces and accesses, surfaces with considerable footfall long F Roads and parking surfaces for lightweight vehicles (total load ≤ kN), access ramps to these surfaces medium short G Surfaces for operation with counterweight stackers medium H Non weight-bearing roofs, except for typical maintenance or repair short K Helicopter normal loads short T Staircases and stair landings short Z Accesses, balconies and similar short Horizontal payloads according to DIN 1055-3 Horizontal payloads from persons on balustrades, landings and the constructions used as barriers Horizontal payloads for achieving adequate longitudinal and transverse rigidity Horizontal loads for helicopter landing pads on flat roofs – for horizontal payloads – for rollover protection Wind loads according to DIN 1055-4 short a short very short short/very short b Snow load and ice load according to DIN 1055-5 Height of construction site above sea level < 1000 m short Height of construction site above sea level > 1000 m medium Impact loads according to DIN 1055-9 very short Horizontal loads from crane and machine operation according to DIN 1055-10 short a Corresponding to the associated loads. wind, kmod the average of short and very short can be used. b For 418 2016 THERM+ H-V Connector technology Timber curtain wall 50/56/76 mm TC timber connector Static dimensioning Table NA.4 – Calculated values for modification coefficients kmod for timber, timber- and plaster materials Extract from DIN EN 1995-1-1/NA:2010-12 – Germany Load effect duration class Building material Standard Laminated beams, cross-laminated timber, solid timber boards Gypsum boards (types GKB, GKF, GKBI and GKFI), gypsum fibre boards Cement bonded chipboards DIN 18180, DIN EN 15283-2 Service class constant effect long effect medium effect short effect very short effect 1 0.60 0.70 0.80 0.90 1.10 2 0.60 0.70 0.80 0.90 1.10 1 0.20 0.40 0.60 0.80 1.10 2 0.15 0.30 0.45 0.60 0.80 1 0.30 0.45 0.65 0.85 1.10 2 0.20 0.30 0.45 0.60 0.80 Please note that the table is taken from the national appendix (D) of the Eurocode. If used in other countries the correspondingly applicable values must be used. Example: Glass loads = inherent weight load = constant effect, kmod = 0.6 Wind loads = average value of short and very short effect kmod = 1.0 Impact loads = very short effect, kmod = 1.10 To dimension the connector, the effects are compared with the load-bearing capacity of the connector. In this case the following applies: FED / FRD ≤ 1 wherein FED = design value of force resulting from the stress FRD = design value of the load-bearing capacity of the fastener resulting from the admissible values, taking into account coefficients. In the event of load case combinations these are superimposed according to the calculation formula (B1.5), see ETA-13/0765 as follows: THERM+ H-V Assembly options (F1,ED / F1,RD)² + (F23,ED / F23,RD)² + (F45,ED / F45,RD)² ≤ 1 2016 419 THERM+ H-V Connector technology Timber curtain wall 50/56/76 mm TC timber connector Static dimensioning ■ Example of calculation on the basis of the façade element shown Field width = 2.3 m Field height upper = 2.6 m Field height lower = 0.9 m Total glass thickness = 16 mm Stanchion load = 1.0 kN/m (cat B) Wind load suction + pressure = 0.5 KN/m² The inherent weight of the transom is not taken into account in this calculation. Gross density of laminated timber = 350 kg/m³ Use: Hotel AW type 1: Triangular load Field height > field width Effects Inherent weight load = glass load on the transom Field height Feldhöhe oben above Field width Feldbreite AW type 2: Trapezoidal load Field height < field width F45,ED = 2.12 KN x 1.35 = 2.86 KN Load surfaces for wind load/stanchion load: The wind suction load case is relevant in this case because it acts in the same direction as the stanchion load. In the case of type 1: Aw = Field width x field width 4 In the case of type 2: Aw = Field width x field height lower Field height lower x field height lower – 2 4 = = 2.3 m x 2.3 m = 1.32 m2 4 2.3 m x 0.9 m 0.9 m x 0.9 m – = 0.83 m2 2 4 Total stress surface = 1.32 m² + 0.83 m² = 2.15 m² Calculating of wind load on the transom: Total wind load = 2.15 m² x 0.5 kN/m² = 1.08 KN Partial safety factor of the effect γQ = 1.50 FW,ED = 1.08 x 1.50 = 1.62 KN Stanchion load FH = transom length x stanchion load = 2.3 m x 1.0 KN/m = 2.3 KN FH,ED = 2.30 x 1.50 = 3.45 KN Superimposition of the wind load and stanchion load: ψO = 0.6 for wind loads / 0.8 for other loads (Germany) LFK1: F3,ED = FW,ED + FH,ED x 0.8 = 1.62 + 3.45 x 0.8 = 4.38 KN LFK2: F3,ED = FH,ED + FW,ED x 0.6 = 3.45 + 1.62 x 0.6 = 4.42 KN Load case combination 2 is relevant. 420 2016 unten below Partial safety factor of the effect ϒG = 1.35 for independent constant loads Field height Feldhöhe Glass weight = 2.3 x 2.6 x 16 x 2.5 ≈ 212 kg = 2.12 KN THERM+ H-V Connector technology Timber curtain wall 50/56/76 mm TC timber connector Static dimensioning Resistance of the connector: SOLO 143 connector is used. On the basis of the gross density, the values from Table C1 – ETA-13/0765 can be used. These are: F1,RK = 4.6 KN F3,RK (wind suction) = 5.8 KN F45,RK = 3.2 KN Please note that these values apply per connection and in the following calculation for a transom they are multiplied by a factor of 2. Resistance of the T-connectors in direction F45 – glass load Kmod for BSH service class 2 = 0.6 Safety factor γM for BSH = 1.30 F45,RD+ = F45,RK x (2 x 0.6 / 1.30) = 2.95 KN Resistance of the T-connection in direction F3 – wind suction Kmod for BSH service class 1 + 2 = 1.0 for wind loads = 1.10 for stanchion loads Because of the different Kmod the lower value of 1.0 is used for the calculation. Safety factor γM for BSH = 1.30 F3,RD = F3,RK x 2 x 1.0 = 8.92 KN 1.3 The load F1 is not taken into account. F45,ED F45,RD = 2,86 2.86 2,95 2.95 = 0,97 4,42 4.42 8,92 8.92 = 0,5 THERM+ H-V Assembly options Proof for F45 Proof for F3 F3,ED F3,RD = Proof for combined load: (F1,ED / F1,RD)² + (F3,ED / F3,RD)² + (F45,ED / F45,RD)² < 1 (0 / 0)² + 0.5² + 0.97² = 0 + 0.24 + 0.94 = 1.19 2016 421 THERM+ H-V Connector technology Timber curtain wall 50/56/76 mm TC timber connector Static dimensioning ■ Result The connector cannot sustain the loads imposed. A lower connector or a KOMBI type connector must be used. In the case of the KOMBI 143, while maintaining the values, the following load-bearing capacities are obtained on the basis of the following values: F1,RK = 4.6 KN F3,RK (wind suction) = 5.8 KN F45,RK = 6.2 KN F45,RD = 6.2 x 2 x 0.6 1.3 F3,RD = 5.8 x 2 x 1.0 = 8.92 KN 1.3 = 5.72 KN Verification for combined loads with the KOMBI type connector: (F1,ED / F1,RD)² + (F3,ED / F3,RD)² + (F45,ED / F45,RD)² = (0 / 0)² + (4.42 / 8.92)² + (2.86 / 5.72)² = 0 + 0.5² + 0.52 = 0.5 This verification is satisfied; the load-bearing capacity of the connector is adequate. The following table provides orientation for the design width of the SOLO and KOMBI T-connectors taking into account the following factors: Gross density timber = 350 kg/m³ Kmod = 0.6 for load type F45 Kmod = 1.0 for load type F2.3 Kmod = 0.6 for load type F1 Partial safety factor of material γM= 1.30 Partial safety factor of constant load γG = 1.35 Partial safety factor of variable load γQ = 1.50 Design value for maximum glass load in direction F45 per transom (load case combinations shall be superimposed) SOLO 116 kg 138 kg 162 kg 182 kg 218 kg 250 kg 276 kg TC60 TC80 TC100 TC120 TC160 TC200 TC240 KOMBI 253 kg 274 kg 367 kg 388 kg 423 kg 455 kg 481 kg Design value for maximum wind pressure-/suction load in direction F2,3 per transom (load case combinations shall be superimposed) TC SOLO/KOMBI 60 TC SOLO/KOMBI 80 TC SOLO/KOMBI 100 TC SOLO/KOMBI 120 TC SOLO/KOMBI 160 TC SOLO/KOMBI 200 TC SOLO/KOMBI 240 422 2016 F2 – wind pressure F3 – wind suction 3.47 KN 5.21 KN 5.21 KN 6.95 KN 6.95 KN 7.18 KN 7.18 KN 3.47 KN 5.21 KN 5.21 KN 5.95 KN 5.95 KN 5.95 KN 5.95 KN THERM+ H-V Glazing/Sealing technology Timber curtain wall 50/56/76 mm Glass load transmission up to 200 kg ■ Technical information Selection of the glass carriers – For glass loads up to 200 kg the load transmission needs one glass carrier per side. - Synthetic glass carrier: Infill thicknesses from 10 up to 64 mm: Fixation with 3 countersunk screws no. 012122 each. Infill Synthetic Infill Aluminium thickness glass carrier thickness glass carrier PU mm No. mm No. 10 to 11 162002 10 to 12 167302 10 pc(s) 12 to 13 162007 13 to 14 167307 10 pc(s) 14 to 15 162012 15 to 16 167312 10 pc(s) 16 to 17 162017 17 to 18 167317 10 pc(s) 18 to 19 162022 19 to 20 167322 10 pc(s) 20 to 21 162027 21 to 22 167327 10 pc(s) 22 to 23 162032 23 to 24 167332 10 pc(s) 24 to 25 162037 25 to 26 167337 10 pc(s) 26 to 27 162042 27 to 28 167342 10 pc(s) 28 to 29 162047 29 to 30 167347 10 pc(s) 30 to 31 162052 31 to 32 167352 10 pc(s) 32 to 33 162057 33 to 34 167357 10 pc(s) 34 to 35 162062 35 to 36 167362 10 pc(s) 36 to 37 162067 37 to 38 167367 10 pc(s) 38 to 39 162072 39 to 40 167372 10 pc(s) 40 to 41 162077 41 to 42 167377 10 pc(s) 42 to 43 162082 43 to 44 167382 10 pc(s) 167387 10 pc(s) 44 to 45 162087 45 to 46 46 to 47 162092 47 to 48 167392 10 pc(s) 48 to 49 162097 49 to 50 167397 10 pc(s) 50 to 51 162102 51 to 52 167402 10 pc(s) 52 to 53 162107 53 to 54 167907 10 pc(s) 54 to 55 162112 55 to 56 167912 10 pc(s) 56 to 57 162117 57 to 58 167917 10 pc(s) 58 to 59 162122 59 to 60 167922 10 pc(s) 60 to 61 162127 61 to 62 167927 10 pc(s) 62 to 63 162132 63 to 64 167932 10 pc(s) 64 to 65 162137 - Aluminium glass carrier: Infill thickness up to 14 mm fixed by 3 countersunk screws no. 902805 each. Infill thickness from 15 mm fixed by 3 flat fillister head screws no. 012099 each. – Two special timber screws no. 908020 additionally on top of the glass carrier. THERM+ H-V Assembly options – Max. load per glass carrier: 100 kg. KHV-0560 2016 423 THERM+ H-V Glazing/Sealing technology Timber curtain wall 50/56/76 mm Glass load transmission up to 300 kg ■ Technical information Selection of the glass carriers – For glass loads up to 300 kg the load transmission needs one glass carrier per side. - Synthetic glass carrier: Infill thicknesses from 10 up to 64 mm: Fixation with 3 countersunk screws no. 012122 each. Infill Synthetic Infill Aluminium thickness glass carrier thickness glass carrier PU mm No. mm No. 10 to 11 162002 10 to 12 167302 10 pc(s) 12 to 13 162007 13 to 14 167307 10 pc(s) 14 to 15 162012 15 to 16 167312 10 pc(s) 16 to 17 162017 17 to 18 167317 10 pc(s) 18 to 19 162022 19 to 20 167322 10 pc(s) 20 to 21 162027 21 to 22 167327 10 pc(s) 22 to 23 162032 23 to 24 167332 10 pc(s) 24 to 25 162037 25 to 26 167337 10 pc(s) 26 to 27 162042 27 to 28 167342 10 pc(s) 28 to 29 162047 29 to 30 167347 10 pc(s) 30 to 31 162052 31 to 32 167352 10 pc(s) 32 to 33 162057 33 to 34 167357 10 pc(s) 34 to 35 162062 35 to 36 167362 10 pc(s) 36 to 37 162067 37 to 38 167367 10 pc(s) 38 to 39 162072 39 to 40 167372 10 pc(s) 40 to 41 162077 41 to 42 167377 10 pc(s) 42 to 43 162082 43 to 44 167382 10 pc(s) 167387 10 pc(s) 44 to 45 162087 45 to 46 46 to 47 162092 47 to 48 167392 10 pc(s) 48 to 49 162097 49 to 50 167397 10 pc(s) 50 to 51 162102 51 to 52 167402 10 pc(s) 52 to 53 162107 53 to 54 167907 10 pc(s) 54 to 55 162112 55 to 56 167912 10 pc(s) 56 to 57 162117 57 to 58 167917 10 pc(s) 58 to 59 162122 59 to 60 167922 10 pc(s) 60 to 61 162127 61 to 62 167927 10 pc(s) 62 to 63 162132 63 to 64 167932 10 pc(s) 64 to 65 162137 - Aluminium glass carrier: Infill thickness up to 14 mm fixed by 3 countersunk screws no. 902805 each. Infill thickness from 15 mm fixed by 3 flat fillister head screws no. 012099 each. – Three special timber screws no. 908020 additionally on top of the glass carrier. – Max. load per glass carrier: 150 kg. 424 2016 KHV-0562 THERM+ H-V Glazing/Sealing technology Timber curtain wall 50/56/76 mm Glass load transmission up to 450 kg ■ Technical information Selection of the glass carriers – For glass loads up to 450 kg the load transmission needs two glass carrier per side. - Synthetic glass carrier: Infill thicknesses from 10 up to 64 mm: Fixation with 3 countersunk screws no. 012122 each. Infill Synthetic Infill Aluminium thickness glass carrier thickness glass carrier PU mm No. mm No. 10 to 11 162002 10 to 12 167302 10 pc(s) 12 to 13 162007 13 to 14 167307 10 pc(s) 14 to 15 162012 15 to 16 167312 10 pc(s) 16 to 17 162017 17 to 18 167317 10 pc(s) 18 to 19 162022 19 to 20 167322 10 pc(s) 20 to 21 162027 21 to 22 167327 10 pc(s) 22 to 23 162032 23 to 24 167332 10 pc(s) 24 to 25 162037 25 to 26 167337 10 pc(s) 26 to 27 162042 27 to 28 167342 10 pc(s) 28 to 29 162047 29 to 30 167347 10 pc(s) 30 to 31 162052 31 to 32 167352 10 pc(s) 32 to 33 162057 33 to 34 167357 10 pc(s) 34 to 35 162062 35 to 36 167362 10 pc(s) 36 to 37 162067 37 to 38 167367 10 pc(s) 38 to 39 162072 39 to 40 167372 10 pc(s) 40 to 41 162077 41 to 42 167377 10 pc(s) 42 to 43 162082 43 to 44 167382 10 pc(s) 167387 10 pc(s) 44 to 45 162087 45 to 46 46 to 47 162092 47 to 48 167392 10 pc(s) 48 to 49 162097 49 to 50 167397 10 pc(s) 50 to 51 162102 51 to 52 167402 10 pc(s) 52 to 53 162107 53 to 54 167907 10 pc(s) 54 to 55 162112 55 to 56 167912 10 pc(s) 56 to 57 162117 57 to 58 167917 10 pc(s) 58 to 59 162122 59 to 60 167922 10 pc(s) 60 to 61 162127 61 to 62 167927 10 pc(s) 62 to 63 162132 63 to 64 167932 10 pc(s) 64 to 65 162137 - Aluminium glass carrier: Infill thickness up to 14 mm fixed by 3 countersunk screws no. 902805 each. Infill thickness from 15 mm fixed by 3 flat fillister head screws no. 012099 each. – Eight special timber screws no. 908020 additionally on top of the glass carrier. THERM+ H-V Assembly options – Max. load per glass carrier: 225 kg. KHV-0561 2016 425 THERM+ H-V Glazing/Sealing technology Timber curtain wall 50/56/76 mm Assembly cross point glass carrier ■ Technical information – Admissable glass loads: Infill thicknesses 35 mm to 52 mm: 450 kg to 600 kg Infill thicknesses 53 mm to 64 mm: 450 kg to 500 kg. T145 – Max. load per support point = max. glass load : 2. – Do not use the cross point glass carrier with specific flat pressure profiles. – Please contact your glass vendor for clarifying the reduced distance of the setting block to axis of the mullion (50 mm). – The load transmission across the cross point glass carrier must be taken by the structural construction. – The base profile must be screwed down additionally (see Processing). – T144 = Glass shim. – T145 = Cross point glass carriers set (selection see table). – T149 = External view. 426 2016 KHV-0010 THERM+ H-V Glazing/Sealing technology Timber curtain wall 50/56/76 mm Assembly and installation cross point glass carriers ■ Technical information Selection of the cross point glass carriers – T82 = Mullion element. Infill thickness mm 35 to 36 37 to 38 39 to 40 41 to 42 43 to 44 45 to 46 47 to 48 49 to 50 51 to 52 53 to 54 55 to 56 57 to 58 59 to 60 61 to 62 63 to 64 – T86 = Transom element. to No. Article PU 163930 163932 163934 163936 163938 163940 163942 163944 163946 163948 163950 163952 163954 163956 163958 Cross point glass carrier set 35 to 36 Cross point glass carrier set 37 to 38 Cross point glass carrier set 39 to 40 Cross point glass carrier set 41 to 42 Cross point glass carrier set 43 to 44 Cross point glass carrier set 45 to 46 Cross point glass carrier set 47 to 48 Cross point glass carrier set 49 to 50 Cross point glass carrier set 51 to 52 Cross point glass carrier set 53 to 54 Cross point glass carrier set 55 to 56 Cross point glass carrier set 57 to 58 Cross point glass carrier set 59 to 60 Cross point glass carrier set 61 to 62 Cross point glass carrier set 63 to 64 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) 1 pc(s) Content per set: 2 cross point glass carriers each (1 set per transom). Selection of screws Alternative: individual order (number of screws per cross point glass carrier) or 163791 Connection mullion with transom piece Screw connection in mullion Screw connection in transom Double-sided Unilateral No. No. No. No. 2x 012099 3x 012151 6x 012099 3x 012099 THERM+ H-V Assembly options Screw set no. Content per set: screws for 2 cross point glass carriers (1 set per transom needed). Assembly cross point glass carrier set Assembly cross point glass carrier set – Assembly double-sided (e. g. in cross point). – Unilateral assembly (e. g. im the edge region). The transom piece has to be shortened accordingly. – Screws have to be ordered separately (see table). – Screws have to be ordered separately (see table). KHV-0010 2016 427 THERM+ H-V Glazing/Sealing technology Timber curtain wall 50/56/76 mm Interior sealing system Curtain wall, standard ■ Technical information The timber construction must be flush on the glazing side. Max. misalignment between mullion and transom = ± 0.5 mm. – Applicable gaskets - - Gasket for mullion with notching by special tool (see Processing) No. 153005 Gasket for mullion 50 V No. 153105 Gasket for mullion 56 V No. 153205 Gasket for mullion 76 V No. 153040 to 153050 Gasket for mullion 50 V polygon No. 153140 to 153150 Gasket for mullion 56 V polygon - - Gasket for transom with notching by special tool (see Processing) No. 153010 Gasket for transom 50 V No. 153110 Gasket for transom 56 V No. 153210 Gasket for transom 76 V Sealing piece gasket for transom No. 152012 Transom sealing piece 50 V No. 152017 Transom sealing piece 56 V No. 152058 Transom sealing piece 76 V - PU = 10 pcs. - Assembly without sealing material. – T188 = Transom sealing piece. 428 2016 KHV-0601 THERM+ H-V Glazing/Sealing technology Timber curtain wall 50/56 mm Interior sealing system Curtain wall, expansion mullion for assembling elements ■ Technical information The timber construction must be flush on the glazing side. Max. misalignment between mullion and transom = ± 0.5 mm. – Applicable gaskets - Gasket for mullion with notching by special tool (see Processing) No. 153305 Gasket for mullion 50 H V No. 153335 Gasket for mullion 56 H V No. 168220 Insertion profile 16/10 V - Gasket for transom with notching by special tool (see Processing) No. 153010 Gasket for transom 50 V No. 153110 Gasket for transom 56 V Sealing piece gasket for transom No. 152012 Transom sealing piece 50 V No. 152017 Transom sealing piece 56 V - PU = 10 pcs. - Assembly without sealing material. THERM+ H-V Assembly options – T188 = Transom sealing piece. KHV-0001 2016 429 THERM+ H-V Glazing/Sealing technology Timber curtain wall 50/56 mm Interior sealing system Curtain wall, gasket for transom with flap ■ Technical information The timber construction must be flush on the glazing side. Max. misalignment between mullion and transom = ± 0.5 mm. – Applicable gaskets - Gasket for mullion with notching by special tool (see Processing) No. 153005 Gasket for mullion 50 V No. 153105 Gasket for mullion 56 V No. 153040 to 153050 Gasket for mullion 50 V polygon No. 153140 to 153150 Gasket for mullion 56 V polygon - Gasket for transom with notching by special tool (see Processing) No. 153015 Gasket for transom 50 V, flap No. 153115 Gasket for transom 56 V, flap Sealing piece gasket for transom No. 152012 Transom sealing piece 50 V No. 152017 Transom sealing piece 56 V - PU = 10 pcs. - Assembly without sealing material. – T188 = Transom sealing piece. – T197 = Belay sheet no. 167008. – T198 = Srew no. 908118. 430 2016 KHV-0002 THERM+ H-V Glazing/Sealing technology Timber curtain wall 50/56 mm Interior sealing system Curtain wall, base gasket with flap ■ Technical information The timber construction must be flush on the glazing side. Max. misalignment between mullion and transom = ± 0.5 mm. – Applicable gaskets - Base gasket with notching by special tool (see Processing) No. 153020 Base gasket 50 V, flap No. 153120 Base gasket 56 V, flap Sealing piece base gasket No. 152075 Base transom sealing piece V, applicable for all system width. - PU = 10 pcs. - Assembly with sealing material D2, no. 952015. – T197 = Belay sheet no. 167008. – T198 = Screw no. 908118. THERM+ H-V Assembly options – T199 = Sealing piece. KHV-0004 2016 431 THERM+ H-V Glazing/Sealing technology Timber curtain wall 50/56 mm Interior sealing system Curtain wall, base gasket with flap, version center mullion ■ Technical information The timber construction must be flush on the glazing side. Max. misalignment between mullion and transom = ± 0.5 mm. – Applicable gaskets Base gasket with notching by special tool (see Processing) No. 153020 Base gasket 50 V, flap No. 153120 Base gasket 56 V, flap Sealing piece base gasket No. 152075 Base transom sealing piece V, applicable for all system width. - PU = 10 pcs. - Assembly with sealing material D2, no. 952015. 432 2016 KHV-0007 THERM+ H-V Glazing/Sealing technology Timber curtain wall 50/56 mm Interior sealing system 3 drainage levels ■ Technical information Interior gaskets for drainage level 1 – T38 = Level 2. Article No. PU – T39 = Level 3. Gasket for transom 50 V 153010 40 m – T40 = Level 1. Gasket for transom 56 V 153110 40 m – T151 = Interior gasket E3. – T152 = Interior gasket E2. – T153 = Interior gasket E1. – T159 = Interior gasket E2 with flap. Interior gaskets for drainage level 2 Article No. PU Interior gasket 50 E2 V 153013 40 m Interior gasket 50 E2 V, flap 153018 40 m Interior gasket 56 E2 V 153113 40 m Interior gasket 56 E2 V, flap 153118 40 m Interior gaskets for drainage level 3 Article No. PU Interior gasket 50 E3 V 153008 40 m Interior gasket 56 E3 V 153108 40 m Article No. PU Transom sealing piece 50 V 152012 10 pc(s) Transom sealing piece 56 V 152017 10 pc(s) Transom sealing pieces for drainage level 2 Article KV-0011 No. PU Transom sealing pc 50 E2 V 152013 10 pc(s) Transom sealing pc 56 E2 V 152018 10 pc(s) 2016 433 THERM+ H-V Assembly options Transom sealing pieces for drainage level 1 THERM+ H-V Glazing/Sealing technology Timber curtain wall 50/56 mm Interior sealing system Curtain wall, drainage level 1 to level 2 ■ Technical information The timber construction must be flush on the glazing side. Max. misalignment between mullion and transom = ± 0.5 mm. – Applicable gaskets - Gasket for transom with notching by special tool (see Processing) No. 153010 Gasket for transom 50 V No. 153110 Gasket for transom 56 V - Interior gasket with notching by special tool (see Processing) No. 153013 Interior gasket 50 E2 V No. 153113 Interior gasket 56 E2 V Sealing piece for transom gasket No. 152012 Transom sealing piece 50 V No. 152017 Transom sealing piece 56 V - PU = 10 pcs. - Assembly without sealing material. – T38 = Level 2. – T40 = Level 1. – T188 = Transom sealing piece. 434 2016 KHV-0006 THERM+ H-V Glazing/Sealing technology Timber curtain wall 50/56 mm Interior sealing system Curtain wall, drainage level 2 to level 3 ■ Technical information The timber construction must be flush on the glazing side. Max. misalignment between mullion and transom = ± 0.5 mm. – Applicable gaskets - Gasket for transom with notching by special tool (see Processing) No. 153008 Interior gasket 50 E3 V No. 153108 Interior gasket 56 E3 V - Gasket for transom with notching by special tool (see Processing) No. 153013 Interior gasket 50 E2 V No. 153113 Interior gasket 56 E2 V Sealing piece for transom gasket No. 152013 Transom sealing piece 50 E2 V No. 152018 Transom sealing piece 56 E2 V - PU = 10 pcs. - Assembly without sealing material. – T38 = Level 2. – T39 = Level 3. THERM+ H-V Assembly options – T188 = Transom sealing piece. KHV-0005 2016 435 THERM+ H-V Glazing/Sealing technology Timber curtain wall 50/56 mm Interior sealing system Curtain wall, drainage level 2 to level 3 with flaps ■ Technical information – Applicable gaskets - Gasket for mullion with notching by special tool (see Processing) No. 153008 Interior gasket 50 E3 V No. 153108 Interior gasket 56 E3 V - Gasket for transom with notching by special tool (see Processing) No. 153018 Interior gasket 50 E2 V flap No. 153118 Interior gasket 56 E2 V flap Sealing piece gasket for transom No. 152013 Transom sealing piece 50 E2 V No. 152018 Transom sealing piece 56 E2 V - PU = 10 pcs. - Assembly without sealing material. – T38 = Level 2. – T39 = Level 3. – T188 = Transom sealing piece. – T197 = Belay sheet no. 167008. – T198 = Screw no. 908118. 436 2016 KHV-0016 THERM+ H-V Glazing/Sealing technology Timber curtain wall 50/56 mm Interior sealing system Vertical joint ■ Technical information Selection stainless steel sealing piece – The joint areas must be sealed carefully with sealing material D2, no. 952015. The stainless steel sealing pieces must be fixed with two screws no. 908118 each. System width mm No. PU 50 167100 10 pc(s) 56 167110 10 pc(s) – T135 = For system 50. THERM+ H-V Assembly options – T136 = For system 56. Mullion gasket KHV-0008 2016 437 THERM+ H-V Glazing/Sealing technology Timber curtain wall 50/56 mm Interior sealing system Pressure compensation via mullion rebate ■ Technical information Measure x for the shortening of the sealing piece – The synthetic sealing piece supports the ventilation as well as the condensate drainage. – Shorten the sealing piece according to the infill thickness (see table) and fix it with a pan head tapping screw no. 012103. – Assembly with sealing material D2, no. 952015. 118005 118010 438 2016 013018 013038 013007 013027 013008 013028 013014 24 28 – 28 30 25 to 26 26 30 26 28 27 to 28 24 28 24 26 29 to 30 22 26 22 24 31 to 32 20 24 20 22 33 to 34 18 22 18 20 35 to 36 16 20 16 18 37 to 38 14 18 14 16 39 to 40 12 16 12 14 41 to 42 10 14 10 12 43 to 44 8 12 8 10 45 to 46 6 10 6 8 47 to 48 4 8 4 6 49 to 50 2 6 2 4 51 to 52 0 4 0 2 to measure x – For more information see Processing. Pressure profile no. Infill thickness mm KV-0010 THERM+ H-V Glazing/Sealing technology Timber curtain wall 50/56/76 mm Exterior sealing system Pressure profiles and snap-in cover profiles ■ Technical information Stainless steel cross point sealing plates self-adhesive, assembly at the glass edge – T162 = Cross point sealing plate. No. – T163 = Sealing piece for pressure profile. Article PU 016050 Pressure profiles 50 mm 10 pc(s) 016051 Pressure profiles 56 mm 10 pc(s) 016052 Pressure profiles 76 mm 10 pc(s) EPDM sealing pieces for pressure profiles self-adhesive, assembly at the interior side of the pressure profile No. Article PU Pressure profiles 50 mm 10 pc(s) 014036 Pressure profiles 56 mm 10 pc(s) 014037 Pressure profiles 76 mm 10 pc(s) THERM+ H-V Assembly options 014035 KHV-0200 2016 439 THERM+ H-V Glazing/Sealing technology Timber curtain wall 50/56/76 mm Exterior sealing system Pressure profiles with visible screw connection ■ Technical information Stainless steel cross point sealing plates self-adhesive, assembly at the glass edge – T162 = Cross point sealing plate. No. – T163 = Sealing piece for pressure profile. Article PU 016050 Pressure profiles 50 mm 10 pc(s) 016051 Pressure profiles 56 mm 10 pc(s) 016052 Pressure profiles 76 mm 10 pc(s) EPDM sealing pieces for pressure profiles self-adhesive, assembly at the interior side of the pressure profile No. 440 2016 KHV-0202 Article PU 014035 Pressure profiles 50 mm 10 pc(s) 014036 Pressure profiles 56 mm 10 pc(s) 014037 Pressure profiles 76 mm 10 pc(s) THERM+ H-V Glazing/Sealing technology Timber curtain wall 50/56/76 mm Exterior sealing system Flat pressure profiles ■ Technical information Stainless steel cross point sealing plates self-adhesive, assembly at the glass edge – Notching the end of the transom pressure profile (dimensions see handling manual). No. – T41 = Notching. 016053 – T162 = Cross point sealing plate. – T163 = Sealing piece for pressure profile. 016054 016055 Article PU Flat pressure profile 50 no. 013300 Flat pressure profile 56 no. 013310 Flat pressure profile 76 no. 013313 10 pc(s) 10 pc(s) 10 pc(s) EPDM sealing pieces for pressure profiles self-adhesive, assembly at the interior side of the pressure profile No. 014038 014039 PU 10 pc(s) 10 pc(s) 10 pc(s) THERM+ H-V Assembly options 014041 Article Flat pressure profile 50 no. 013300 Flat pressure profile 56 no. 013310 Flat pressure profile 76 no. 013313 KHV-0201 2016 441 THERM+ H-V Glazing/Sealing technology Timber curtain wall 50/56/76 mm Exterior sealing system Assembly of insulating blocks ■ Technical information – All insulating blocks must be notched with a special tool at the end of the transom gasket (A) for assembling the sealing piece for pressure profile (see Processing). – The version with insulating blocks 21 and P must be notched (B) additionally with a special tool in the area of the glass support (see Processing). – PU of the insulating blocks: 50 m. – T50 = Notching A. – T51 = Notching B. – T162 = Cross point sealing plate. – T163 = Sealing piece for pressure profile. 442 2016 KHV-0203 THERM+ H-V Glazing/Sealing technology Timber curtain wall 50/56/76 mm Exterior sealing system Cover profile joint curtain wall A B ■ Technical information Selection of interior joint plate and profile joint sealing plate – Do not joint the pressure profile at the cross point. Sealing piece for pressure profile no. Interior joint plate no. Profile joint sealing plate no. 013003 (50x15) 014035 167230 016070 013210 (50x20) 014035 167232 016070 141106 (50x30) 014035 167236 016070 – T176 = Pressure profile gasket. 013023 (56x15) 014036 167250 016071 – T177 = Interior joint plate. 013410 (56x20) 014036 167252 016071 – T178 = Profile joint sealing plate. 141307 (56x32) 014036 167257 016071 013610 (76x20) 014037 167272 016072 013050 (76x15) 014037 167270 016072 013615 (76x25) 014037 167274 016072 013620 (76x30) 014037 167276 016072 – T160 = Joint at intermediate range. – T161 = Joint at the cross point. – T163 = Sealing piece for pressure profile. – T174 = Pressure profile. – T175 = Cover profile. THERM+ H-V Assembly options Cover profile no. – Length exterior gasket = length pressure profile + 0.5 %. K-0016 2016 443 THERM+ H-V Glazing/Sealing technology Timber curtain wall 50/56/76 mm Exterior sealing system Pressure profile joint curtain wall ■ Technical information Selection of profile joint sealing plate – Do not joint the pressure profile at the cross point. – Length exterior gasket = length pressure profile + 0.5 %. – T41 = Notching. – T163 = Sealing piece for pressure profile. – T174 = Pressure profile. – T176 = Pressure profiles gasket. – T178 = Profile joint sealing plate. 444 2016 K-0017, K-0018 Pressure profile no. Profile joint sealing plate no. Sealing piece for pressure profile no. 013300 (50x3) 014038 016073 013310 (56x3) 014039 016074 013313 (76x3) 014041 016075 013008 (50x9) 014035 016070 013007 (50x12) 014035 016070 013028 (56x9) 014036 016071 013027 (56x12) 014036 016071 THERM+ H-V Glazing/Sealing technology Timber curtain wall 50/56/76 mm Exterior sealing system Cross point sealing plates and transom sealing pieces sloping connection ■ Technical information Selection of transom sealing piece – Pressure profiles sealing pieces No. 014080 to 014085, 152402 to 152422 for self-cutting acc. to angle (90°– α). Angle α – Cross point sealing plates No. 016080 to 016085 for self-cutting acc. to angle (90°– α). Cutted pieces have to be plane and burr-free. 90° to 84° 83° to 74° to 59° to 44° to – T41 = Notch. – T155 = Transom gasket. 75° 60° 45° 35° Left Right Left E2 Right E2 no. no. no. no. 152012 (50) 152012 (50) 152013 (50) 152013 (50) 152017 (56) 152017 (56) 152018 (56) 152018 (56) 152058 (76) 152058 (76) 152059 (76) 152059 (76) 152058 152058 152059 152059 152033 152036 152060 152063 152034 152037 152061 152064 152035 152038 152062 152065 – T186 = Self-cutting. – T188 = Transom sealing piece. Selection cross-point sealing plate and pressure profile sealing piece (self-cutting acc. to angle) Exterior gasket 5 mm System width mm Pressure and cover profile Pressure Pressure Cross point profile sealing profile sealing sealing plate Width x piece piece no. mm no. no. PU = 10 pc(s) PU = 5 pc(s) PU = 5 pc(s) For pressure and cover profile 50 016080 36 014080 56 016081 37 014081 152402 152412 76 016082 39 014082 152422 50 016083 28 014083 56 016084 29 014084 76 016085 31 014085 THERM+ H-V Assembly options For flat pressure profile Flat pressure profile KV-0009 2016 445 THERM+ H-V Glazing/Sealing technology Timber curtain wall 50 mm Cutting and draw off dimensions ■ Technical information – RB = Grid width RH = Grid height. – T53 = Length pressure profile = RB - 51. – T54 = Length pressure profile with visible screwed connection = RB - 51. – T55 = Length cover profile clipped = RB - 51. – T56 = Length pressure profile = RB - 55. – T57 = Glass dimension = RB or RH - 26. – T58 = Length transom gasket = RB - 28 + 0.5% add-on. – T66 = Length base profile = RB - 56. 446 2016 KHV-0800 THERM+ H-V Glazing/Sealing technology Timber curtain wall 56 mm Cutting and draw off dimensions ■ Technical information – RB = Grid width RH = Grid height. – T60 = Length pressure profile = RB - 57. – T61 = Length pressure profile with visible screwed connection = RB - 57. – T62 = Length cover profile clipped = RB - 57. – T63 = Length pressure profile = RB - 61. – T64 = Glass dimensions = RB or RH - 30. – T65 = Length transom gasket = RB - 34 + 0.5 % add-on. THERM+ H-V Assembly options – T91 = Length of the base profile = RB - 62. KHV-0801 2016 447 THERM+ H-V Glazing/Sealing technology Timber curtain wall 76 mm Cutting and draw off dimensions ■ Technical information – RB = Grid width RH = Grid height. – T64 = Glass dimensions = RB or RH - 30. – T93 = Length pressure profile = RB - 81. – T94 = Glass dimensions = RB or RH - 46. – T95 = Length transom gasket = RB - 54 + 0.5% add-on. – T96 = Length profile = RB - 86. – T106 = Length of the flat pressure profile = SW - 77. – T107 = Length of the cover profile = SW - 77. Passive house with insulating block P no. 168526 448 2016 KHV-0802 THERM+ H-V Glazing/Sealing technology Timber curtain wall 50/56/76 mm Screw selection Pressure profiles with exterior gasket 3 mm ■ Technical information – For the application of the pressure profile gaskets 4, 6, 7, 8, 9, 11 and 13 extended screws must be used. Infill tickness mm 10 to 11 12 to 13 14 to 15 16 to 18 19 to 21 22 to 23 24 to 25 26 to 28 29 to 31 32 to 33 34 to 35 36 to 38 39 to 41 42 to 43 44 to 45 46 to 48 49 to 51 52 to 53 54 to 55 56 to 58 59 to 61 62 to 63 64 No. 012107 012108 012109 012110 012111 012112 012113 012114 012115 012116 012117 012118 012119 012129 012123 012124 012125 012106 012126 012144 012127 012200 012128 Length mm 25 28 30 32 35 38 40 42 45 48 50 52 55 58 60 62 65 68 70 72 75 78 80 – For pressure profile no. 013007, 013027. Infill tickness mm 10 11 to 13 14 to 16 17 to 18 19 to 20 21 to 23 24 to 26 27 to 28 29 to 30 31 to 33 34 to 36 37 to 38 39 to 40 41 to 43 44 to 46 47 to 48 49 to 50 51 to 53 54 to 56 57 to 58 59 to 60 61 to 63 64 No. 012138 012010 012011 012012 012139 012013 012014 012140 012015 012141 012016 012142 012017 012143 012018 012020 012146 012147 012148 012260 012149 012261 012262 KHV-0040 Length mm 30 32 35 38 40 42 45 48 50 52 55 58 60 62 65 68 70 72 75 78 80 82 85 – For pressure profile no. 013014, 013008, 013028. Infill tickness mm 10 to 11 12 to 13 14 to 15 16 to 18 19 to 21 22 to 23 24 to 25 26 to 28 29 to 31 32 to 33 34 to 35 36 to 38 39 to 41 42 to 43 44 to 45 46 to 48 49 to 51 52 to 53 54 to 55 56 to 58 59 to 61 62 to 63 64 No. 012137 012138 012010 012011 012012 012139 012013 012014 012140 012015 012141 012016 012142 012017 012143 012018 012020 012146 012147 012148 012260 012149 012261 2016 Length mm 28 30 32 35 38 40 42 45 48 50 52 55 58 60 62 65 68 70 72 75 78 80 82 449 THERM+ H-V Assembly options – For pressure profile no. 118505, 118510, 118515, 118005, 118010, 118015. THERM+ H-V Glazing/Sealing technology Timber curtain wall 50/56/76/96 mm Screw selection Pressure profiles with exterior gasket 5 mm – For pressure profile no. 013007, 013027. – For pressure profile no. 013014, 013008, 013028. 5 – For pressure profile no. 118005, 118010, 118015. Infill tickness mm 10 11 to 12 13 to 14 15 to 17 18 to 20 21 to 22 23 to 24 25 to 27 28 to 30 31 to 32 33 to 34 35 to 37 38 to 40 41 to 42 43 to 44 45 to 47 48 to 50 51 to 52 53 to 54 55 to 57 58 to 60 61 to 62 63 to 64 450 2016 No. 012107 012108 012109 012110 012111 012112 012113 012114 012115 012116 012117 012118 012119 012129 012123 012124 012125 012106 012126 012144 012127 012200 012128 Length mm 25 28 30 32 35 38 40 42 45 48 50 52 55 58 60 62 65 68 70 72 75 78 80 Infill tickness mm 10 to 12 13 to 15 16 to 17 18 to 19 20 to 22 23 to 25 26 to 27 28 to 29 30 to 32 33 to 35 36 to 37 38 to 39 40 to 42 43 to 45 46 to 47 48 to 49 50 to 52 53 to 55 56 to 57 58 to 59 60 to 62 63 to 64 No. 012010 012011 012012 012139 012013 012014 012140 012015 012141 012016 012142 012017 012143 012018 012020 012146 012147 012148 012260 012149 012261 012262 KHV-0064 Length mm 32 35 38 40 42 45 48 50 52 55 58 60 62 65 68 70 72 75 78 80 82 85 Infill tickness mm 10 11 to 12 13 to 14 15 to 17 18 to 20 21 to 22 23 to 24 25 to 27 28 to 30 31 to 32 33 to 34 35 to 37 38 to 40 41 to 42 43 to 44 45 to 47 48 to 50 51 to 52 53 to 54 55 to 57 58 to 60 61 to 62 63 to 64 No. 012137 012138 012010 012011 012012 012139 012013 012014 012140 012015 012141 012016 012142 012017 012143 012018 012020 012146 012147 012148 012260 012149 012261 Length mm 28 30 32 35 38 40 42 45 48 50 52 55 58 60 62 65 68 70 72 75 78 80 82 THERM+ H-V Glazing/Sealing technology Timber curtain wall 50/56/76 mm Screw selection Flat pressure profiles with exterior gasket 2 mm Infill tickness mm 18 19 to 20 21 to 22 23 to 25 26 to 28 29 to 30 31 to 32 33 to 35 36 to 38 39 to 40 41 to 42 43 to 45 46 to 48 49 to 50 51 to 52 53 to 55 56 to 58 59 to 60 61 to 62 63 to 64 No. 012136 012137 012138 012010 012011 012012 012139 012013 012014 012140 012015 012141 012016 012142 012017 012143 012018 012020 012146 012147 Length mm 25 28 30 32 35 38 40 42 45 48 50 52 55 58 60 62 65 68 70 72 – For pressure profile no. 013300, 013310, 013313. Infill tickness mm 18 19 to 20 21 to 23 24 to 26 27 to 28 29 to 30 31 to 33 34 to 36 37 to 38 39 to 40 41 to 43 44 to 46 47 to 48 49 to 50 51 to 53 54 to 56 57 to 58 59 to 60 61 to 63 64 No. 012171 012172 012173 012174 012175 012176 012177 012178 012179 012180 012181 012182 012183 012184 012185 012186 012190 012187 012192 012188 KHV-0042 Length mm 28 30 32 35 38 40 42 45 48 50 52 55 58 60 62 65 68 70 72 75 – For pressure profile no. 013300, 013310, 013313. Infill tickness mm 18 to 19 20 to 22 23 to 24 25 to 26 27 to 29 30 to 32 33 to 34 35 to 36 37 to 39 40 to 42 43 to 44 45 to 46 47 to 49 50 to 52 53 to 54 55 to 56 57 to 59 60 to 62 63 to 64 No. 012107 012108 012109 012110 012111 012112 012113 012114 012115 012116 012117 012118 012119 012129 012123 012124 012125 012106 012126 2016 Length mm 25 28 30 32 35 38 40 42 45 48 50 52 55 58 60 62 65 68 70 451 THERM+ H-V Assembly options – For pressure profile no. 013300, 013310, 013313. THERM+ H-V Glazing/Sealing technology Timber curtain wall 50/56 mm Screw selection Glazing with silicone joint and suction discs – For suction disc no. 163807, 163810, 163812. Infill tickness mm RAL 9004 No. 20 to 21 22 to 23 24 to 25 26 to 27 28 to 29 30 to 31 32 to 33 34 to 35 36 to 37 38 to 39 40 to 41 42 to 43 44 to 45 46 to 47 48 to 49 50 to 51 52 to 53 54 to 55 56 to 57 58 to 60 61 to 63 64 907202 907204 907206 907208 907210 907212 907214 907216 907218 907220 907222 907224 907226 907228 907230 907232 907234 907236 907238 907240 907242 907244 452 2016 Stainless steel No. 907252 907254 907256 907258 907260 907262 907264 907266 907268 907270 907272 907274 907276 907278 907280 907282 907284 907286 907288 907290 907292 907294 Length mm 36 39 41 43 45 47 49 51 53 55 57 59 61 63 65 67 69 71 73 75 78 81 KHV-0062 THERM+ H-V Accessories Timber curtain wall 50/56/76 mm Fixation of sun protection Assembly and information ■ Technical information Selection of sockets – The fixation of the sun protection can be used for all system widths and pressure and cover profiles. No. – Assembling at any time, even at existing curtain walls. – For the selection of stainless steel sockets see table. The length results from the selection of pressure and cover profiles as well as from the infill thickness (detailed information see handling manual). – Applied load figures see following pages. – Max. usability force FH regarding to one pair of sockets. – Max. usability force FH is constant at every load distance → FH = 0.80 kN. – A force crosswise to the mullion cannot be taken → FQ = 0 kN. – The indicated loads are dimensioning loads. – A connection plate by the customer (min. 40 x 10 mm) is used for leading the forces into the the screws. – The screws 5.5 has to be bolted with a bolting torque of min. 8 Nm. – The fixation of sun protection can only be used by pairs. – For each assembling situation a statical calculation is mandatory. The influencing variables according to EUROCODE 1 and DIN 1055 have to be considered. – T13 = Infill thickness. – T33 = Fixation of sun protection. 169942 169946 169950 169954 169958 169962 169966 169970 169974 169978 169982 169986 169990 169994 169998 169999 Length mm 42 46 50 54 58 62 66 70 74 78 82 86 90 94 98 102 Selection of sleeves No. 169900 169901 169902 169903 169904 169905 169906 169907 169908 169909 169910 169911 169912 169913 169914 169915 169917 169918 169919 Length mm 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 42 44 46 – T34 = Length of socket. – T35 = Offset point of application a. – T185 = Dimensioning example for connection plate provided by customer. THERM+ H-V Assembly options – T224 = See table. ZHV-1021 2016 453 THERM+ H-V Accessories Timber curtain wall 50/56/76 mm Fixation of sun protection Screw distance 90 mm Vertical force in use F [kN] ■ Technical information 1.15 Calculation basis: 1.10 1.05 – Horizontal force FH: 0,8 kN. 1.00 – Thickness of connection plate: 10 mm. 0.95 – Material connection plate: aluminium. 0.90 0.85 0.80 – Assembling and additional information see previous page. 0.75 0.70 – a = Offset point of application 0.65 0.60 0.55 0.50 0.45 0.40 0.35 0.30 Length of socket [mm] Screw distance 130 mm Screw distance 110 mm Vertical force in use F [kN] Vertical force in use F [kN] 1.15 1.15 1.10 1.10 1.05 1.05 1.00 1.00 0.95 0.95 0.90 0.90 0.85 0.85 0.80 0.80 0.75 0.75 0.70 0.70 0.65 0.65 0.60 0.60 0.55 0.55 0.50 0.50 0.45 0.45 0.40 0.40 0.35 0.35 0.30 0.30 Length of socket [mm] Length of socket [mm] Screw distance 150 mm Screw distance 170 mm Vertical force in use F [kN] Vertical force in use F [kN] 1.15 1.15 1.10 1.10 1.05 1.05 1.00 1.00 0.95 0.95 0.90 0.90 0.85 0.85 0.80 0.80 0.75 0.75 0.70 0.70 0.65 0.65 0.60 0.60 0.55 0.55 0.50 0.50 0.45 0.45 0.40 0.40 0.35 0.35 0.30 0.30 Length of socket [mm] 454 2016 ZHV-1020 Length of socket [mm] THERM+ H-V Accessories Timber curtain wall 50/56/76 mm Fixation of sun protection for cover profiles 12 mm Exterior gasket 3 mm ■ Technical information – Pressure profiles: No. 118005 (50 mm) No. 118010 (56 mm) No. 118015 (76 mm) – Cover profiles: No. 013004 (50 mm) No. 013024 (56 mm) No. 013051 (76 mm) – T74 = Infill thickness Infill thickness mm 20 to 22 23 to 24 25 to 26 27 to 28 29 to 30 31 to 32 33 to 34 35 to 36 37 to 38 39 to 40 41 to 42 43 to 44 45 to 46 47 to 48 49 to 50 51 to 52 53 to 54 55 to 56 57 to 58 59 to 60 61 to 62 63 to 64 ZHV-1000 No. socket No. sealing sleeve 169946 169950 169950 169954 169954 169958 169958 169962 169962 169966 169966 169970 169970 169974 169974 169978 169978 169982 169982 169986 169986 169990 169904 169904 169903 169904 169903 169904 169903 169904 169903 169904 169903 169904 169903 169904 169903 169904 169903 169904 169903 169904 169903 169904 2016 THERM+ H-V Assembly options T74 ■ List of sockets and sealing sleeves 455 THERM+ H-V Accessories Timber curtain wall 50/56/76 mm Fixation of sun protection for cover profiles 12 mm Exterior gasket 5 mm ■ Technical information – Pressure profiles: No. 118005 (50 mm) No. 118010 (56 mm) No. 118015 (76 mm) – Cover profiles: No. 013004 (50 mm) No. 013024 (56 mm) No. 013051 (76 mm) – T74 = Infill thickness ■ List of sockets and sealing sleeves T74 Infill thickness mm 20 to 21 22 to 23 24 to 25 26 to 27 28 to 29 30 to 31 32 to 33 34 to 35 36 to 37 38 to 39 40 to 41 42 to 43 44 to 45 46 to 47 48 to 49 50 to 51 52 to 53 54 to 55 56 to 57 58 to 59 60 to 61 62 to 63 64 456 2016 ZHV-1000 No. socket No. sealing sleeve 169946 169950 169950 169954 169954 169958 169958 169962 169962 169966 169966 169970 169970 169974 169974 169978 169978 169982 169982 169986 169986 169990 169990 169903 169904 169903 169904 169903 169904 169903 169904 169903 169904 169903 169904 169903 169904 169903 169904 169903 169904 169903 169904 169903 169904 169903 THERM+ H-V Accessories Timber curtain wall 50/56/76 mm Fixation of sun protection for cover profiles 15 mm Exterior gasket 3 mm ■ Technical information – Pressure profiles: No. 118005 (50 mm) No. 118010 (56 mm) No. 118015 (76 mm) – Cover profiles: No. 013003 (50 mm) No. 013023 (56 mm) No. 013050 (76 mm) – T74 = Infill thickness ■ List of sockets and sealing sleeves ZHV-1001 No. socket No. sealing sleeve 169950 169950 169950 169954 169954 169954 169958 169958 169958 169962 169962 169962 169966 169966 169966 169970 169970 169970 169974 169974 169974 169978 169978 169978 169982 169982 169982 169986 169986 169986 169990 169990 169990 169994 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 2016 THERM+ H-V Assembly options T74 Infill thickness mm 20 21 to 22 23 24 25 to 26 27 28 29 to 30 31 32 33 to 34 35 36 37 to 38 39 40 41 to 42 43 44 45 to 46 47 48 49 to 50 51 52 53 to 54 55 56 57 to 58 59 60 61 to 62 63 64 457 THERM+ H-V Accessories Timber curtain wall 50/56/76 mm Fixation of sun protection for cover profiles 15 mm Exterior gasket 5 mm ■ Technical information – Pressure profiles: No. 118005 (50 mm) No. 118010 (56 mm) No. 118015 (76 mm) – Cover profiles: No. 013003 (50 mm) No. 013023 (56 mm) No. 013050 (76 mm) – T74 = Infill thickness ■ List of sockets and sealing sleeves T74 Infill thickness mm 20 to 21 22 23 24 to 25 26 27 28 to 29 30 31 32 to 33 34 35 36 to 37 38 39 40 to 41 42 43 44 to 45 46 47 48 to 49 50 51 52 to 53 54 55 56 to 57 58 59 60 to 61 62 63 64 458 2016 ZHV-1001 No. socket No. sealing sleeve 169950 169950 169954 169954 169954 169958 169958 169958 169962 169962 169962 169966 169966 169966 169970 169970 169970 169974 169974 169974 169978 169978 169978 169982 169982 169982 169986 169986 169986 169990 169990 169990 169994 169994 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 THERM+ H-V Accessories Timber curtain wall 50/56/76 mm Fixation of sun protection for cover profiles 20 mm Exterior gasket 3 mm ■ Technical information – Pressure profiles: No. 118005 (50 mm) No. 118010 (56 mm) No. 118015 (76 mm) – Cover profiles: No. 013210 (50 mm) No. 013410 (56 mm) No. 013610 (76 mm) – T74 = Infill thickness ■ List of sockets and sealing sleeves ZHV-1002 No. socket No. sealing sleeve 169954 169954 169958 169958 169958 169962 169962 169962 169966 169966 169966 169970 169970 169970 169974 169974 169974 169978 169978 169978 169982 169982 169982 169986 169986 169986 169990 169990 169990 169994 169994 169994 169998 169998 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 2016 THERM+ H-V Assembly options Infill thickness mm 20 to 21 22 23 24 to 25 26 27 28 to 29 30 31 32 to 33 34 35 36 to 37 38 39 40 to 41 42 43 44 to 45 46 47 48 to 49 50 51 52 to 53 54 55 56 to 57 58 59 60 to 61 62 63 64 459 THERM+ H-V Accessories Timber curtain wall 50/56/76 mm Fixation of sun protection for cover profiles 20 mm Exterior gasket 5 mm ■ Technical information – Pressure profiles: No. 118005 (50 mm) No. 118010 (56 mm) No. 118015 (76 mm) – Cover profiles: No. 013210 (50 mm) No. 013410 (56 mm) No. 013610 (76 mm) – T74 = Infill thickness ■ List of sockets and sealing sleeves Infill thickness mm 20 21 22 23 to 24 25 26 27 to 28 29 30 31 to 32 33 34 35 to 36 37 38 39 to 40 41 42 43 to 44 45 46 47 to 48 49 50 51 to 52 53 54 55 to 56 57 58 59 to 60 61 62 63 to 64 460 2016 ZHV-1002 No. socket No. sealing sleeve 169954 169954 169958 169958 169958 169962 169962 169962 169966 169966 169966 169970 169970 169970 169974 169974 169974 169978 169978 169978 169982 169982 169982 169986 169986 169986 169990 169990 169990 169994 169994 169994 169998 169998 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 169907 169909 169908 THERM+ H-V Accessories Timber curtain wall 50/56/76 mm Fixation of sun protection for cover profiles 25 mm Exterior gasket 3 mm ■ Technical information – Pressure profiles: No. 118005 (50 mm) No. 118010 (56 mm) – Cover profiles: No. 013005 (50 mm) No. 013025 (56 mm) No. 013201 (50 mm) No. 013400 (56 mm) No. 141505 (76 mm) – T74 = Infill thickness ■ List of sockets and sealing sleeves No. sealing sleeve 169954 169958 169958 169962 169962 169966 169966 169970 169970 169974 169974 169978 169978 169982 169982 169986 169986 169990 169990 169994 169994 169998 169998 169908 169909 169908 169909 169908 169909 169908 169909 169908 169909 169908 169909 169908 169909 169908 169909 169908 169909 169908 169909 169908 169909 169908 THERM+ H-V Assembly options No. socket T74 Infill thickness mm 20 to 21 22 to 23 24 to 25 26 to 27 28 to 29 30 to 31 32 to 33 34 to 35 36 to 37 38 to 39 40 to 41 42 to 43 44 to 45 46 to 47 48 to 49 50 to 51 52 to 53 54 to 55 56 to 57 58 to 59 60 to 61 62 to 63 64 ZHV-1006 2016 461 THERM+ H-V Accessories Timber curtain wall 50/56/76 mm Fixation of sun protection for cover profiles 25 mm Exterior gasket 5 mm ■ Technical information – Pressure profiles: No. 118005 (50 mm) No. 118010 (56 mm) – Cover profiles: No. 013005 (50 mm) No. 013025 (56 mm) No. 013201 (50 mm) No. 013400 (56 mm) No. 141505 (76 mm) – T74 = Infill thickness ■ List of sockets and sealing sleeves T74 Infill thickness mm 20 21 to 22 23 to 24 25 to 26 27 to 28 29 to 30 31 to 32 33 to 34 35 to 36 37 to 38 39 to 40 41 to 42 43 to 44 45 to 46 47 to 48 49 to 50 51 to 52 53 to 54 55 to 56 57 to 58 59 to 60 61 to 62 63 to 64 462 2016 ZHV-1006 No. socket No. sealing sleeve 169954 169958 169958 169962 169962 169966 169966 169970 169970 169974 169974 169978 169978 169982 169982 169986 169986 169990 169990 169994 169994 169998 169998 169908 169909 169908 169909 169908 169909 169908 169909 169908 169909 169908 169909 169908 169909 169908 169909 169908 169909 169908 169909 169908 169909 169908 THERM+ H-V Accessories Timber curtain wall 50/56 mm Fixation of sun protection for pressure profiles 9 mm Exterior gasket 3 mm ■ Technical information – Pressure profiles: No. 013008 (50 mm) No. 013028 (56 mm) – T74 = Infill thickness Infill thickness mm 20 21 to 22 23 to 24 25 to 26 27 to 28 29 to 30 31 to 32 33 to 34 35 to 36 37 to 38 39 to 40 41 to 42 43 to 44 45 to 46 47 to 48 49 to 50 51 to 52 53 to 54 55 to 56 57 to 58 59 to 60 61 to 62 63 to 64 ZHV-1008 No. socket No. sealing sleeve 169946 169946 169950 169950 169954 169954 169958 169958 169962 169962 169966 169966 169970 169970 169974 169974 169978 169978 169982 169982 169986 169986 169990 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 2016 THERM+ H-V Assembly options T74 16 - 19 ■ List of sockets and sealing sleeves 463 THERM+ H-V Accessories Timber curtain wall 50/56 mm Fixation of sun protection for pressure profiles 9 mm Exterior gasket 5 mm ■ Technical information – Pressure profiles: No. 013008 (50 mm) No. 013028 (56 mm) – T74 = Infill thickness ■ List of sockets and sealing sleeves T74 16 - 19 Infill thickness mm 20 to 21 22 to 23 24 to 25 26 to 27 28 to 29 30 to 31 32 to 33 34 to 35 36 to 37 38 to 39 40 to 41 42 to 43 44 to 45 46 to 47 48 to 49 50 to 51 52 to 53 54 to 55 56 to 57 58 to 59 60 to 61 62 to 63 64 464 2016 ZHV-1008 No. socket No. sealing sleeve 169946 169950 169950 169954 169954 169958 169958 169962 169962 169966 169966 169970 169970 169974 169974 169978 169978 169982 169982 169986 169986 169990 169990 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 THERM+ H-V Accessories Timber curtain wall 50/56 mm Fixation of sun protection for pressure profiles 12 mm Exterior gasket 3 mm ■ Technical information – Pressure profiles: No. 013007 (50 mm) No. 013027 (56 mm) – T74 = Infill thickness Infill thickness mm 20 to 21 22 to 23 24 to 25 26 to 27 28 to 29 30 to 31 32 to 33 34 to 35 36 to 37 38 to 39 40 to 41 42 to 43 44 to 45 46 to 47 48 to 49 50 to 51 52 to 53 54 to 55 56 to 57 58 to 59 60 to 61 62 to 63 64 ZHV-1003 No. socket No. sealing sleeve 169950 169950 169954 169954 169958 169958 169962 169962 169966 169966 169970 169970 169974 169974 169978 169978 169982 169982 169986 169986 169990 169990 169994 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 2016 THERM+ H-V Assembly options T74 ■ List of sockets and sealing sleeves 465 THERM+ H-V Accessories Timber curtain wall 50/56 mm Fixation of sun protection for pressure profiles 12 mm Exterior gasket 5 mm ■ Technical information – Pressure profiles: No. 013007 (50 mm) No. 013027 (56 mm) – T74 = Infill thickness ■ List of sockets and sealing sleeves T74 Infill thickness mm 20 21 to 22 23 to 24 25 to 26 27 to 28 29 to 30 31 to 32 33 to 34 35 to 36 37 to 38 39 to 40 41 to 42 43 to 44 45 to 46 47 to 48 49 to 50 51 to 52 53 to 54 55 to 56 57 to 58 59 to 60 61 to 62 63 to 64 466 2016 ZHV-1003 No. socket No. sealing sleeve 169950 169950 169954 169954 169958 169958 169962 169962 169966 169966 169970 169970 169974 169974 169978 169978 169982 169982 169986 169986 169990 169990 169994 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 THERM+ H-V Accessories Timber curtain wall 50 mm Fixation of sun protection for pressure profiles 25 mm Exterior gasket 3 mm ■ Technical information – Pressure profiles: No. 013014 (50 mm) – T74 = Infill thickness Infill thickness mm 20 21 22 23 to 24 25 26 27 to 28 29 30 31 to 32 33 34 35 to 36 37 38 39 to 40 41 42 43 to 44 45 46 47 to 48 49 50 51 to 52 53 54 55 to 56 57 58 59 to 60 61 62 63 to 64 ZHV-1007 No. socket No. sealing sleeve 169954 169954 169958 169958 169958 169962 169962 169962 169966 169966 169966 169970 169970 169970 169974 169974 169974 169978 169978 169978 169982 169982 169982 169986 169986 169986 169990 169990 169990 169994 169994 169994 169998 169998 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 2016 THERM+ H-V Assembly options T74 ■ List of sockets and sealing sleeves 467 THERM+ H-V Accessories Timber curtain wall 50 mm Fixation of sun protection for pressure profiles 25 mm Exterior gasket 5 mm ■ Technical information – Pressure profiles: No. 013014 (50 mm) – T74 = Infill thickness ■ List of sockets and sealing sleeves T74 Infill thickness mm 20 21 22 to 23 24 25 26 to 27 28 29 30 to 31 32 33 34 to 35 36 37 38 to 39 40 41 42 to 43 44 45 46 to 47 48 49 50 to 51 52 53 54 to 55 56 57 58 to 59 60 61 62 to 63 64 468 2016 ZHV-1007 No. socket No. sealing sleeve 169954 169958 169958 169958 169962 169962 169962 169966 169966 169966 169970 169970 169970 169974 169974 169974 169978 169978 169978 169982 169982 169982 169986 169986 169986 169990 169990 169990 169994 169994 169994 169998 169998 169998 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 169906 169905 169904 THERM+ H-V Accessories Timber curtain wall 50/56/76 mm Fixation of sun protection for flat pressure profiles Exterior gasket 2 mm ■ Technical information – Pressure profiles: No. 013300 (50 mm) No. 013310 (56 mm) No. 013313 (76 mm) – T74 = Infill thickness Infill thickness mm 24 to 25 26 to 27 28 to 29 30 to 31 32 to 33 34 to 35 36 to 37 38 to 39 40 to 41 42 to 43 44 to 45 46 to 47 48 to 49 50 to 51 52 to 53 54 to 55 56 to 57 58 to 59 60 to 61 62 to 63 64 ZHV-1009 No. socket No. sealing sleeve 169942 169946 169946 169950 169950 169954 169954 169958 169958 169962 169962 169966 169966 169970 169970 169974 169974 169978 169978 169982 169982 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 169901 169900 2016 THERM+ H-V Assembly options T74 ■ List of sockets and sealing sleeves 469 THERM+ H-V Accessories Timber curtain wall 50/56/76 mm Assembly scaffolding anchors ■ Technical information Selection of fastening screws – The base profile ist screwed to the scaffolding anchors range in addition. – Scaffolding fixation no. 166240 with screw no. 012108. – Expansion structure profile cannot take forces right-angled to the structural profile (Frt). – Please order additionally: - 1 halfen screw no. 907605. - 1 cover 15 white no. 167075 or - 1 cover 15 black no. 167076. – Application of flat pressure profile possible from an infill thickness of 28 mm. – The number and position of the fixation points depends on the specific requirements of the scaffold. The max. load transmission into the curtain wall construction is system immanent and can be taken from the table Representative parameter. Representative parameter – T182 = Assembly scaffolding anchor. – T183 = Offset posts. – T184 = Height of scaffold. 470 2016 ZHV-0007 Right-angled to structural profile Frt Parallel to structural profile Fpt Right-angled to curtain wall Frf 0.47 kN 4.53 kN 8.81 kN THERM+ H-V Accessories Timber curtain wall 50/56/76 mm Fixture unit ■ Technical information – Assembling the fixture unit no. 166210 with: 3 pc. screws no. 908655 (PU = 100 pcs.). 6 pc. screws no. 908020 (PU = 100 pcs.). – Fixation in consideration of construction circumstances and statical requirements. – For each assembling situation a statical calculation is mandatory. The influencing variables of DIN 1055 has to be considered. – Please consider several international, national, regional and local laws and rules. – The common and accepted rules of technique has to be considered. – T68 = Offset action point a. Additional loads Vertical load Fv in combination with horizontal load Fh (offset action point a = 100) Fv [kN] 6.5 6.0 5.0 4.0 3.0 2.0 1.5 1.0 Fh [kN] 0.4 0.8 1.8 2.7 3.7 4.6 5.1 5.6 Vertical load Fv in combination with horizontal load Fh (offset action point a = 180) Fv [kN] 3.5 3.0 2.5 2.0 1.5 1.0 Fh [kN] 0.5 1.4 2.3 3.1 4.0 4.8 Diagonal pull Fd in consideration of angle α (offset action point a = 100) α [°] 50 45 40 35 30 Fd [kN] 4.7 4.7 4.8 4.8 4.9 – T69 = Fixation bracket. – T164 = Finished situation. THERM+ H-V Assembly options – T165 = Illustration without glass and exterior gasket. ZHV-0006 2016 471 THERM+ H-V Accessories Timber curtain wall 50/56/76 mm Connection profiles for transom and mullion gasket Connection with gasket without flap ■ Technical information – Bolted with no. 908118. – *Gasket easy to tear off to 3 / 7 / 9 mm. – ** With sheet t = 3 mm (self-production) instead of no. 051012 (t = 2.2 mm). – T13 = Infill thickness. 472 2016 Selection of gaskets and profiles Infill thickness mm 24 25** 26 27 28 29 30 31 32 33 34 35** 36 37 38 39 40 41 42 43 44 45** 46 47 48 49 50 51 52 53 54 55** 56 57 58 59 60 61 62 63 64 ZHV-0011 Compensation gasket no. – – 227010 227032 227015 227032 227020 227032 227025 227032 227030 – 227010 227032 227015 227032 227020 227032 227025 227032 – – 227010 227032 227015 227032 227020 227032 227025 227032 227030 – 227010 227032 227015 227032 227020 227032 227025 227032 227030 Compensation profile no. – – – – – – – – – – – 227006 227006 227006 227006 227006 227006 227006 227006 227006 – – – – – – – – – – – 227006 227006 227006 227006 227006 227006 227006 227006 227006 227006 Connection profile no. 168023 (50/56) 168028 (76) 168040 (50/56) 168044 (76) THERM+ H-V Accessories Timber curtain wall 50/56/76 mm Connection profiles for transom and mullion gasket Base point connection with gasket and flap ■ Technical information – T248 = Compensation gasket. Connection profile no. 168005 with 2 mm sheet Connection profile no. 168005 with 3 mm sheet Selection compensation gasket Selection compensation gasket Gasket No. – 011080 011070 011077 011073 011076 011074 011071 011075 011072 011078 No. Infill thickness mm 25 27 28 29 30 31 32 33 34 36 38 PU – 100 m 100 m 100 m 100 m 100 m 100 m 100 m 100 m 100 m 50 m No. No. No. Gasket No. – 011080 011070 011077 011073 011076 011074 011071 011075 011072 011078 PU – 100 m 100 m 100 m 100 m 100 m 100 m 100 m 100 m 100 m 50 m THERM+ H-V Assembly options Infill thickness mm 24 26 27 28 29 30 31 32 33 35 37 No. No. 168005 No. No. No. No. ZHV-0001 No. 2016 473 THERM+ H-V Accessories Timber curtain wall 50/56/76 mm Connection profiles Connection frame profile ■ Technical information Selection of articles – Connection profile no. 168080: - Continuous insertion for bottom and top connection. - Cut out in mullion area for drainage/ventilation. Article – Observe the different rates of thermal expansion for the screw connection of the aluminium window sill with the synthetic connection profile. 474 2016 ZHV-0008 No. PU Connection profile 55/15 168080 6m Connection profile 39/22 V 168023 6m Connection profile 48/22 V 168028 6m Connection profile 39/42 V 168040 6m Connection profile 48/42 V 168044 6m THERM+ H-V Accessories Timber curtain wall 50/56/76 mm Connection profiles Ventilated/non-ventilated façade ■ Technical information List of glass thickness compensation – Max. weight of the pane at the connection profile: 50 kg. Difference allowed mm – For higher offsets between the two infill thicknesses (infill thickness 1 – infill thickness 2) the compensation profile 12 no. 013090, compensation height 12 mm, may be used. (PU = 6 m). 18 19 20 21 22 23 24 25 26 27 28 – IT = Infill thickness. – For more information see Processing. Compensation gasket No. 011070 011077 011073 011076 011074 011071 011075 – 011072 – 011078 Height mm 3 4 5 6 7 8 9 – 11 – 13 PU 100 m – 100 m – 50 m THERM+ H-V Assembly options Difference D between the two glass infill thicknesses is necessary for the selection. (D = IT1 minus IT2; IT1 = 20 to 64 mm, IT2 = 2 to 46 mm). IT 2 No. 168060 IT 1 ZHV-0003 2016 475 THERM+ H-V Accessories Timber curtain wall 50/56/76 mm Connection profiles Terminal clamp as assembly aid for sheets and profiles ■ Technical information – Applicable as an assembly aid or for the fixation of sheets and connection profiles at hard-toreach places. – Clamp thickness 1.5 to 3 mm. – Fixation with a suitable screw for hole Ø 6 mm. 476 2016 ZHV-0005 THERM+ H-V Accessories Timber curtain wall 50/56 mm Connection profiles Fixture spring – interior compensation of different infill thicknesses ■ Technical information – Table for the selection of the compensation gasket see following page. – Reduced glass weights have to be obtained in individual cases THERM+ H-V Assembly options – T13 = Infill thickness (IT). ZHV-0012 2016 477 478 2016 220327 220326 220325 220324 220323 220322 220321 220320 26 64 62 60 58 56 54 52 50 48 46 44 42 40 38 36 34 32 30 18 20 22 24 26 30 32 34 36 38 40 42 44 46 48 50 52 54 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 28 IT 2 (mm) 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 220327 220326 220325 220324 220323 220322 220321 220320 220326 220325 220324 220323 220322 220321 220320 28 220325 220324 220323 220322 220321 220320 16 24 14 22 12 220324 220323 220322 220321 220320 10 20 8 220323 220322 220321 220320 6 220322 220321 220320 4 18 2 16 IT 1 (mm) Selection compensation gasket THERM+ H-V Accessories Timber curtain wall 50/56 mm Connection profiles Table for the selection of compensation gasket THERM+ H-V Accessories Timber curtain wall 50/56 mm Connection profiles Stainless steel retainer for panel fixing ■ Technical information Selection of retainer – For fixing the panel before assembling the pressure profile. Infill thickness mm 24 25 to 26 27 to 28 29 to 30 31 to 32 33 to 34 35 to 36 37 to 38 39 to 40 41 to 42 43 to 44 45 to 46 47 to 48 59 to 50 51 to 52 – Retainer may stay at glass rebate. 167167 167169 167171 167173 167175 167177 167179 167181 167183 167185 167187 167189 167191 167193 167195 THERM+ H-V Assembly options T13 – T13 = Infill thickness (IT). No. Art.-Nr. No. 167167 167167–to167195 167195 No. Art.-Nr. 012097 012103 ZHV-0004 2016 479 THERM+ H-V Accessories Timber curtain wall 50/56/76 mm Connection profiles Selection of assembly angles for integration outer frame FRAME+ 75 WB ■ Technical information Gap dimensions x and y – For the positioning of assembly angles see Processing. System width mm – T13 = Infill thickness. – T141 = Selection of assembly angle and screws see table. Dim. x Dim. y No. 207666 Dim. x No. 207667 50 9 5 14 10 50 8 4 13 7 60 76 – – 11 5 80 y Assembly angle and screws 75 WB for THERM+ V 480 22 mm – 25 mm 25 mm 28 mm 28 mm 28 mm 30 mm 30 mm 32 mm 32 mm – 35 mm 35 mm 38 mm 38 mm 38 mm 40 mm 40 mm 42 mm 42 mm 2016 012105 – 012107 012107 012108 012108 012108 012109 012109 012110 012110 – 012111 012111 012112 012112 012112 012113 012113 012114 012114 Assembly angle for 50 mm 167606 – 167608 167609 167610 167611 167612 167613 167614 167615 167616 – 167618 167619 167620 167621 167622 167623 167624 167625 167626 Assembly angle for 56 mm 167656 – 167658 167659 167660 167661 167662 167663 167664 167665 167666 – 167668 167669 167670 167671 167672 167673 167674 167675 167676 Assembly angle for 76 mm in-house production Screw Length / No. Profile width mm 56 x Infill thickness mm 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 Dim. y KHV-0009 EPDM compensation gasket without without – – 2 mm 227010 3 mm 227032 4 mm 227015 5 mm 227032 6 mm 227020 7 mm 227032 8 mm 227025 9 mm 227032 10 mm 227030 – – 2 mm 227010 3 mm 227032 4 mm 227015 5 mm 227032 6 mm 227020 7 mm 227032 8 mm 227025 9 mm 227032 10 mm 227030 Synthetic compensation profile without without – – without without without without without without without without without without without without without without without without without without – – 10 mm 227006 10 mm 227006 10 mm 227006 10 mm 227006 10 mm 227006 10 mm 227006 10 mm 227006 10 mm 227006 10 mm 227006 THERM+ H-V Accessories Timber curtain wall 50/56 mm Connection profiles Selection of assembly angles for integration outer frame FRAME+ 75 WB ■ Technical information Gap dimensions x and y – For the positioning of assembly angles see Processing. – T13 = Infill thickness. – T141 = Selection of assembly angle and screws see table. System width mm Dim. x 50 9 5 50 56 8 4 60 Dim. y No. 207670 Profile width mm x THERM+ H-V Assembly options y Assembly angle and screws 75 WB for THERM+ V Infill thickness mm 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 Screw Length / No. 35 mm – 35 mm 38 mm 38 mm 40 mm 40 mm 42 mm 42 mm 42 mm 45 mm – 45 mm 48 mm 48 mm 50 mm 50 mm 52 mm 52 mm 52 mm 52 mm 012111 – 012111 012112 012112 012113 012113 012114 012114 012114 012115 – 012115 012116 012116 012117 012117 012118 012118 012118 012118 Assembly angle for 50 mm 167618 – 167620 167621 167622 167623 167624 167625 167626 167627 167628 – 167630 167631 167632 167633 167634 167635 167636 167637 167638 Assembly angle for 56 mm 167668 – 167670 167671 167672 167673 167674 167675 167676 167677 167678 – 167680 167681 167682 167683 167684 167685 167686 167687 167688 EPDM compensation gasket without without – – 2 mm 227010 3 mm 227032 4 mm 227015 5 mm 227032 6 mm 227020 7 mm 227032 8 mm 227025 9 mm 227032 10 mm 227030 – – 2 mm 227010 3 mm 227032 4 mm 227015 5 mm 227032 6 mm 227020 7 mm 227032 8 mm 227025 9 mm 227032 10 mm 227030 KHV-0012 Synthetic compensation profile without without – – without without without without without without without without without without without without without without without without without without – – 10 mm 227006 10 mm 227006 10 mm 227006 10 mm 227006 10 mm 227006 10 mm 227006 10 mm 227006 10 mm 227006 10 mm 227006 2016 481 THERM+ H-V Accessories Timber curtain wall 50/56 mm Suction disc Mullion section with silicone joint ■ Technical information – Only insulated glass with UV resistance edge seal or optional with enameling/screen printing may be used. – The necessary infill thicknesses have to be coordinated with the glass supplier. – The legal glazing instructions have to be taken into consideration and if necessary an approval in individual cases has to be obtained. – The suction discs can be also used as a mechanical saving in combination with the SG2 system for all heights larger than 8 m (min. infill thickness 32 mm). – From an infill thickness of 23 mm possible with insulating blocks SG. – Selection of screws see screw selection tables. 20 to - 64 mm – Please consider DIN EN 18008, TRLV and TRPV. Suction disc set 75 No. 163807 482 2016 Suction disc set 56/90 No. 163812 Suction disc set 50/90 No. 163810 HV-0172 THERM+ H-V Accessories Timber curtain wall 50/56/76 mm Belay sheet Protection of vertical cover profile to prevent slipping ■ Technical information THERM+ H-V Assembly options – Rotate drilling jig for pre-drilling the belay sheet 180° for pre-drilling the belay sheet. No. Art.-Nr. 127100 127100 No. Art.-Nr. 902511 902511 ZH-0020 2016 483 THERM+ H-V Accessories Timber curtain wall 50/56/76 mm Static table Vertical glazing Pre-dimensioning list: – The shown list is only for pre-dimensioning of necessary cross sections for mullion and transom within the glass construction. This is no compensation for necessary tension and stabilty certification. – Please account for the factors by using other E-modules for the mullion material: –Timber-E-Module 5500: Conversion factor E-Module 2 Timber-E-Module 12000: Conversion factor E-Module 0.92 Timber-E-Module 13000: Conversion factor E-Module 0.85 Timber-E-Modul 14000: Conversion factor E-Module 0.79 – The following parameters are used for determinate the list: wind load referred to DIN EN 1991-1-4: 0 m to 8 m assembly height 0.5 KN/m² > 8 m to 20 m assembly height 0.8 KN/m² (conversion factor 1.6) > 20 m to 100 m assembly height 1.1 KN/m² (conversion factor 2.2) Pressure cp: 0.8 Load increasing for singular items: 25 % max. deflection referred to. DIN EN 13830: - I/200, when L ≤ 3000 mm - L/300 + 5 mm, when 3000 mm < L < 7500 mm – The listed parameters are based on 1-fieldbearing. For 2-fields-bearing the deflections and the necessary torque of inertia will be reduced by a factor of 0.42. For 2-fieldsbearing a tension certification is mandatory. Possible deviating max. deflections of the glass manufacturer’s technical specifications have to be respected. Balustrade loads are not taken into consideration. – T133 = 1-field-bearing – T134 = 2-fields-bearing Result Ix [cm4] at assembly height 0 m to 8 m, E-Module 11000 N/mm² (BS 11/BS 14 glued-laminated timber) Influencing parameter e [m] 0.50 0.75 1.00 1.25 1.50 1.75 2.00 2.25 2.50 2.75 3.00 Lenght of mullion L [m] / length of transom B [m] ■ Technical information 6.00 1534 2301 3068 3835 4602 5369 6136 6903 7670 8438 9205 5.90 1454 2181 2907 3634 4361 5088 5815 6542 7269 7996 8722 5.80 1376 2064 2752 3441 4129 4817 5505 6193 6881 7569 8257 5.70 1302 1952 2603 3254 3905 4556 5206 5857 6508 7159 7810 5.60 1230 1845 2459 3074 3689 4304 4919 5534 6149 6763 7378 5.50 1161 1741 2321 2901 3482 4062 4642 5222 5803 6383 6963 5.40 1094 1641 2188 2735 3282 3829 4376 4923 5470 6017 6564 5.30 1030 1545 2060 2575 3090 3606 4121 4636 5151 5666 6181 5.20 969 1453 1938 2422 2906 3391 3875 4360 4844 5329 5813 5.10 910 1365 1820 2275 2730 3185 3640 4095 4550 5005 5460 5.00 854 1280 1707 2134 2561 2988 3415 3841 4268 4695 5122 4.90 800 1200 1599 1999 2399 2799 3199 3599 3998 4398 4798 4.80 748 4.70 699 1048 1397 1747 2096 2446 2795 3144 3494 3843 4192 4.60 652 977 1303 1629 1955 2281 2607 2932 3258 3584 3910 4.50 607 910 1213 1517 1820 2124 2427 2730 3034 3337 3640 4.40 564 846 4.30 523 785 1047 1308 1570 1832 2093 2355 2617 2878 3140 4.20 485 727 969 1212 1454 1696 1939 2181 2423 2666 2908 4.10 448 672 896 4.00 413 620 826 1033 1240 1446 1653 1860 2066 2273 2479 3.90 380 571 761 951 3.80 349 524 699 873 1048 1222 1397 1572 1746 1921 2096 3.70 320 480 640 800 960 3.60 292 439 585 731 877 1023 1170 1316 1462 1608 1754 3.50 266 400 533 666 799 933 1066 1199 1332 1465 1599 3.40 242 363 484 605 726 847 968 1090 1211 1332 1453 3.30 219 329 439 548 658 768 877 987 1097 1206 1316 3.20 198 297 396 495 594 693 792 891 990 1089 1188 3.10 178 267 356 446 535 624 713 802 891 980 1069 3.00 160 240 320 400 479 559 639 719 799 879 959 2.75 123 185 246 308 369 431 492 554 615 677 739 2.50 92.5 139 185 231 277 324 370 416 462 509 555 2.25 67.4 101 135 169 202 236 270 303 337 371 404 2.00 47.3 71.0 94.7 118 142 166 189 213 237 260 284 1.75 31.7 47.6 63.4 79.3 95.2 111 127 143 159 174 190 1.50 20.0 30.0 40.0 49.9 59.9 69.9 79.9 89.9 99.9 110 120 1122 1496 1870 2244 2618 2992 3366 3740 4114 4488 1128 1410 1692 1974 2256 2538 2820 3102 3384 1120 1344 1568 1792 2016 2240 2464 2688 1141 1331 1521 1712 1902 2092 2282 1120 1280 1440 1600 1760 1920 1.25 11.6 17.3 23.1 28.9 34.7 40.5 46.2 52.0 57.8 63.6 69.4 1.00 5.9 8.9 11.8 14.8 17.8 20.7 23.7 26.6 29.6 32.6 35.5 Caluclation example: Influencing parameter B: Height of mullion L: 1.25 m 2.5 m Solution for assembly heights 0 m to 8 m: Ix mullion = 231 cm4 (see list) Solution for assembly heights > 8 m to 20 m (conversion factor 1.6) Ix mullion = 231 cm4 x 1.6 = 370 cm4 Solution for assembly heights > 20 m to 100 m and timber with E-Module 13000: (Factor wind 2.2 and factor E-module 0.85) Ix mullion = 231 cm4 x 2.2 x 0.85 = 432 cm4 484 2016 KH-0601 THERM+ H-V Accessories Timber curtain wall 50/56/76 mm Static table Statical and technical parameters ■ Technical information – Caluclation example: Determined necessary statical parameter lx = 231cm4. – Used timber profile: 50 x 90 or 60 x 80 mm. List 1: Statical parameters lx Mullion width (mm) Mullion depth (mm) 50 60 70 80 90 100 50 52.08 62.50 72.92 83.33 93.75 104.17 60 90.00 108.00 126.00 144.00 162.00 180.00 70 142.92 171.50 200.08 228.67 257.25 285.83 80 213.33 256.00 298.67 341.33 384.00 426.67 90 303.75 364.50 425.25 486.00 546.75 607.50 100 416.67 500.00 583.33 666.67 750.00 833.33 120 720.00 864.00 1008.00 1152.00 1296.00 1440.00 140 1143.33 1372.00 1600.67 1829.33 2058.00 2286.67 160 1706.67 2048.00 2389.33 2730.67 3072.00 3413.33 180 2430.00 2916.00 3402.00 3888.00 4374.00 4860.00 200 3333.33 4000.00 4666.67 5333.33 6000.00 6666.67 220 4436.67 5324.00 6211.33 7098.67 7986.00 8873.33 240 5760.00 6912.00 8064.00 9216.00 10368.00 11520.00 260 7323.33 8788.00 10252.67 11717.33 13182.00 14646.67 280 9146.67 10976.00 12805.33 14634.67 16464.00 18293.33 300 11250.00 13500.00 15750.00 18000.00 20250.00 THERM+ H-V Assembly options result Ix [cm4] List 2: Statical parameters ly Mullion width (mm) Mullion depth (mm) 50 60 70 80 90 100 50 52.08 90.00 142.92 213.33 303.75 416.67 60 62.50 108.00 171.50 256.00 364.50 500.00 70 72.92 126.00 200.08 298.67 425.25 583.33 80 83.33 144.00 228.67 341.33 486.00 666.67 90 93.75 162.00 257.25 384.00 546.75 750.00 100 104.17 180.00 285.83 426.67 607.50 833.33 120 125.00 216.00 343.00 512.00 729.00 1000.00 140 145.83 252.00 400.17 597.33 850.50 1166.67 160 166.67 288.00 457.33 682.67 972.00 1333.33 180 187.50 324.00 514.50 768.00 1093.50 1500.00 200 208.33 360.00 571.67 853.33 1215.00 1666.67 220 229.17 396.00 628.83 938.67 1336.50 1833.33 240 250.00 432.00 686.00 1024.00 1458.00 2000.00 260 270.83 468.00 743.17 1109.33 1579.50 2166.67 280 291.67 504.00 800.33 1194.67 1701.00 2333.33 300 312.50 540.00 857.50 1280.00 1822.50 2500.00 result Iy [cm4] 2016 485 486 2016 Content Integration elements 489 490 491 THERM+ 50 H-V with WING 50 SK THERM+ 50 H-V with WING 50 A THERM+ 50 H-V with FRAME+ 75 DI 492 493 494 THERM+ H-I/H-V Integration elements THERM+ 50 H-I with FRAME+ 75 WB THERM+ 50 H-I with FRAME+ 75 WA THERM+ 50 H-I with FRAME+ 90 WB-T 2016 487 488 2016 THERM+ H-V Integration elements 50/56/76 mm Timber curtain wall + 50 H-I with FRAME+ + 75 WB with frame 26/50/21 THERM+ Mullion section hinge side - turn-tilt sash ■ Technical information ■ Profiles – Dimensions and article numbers may vary in the different system widths 56 and 76 mm. Article Integration outer frame 26/50/21 Casement sash profile 51/35 Driving rod 20 No. PU 207666 6m 214902 6m 225530 6m ■ Gaskets Article No. PU Exterior glazing gasket 220300 100 m Interior gasket 11 220324 75 m Interior stop gasket 7 220337 200 m Insulating block medial gasket 220611 50 m Compensation gasket 2 227010 100 m No. PU 167606 10 pc(s) Article Assembly angle piece 50/6 THERM+ H-I/H-V Integration elements ■ Accessories 220324 HI-0533 2016 489 THERM+ H-V Integration elements 50/56/76 mm Timber curtain wall + 50 H-I with FRAME+ + 75 WA with frame 42/17 THERM+ Transom section head end - top-hung sash ■ Technical information ■ Profiles – Dimensions and article numbers may vary in the different system widths 56 and 76 mm. Article No. PU Integration outer frame 42/17 217010 6m Sash profile 45/92.5 217015 6m Glazing bead 22/47 218447 6m Driving rod 20 225530 6m ■ Gaskets Article No. PU Rope 4 220075 100 pc(s) Stop gasket 220214 200 m Glazing gasket 5 to 6 F 220405 100 m Exterior glazing gasket 4.5 220550 100 m Exterior noise protection gasket 220552 100 m Sealing frame vulcanised 220615.R Sealing frame vulcanised 220615.RT Compensation gasket 2 490 2016 HI-0534 227010 100 m THERM+ H-V Integration elements 50/56/76 mm Timber curtain wall + 50 H-I with FRAME+ + 90 WB-T with frame 27/67 THERM+ Transom section base point - turn-tilt sash ■ Technical information ■ Profiles – Dimensions and article numbers may vary in the different system widths 56 and 76 mm. Article No. PU Integr. outer frame 27/67 215380 6m Sash profile 68/32.5 215385 6m Glazing bead external 218250 6m Driving rod 20 225530 6m ■ Gaskets Article Exterior glazing gasket Corner vulcanisation for medial gasket Corner vulcanisation for medial gasket Stop gasket 10.5 No. PU 220650 100 m 220660.R 1 pc(s) 220660.RT 1 pc(s) 220670 200 m Interior gasket 9 220686 50 m Compensation gasket 4 227015 100 m ■ Accessories No. PU Glass carrier 225025 100 pc(s) Insulation insertion 16/47 227951 50 m Insul. insertion 20.5/41.5 Pan head wood screw 3.5x10 Pan head wood screw 3.5x20 227966 50 m 907551 100 pc(s) 907552 100 pc(s) THERM+ H-I/H-V Integration elements Article HI-0535 2016 491 THERM+ H-V Integration elements 50/56/76 mm Timber curtain wall + 50 H-V with WING 50 SK with stepped edge glazing THERM+ Transom section base point - top hung sash ■ Technical information ■ Profiles – Dimensions and article numbers may vary in the different system widths 56 and 76 mm. Article No. PU Interior sash profile 12/55 204000 6m Exterior sash profile 204110 6m Outer frame 35/72 205000 6m Frame profile 218040 6m Glazing profile 6 218082 6m Article No. PU Rope 3 220065 200 m Interior glazing gasket 5 to 6 220110 100 m Cover gasket 220190 100 m Stop gasket 220214 200 m 220226.R 1 pc(s) ■ Gaskets Corner vulcanised medial gasket Corner vulcanised medial gasket 220226.RT 1 pc(s) ■ Accessories Article Driving rod 20 Special flat fillister head screw 4.8x19 Special countersunk sheet metal screw 3.9x13 492 2016 HV-0533 No. PU 225505 6m 230070 100 pc(s) 230075 100 pc(s) THERM+ H-V Integration elements 50/56/76 mm Timber curtain wall + 50 H-V with WING 50 A as bottom-hung sash THERM+ Transom section base point with hinge - bottom-hung sash ■ Technical information ■ Profiles – Dimensions and article numbers may vary in the different system widths 56 and 76 mm. Article No. PU Interior sash profile 12/55 204000 6m Exterior sash profile 204100 6m Outer frame 45/82/6 205100 6m Frame profile 18 218041 6m ■ Gaskets Article No. PU Rope 3 220065 200 m Interior glazing gasket 5 to 6 220110 100 m Cover gasket 220190 100 m Gasket for pressure profile 2/16 220205 100 m Stop gasket 220214 200 m 220226.R 1 pc(s) Corner vulcanised medial gasket Corner vulcanised medial gasket 220226.RT 1 pc(s) ■ Accessories No. PU Driving rod 20 225505 6m Special flat fillister head screw 4.8x19 230070 100 pc(s) THERM+ H-I/H-V Integration elements Article HV-0534 2016 493 THERM+ H-V Integration elements 50/56/76 mm Timber curtain wall + 50 H-V with FRAME+ + 75 DI with frame 44/65/21 Basic Style THERM+ Mullion section hinge side - door ■ Technical information ■ Profiles – Dimensions and article numbers may vary in the different system widths 56 and 76 mm. Article No. PU Glazing bead 22/47 218447 6m Integration outer frame 44/65/21 314002 6m Sash profile 84/71 314100 6.5 m ■ Gaskets Article No. PU Rope 4 220075 100 pc(s) Glazing gasket 5 to 6 F 220405 100 m Exterior glazing gasket 4.5 220550 100 m Compensation gasket 2 227010 100 m Kederdichtung 320002 200 m Stop gasket 7 320100 200 m No. PU 167608 10 pc(s) ■ Accessories Article Assembly angle piece 50/8 494 2016 HV-0535 Content Thermal insulation 497 508 521 THERM+ H-I/H-V Thermal insulation Basic information on curtain wall systems Uf-values THERM+ H-I Uf-values THERM+ H-V 2016 495 496 2016 THERM+ H-I/H-V Thermal insulation Determination of the Ucw-value Different possibilities Used symbols and indices Abbreviations: Ag, A p Af, At, Am U g, U p Uf, Ut, Um Ψf,g, Ψm,g, Ψt,g, Ψp Ψm,f, Ψt,f Surface ratios of the fillings Surface ratios of the profiles Thermal transmission coefficient of the fillings Thermal transmission coefficient of the frame, the transom and the mullion Length-related thermal transmission coefficient due to combined thermal effects between glazing, panel, and frame to mullion/transom. Length-related thermal transmission coefficient due to combined thermal effects between frame to mullion/transom. More used symbols: A b B U I ε λ Ψ Surface Width of the thermal separation zone in a profile Facing width of a profile Thermal transmission coefficient (U value) Length of the linear thermal bridge Emission ratio Thermal conductivity Linear thermal transmission coefficient Used indices: cw f g m p t w curtain wall frame glasss mullion panel transom window m2 mm mm W/m2K m W/mK W/mK Determination of the Ucw-value according to DIN EN ISO 12631: 2012 For calculating the UCW-value for curtain walls the standard DIN EN ISO 12631: 2012 offers three different procedures: 1. Determination of the UCW-value by means of the surface-related thermal transmission coefficient of joints UTJ 2. Determination of the UCW-value by means of the length-related thermal transmission coefficient of joints ΨTJ 3. Determination of the UCW-value by evaluating the individual components In the following, the third procedure ‘Determination of the UCW-value by evaluating the individual components’ will be described and explained. Whatever information the customer needs for calculating UCW-values on his or her own will be provided here. Determination of the Ucw-value by evaluating the individual components This prodecure applies to curtain walls, such as element façades, stick systems (mullion/transom), and dry glazing. Do not use it for structural glazing with silicone adhesion, rear-ventilated façades, nor SG glazing. For calculating the UCW-value a representative element of the overall façade is selected and its value calculated. Not only the U values of the individual components but also the edge bond of insulation glass and façade panels acting as a thermal bridge have to be considered along with the Ψ-value. The thermal transmission coefficient of a single element of the curtain wall UCW is calculated according to the following formula: ΣAgUg + ΣApUp + ΣAmUm + ΣAtUt + ΣAfUf+ Σlf,gΨf,g + Σlm,gΨm,g + Σlt,gΨt,g + ΣlpΨp + Σlm,f Ψm,f + Σlt,f Ψt,f Acw Determination of the total surface of the façade: Acw = Ag + Ap + Af + Am + At If a façade consists of different elements, an average value of the thermal transmission coefficient regarding the various surfaces must be calculated. This is done with the help of the following formula: Ucw, tot = Σ(Ucw, j Acw, j) ΣAcw, j Σ(Ucw, j Acw, j) = Sum of the products of the thermal transmission coefficients and the respective surfaces of the various modules. ΣAcw, j = Sum of the surfaces of the various elements. 2016 497 THERM+ H-I/H-V Thermal insulation Ucw = THERM+ H-I/H-V Thermal insulation Definition of the surfaces Glazed surfaces The glazed surface Ag or the surface of a panel Ap of a component respectively, is the smallest of the surfaces visible from both sides (see illustrations below). The overlapping of panel or glazing because of the sealings can be neglected. Visible total length of the perimeter of the glazing/the panel The total perimeter length of glazing lg or of panel lp is the sum of the glazing’s, or panel’s, visible perimeters. In case of varying visible perimeters, it is defined by the cutting site of the glass pane and the frame (see illustration above). Surface ratios of frame, mullion, and transom The division of the surface ratios must be done according to the illustration below: assembly 498 2016 THERM+ H-I/H-V Thermal insulation Division of the surface of a curtain wall section 1 to 1 Af Am Af window section 2 to 2 Panel Af At fixed glazing section 3 to 3 section 4 to 4 section 6 to 6 Am At At THERM+ H-I/H-V Thermal insulation section 5 to 5 Am Af 2016 499 THERM+ H-I/H-V Thermal insulation Representative elements In order to calculate the UCW-value of a curtain wall it is necessary to select a representative element. It is important that the chosen element mirrors the surface ratios with various thermal qualities of the overall façade, such as glazings, window parapets and so on, and how they are attached (by mullion and transom, silicon joint, etc.). Said element is limited by section planes which must be within an adiabatic range. These may either be – symmetry planes or – planes where the heat flow runs at a right angle to the plane of the curtain wall, i. e. there are no influences from the edge (for example, having a distance of at least 190 mm to the edge of a window with double glazing). The illustration below shows the adiabatic lines (in the center of the glass pane, or panel, at a sufficient distance to the frame). Section planes are permissible here because the heat flow runs at a right angle to the glass panes. Notice: The section planes must not necessarily be geometrical limits of the elements (such as the frame) to due to the fact that the center of a frame often is not necessarily an adiabatic limit. This circumstance might be caused by the asymmetrical geometrical form of the frame, asymmetrical qualities of the material (such as components with differing heat conductivity on both sides of the frame), or the asymmetrical attachment of the panels in a symmetrical frame. 500 2016 THERM+ H-I/H-V Thermal insulation Calculation of th Ψg-value Ψg value of glazings Length-related thermal transmission coefficient Ψm,g, Ψt,g and Ψf,g in W/(mK) Type of mullion/transom/window frame Double or triple insulation glazing, uncoated glass, air or gas interspace Double or triple insulation glazing with low emission value, air or gas interspace. - Single coating with double glazing - Double coating with triple glazing Chart B.1 Appendix B DIN EN ISO 12631 Distance pieces made of aluminium and steel in mullion or transom profiles Ψm,g, Ψt,g Timber to Aluminium Metal frames with thermal separation Chart B.2 Appendix B DIN EN ISO 12631 0.08 0.11 di 100 mm: 0.13 di 200 mm: 0.15 di 100 mm: 0.17 di 200 mm: 0.19 Thermally improved distance pieces in mullion profiles or transom profiles Ψm,g, Ψt,g (See Chapter 2.1.2 on a definition of thermally improved distance pieces.) Timber to Aluminium Metal frames with thermal separation Chart B.3 Appendix B DIN EN ISO 12631 0.06 0.08 di 100 mm: 0.09 di 200 mm: 0.10 di 100 mm: 0.11 di 200 mm: 0.12 Distance pieces made of aluminium or steel Ψf,g in window elements (also insert elements in façades) Timber and synthetics 0.06 0.08 Metal frames with thermal separation 0.08 0.11 Metal frames without thermal separation 0.02 0.05 Chart B.4 Appendix B DIN EN ISO 12631 Thermally improved distance pieces Ψf,g in window elements (also insert elements in façades) Timber and synthetics 0.05 0.06 Metal frames with thermal separation 0.06 0.08 Metal frames without thermal separation 0.01 0.04 THERM+ H-I/H-V Thermal insulation (di = room-sided depth of the mullion/transom) 2016 501 THERM+ H-I/H-V Thermal insulation Determination of the Ψg-value Determination for curtain walls with double or triple insulation glazing Since the data sheets issued by the German association Bundesverband Flachglas apply to window systems and not to curtain wall systems, the Ψg-values for curtain walls have to be calculated. The basis for this is the ift guideline WA-13/1 “Ψ-values for curtain walls”. In the glazing, a distinction is made between double and triple insulation glazing. Outside Inside Interspace between glass panes The representative structure of a Spacer – Double insulation glazing is 6/16/6 with Ug = 1.1 W/(m K). 2 Secondary seal – Triple insulation glazing is 6/14/4/14/6 with Ug = 0.7 W/(m2K). The transmissions on other glass structures are possible, as shown in the two illustrations. The Ψ-values can be transmitted on – Double insulation glazings with Ug ≥ 1.0 W/(m2K). – Triple insulation glazings with Ug ≥ 0.5 W/(m2K). Double insulation glazing Outside Inside Interspace between glass panes Spacer Secondary seal Triple insulation glazing 502 2016 THERM+ H-I/H-V Thermal insulation Determination of the Ψ-value Ψ-values double insulation glazing THERM+ Timber H-I/H-V Ψg-values in W/(m2K) THERM+ H-I without insulating block THERM+ H-I with insulating block P THERM+ H-V without insulating block THERM+ H-V with insulating block P ACS plus 0.039 0.042 0.038 0.042 Swisspacer Ultimate 0.039 0.042 0.038 0.042 Swisspacer V 0.043 0.046 0.041 0.045 Super Spacer TriSeal 0.045 0.048 0.043 0.047 Ködispace 0.047 0.050 0.045 0.050 Nirotec EVO 0.050 0.054 0.048 0.053 Chromatech Ultra F 0.051 0.055 0.049 0.054 TGI-Spacer 0.053 0.056 0.050 0.056 TGI-Spacer M 0.053 0.057 0.051 0.057 THERMIX TX.N 0.054 0.058 0.052 0.058 GTS 0.065 0.069 0.063 0.069 Nirotec 15 0.067 0.071 0.064 0.070 Swisspacer 0.066 0.071 0.064 0.071 Chromatech Plus 0.068 0.072 0.065 0.072 Nirotec 17 0.069 0.074 0.067 0.073 Chromatech 0.072 0.077 0.069 0.076 WEP classic 0.072 0.077 0.069 0.076 Aluminium 0.103 0.108 0.100 0.108 THERM+ H-I/H-V Thermal insulation System 2016 503 THERM+ H-I/H-V Thermal insulation Determination of the Ψ-value Ψ-values triple insulation glazing THERM+ Timber H-I/H-V Ψg-values in W/(m2K) THERM+ H-I without insulating block System THERM+ H-I with insulating block P THERM+ H-V without insulating block THERM+ H-V with insulating block P THERM+ H-V with insulating block PH ACS plus 0.031 0.034 0.030 0.033 0.032 Swisspacer Ultimate 0.031 0.034 0.030 0.034 0.032 Swisspacer V 0.034 0.037 0.033 0.037 0.036 Super Spacer TriSeal 0.036 0.039 0.035 0.039 0.037 Ködispace 0.038 0.042 0.037 0.041 0.040 Nirotec EVO 0.041 0.045 0.040 0.045 0.043 Chromatech Ultra F 0.042 0.046 0.041 0.046 0.044 TGI-Spacer 0.044 0.047 0.042 0.047 0.046 TGI-Spacer M 0.044 0.048 0.043 0.048 0.046 THERMIX TX.N 0.045 0.049 0.044 0.049 0.047 Swisspacer 0.055 0.060 0.054 0.060 0.058 GTS 0.057 0.062 0.055 0.061 0.059 Nirotec 15 0.058 0.063 0.056 0.063 0.060 Chromatech Plus 0.060 0.065 0.058 0.064 0.062 Nirotec 17 0.061 0.066 0.059 0.066 0.063 Chromatech 0.065 0.070 0.063 0.069 0.067 WEP classic 0.065 0.070 0.063 0.069 0.067 Aluminium 0.105 0.111 0.102 0.110 0.103 504 2016 THERM+ H-I/H-V Thermal insulation Ψp-value of panels Length-related thermal transmission coefficient Ψp according to DIN EN ISO 12631 Heat conductivity of distance piece λW/(mK) Length-related thermal transmission coefficient Ψp W/(mK) – 0.13 Aluminium/Aluminium 0.2 0.4 0.20 0.29 Aluminium/Glass 0.2 0.4 0.18 0.20 Steel/Glass 0.2 0.4 0.14 0.18 Type of filling Aluminium/Aluminium Panel type 1 with cladding Aluminium/Glass Steel/Glass Panel type 2 with cladding The Ψp-values may be used if no other values from measuring or detailed calculations are available. Panel type 1 1 Panel type 2 3 1 2 4 2 6 5 5 Abbreviations: 1 Aluminium 2.5 mm/Steel 2.0 mm 3 4 Abbreviations: 1 Aluminium 2.5 mm/Steel 2.0 mm 2 Insulating material λ = 0.025 W/(mK) to 0.04 W/(mK) 2 Insulating material λ = 0.025 W/(mK) to 0.04 W/(mK) 3 Air filled interspace 0 to 20 mm 3 Aluminium 2.5 mm/Glass 6 mm 4 Aluminium 2.5 mm/Glass 6 mm 4 Distance piece λ = 0.2 W/(mK) to 0.4 W/(mK) 5 Distance piece λ = 0.2 W/(mK) to 0.4 W/(mK) 5 Aluminium THERM+ H-I/H-V Thermal insulation 6 Aluminium 2016 505 THERM+ H-I/H-V Thermal insulation Ψp-value of insert elements The Ψ-value between mullion/transom and clamping frame (Ψm/t,f-value) can be calculated according to DIN EN ISO 10077-2 or read from Chart B.6 DIN EN ISO 12631 if no measuring results are available. Length related thermal transmission coefficient Ψm,f and Ψt,f in W/(mK) Illustration 506 2016 Type of attachment Description Length-related thermal transmission coefficient Ψm,f or Ψt,f W/(mK) A Mounting of the frame in the mullion/transom, with additional aluminium profile with thermotechnical separation zone 0.11 B Mounting of the frame in the mullion/transom, with plastic adapter profile, e. g. polyamide plastic 6.6 with a glass fibre content of 25% (λ ≤ 0.3 W/(mK)) 0.05 C1 Mounting of the frame in the mullion/transom, with extended thermal separation of the frame 0.07 C2 Mounting of the frame in the mullion/transom, with extended thermal separation of the frame, e. g. polyamide plastic 6.6 with a glass fibre content of 25% (λ ≤ 0.3 W/(mK)) 0.07 D Mounting of the frame in the mullion/transom, with extended exterior aluminium profile and filling material of low heat conductivity (λ ≤ 0.3 W/(mK)) 0.07 THERM+ H-I/H-V Thermal insulation Determination of the U-value in general Up-values of panels The Up-values of panels are available from the panel manufacturer. Uf values for RAICO window systems For the values of all FRAME+ aluminium window systems, please see chapter Thermal insulation in our catalogues FRAME+ aluminium window systems. Uf-values for RAICO door systems The Uf-values of RAICO door systems 75 DI are shown in chapter Thermal insulation in our catalogues FRAME+ aluminium door systems. Uf-values for RAICO curtain wall systems For the Uf-values of RAICO curtain wall systems, please refer to the catalogues THERM+, chapter Thermal insulation. Influence of screws Calculating the U-values of mullions and transoms of a stick-system façade (Um/Ut) according to DIN EN ISO 10077-2, the influence of screws acting as an additional thermal bridge is not considered. Therefore, that influence’s value must be added as well: Um/t = U0 + ΔU Abbreviations: Um/t Thermal transmission coefficient mullion/transom considering the influence of the screws U0 Thermal transmission coefficient mullion/transom without the influence of the screws ΔU Thermal transmission coefficient of the screws ΔU can be determined by means of the following procedures: – Calculation according to DIN EN ISO 10211 – Calculation according to DIN EN ISO 12631, Appendix C – Measuring according to DIN EN 12412-2 – Reading from Chart 2 DIN EN ISO 12631 Chart 2 in DIN EN ISO 12631: Screw diameter (made of stainless steel) Distance between screws (made of stainless steel) ΔU value ≤ 6 mm 200 mm to 300 mm 0.3 THERM+ H-I/H-V Thermal insulation Important! Regarding the Uf-values of mullions and transoms illustrated in the catalogues THERM+, the influence of the screws as determined by the ift Rosenheim has been considered. 2016 507 THERM+ H-I/H-V Thermal insulation THERM+ H-I 50/56/76/96 mm Uf-values pressure profile uncoated and cover profile Mullion section/transom section ■ Technical information – Uf-value in W/(m2K) acc. to DIN EN ISO 10077-2 including screw influence 0.18. – Values also valid for all approved interior gasket variants. – Values valid for exterior gasket 3 mm and all standard cover profile options. – T13 = Infill thickness. Uf-values mullion Infill thickness mm System width mm 50 56 76 96 24 1.68 1.57 1.52 1.53 28 1.63 1.52 1.47 1.50 32 1.58 1.49 1.43 1.47 36 1.54 1.46 1.40 1.45 40 1.51 1.43 1.38 1.43 44 1.49 1.41 1.36 1.40 48 1.47 1.39 1.34 1.38 52 1.45 1.38 1.32 1.38 56 1.43 1.36 1.30 1.37 60 1.42 1.35 1.29 1.36 64 1.40 1.34 1.28 1.36 Uf-values transom 508 2016 HI-0152 Infill thickness mm System width mm 50 56 76 96 24 1.78 1.62 1.42 1.43 28 1.71 1.57 1.39 1.40 32 1.66 1.52 1.36 1.38 36 1.61 1.49 1.34 1.36 40 1.57 1.45 1.32 1.35 44 1.54 1.44 1.30 1.34 48 1.51 1.40 1.28 1.31 52 1.49 1.39 1.27 1.31 56 1.47 1.37 1.26 1.30 60 1.46 1.35 1.25 1.30 64 1.44 1.34 1.24 1.30 THERM+ H-I/H-V Thermal insulation THERM+ H-I 50/56/76/96 mm Uf-values pressure profile coated Mullion section/transom section ■ Technical information – Uf-value in W/(m2K) acc. to DIN EN ISO 10077-2 including screw influence 0.18. – Values also valid for all approved interior gasket variants. – Values valid for exterior gasket 3 mm and all standard pressure profile options. – T13 = Infill thickness. Uf-values mullion Infill thickness mm System width mm 50 56 76 96 24 2.09 2.03 2.11 2.12 28 2.02 1.98 2.07 2.09 32 1.98 1.94 2.03 2.07 36 1.94 1.91 1.99 2.04 40 1.91 1.89 1.97 2.03 44 1.88 1.86 1.94 1.99 48 1.85 1.85 1.92 1.98 52 1.84 1.83 1.90 1.97 56 1.82 1.82 1.88 1.96 60 1.80 1.80 1.87 1.95 64 1.79 1.79 1.85 1.95 Uf-values transom HI-0153 Infill thickness mm System width mm 50 24 2.20 2.11 2.00 1.99 28 2.12 2.05 1.97 1.97 32 2.07 2.00 1.94 1.96 76 96 36 2.02 1.96 1.91 1.94 40 1.98 1.93 1.89 1.93 44 1.94 1.90 1.87 1.91 48 1.92 1.86 1.85 1.89 52 1.90 1.85 1.84 1.88 56 1.87 1.83 1.83 1.88 60 1.86 1.82 1.81 1.87 64 1.84 1.80 1.80 1.87 2016 509 THERM+ H-I/H-V Thermal insulation 56 THERM+ H-I/H-V Thermal insulation THERM+ H-I 50/56/76 mm Uf-values flat pressure profile coated Mullion section/transom section ■ Technical information – Uf-value in W/(m2K) acc. to DIN EN ISO 10077-2 including screw influence 0.18. – Values also valid for all approved interior gasket variants. – Values also valid for all approved screw connection variants. – T13 = Infill thickness. Uf-values mullion Infill thickness mm System width mm 50 56 76 24 2.45 2.35 2.41 28 2.32 2.24 2.31 32 2.24 2.17 2.23 36 2.18 2.11 2.18 40 2.11 2.06 2.12 44 2.07 2.02 2.10 48 2.03 2.00 2.07 52 2.00 1.97 2.04 56 1.98 1.95 2.02 60 1.96 1.93 2.00 64 1.94 1.91 1.98 Uf-values transom 510 2016 HI-0154 Infill thickness mm System width mm 50 56 76 24 2.56 2.46 2.28 28 2.41 2.32 2.19 32 2.32 2.24 2.12 36 2.23 2.17 2.07 40 2.17 2.11 2.04 44 2.12 2.06 2.01 48 2.07 2.03 1.99 52 2.04 1.99 1.97 56 2.01 1.97 1.95 60 1.98 1.94 1.94 64 1.96 1.92 1.92 THERM+ H-I/H-V Thermal insulation THERM+ H-I 50/56/76 mm Uf-values insulating block 9 Mullion section/transom section ■ Technical information – Uf-value in W/(m2K) acc. to DIN EN ISO 10077-2 including screw influence 0.18. – Values also valid for all approved interior gasket variants. – Values valid for exterior gasket 3 mm and all standard pressure profile options. – Values also valid für all standard cover and pressure profile options with insulating block 9. – T13 = Infill thickness. Uf-values mullion Infill thickness mm System width mm 50 56 76 24 1.70 1.63 1.64 28 1.63 1.57 1.60 32 1.59 1.53 1.57 36 1.56 1.51 1.55 40 1.53 1.49 1.53 44 1.51 1.47 1.51 48 1.50 1.46 1.49 52 1.48 1.45 1.48 56 1.47 1.43 1.46 60 1.46 1.42 1.46 64 1.45 1.42 1.44 Uf-values transom HI-0146 System width mm 50 56 76 24 1.74 1.67 1.58 28 1.68 1.61 1.54 32 1.63 1.58 1.52 36 1.59 1.54 1.50 40 1.56 1.52 1.48 44 1.54 1.49 1.46 48 1.52 1.48 1.45 52 1.50 1.46 1.44 56 1.48 1.45 1.43 60 1.47 1.44 1.42 64 1.46 1.42 1.42 2016 511 THERM+ H-I/H-V Thermal insulation Infill thickness mm THERM+ H-I/H-V Thermal insulation THERM+ H-I 50/56/76 mm Uf-values insulating block 21 Mullion section/transom section ■ Technical information – Uf-value in W/(m2K) acc. to DIN EN ISO 10077-2 including screw influence 0.18. – Assembly of insulating block 17, no. 151035 for system width 76 mm. – Values also valid for all approved interior gasket variants. – Values valid for all standard cover profile options. – T13 = Infill thickness. Uf-values mullion Infill thickness mm System width mm 50 56 76 24 1.43 1.37 1.45 28 1.30 1.25 1.43 32 1.25 1.21 1.40 36 1.21 1.17 1.38 40 1.18 1.15 1.37 44 1.17 1.13 1.35 48 1.16 1.13 1.34 52 1.16 1.12 1.33 56 1.15 1.12 1.32 60 1.14 1.11 1.31 64 1.14 1.11 1.31 Uf-values transom 512 2016 HI-0147 Infill thickness mm System width mm 50 56 76 24 1.44 1.38 1.42 28 1.31 1.26 1.39 32 1.26 1.23 1.36 36 1.22 1.19 1.34 40 1.20 1.17 1.33 44 1.18 1.15 1.32 48 1.17 1.14 1.30 52 1.16 1.13 1.30 56 1.16 1.13 1.29 60 1.15 1.12 1.29 64 1.14 1.11 1.28 THERM+ H-I/H-V Thermal insulation THERM+ H-I 50/56/76 mm Uf-values insulating block 21 Mullion section/transom section ■ Technical information – Uf-value in W/(m2K) acc. to DIN EN ISO 10077-2 including screw influence 0.18. – Assembly of insulating block 17, no. 151035 for system width 76 mm. – Values also valid for all approved interior gasket variants. – Values valid for all standard pressure profile options. – T13 = Infill thickness. Uf-values mullion Infill thickness mm System width mm 50 56 76 24 1.44 1.38 1.47 28 1.30 1.26 1.44 32 1.25 1.22 1.42 36 1.21 1.18 1.39 40 1.18 1.15 1.38 44 1.17 1.14 1.36 48 1.16 1.13 1.35 52 1.15 1.13 1.34 56 1.15 1.13 1.33 60 1.14 1.11 1.32 64 1.14 1.11 1.32 Uf-values transom HI-0151 System width mm 50 56 76 24 1.45 1.39 1.43 28 1.31 1.27 1.40 32 1.27 1.24 1.38 36 1.22 1.19 1.35 40 1.20 1.17 1.34 44 1.19 1.16 1.33 48 1.18 1.15 1.31 52 1.17 1.14 1.31 56 1.16 1.13 1.30 60 1.15 1.13 1.29 64 1.14 1.12 1.29 2016 513 THERM+ H-I/H-V Thermal insulation Infill thickness mm THERM+ H-I/H-V Thermal insulation THERM+ H-I 50/56/76 mm Uf-values insulating block P Mullion section/transom section ■ Technical information Selection insulating block – Uf-value in W/(m K) acc. to DIN EN ISO 10077-2 including screw influence 0.18. – Values also valid for all coated standard pressure profiles with visible screw connection. – Values also valid for all approved interior gasket variants. – Values valid for exterior gasket 3 mm and all standard cover profile options. – All values passive house standard. – T13 = Infill thickness. 2 Infill thickness mm System width mm 50 56 76 No. No. No. 24 to 29 168509 168515 168521 30 to 43 168510 168516 168522 44 to 64 168514 168520 168522 Uf-values mullion Infill thickness mm System width mm 50 56 76 24 1.42 1.35 1.28 28 1.30 1.25 1.21 32 1.18 1.14 1.10 36 1.14 1.10 1.08 40 1.10 1.07 1.06 44 1.02 0.99 1.05 48 0.97 0.95 1.04 52 0.96 0.94 1.04 56 0.96 0.94 1.03 60 0.95 0.93 1.03 64 0.95 0.93 1.03 Uf-values transom 514 2016 HI-0148 Infill thickness mm System width mm 50 56 76 24 1.43 1.36 1.26 28 1.31 1.26 1.19 32 1.19 1.15 1.08 36 1.15 1.12 1.06 40 1.11 1.09 1.04 44 1.03 1.00 1.03 48 0.98 0.96 1.02 52 0.97 0.95 1.02 56 0.97 0.95 1.01 60 0.96 0.94 1.01 64 0.96 0.94 1.01 THERM+ H-I/H-V Thermal insulation THERM+ H-I 50/56/76 mm Uf-values insulating block P Mullion section/transom section ■ Technical information Selection insulating block – Uf-value in W/(m K) acc. to DIN EN ISO 10077-2 including screw influence 0.18. 2 – Values also valid for all approved interior gasket variants. – Values also valid for all approved screw connection variants. – All values passive house standard. – T13 = Infill thickness. Infill thickness mm System width mm 50 56 76 No. No. No. 32 to 39 168509 168515 168521 40 to 53 168510 168516 168522 54 to 64 168514 168520 168522 Uf-values mullion Infill thickness mm System width mm 50 56 76 32 1.33 1.29 1.21 36 1.22 1.18 1.14 40 1.12 1.09 1.04 44 1.07 1.04 1.01 48 1.03 1.01 1.00 52 0.93 0.91 0.99 56 0.89 0.87 0.97 60 0.88 0.86 0.97 64 0.87 0.85 0.96 Uf-values transom HI-0149 System width mm 50 56 76 32 1.34 1.29 1.20 36 1.23 1.19 1.12 40 1.12 1.09 1.03 44 1.08 1.05 1.00 48 1.05 1.02 0.97 52 0.94 0.91 0.96 56 0.90 0.87 0.96 60 0.89 0.87 0.96 64 0.88 0.86 0.94 2016 515 THERM+ H-I/H-V Thermal insulation Infill thickness mm THERM+ H-I/H-V Thermal insulation THERM+ H-I 50/56 mm Uf-values pressure profile uncoated and cover profile, insulating block PH Mullion section/transom section ■ Technical information – Uf-value in W/(m2K) acc. to DIN EN ISO 10077-2 including screw influence 0.18. – Values also valid for all approved interior gasket variants. – Values valid for exterior gasket 3 mm and all standard cover profile options. – All values passive house standard. – T13 = Infill thickness. Uf-values mullion Infill thickness mm System width mm 50 56 36 1.12 1.10 40 0.99 0.98 44 0.92 0.90 48 0.85 0.85 52 0.83 0.82 56 0.81 0.81 60 0.79 0.79 64 0.78 0.78 Uf-values transom Infill thickness mm 516 2016 HI-0201 System width mm 50 56 36 1.12 1.10 40 1.02 1.00 44 0.96 0.94 48 0.91 0.90 52 0.89 0.88 56 0.87 0.86 60 0.85 0.85 64 0.84 0.84 THERM+ H-I/H-V Thermal insulation THERM+ H-I 50/56 mm Uf-values insulating block P passive house Mullion section/transom section ■ Technical information – Uf-value in W/(m2K) acc. to DIN EN ISO 10077-2 including screw influence 0.18. – Values also valid for all coated standard pressure profiles with visible screw connection. – Values also valid for all approved interior gasket variants. – Values valid for exterior gasket 5 mm and all standard cover profile options. - Execution with exterior gasket 5 mm, glass bite 13 mm (for 50 und 56) and insulating block P no. 168514 (50) or 168520 (56). – All values passive house certified. – T13 = Infill thickness. Uf-values mullion Infill thickness mm System width mm 50 56 44 0.99 0.98 48 0.96 0.97 52 0.95 0.96 56 0.94 0.95 60 0.93 0.95 64 0.93 0.95 Uf-values transom HI-0204 System width mm 50 56 44 1.00 0.99 48 0.97 0.99 52 0.96 0.97 56 0.95 0.97 60 0.94 0.96 64 0.94 0.96 2016 517 THERM+ H-I/H-V Thermal insulation Infill thickness mm THERM+ H-I/H-V Thermal insulation THERM+ H-I 76 mm Uf-values pressure profile uncoated and cover profile, insulating block P Mullion section/transom section ■ Technical information – Uf-value in W/(m2K) acc. to DIN EN ISO 10077-2 including screw influence 0.18. – Values also valid for all approved interior gasket variants. – Values valid for exterior gasket 5 mm and all standard cover profile options. – All values passive house certified. – T13 = Infill thickness. Uf-values mullion Infill thickness mm System width mm 44 0.87 48 0.86 76 52 0.84 56 0.83 60 0.82 64 0.82 Uf-values transom 518 2016 HI-0150 Infill thickness mm System width mm 44 0.87 48 0.86 52 0.83 76 56 0.83 60 0.82 64 0.81 THERM+ H-I/H-V Thermal insulation THERM+ H-I 50/56 mm Uf-values pressure profile coated, insulating block PH Mullion section/transom section ■ Technical information – Uf-value in W/(m2K) acc. to DIN EN ISO 10077-2 including screw influence 0.18. – Values also valid for all approved interior gasket variants. – Values valid for exterior gasket 3 mm and all standard pressure profile options. – All values passive house standard. – T13 = Infill thickness. Uf-values mullion Infill thickness mm System width mm 50 56 36 1.11 1.10 40 0.99 0.98 44 0.92 0.90 48 0.85 0.86 52 0.83 0.82 56 0.81 0.81 60 0.79 0.79 64 0.78 0.78 Uf-values transom HI-0202 System width mm 50 56 36 1.11 1.10 40 1.02 1.00 44 0.96 0.94 48 0.91 0.90 52 0.89 0.88 56 0.87 0.86 60 0.85 0.85 64 0.84 0.84 2016 519 THERM+ H-I/H-V Thermal insulation Infill thickness mm THERM+ H-I/H-V Thermal insulation THERM+ H-I 50/56 mm Uf-values flat pressure profile coated, insulating block PH Mullion section/transom section ■ Technical information – Uf-value in W/(m2K) acc. to DIN EN ISO 10077-2 including screw influence 0.18. – Values also valid for all approved interior gasket variants. – Values also valid for all approved screw connection variants. – All values passive house standard. – T13 = Infill thickness. Uf-values mullion Infill thickness mm System width mm 50 56 44 1.03 1.02 48 0.94 0.92 52 0.87 0.86 56 0.81 0.80 60 0.78 0.78 64 0.77 0.76 Uf-values transom Infill thickness mm 520 2016 HI-0203 System width mm 50 56 44 1.04 1.02 48 0.96 0.94 52 0.90 0.89 56 0.86 0.85 60 0.84 0.82 64 0.82 0.81 THERM+ H-I/H-V Thermal insulation THERM+ H-V 50/56/76 mm Uf-values pressure profile uncoated and cover profile Mullion section/transom section ■ Technical information – Uf-value in W/(m2K) acc. to DIN EN ISO 10077-2 including screw influence 0.18. – Values also valid for all approved interior gasket variants. – Values valid for exterior gasket 3 mm and all standard cover profile options. – T13 = Infill thickness. Uf-values mullion Infill thickness mm System width mm 50 56 76 24 1.71 1.57 1.40 28 1.65 1.53 1.37 32 1.61 1.49 1.34 36 1.57 1.46 1.32 40 1.54 1.43 1.30 44 1.51 1.41 1.28 48 1.48 1.39 1.27 52 1.47 1.37 1.25 56 1.45 1.36 1.25 60 1.43 1.34 1.24 64 1.42 1.33 1.23 Uf-values transom HV-0141 System width mm 50 56 76 24 1.65 1.51 1.33 28 1.60 1.47 1.31 32 1.57 1.44 1.29 36 1.53 1.41 1.27 40 1.51 1.39 1.26 44 1.48 1.36 1.24 48 1.46 1.35 1.24 52 1.44 1.33 1.23 56 1.43 1.32 1.22 60 1.41 1.31 1.21 64 1.40 1.30 1.20 2016 521 THERM+ H-I/H-V Thermal insulation Infill thickness mm THERM+ H-I/H-V Thermal insulation THERM+ H-V 50/56/76 mm Uf-values pressure profile coated Mullion section/transom section ■ Technical information – Uf-value in W/(m2K) acc. to DIN EN ISO 10077-2 including screw influence 0.18. – Values also valid for all approved interior gasket variants. – Values valid for exterior gasket 3 mm and all standard pressure profile options. – T13 = Infill thickness. Uf-values mullion Infill thickness mm System width mm 50 56 76 24 2.12 2.09 1.96 28 2.06 2.03 1.93 32 2.02 1.99 1.91 36 1.97 1.95 1.88 40 1.94 1.93 1.87 44 1.91 1.90 1.85 48 1.88 1.88 1.83 52 1.86 1.86 1.82 56 1.84 1.84 1.80 60 1.83 1.82 1.79 64 1.81 1.81 1.78 Uf-values transom 522 2016 HV-0142 Infill thickness mm System width mm 50 56 76 24 2.05 2.00 1.88 28 2.00 1.96 1.85 32 1.96 1.93 1.83 36 1.93 1.89 1.82 40 1.90 1.86 1.80 44 1.87 1.84 1.79 48 1.85 1.82 1.78 52 1.83 1.80 1.77 56 1.82 1.79 1.76 60 1.80 1.78 1.75 64 1.79 1.77 1.74 THERM+ H-I/H-V Thermal insulation THERM+ H-V 50/56/76 mm Uf-values flat pressure profile coated Mullion section/transom section ■ Technical information – Uf-value in W/(m2K) acc. to DIN EN ISO 10077-2 including screw influence 0.18. – Values also valid for all approved interior gasket variants. – Values also valid for all approved screw connection variants. – T13 = Infill thickness. Uf-values mullion Infill thickness mm System width mm 50 56 76 24 2.43 2.39 2.20 28 2.32 2.29 2.13 32 2.24 2.22 2.08 36 2.17 2.15 2.04 40 2.11 2.11 2.01 44 2.07 2.06 1.98 48 2.03 2.03 1.96 52 2.00 2.00 1.95 56 1.97 1.97 1.93 60 1.95 1.95 1.91 64 1.93 1.93 1.90 Uf-values transom HV-0143 System width mm 50 56 76 24 2.34 2.28 2.09 28 2.24 2.20 2.04 32 2.18 2.14 2.00 36 2.11 2.08 1.96 40 2.07 2.04 1.94 44 2.03 2.00 1.92 48 1.99 1.97 1.90 52 1.97 1.94 1.88 56 1.94 1.91 1.87 60 1.92 1.90 1.86 64 1.90 1.88 1.85 2016 523 THERM+ H-I/H-V Thermal insulation Infill thickness mm THERM+ H-I/H-V Thermal insulation THERM+ H-V 50/56/76 mm Uf-values insulating block 9 Mullion section/transom section ■ Technical information – Uf-value in W/(m2K) acc. to DIN EN ISO 10077-2 including screw influence 0.18. – Values also valid for all approved interior gasket variants. – Values valid for exterior gasket 3 mm and all standard pressure profile options. – Values also valid für all standard cover and pressure profile options with insulating block 9. – T13 = Infill thickness. Uf-values mullion Infill thickness mm System width mm 50 56 76 24 1.67 1.64 1.55 28 1.63 1.59 1.52 32 1.59 1.56 1.50 36 1.55 1.53 1.48 40 1.53 1.51 1.46 44 1.51 1.49 1.45 48 1.49 1.47 1.43 52 1.48 1.46 1.43 56 1.46 1.45 1.42 60 1.45 1.44 1.41 64 1.44 1.43 1.40 Uf-values transom 524 2016 HV-0135 Infill thickness mm System width mm 50 56 76 24 1.63 1.59 1.49 28 1.59 1.55 1.47 32 1.55 1.52 1.45 36 1.53 1.49 1.44 40 1.51 1.47 1.42 44 1.48 1.46 1.41 48 1.47 1.44 1.40 52 1.45 1.43 1.39 56 1.44 1.42 1.39 60 1.43 1.41 1.38 64 1.42 1.40 1.37 THERM+ H-I/H-V Thermal insulation THERM+ H-V 50/56/76 mm Uf-values insulating block 21 Mullion section/transom section ■ Technical information – Uf-value in W/(m2K) acc. to DIN EN ISO 10077-2 including screw influence 0.18. – Assembly of insulating block 17, no. 151035 for system width 76 mm. – Values also valid for all approved interior gasket variants. – Values valid for all standard cover profile options. – T13 = Infill thickness. Uf-values mullion Infill thickness mm System width mm 50 56 76 24 1.33 1.28 1.41 28 1.27 1.23 1.38 32 1.22 1.19 1.36 36 1.19 1.17 1.34 40 1.18 1.15 1.33 44 1.16 1.14 1.32 48 1.16 1.13 1.31 52 1.14 1.12 1.30 56 1.14 1.12 1.29 60 1.13 1.11 1.29 64 1.13 1.11 1.28 Uf-values transom HV-0137 System width mm 50 56 76 24 1.32 1.27 1.38 28 1.25 1.21 1.34 32 1.20 1.17 1.32 36 1.17 1.14 1.31 40 1.16 1.13 1.30 44 1.15 1.12 1.29 48 1.13 1.11 1.28 52 1.13 1.10 1.27 56 1.12 1.10 1.27 60 1.12 1.09 1.26 64 1.12 1.09 1.26 2016 525 THERM+ H-I/H-V Thermal insulation Infill thickness mm THERM+ H-I/H-V Thermal insulation THERM+ H-V 50/56/76 mm Uf-values insulating block 21 Mullion section/transom section ■ Technical information – Uf-value in W/(m2K) acc. to DIN EN ISO 10077-2 including screw influence 0.18. – Assembly of insulating block 17, no. 151035 for system width 76 mm. – Values also valid for all approved interior gasket variants. – Values vaild for all standard pressure profile options. – T13 = Infill thickness. Uf-values mullion Infill thickness mm System width mm 50 56 76 24 1.33 1.28 1.43 28 1.27 1.23 1.39 32 1.23 1.19 1.37 36 1.20 1.17 1.35 40 1.18 1.16 1.34 44 1.17 1.14 1.33 48 1.16 1.13 1.32 52 1.14 1.13 1.31 56 1.14 1.12 1.30 60 1.13 1.11 1.30 64 1.13 1.11 1.29 Uf-values transom 526 2016 HV-0140 Infill thickness mm System width mm 50 56 76 24 1.32 1.27 1.39 28 1.26 1.22 1.35 32 1.21 1.18 1.33 36 1.18 1.15 1.32 40 1.16 1.13 1.30 44 1.15 1.12 1.29 48 1.14 1.11 1.29 52 1.13 1.11 1.28 56 1.13 1.10 1.28 60 1.12 1.10 1.27 64 1.12 1.09 1.27 THERM+ H-I/H-V Thermal insulation THERM+ H-V 50/56/76 mm Uf-values insulating block P Mullion section/transom section ■ Technical information Selection insulating block – Uf-value in W/(m K) acc. to DIN EN ISO 10077-2 including screw influence 0.18. – Values also valid for all coated standard pressure profile options with visible screw connection. – Values also valid for all approved interior gasket variants. – Values valid for exterior gasket 3 mm and all standard cover profile options. – All values passive house standard. – From infill thickness 44 mm: - Passive house certified for system width 50 and 56 mm. - Execution with insulating block P no. 168514 (50 mm) or 168520 (56 mm). – T13 = Infill thickness. 2 Infill thickness mm System width mm 50 56 76 No. No. No. 24 to 27 168509 168515 168521 28 to 41 168510 168516 168522 42 to 64 168514 168520 168522 Uf-values mullion Infill thickness mm System width mm 50 56 76 24 1.32 1.27 1.22 28 1.28 1.24 1.19 32 1.15 1.12 1.08 36 1.12 1.09 1.05 40 1.09 1.07 1.04 44 0.94 0.92 1.03 48 0.93 0.91 1.02 52 0.93 0.91 1.02 56 0.92 0.90 1.02 60 0.92 0.90 1.01 0.91 0.90 1.00 64 Values passive house certified Uf-values transom System width mm 50 56 76 24 1.31 1.26 1.20 28 1.26 1.22 1.17 32 1.14 1.11 1.06 36 1.11 1.07 1.04 40 1.08 1.05 1.02 44 0.94 0.91 1.01 48 0.93 0.90 1.00 52 0.92 0.90 1.00 56 0.91 0.89 1.00 60 0.91 0.89 1.00 0.91 0.89 0.99 64 Values passive house certified HV-0138 2016 527 THERM+ H-I/H-V Thermal insulation Infill thickness mm THERM+ H-I/H-V Thermal insulation THERM+ H-V 50/56/76 mm Uf-values insulating block P Mullion section/transom section ■ Technical information Selection insulating block – Uf-value in W/(m K) acc. to DIN EN ISO 10077-2 including screw influence 0.18. 2 – Values also valid for all approved interior gasket variants. – Values also valid for all approved screw connection variants. – All values passive house standard. – T13 = Infill thickness. Infill thickness mm System width mm 50 56 76 No. No. No. 32 to 37 168509 168515 168521 38 to 51 168510 168516 168522 52 to 64 168514 168520 168522 Uf-values mullion Infill thickness mm System width mm 50 56 76 32 1.25 1.21 1.15 36 1.14 1.11 1.06 40 1.09 1.06 1.02 44 1.05 1.03 0.99 48 1.02 1.00 0.97 52 0.90 0.89 0.96 56 0.89 0.87 0.96 60 0.87 0.86 0.95 64 0.87 0.86 0.94 Uf-values transom 528 2016 HV-0136 Infill thickness mm System width mm 50 56 76 32 1.24 1.20 1.14 36 1.14 1.11 1.05 40 1.08 1.05 1.01 44 1.04 1.02 0.98 48 1.01 0.99 0.97 52 0.90 0.88 0.95 56 0.88 0.86 0.95 60 0.87 0.85 0.93 64 0.87 0.84 0.93 THERM+ H-I/H-V Thermal insulation THERM+ H-V 50/56 mm Uf-values pressure profile uncoated and cover profile, insulating block PH Mullion section/transom section ■ Technical information – Uf-value in W/(m2K) acc. to DIN EN ISO 10077-2 including screw influence 0.18. – Values also valid for all approved interior gasket variants. – Values valid for exterior gasket 3 mm and all standard cover profile options. – All values passive house standard. – From infill thickness 40 mm: - Passiv house certified with system width 50 mm. – T13 = Infill thickness. Uf-values mullion Infill thickness mm System width mm 50 56 36 1.05 1.03 40 0.98 0.97 44 0.93 0.93 48 0.91 0.90 52 0.88 0.88 56 0.87 0.87 60 0.85 0.86 64 0.84 0.85 Values passive house certified Uf-values transom System width mm 50 56 36 1.03 1.02 40 0.97 0.96 44 0.91 0.90 48 0.88 0.87 52 0.86 0.85 56 0.84 0.84 60 0.83 0.83 64 0.82 0.82 THERM+ H-I/H-V Thermal insulation Infill thickness mm Values passive house certified HV-0181 2016 529 THERM+ H-I/H-V Thermal insulation THERM+ H-V 76 mm Uf-values pressure profile uncoated and cover profile, insulating block PH Mullion section/transom section ■ Technical information – Uf-value in W/(m2K) acc. to DIN EN ISO 10077-2 including screw influence 0.18. – Values also valid for all coated standard pressure profiles with visible screw connection. – Values also valid for all approved interior gasket variants. – Values valid for exterior gasket 5 mm and all standard cover profile options. – All values passive house certified. – T13 = Infill thickness. Uf-values mullion Infill thickness mm System width mm 44 0.87 48 0.85 76 52 0.84 56 0.83 60 0.81 64 0.81 Uf-values transom 530 2016 HV-0139 Infill thickness mm System width mm 44 0.86 48 0.84 52 0.82 76 56 0.81 60 0.80 64 0.80 THERM+ H-I/H-V Thermal insulation THERM+ H-I 50/56 mm Uf-values pressure profile coated, insulating block PH Mullion section/transom section ■ Technical information – Uf-value in W/(m2K) acc. to DIN EN ISO 10077-2 including screw influence 0.18. – Values also valid for all approved interior gasket variants. – Values valid for exterior gasket 3 mm and all standard pressure profile options. – All values passive house standard. – T13 = Infill thickness. Uf-values mullion Infill thickness mm System width mm 50 56 36 1.05 1.03 40 0.99 0.97 44 0.94 0.93 48 0.91 0.90 52 0.88 0.88 56 0.87 0.87 60 0.86 0.86 64 0.84 0.85 Uf-values transom HV-0182 System width mm 50 56 36 1.03 1.02 40 0.97 0.95 44 0.91 0.90 48 0.88 0.87 52 0.86 0.85 56 0.84 0.84 60 0.83 0.83 64 0.82 0.82 2016 531 THERM+ H-I/H-V Thermal insulation Infill thickness mm THERM+ H-I/H-V Thermal insulation THERM+ H-I 50/56 mm Uf-values flat pressure profile coated, insulating block PH Mullion section/transom section ■ Technical information – Uf-value in W/(m2K) acc. to DIN EN ISO 10077-2 including screw influence 0.18. – Values also valid for all approved interior gasket variants. – Values also valid for all approved screw connection variants. – All values passive house standard. – T13 = Infill thickness. Uf-values mullion Infill thickness mm System width mm 50 56 44 0.98 0.96 48 0.92 0.91 52 0.88 0.87 56 0.85 0.84 60 0.83 0.83 64 0.82 0.81 Uf-values transom Infill thickness mm 532 2016 HV-0183 System width mm 50 56 44 0.97 0.95 48 0.91 0.89 52 0.86 0.85 56 0.83 0.82 60 0.81 0.80 64 0.80 0.79 Technical Conditions 1. General Conditions All RAICO products have been developed or selected for usage in the construction of façades, windows, and doors. They are meant to be assembled by specialized companies following the acknowledged technical regulations, in particular as applicable to constructing façades, windows, and doors, and also following all directives, norms, regulations and recommendations which are standards within the industry. All RAICO documentation should be considered as non-binding recommendations in regard to the planning, designing, processing, finishing and assembly of these products. They are intended to offer suggestions to the certified specialist, or inform on successful applications. The specialist must always check carefully whether the suggestions and documentations are appropriate also in his particular case, and in every respect. Scope of delivery and RAICO warranty Our scope of delivery covers the contents of our known Sales Terms. We assume no liability for damages caused by the use of system accessories, parts, and hardware which are not named in our product documentation as suitable original parts and hardware. Advisory service by RAICO employees Our specialists offer free-of-charge advisory services and recommendations. All suggestions, proposals, designs and the like, be it in written or oral form, calculations, drawings, sketches etc. provided by our employees in the course of advice given or by mutual correspondence, are to be considered as non-binding suggestions from our company, and thus result in limiting our liability to deliberate intention and culpable negligence only. This limit also applies to construction designs and tender documents. Support in cost estimation Help regarding the estimation of costs is offered to the best of our knowledge and is in any case non-committal. Generally speaking, material prices are calculated only concerning RAICO’s product range. Supplements for operating costs, as well as times for manufacture and assembly are calculated according to manufacturer’s instructions. Statics The statics information published by us, as well as the Chart on the greatest possible window dimensions have been prepared to the best of our knowledge. Construction elements dimensioned according to the correct application of this information and processed expertly are thus sufficiently dimensioned in line with the currently applying industry norms. Supporting structures and enforcements must be defined according to individual static calculations. Our suggestions and proposals regarding statics have to be checked by the processing specialist, by a certified stress analyst, or by the architect before order placement, and be accepted by the orderer. 2. Requirements regarding the processing company Production facilities An essential preliminary for the professional processing of RAICO products is the availability of appropriate technical devices and machinery in the company which will process RAICO materials. Facilities must be furnished in such a way that profiles and construction parts will not be damaged during storage, removal or processing. All materials and parts must be stored in a dry place and in a way that they will not be subject to damage caused by external influences. In particular, they must be safely kept away from lime, mortar, dirt, steel chips, grinding sparks, acids, and the like. Concerning the use of solvents, the Data Sheet (MO 17) published by the Berufsgenossenschaft der chemischen Industrie (the German Government Safety Organization of Chemical Industries) is binding. Instructions and employee training In order to keep up with newest technical standards it is essential to provide the necessary training - by the study of our documentations on how to process our materials and products, by the study of specialist literature, by visiting seminars etc. Dimensions, drawings, statics All measures such as site measuring, cutting measures, glass measures must be determined by the processing company independently. It is necessary to back up details, connections etc. with the help of drawings, and to carry out static calculations for stressed profiles and bracings, and have them checked if applicable. 3. Norms The basis for these Technical Conditions are the following relevant DIN norms (German industrial standards), or DIN EN norms respectively, applying to the construction of façades, windows and doors: DIN 1055 – Parts 1 to Part 5, load assumptions for buildings. – Part 4 A 1 (Additional DIN 1055 Part 4), aerodynamic form co-efficients for building structures DIN 4102 – Parts 5, 13, 18, reaction of building materials and components to fire DIN 4108 – Parts 1 to 5, heat protection in high-building DIN 4109 – Sound proofing in high-building DIN 12209 – Building hardware – locks - mechanically actuated locks and strike plates - requirements and testing procedures DIN 17611 – Anodized semi-finished goods made of aluminium and forgeable aluminium alloys with layer thicknesses of at least 10 mm, technical delivery terms DIN 18056 – Window walls, dimensioning and construction DIN V 18073 – Closing-off by rolling elements, sun protection devices and blinds in construction, definition of terms and requirements DIN 18095 – Parts 1, 2 smoke protection doors DIN 18202 – Tolerances in high-building, buildings DIN 18263 – Part 1 and Part 4, locks and hardware, door locking devices with hydraulic absorption DIN 18273 – Door handle fittings, doors with protection against fire and smoke DIN 18351 – VOB (German Construction Contract Procedures), Part C General technical contractual terms for construction work and façade works DIN 18357 – VOB (German Construction Contract Procedures), Contracting rules for award of public works Part C, General technical regulations for construction work, hardware works DIN 18358 – VOB (German Construction Contract Procedures), Contracting rules for award of public works Part C, General technical regulations for construction work, rolling shutter works DIN 18360 – VOB (German Construction Contract Procedures), Contracting rules for award of public works Part C, General technical regulations for construction work, metal construction work, locksmith works 2016 533 Technical Conditions DIN 18361 – VOB (German Construction Contract Procedures), Contracting rules for award of public works Part C, General technical regulations for construction work, glazing works DIN 18516 – Parts 1, 3, 4, cladding for external walls ventilated at rear DIN 18545 – Parts 1 to 3, sealing of glazings with sealing compounds DIN EN 356 – Assault-inhibiting glazings; testing of features inhibiting assault with cutting and beating tools. Testing of features inhibiting full-penetration throwing, classification DIN EN 573 – Parts 3 and 4, extruded aluminium sheets and sheets made of forgeable aluminium alloys, features and technical delivery terms DIN EN 755 – Parts 1 and 2, extruded aluminium sheets and sheets made of forgeable aluminium alloys, features and technical delivery terms DIN EN 1063 – Assault-inhibiting glazings, definition of terms; testing of feature inhibiting fullpenetration shots, and classification DIN EN 1154 – Door locking devices with hydraulic absorption, automatic door closers with linear operation, door closers DIN EN 1155 – Door closers with hydraulic absorption: lockable door closers with and without override DIN EN 1522 – Windows, doors, closings-off – inhibition of full-penetration shots – requirements and classification DIN EN 1523 – Windows, doors, closings-off - inhibition of full-penetration shots – requirements and testing procedures DIN EN 1627 – Windows, doors, closings-off – burglary inhibition – requirements and classification DIN EN 1628 – Windows, doors, closings-off – burglary inhibition – testing procedures for deter-mining the resistance against static stress DIN EN 1629 – Windows, doors, closings-off – burglary inhibition – testing procedures for deter-mining the resistance against dynamic impact DIN EN 1630 – Windows, doors, closings-off – burglary inhibition – testing procedures for deter-mining the resistance against manual attempts at burglary DIN EN 12152 – Light curtain-wall façades, joint permea-bility, requirements and classifications DIN EN 12153 – Light curtain-wall façades, joint permea-bility, inspection method DIN EN 12154 – Curtain-wall façades, tightness to hard rain, laboratory testing under static stress DIN EN 12179 – Light curtain-wall façades, resistance to wind stress DIN EN 12207 – Windows and doors, air permeability, classification DIN EN 12208 – Windows and doors, tightness to heavy rain, classification – Part 4: Laboratory testing DIN EN ISO 10077-1 – Thermo-technical qualities of windows, doors, and joints TRLV – Technical regulations for the usage of glazings with linear supports TRAV – Technical regulations for the usage of glazings with anti-fall guards 534 2016 All our systems and technical products have been developed in accordance with the preliminaries and conditions of the Deutsche Institut für Normung e. V. (DIN, i. e. German Institute for Industrial Norms). In individual cases, deviations from norms valid outside the coverage of DIN standards may occur. Our customers are advised in any case to make comparisons with valid national norms and standards as well. Quality control The features and functions of our systems, as described and evaluated in test reports, certificates etc. can only be expected when using original RAICO products. In order to ensure perfect quality, only our original parts should be processed. Regulations and recommendations VDI (Association of German Engineers) regulation 2719 – sound protection Chart for determining the exposure categories regarding window glazing – Institut für Fenstertechnik e. V. Rosenheim (Institute for Window Technology), explanatory notes on glazing – Institut des Glaserhandwerks für Verglasungstechnik und Fensterbau (German glazing crafts institute for glazing technology and window construction). Systems admitted by building inspection authorities must be manufactured according to the admittance declarations (DIBt). Deviations from the admittance declarations must in any case be authorized by the superior building supervision authorities. 4. Materials and products Materials delivered by us have been manufactured according to applying norms and standards. Materials and products made of materials produced outside our area of influence are to be selected by the processing company at their own accountability. Aluminium For the manufacture of aluminium windows, façades, etc. we deliver anodized profiles made of AlMgSi 0.5 F 22 alloy. For specific anodizing procedures, such as single-stage procedures, deviating specific alloys must be used. Specific alloys can be delivered by us only upon prior inquiry and agreement from our side. Extruded aluminium sheetsare delivered in accordance with DIN 17615. We deliver metal sheets and bands in accordance with DIN EN 485, Parts 1 and 2. Various materials and forms of delivery (profiles, metal sheets, bands) are to be adjusted according to the required looks and appearance. Profiles made of plastic The qualities of the used molding material corresponds at least to the molding material PVC-U, EDLP, 078-25-28 according to DIN EN ISO 1163, Parts 1 and 2. Slight flat unevenness caused by production are admissible inasmuch as their correct functioning will not be affected. Steel Regarding steel parts necessary for load-bearing construction elements and anchoring constructions, DIN 18800 Part 4 and DIN 18801 apply. All steel parts no longer accessible after assembly must be galvanized. Admitted procedures are hot galvanization and flame spraying galvanization. DIN EN ISO 1461 applies regarding the welding spots of galvanized constructions, and the spots where the corrosion protection of the steel parts is subject to damage during assembly. Parts no longer accessible after assembly must have a surface protection according to DIN 18360 fig. 3.1.8 or higher. Joining elements Connecting elements such as screws, bolts, rivets etc. must be sufficiently protected against corrosion. If used together with aluminium they must be made of specific alloys. Aluminum may be used for parts exposed to less static stress. Technical Conditions Under particular climatic or other environmental influences, fixing elements made of stainless steel A4 must be used, especially when visible outside. The processing company has to make sure about their usage at its own accountability. Hardware According to our specifications, RAICO hardware and relating components are sufficiently dimensioned and protected against corrosion in regard to the expected exposure and wear. Hardware parts are to be selected by the processing company according to the wear and tear expected under normal conditions. Only hardware as approved and admitted by us is to be used. Movable hardware parts must be maintained. Thus the wear and tear of movable parts and their susceptibility to corrosion will be reduced. The intervals for cleaning and care depend on the environmental conditions Glass The particular guidelines issued by glass manufacturers regarding the processing of insulation glass and special glass apply. Glass manufacturers must produce triplex glass in general, and duplex glass from a glass thickness of 36 mm and higher on the standing edge, to ensure even glass load transfer. Sealing compounds for glazing and sealing Used sealing compounds must be resistant to influences of age and climate, and have to be malleable or permanently elastic, depending on the applied load. They must be suitable to their intended purpose, in line with DIN 18545 according to all applying individual requirements. Sealing profiles The sealing profiles which are used must be non-hardening and abrasion-proof, and must keep their elastic qualities including their reset force to a large extent within the existing temperature range. The shore hardness must remain the same with only little tolerances. Sealing profiles have to be resistant to normal atmospheric influences. Assembly of various materials When assembling various materials, it must be ensured that neither corrosion nor other unfavorable influences occur. In particular it must be ensured that no disturbing sounds will be caused by changes in length as a result of temperature influences. System drainage The drainage of the system must be provided for. Penetrating water must be drained off in any case. Please refer to the drainage cross section as shown in RAICO’s processing guidelines. All openings and joints in the frame (such as screw holes, notches of the corner connectors, and the like) must be made tight, particularly regarding the lower horizontal zone. Water tightness at miter joints, joints and crossings of the construction must be ensured. Assembly of the components Where the construction makes joints necessary, additional polytuft brushes, or EPDM/chloroprene sealings respectively, must be used for soundless moving and gliding. Where directly joined or screwed profiles and components have been used, functional sealing bands or interlayers are to be used in order to avoid permeability, sound emission caused by expansion, and contact erosion. Static requirements All components must absorb the affecting forces and transfer them to the supporting structure of the building. DIN 18056 on window walls, dimensions and processing applies. Wind loads Wind loads must be considered according to DIN 1055, Part 4 with the addition on increased suction coefficients (at the building edges), if no exceeding loads are indicated. Superficial loads If the load of a person leaning out affects the transom (when the window wing is open), the additional vertical load which is then required must be considered as well. In case of ceiling-high infills the horizontal superficial loads (caused by persons pressing against the mullion or transom from the inside) must be accounted for. Special loads Additional loads, such as sun protection devices, scaffolds, etc. must be considered in the static calculations. Our standard products and systems are not to be used in maritime environments, swimming pools and spas without prior modifications. Bending 5. Construction features The determined flection of mullion and transom must be in accordance with the requirements as defined in DIN 18056. Additional requirements, especially for the utilisation of special glass panes, must be considered when calculating the admissible flection. System profiles Protection against heat and humidity We only deliver profile systems which have been tested, admitted and certified, if necessary, by an acknowledged test institute or by the DIBt. The processing company will itself select the profile systems to be used, considering the expected requirements. Profile dimensions regarding frame, wing, mullion and transom are to be determined according to statics for profiles and hardware. For blind frames and sashes, hollow profiles are to be used in general. According to DIN 4108 on heat protection in high-building, building components are among light external walls when featuring weights of up to 300 kg/m². The resulting influences on the room climate must be particularly considered, above all regarding the type and location of heating and air conditioning, heat storage, wall surfaces, and the respective solar radiation. The builder’s requirements are to be tuned to the economical and technical possibilities in window construction. In particular, DIN 4108 applies here. Drainage measures must be agreed. The applicable insulation and avoidance of thermal bridges must be considered when external wall claddings, carriers, supports, panels and other fillings are used. Corner connectors and T-connectors The production of corner connectors, T-connectors, butt joints and angle couplings for construction elements, by welding, screwing and bonding, bonding with off-center pins, pressing and bonding, must be done in accordance with the valid regulations. For an adhesive a cold-hardening two-component glue is to be used. The joints must feature sufficient firmness, stiffness and tightness throughout the complete profile’s cross-section. Rear-ventilated wall claddings Wall claddings and socle wainscotings ventilated from the rear must be done in a fashion that little quantities of water having penetrated the ventilation gap are led to the outside in a con- 2016 535 Technical Conditions trolled manner. Inasmuch as is required, anti-drumming devices have to be built in. The openings for entering and escaping ventilation air must be distributed evenly over the width, their total resulting in a sufficient cross section. In any case, a rear-ventilated façade requires a perfectly insulated and airtight wall. Sound proofing For bigger sheet surfaces, claddings, cover profiles and window sills, anti-drumming materials must be used. VDI guideline 2719 on the sound protection of windows and DIN 4109 on sound protection in high-building are the basics. If higher requirements than those defined in sound-protection category 2 are demanded, particular requirements must be considered and agreed. Sun protection Sun protection devices and the resulting construction design must be agreed between the processing company and the builder. Protection against fire and smoke Due to building regulations and obligations by local authorities differing regionally, protective measures against fire and smoke must be taken from the tender documentation, or agreed with the orderer. Movement and deformation of building and building components Building components must not absorb loads from the structure. Snow loads, differences in temperature, as well as lowering and shrinking must be considered. Expansion joints must be done accounting for differences in temperature from - 20° to + 60° Centigrade with light surfaces of natural color; with colored and dark surfaces from -20° to +80° Centigrade. 6. Production Accuracy grade, surface qualities and deformation risks have to be checked before cutting. For the manufacture and processing of our constructions we provide multiple processing guidelines, tools, and auxiliary means to the processing company, which serve as a help to reach the required quality standards. General basic processing instructions will not be mentioned here. For reasons of quality assurance profile parts up to a length of 10 cm of each batch are taken from some parts of the RAICO composites. Processing The focus must be on the angular accuracy during cutting and assembly in particular. With steel profiles or heat-insulated profiles, fitting pieces should be used for precise cutting. The effect caused by released internal stress, deflection and the like in the profiles must be checked not only before and after cutting, but also after milling and stamping. The cutting edges must be deburred carefully. Especially the burs from the workpiece must be removed wherever they inhibit correct functioning or result in possible accident hazards. During production, the following issues must be carefully observed: a) Accuracy of fit, flush corner connections and joints b) Dimensional accuracy of profiles and components c) Build-in of sealings and tightness, fitting accuracy of corners and joints d) Drainage (dimensioning and distribution) e) Sealing of all profile joints, notches, and screwing f) Fitting accuracy of the wing bearing 536 2016 g) Damages to the surface h) Hardware must be mounted according to the newest state-ofthe-art technology and to our specific instructions in such a way that the smooth-running motion (by lubrification), correct fit of the hardware, and tightness of the component will all be ensured. i) Lubrification of all moving parts (lock bars, scissors, handles, etc.) Function test RAICO components, being high-quality items with long life cycles, should fulfill, among others, the following requirements: Tightness against heavy rain A window’s tightness against water penetration is defined according to DIN EN 12208, and is categorized by four exposure groups. The exposure group to be chosen depends on the geographical location, a normal or excessive wind load, the form of the building, the position of the building and its height. If not agreed otherwise, DIN EN 12208 applies. Hardware function Ensuring the easy operation of all hardware. Faultless functioning of the safety devices, or the faulty-operation blockers respectively. Surface treatment of aluminium All component surfaces have to be protected against influences normally expected. The processing company decides at its own accountability on the suitable individual surface treatment. It will also make sure that specific features of the construction, such as the combination with metals of higher value within the electrochemical series (Cu, Sn, Pb etc.), will be considered, as well as specific emissions caused by the individual location including the effect of sea water. We do not give any warranty for profiles hardware and components which have been anodized or colorcoated outside our area of influence; in particular this applies to combinations of heat-insulated profiles. Anodic oxidation The surface treatment of components made of aluminium must be carried out in accordance with DIN 17611. The look of the surface in regard to shine, structure, color shade, and evenness, and the required surface treatment (E0 – E6) are to be taken from the tender documentation or agreed individually. For color shading only procedures are admissible which create oxidation layers that are color-fast and light resistant without exception. For judging varieties in appearance and color, an evaluation by means of average or limit samples must be agreed. Please observe: The E0 procedure is only applicable in case that there are no demands whatsoever regarding an even, decorative surface. The E6 procedure may only be applied under the condition that the factory-packed aluminium can be transported within an assuredly short time from the manufacturing factory to the anodizing workshop. The profiles must not be exposed to humidity and/or affected by human sweat, or subjected to lack of packaging during transport, storage, inappropriate handling and the like. If these preliminaries are not observed, RAICO cannot accept any warranty claims. Coating Color coating procedures of the surface of aluminium components are not standardized. Due to the various possible procedures, details are to be taken from the tender documentation, or agreed with the orderer and RAICO (in case we deliver surface-coated Technical Conditions profiles). Regarding high-gloss colors undesirable effects may be more clearly visible than in case of standard coating. This cannot be influenced by RAICO. At offshore locations and in indoor swimming pools with brine water or sea water, filiform corrosion may occur. In these cases the usage of pre-anodized profiles is recommended. Please inquire for more details. Protective measures during completion time According to VOB (Contracting Rules for Award of Public Works), the building owner is liable to all damages regarding his services until buy-off through the building owner. For temporarily protecting the components during completion time, in particular against mechanical damage or damaging effects of plaster, mortar, cement, color and the like, adhesive tapes, plastic foils and suitable protective paint can be used which can be removed later without leaving traces. 7. Transport and assembly During transport and storage, appropriate protective measures are to be taken in order to avoid damages. Assembly of the components is to be done only after having finished all plastering work. On demand of the building owner and for a certain compensation to be agreed on, the components must be protected against possible damage with the help of protective bands or foils in case later plastering work is carried out. Fastening Build-in and bracing must be carried out according to DIN 18056 and DIN 18360. It must be ensured that the bracing safely transfers forces from the building component to the structure. The fixing elements must be adjusted to the building shell, supporting the adjoining profiles in such a way that they will be protected against torsion and bending. In case the firmness in the bracing spots seem doubtful, the orderer must be informed without delay according to VOB/B § 4, Paragraph 3 (German Construction Contract Procedures). If components with moving wings, mullions and transoms are used, the blind frames must be mounted in such a way that the forces emanating from bands, bearings, mullions and transoms will be transferred to the structure. Each side of the window wall must be joined to the structure at least at two points. The maximum distance of the bracing spots is 80 cm. The necessary assembly clearance, caused by thermal expansion of the building components, necessary sealing joints, and dimensional changes of the adjacent components has to be controlled by means of expansion joints. If required, gliding elements for expansion compensation which are soundproof, airtight and watertight must be used. During mounting and plastering, door frames should be planned, also considering heat insulation and moisture barriers. Sealing If not defined otherwise in the tender documentation, the parts of the building which serve as brick partitions (such as windows, window walls, doors, etc.) must be sealed in the joints of the building structure and the components by suitable sealing materials. The joints must be tight and sealed according to DIN 18360 and DIN 18540. Bigger hollow spaces at joining walls or joints in the construction have to be rear-ventilated by using water-repellent bands to fill the joints, with pore blocking. Only bands are allowable which can change their volume elastically due to their structure. Exterior joints and joining walls are sealed by means of permanent sealing agents or EPDM foils to be glued or clamped. For proper processing, sealing joints must be clean, dry and greaseless. The sealing joints must be dimensioned according to the instructions given by the manufacturers producing sealing agents. Glazing The glazing of window panes, panels, fillings and the like is to be carried out according to DIN 18361 (glazing work). Glass manufacturers’ guidelines on glazing procedures must be observed. The company in charge of window construction, if not carrying out the glazing itself, upon order receipt must agree on the precise manner and execution of glazing works with the glazing company before placing the order on glass. The glazing contractor has to be informed on the selected system type, or way of mounting. The guidelines issued by the German Institute of Glazing Crafts referring to glazing technology and window construction, and the processing guidelines issued by the sub-suppliers of glass panels and insulation glass must be considered. Wet glazing For wet glazing the ‘Chart for determining the exposure categories of window glazing’, published by the German Institute for Window Technology must be considered. Dry glazing For dry glazing with duplex sealing profiles, the rebate must generally be equipped with a ventilation system and a controlled drainage system towards the outside. Materials used for the sealing profiles will be selected according to expected exposure. When processing the sealing profiles it is important that the tolerances and dimensions of the rebate width without sealing, of the sealing itself, and of the filling elements (e. g. the glass pane) will be adjusted to each other, ensuring that the adding tolerance values will not exceed the maximum allowances, and that they will remain water-tight (please see processing guidelines). Principally, however, the guidelines on glazing are to be considered. Pressure glazing For pressure glazing the specific processing guidelines issued by glass manufacturers and system producers must be followed. Usage of blocks With glass panes, panels, fillings and the like, blocks made of plastic or impregnated water-proofed hardwood featuring a minimum length of 10 cm must be used in an expert way dependent on the type of wing and rebate, to ensure that the wings will not touch and scrape. When single-sheet glazing and insulation glass are used, the guidelines on the use of blocks with even glass panes must be observed (as issued by the German Institute of Glazing Crafts for Glazing Technology and Window Construction). Controlled drainage Rain water and leak water penetrating from other building components must be collected right above the metal construction, and drained off in a controlled manner. Water caused by rain, condensation and leak caught in the construction itself must be collected and drained off in a controlled manner within the lower horizontal of each zone, whether applying to glazing zones or wings with differing varieties of opening. When collecting this water, the maximum level the water will rise inside the collecting chamber must be taken into account, also considering external pressure. The rising level should be at least 10 mm and must be increased according to the expected maximum external pressure. Collected water must be drained off in a controlled manner to the outside, preventing it to penetrate the building structure. 2016 537 Technical Conditions Cleaning Assembled components must be cleaned before buyoff, dirt and soil caused by mounting must be removed. Only allowable cleaning detergents may be used. Additional cleaning procedures have been defined in Explanatory Note A 5 on cleaning aluminium in construction (issued by the German Aluminum Center). Protective measures To ensure faultless functioning and long life-cycles of hardware parts, suitable lubricants and grease have to be applied to moving hardware elements. Final inspection Before delivery of the building components to the orderer, the following functions must be checked: a) the evenness of joints between frame and window sash, and the even circumferential wing bearing b) the easy motion and correct functioning of all hardware parts c) the operation blockers d) the correct and faultless fit of the wing seals e) the openings for ventilation and drainage of the rebate. 538 2016 General terms of sale § 1 Validity of the General Terms of Sale 1. Our Terms of Sale shall apply exclusively. They shall apply even where we unreservedly effect delivery to the Customer whilst aware of the Customer’s conflicting provisions or provisions at variance with our Terms of Sale. Customer’s diverging General Terms of Business are hereby strictly opposed. These shall only form part of the Contract when their validity for each individual contract has been explicitly confirmed in writing by us. Our failure to reply to a letter of confirmation from the Customer requesting the incorporation of Customer’s Terms of Business into the Contract shall not lead to the Customer’s Terms of Business being incorporated here but rather this shall be deemed as a rejection in this respect. Conclusion of the Contract shall not fail due to conflicting General Terms of Business. Each provision within these Terms and Conditions shall be valid on its own. Our Terms of Sale shall only apply to entrepreneurs pursuant to § 14, Section 1 of the German Civil Code (BGB) and to legal entities under public law or to special public funds. 2.Where colliding General Terms of Business tally with one another, the concurring resolutions shall apply. Beyond this, those sections of our Terms of Sale shall be deemed accepted where no provision in the Customer’s General Terms of Business collides with them. On the other hand, those provisions in the Customer’s General Terms of Business not fully concurring with the contractual substance of our General Terms of Business shall not form part of the Contract. In all other cases jus dispositivum shall apply . 3.These Terms of Sale shall apply in their current version also for all future contracts on the delivery of goods and on subsequent deliveries between the Parties in this business relationship without there being a need for repeated inclusion of, or reference to, these Terms of Sale after the initial agreement. 4. In the case of written documents appended with a translation into a foreign language relating to a Contract for which German is the official language, the translation shall only serve as information. The German wording alone shall be conclusive in determining the subject of the Contract. 5. All agreements concluded between ourselves and the Customer for the purpose of implementing this Contract must be set down in writing within this Contract. Additional agreements, subsequent changes to the Contract and provisions of guarantees, in particular assurances of characteristics or the assumption of procurement risks by non-authorised persons, must all be made in writing. § 2 Offers/Quotes 1. Offers made by us shall be subject to change. These represent an invitation to the Customer to place a binding offer for the conclusion of a Contract (order) and are therefore not yet binding for us at this stage. We are entitled to accept orders within a period of 4 weeks. During such time the Customer is legally bound to honour his order offer. 2. Contracts shall not be binding for us unless we accept the order by means of written order confirmation. We shall not be required to oppose a potential Customer’s written order relating to an offer of this kind should the Contract fail to be concluded . 3. Descriptions and photographs of our goods and products in catalogues, leaflets, circulars, advertisements and price lists, insofar as these are not part of our quotation are always only approximate and shall only become subject of the Contract when this is expressly indicated and laid down in the Contract. Drawings, illustrations, dimensions, weights or other performance data shall only be binding where this is expressly agreed in writing. 4. We reserve the right to make changes at any time to the subject of the Contract prompted by technical progress, rationalisation or design requirements insofar as these changes are within those that are customary in the trade and are reasonable to the Customer. We also reserve the right to make those changes to colour, weight etc. that are customary in the trade. 5. Should a change to the subject of the Contract not fall within those customary in the trade and should it also not be reasonable to the Customer, the Customer shall be entitled to cancel the Contract – a right which he can exercise in writing within 2 weeks of receiving relevant notification from us. Cancellation at a later date shall be excluded due to the relevant amendment to the Contract having taken effect by then. § 3 Offer Charges, Offer Documentation and Copyrights 1. As a rule, the initial processing of an offer is free-of-charge. Further offers and planning work shall only be free-of-charge when the delivery contract becomes valid and remains so. 2. We reserve ownership and copyrights on illustrations, drawings, designs, sketches, calculations and other documents; access to these may not be given to third parties without our written consent. These may neither be copied nor reproduced in any other manner without our consent and on request they must be returned to us once the order has been carried out. 3. Those moulds, samples and dies produced by us in order to fulfil the Contract shall remain our property. Furthermore, we shall not be obliged to surrender these to the Customer even if the price for these has been indicated separately in the Contract or invoice, in the absence of explicit contractual agreements to the contrary. We shall be entitled to the copyrights for the said moulds, samples and dies. 4. With goods manufactured to the Customer’s drawings, specimens or other specifications, the Customer shall assume liability where patents and other copyrights of third parties are violated. The Customer shall undertake to release us from any such claims to this effect. § 4 Prices 1. Unless agreed otherwise, all prices shall be net “ex works” plus statutory VAT valid at the invoice issue date. Additional costs such as packaging, freight, forwarding expenses, customs, assembly, insurance and bank charges shall be charged separately. 2. In the absence of any other agreement to the contrary, we shall be bound to the prices agreed for a period of 30 days. Should costs then change (in particular due to wage settlements or changes in the cost of materials) once the commitment period has come to an end but prior to delivery, we shall be entitled to alter the agreed prices respectively. On request we shall provide proof of this change in costs. 3. With repeat orders prices shall be agreed upon afresh. Should no such agreement materialise, we shall be entitled to set the prices unilaterally at our discretion. 4. Where value added tax is not included in our invoice - particularly because notification by the Customer suggests an “intracommunity” delivery pursuant to §, 4 No. 1 b in conjunction with § 6 a of the German VAT law (UstG) and because we shall be subject to subsequent VAT (§ 6 a, IV of the German VAT law - UStG) - the Customer shall be obliged to pay us the sum we shall be charged in this context. This obligation shall stand regardless of whether we are subsequently required to pay value added tax, turnover tax on imports or any comparable taxes domestically or abroad. § 5 Lead Time, Delivery Periods, Delays, Neglect of Duty and Acts of God 1. In the absence of any contractual agreements to the contrary, agreed delivery deadlines shall be deemed as observed when, by this time, the delivery item left our works, was handed over to the forwarding agent at our works or was indicated ready for dispatch to the Customer. 2. Where fulfilment of the order depends on documents and permits being furnished or essential questions being clarified by the Customer, any delivery deadline consented to or agreed upon by us shall only remain binding once the Customer has clarified the said question or furnished the said documents or permits by the start of the 10th week prior to the delivery deadline. What documents and clarifications are to be furnished in the context of this stipulation shall depend on the separate provisions of both Parties to the Contract or shall result from the nature of the Contract. 3. In the absence of agreements to the contrary, delivery periods shall commence once the order confirmation has been sent. 4. Delivery periods shall, however, not commence until the Customer has furnished the required documents and permits and has clarified those questions essential for the implementation of the Contract. What documents and permits are to be furnished and what questions are to be clarified by the Customer shall be determined by the individual contractual agreements made by the Parties or by the nature of the Contract itself. 5. Observance of the delivery period shall depend on the Customer fulfilling his agreed advance payment obligations. Beyond this, the delivery period shall likewise commence on fulfilment of those contractual obligations of the Customer which are laid down separately with reference to this provision in each individual contract or which result from the nature of the Contract. Furthermore, the delivery period shall only commence subsequent to the full and faultless fulfilment of all those contractual obligations of the Customer which are essential and necessary for the performance of our obligation. 6. Should we accept a request for a change to the contractual services expressed by the Customer subsequent to concluding the Contract, those delivery periods and deadlines agreed upon shall become non-binding. We shall make every effort to indicate to the Customer new delivery, commissioning and acceptance deadlines for the goods he has ordered as swiftly as possible. We shall, however, be entitled to give priority consideration to other obligations when finding new deadlines in this context. 7. In the event of delays in delivery as laid down in the above-mentioned provisions, a new delivery and/or assembly date shall only be binding subject to written consent by us or an authorised member of our staff. The same shall apply in cases where the date has become non-binding due to legal regulations. 8. Delivery periods shall extend appropriately or the delivery date shall be postponed by a reasonable period due to circumstances prompted by industrial action, in particular strikes or lock-outs, or due to the advent of unforeseen hindrances beyond our volition such as breakdowns, energy or raw material shortages, traffic disruption, energy supply problems, measures taken on the part of the authorities, sovereign interventions or orders in so far as those hindrances are proven to have a significant influence on the completion or delivery of the items. This shall also apply where such circumstances have effected upstream suppliers. The same shall apply for hindrances caused by Acts of God. Likewise, we cannot be held responsible for the circumstances described above where they occur during an already existent delay. Should the disruption last for over 3 months, each Party to the Contract shall be entitled to withdraw from that hitherto unfulfilled section of the Contract in writing within a period of 2 weeks without recourse to claims for compensation. Should withdrawal arise, the outlay for work already carried out incl. material must be reimbursed. At the request of either Party to the Contract, the respective other Party must declare whether he wishes to adhere to the Contract once the 3-month delay period has expired. We shall be obliged to notify the Customer in writing of any delay at the earliest possible convenience. The same shall apply when the delay ceases to apply. 9. We always reserve the right to honour our delivery obligations subject to the correct and timely delivery of our own supplies. 10. In the event of us being responsible for a transgression or failure to observe the delivery periods, the Customer shall be entitled to cancel the Contract in accordance with legal provisions, subsequent to his setting us a deadline of at least 2 weeks in writing and this deadline also expiring without being met. He may cancel without setting any deadline where the conditions laid down in § 323, Section 2 of the German Civil Code (BGB) are met. Declarations of cancellation or refusal and the fixing of final deadlines can only be made in writing. 11. In the event of neglect of duty on our part however, we shall only be obliged to compensate for damages where premeditation or gross negligence can be ascribed to us or one of our vicarious agents employed. This shall not apply in the case of a firm deal. Legal provisions concerning the burden of proof shall remain unaffected by this. § 6 On-Demand Delivery 1. We can dispatch orders as part deliveries insofar as these remain within those customary in the trade and are reasonable to the Customer. These part deliveries must each be paid for separately in accordance with our terms of payment. Once we have effected part delivery, the Customer shall be entitled to assert his rights arising from § 5, Nos. 10 and 11 of these General Terms of Business, also in terms of the entire Contract, should the conditions laid down therein prevail and the Customer have no interest in part delivery. 2. Should delivery on demand be agreed upon, we shall be entitled to cancel the Contract and/or claim for damages instead of demanding payment where the Customer delays in demanding delivery and we have set an appropriate deadline to no avail. Claims for damages shall not be permitted should the Customer not be responsible for the delay. Our claim for compensation due to delay pursuant to § 280, Section 1, Section 2 of the German Civil Code BGB in conjunction with § 286 of the German Civil Code (BGB) shall remain unaffected by this. Alternatively in this case, we shall be entitled to demand the agreed purchase price for preparation of the entire delivery. 3. Goods ordered for delivery on demand must be requested in full within no more than 3 months subsequent to order confirmation where no other deadline has been agreed. § 7 Passing of Risk and Transport 1. In the absence of other separate agreements to the contrary, delivery shall be effected ex works at 87772 Pfaffenhausen. This shall also apply for part deliveries. 2. Where the goods are sent to the Customer at his request or as agreed, the risk of accidental loss/destruction and accidental deterioration shall pass (insofar as this is legally permitted) to the Customer as soon as the goods leave our works - also in the case of part deliveries. This shall apply regardless of whether the goods are dispatched from the place of fulfilment or from another location and regardless of who bears the freight costs or who transported the goods to the Customer or to a forwarding agent. 3. Where those goods to be dispatched to the Customer or collected by the Customer pursuant to the above provision are surrendered to the forwarding agent or the Customer at the works, the risk shall then pass to the Customer to the extent described above. 4. In the absence of other agreements to the contrary, we shall determine the means of transport and the transport route chosen here without there being any onus on us to select the fastest and cheapest option here. Where the Customer so wishes we shall insure the consignment against damage incurred during transit, storage and assembly on behalf and at the cost of the Customer. Where the Customer’s place of business is both place of performance and place of effect as a result of an explicit agreement, we shall be entitled to insure the consignment against damage incurred during transit, storage and assembly on behalf and at the cost of the Customer. 5. Where the goods are transported by third parties and where the goods remain uninsured, particularly at the explicit request of the Customer, these goods shall be transported at the Customer’s own risk. 6. Insofar as we bear the transport risk pursuant to the above provisions, the Customer shall be obliged to facilitate the settlement of claims with insurance companies for us to the best of his endeavours. More specifically, the Customer must satisfy himself of the condition of the consignment immediately on its arrival and must have any possible damage in transit assessed forthwith by the relevant body (station of arrival, delivery post office, forwarding agent) and must relay this information to us without delay. Where the insurance company effects reduced payment to us due to insufficient involvement of the Customer in assessing the damage and in settling the claim, we shall be entitled to charge the Customer the insurance company’s shortfall in payment. 7. Where the goods are ready for dispatch and where their dispatch or acceptance is delayed for reasons for which we are not responsible, the risk shall pass to the Customer on receipt of notification announcing the goods’ readiness for dispatch. The same shall apply where the goods are not called up for delivery within the set period in the case of delivery on call. § 8 Acceptance 1. The Customer must take acceptance of delivered items – even those which are defective. Where he refuses to do so indicating the alleged defects, he shall not be entitled to derive claims for damages from his inability to use the said goods. He shall also bear the risk of further deterioration in this respect. His rights in the event of defects shall remain unaffected by this. Acceptance of the delivered items shall not be subject here to an acceptance of goods pursuant to § 640 of the German Civil Code - BGB). 2. Where delivered items are taken into operation without any reservations, this shall be deemed as an acceptance regardless of whether consignments or other services, in particular assembly, are yet to be effected by us. 3. In case of our exceptional voluntary agreement given in advance and in writing without implying any acceptance of a statutory duty, to partially or completely accept goods returned to us, the following applies: Only goods returned in a faultless technical and optical condition coming in their original packing, in complete packing units, and without any missing items, will be accepted by us. The original Bill of Delivery must be included in the return shipment, which has to be sent by the purchaser to us free of postage and handling. After corresponding receipt of the goods, the customer then receives a goods credit note less the costs of putting back into storage, which depend on the value of the goods returned. In the case of a goods value of < 300 € the fee for putting back into storage is 30 %, 20 % for a goods value of > 300 € to < 600 €; 15 % for a goods value > 600 € to <1,000 €; 10 % from a goods value of > 1,000 €. § 9 Terms of Payment 1. Our invoices are payable with a 2 % discount within 10 days of the invoice date or 30 days net, departing from the net value of the goods (as per payment received date). 2. We shall 2016 539 General terms of sale only accept means of payment going beyond cash or transfers to those accounts indicated on the invoices for the sake of fulfilling the Contract – this shall particularly apply in the case of bills of exchange or cheques. All payments must be effected free of charge to us. Bank, discount and collection charges shall be borne by the Customer. Payment by bill of exchange shall be subject to prior agreement. Discount on payments by bill of exchange shall not be granted. The surrender of bills of exchange and cheques as such shall not be considered as settlement of outstanding accounts. 3. In the event of culpable default on payment subsequent to the due date we can, without the need for any reminders, demand interest of 8 percentage points above the current base interest rate from the Customer as a contractual penalty. Where we are in a position to prove greater delay-related damage, we shall be entitled to assert this claim. As soon as those pre-conditions required to lodge a claim for compensation prevail, our claims shall be regulated in accordance with § 11 of these General Terms of Business. 4. The Customer shall neither be entitled to withhold any payments nor to set off any payment obligations in the event of counter claims being disputed, not recognised by us or not legally enforceable. 5. Where the Customer defaults on payment for more than 10 days, where bills of exchange or cheques are not honoured punctually or where a substantial deterioration of the purchaser’s financial circumstances should come to our attention (regardless of whether this occurred prior or subsequent to conclusion of the Contract), we shall have the option of demanding either a) advance payment on all those services not yet provided (including bills receivable) or b) the provision of collateral in respect of these claims. For such time as these claims remain unfulfilled we shall not be obliged to effect further deliveries arising from current contracts. 6. Each part delivery shall be considered a separate transaction. 7. Part payments are subject to special written agreement. § 10 Retention of Title 1. We shall retain title of ownership on the delivered items until such time as the Customer has paid all claims arising from his business relationship with us (extended retention of title to ownership). Thus, this retention of title on the delivered items also safeguards claims lodged against the Customer arising from contracts not relating to the delivered items. The Customer shall secure ownership by way of security for us. 2. Where the extended retention of title to ownership has not become part of the Contract due to the Customer having conflicting General Terms of Business, delivery based upon ordinary retention of title can be used as an alternative. 3. The Customer may only sell the delivered items in ordinary business transactions where he is not in default of payment and where he has not suspended payments. In such cases resale shall not be permitted. 4. On concluding the purchase contract with us the Customer shall, by way of collateral, already assign to us the claims he would be entitled to against his buyer on the basis of the sale or any other legal reason with respect to the subject of the Contract along with all secondary rights, at an amount corresponding to the percentage value of the subject of our Contract. The Customer shall be entitled to collect the claim as long as he does not default on his payments to us or has not suspended payments generally. 5. The Customer must immediately inform us in writing of any attachments, seizures or other dispositions by third parties on the item subject to retention of title and enclose all relevant documents (fieri feci etc.). Where a third party is unable to reimburse us the judicial and extra-judicial costs of an action pursuant to § 771 of the German Code of Civil Procedure (ZPO), the Customer shall be held liable to cover this shortfall incurred by us. 6. We can demand that the Customer makes notification of the assignment to his buyers and that he furnishes us with all information and documents necessary to collect the assigned claims. 7. Where those Customer’s claims - arising from resale of the goods subject to our retention of title or from the resale of goods of which we are co-owners - are incorporated into a current account, the Customer must immediately assign his payment claim to us to the value of the current and recognised balance – i.e. to the amount of our claims against the Customer. 8. The Customer shall be obliged, for as long as title is retained, to treat the goods with care and to keep them in proper condition. Any necessary repairs must be performed immediately by us – with the exception of emergencies – at the Customer’s cost. We shall bear the cost of these repairs where we are obliged to provide services in lieu or remedy defects as part of the provisions laid down in these General Terms of Business relating to warranties. 9. We shall be entitled, at the Customer’s cost, to sufficiently insure - to reinstatement value those goods subject to retention of title against theft and damage of all kinds, in particular fire or water damage where the Customer fails to prove he has taken insurance cover of this kind. 10. Where the realisable value of that collateral to which we are entitled shall exceed by more than 15 % the claims to be safeguarded arising from this business relationship, we shall be obliged, upon the Customer’s request, to release the collateral in this respect. The choice of collateral to be released shall fall to us. 11. The processing and transformation of the delivered items by the Customer shall always be performed for us. Where the delivered items are processed along with items not belonging to us we shall acquire co-ownership of the new item corresponding to the value of the delivered item in relation to the other items processed at the time of processing. The items arising from processing shall be subject to the same provisions as the items delivered subject to retention of title. 12. Where the goods subject to retention of title are connected to a plot of land of which the goods form an essential part, the Customer shall be obliged to allow us to view this plot of land and have access to it and shall be obliged to assign to us his claims in respect of the owners of the land or to grant other collateral securities of equal value should he be the owner of the land himself. Should a substantial deterioration of the financial circumstances of the Customer occur we shall be entitled, with the consent of the owner of the land or the landlord, to step into the legal position of the Customer vis-à-vis the former. 13. The assertion of our claims arising from ownership by way of security shall not mean cancellation of the Contract. § 11 Delay of the Customer 1. Where the Customer fails to accept the goods on the agreed delivery deadline or once the delivery period has come to an end, due to circumstances for which he is responsible, we can demand compensation for the additional expenses we have incurred as a result. 2. In the event of default by the Customer we shall be entitled, regardless of the possibility of asserting a greater claim for actual damage, to demand interest on the sum for which the Customer is in default at 8 percentage points above the current base interest rate. 3. Where we are entitled to claim damages instead of performance we can, regardless of the possibility of asserting a greater claim for actual damage, demand 15 % of our price as damages provided the Customer fails to prove that there was no damage caused at all or damage is considerably lower than the lumpsum compensation. § 12 Claims for Defects 1. Where defective goods exist for which we are responsible we shall be entitled to either remedy the defect or to effect subsequent deliveries. Any replaced component shall transfer to our ownership. 2. The assertion of claims for defects by the commercial Customer shall be dependent on the latter having fulfilled his due obligations in terms of examining the goods and giving notice of any defects pursuant to § 377 of the German Commercial Code (HGB). Other entrepreneurs must notify us within 14 days of receiving the goods of visible defects otherwise the Customer’s right to make claims for defects shall be for-feited. Any notification of defects must be made in writing detailing the specific defect involved. 3. We can refuse to remedy the defects for such time as the Customer has failed to fulfil all his payment obligations, with the exception of a sum corresponding to the price reduction on the defective goods. In this case, the Customer shall only be obliged to effect advance payment where we have confirmed our liability for defects within the ambit of these General Terms of Business to him in writing. 4. We must be given the opportunity to inspect the notified defects on the spot. This inspection must be performed by us without delay where the Customer is interested in immediate settlement of the matter. Claims for defects shall not be permitted where merely insignificant deviations from the properties of the goods or where merely an insignificant impairment of the serviceability of the goods shall prevail. 5. We can demand from the Customer those additional costs incurred for the purpose of subsequent fulfilment of obligations - in particular transport costs, tolls, work and material costs - where the outlay is increased as a result of transferring the goods to be delivered to location other than the delivery address, unless transfer occurs in accordance with the usage set out in the 540 2016 Contract. 6. Claims under the right of recourse on the part of the Customer in the case of the purchase of consumer goods (§ 478 of the German Civil Code - BGB) shall be excluded in this respect when relating to agreements made by the Customer with his buyer going beyond the legal claims for defects of that buyer. The Customer must inform us in good time of any claims for defects lodged by his buyer so that we are in a position to meet the claims of the buyer instead of the Customer if we so wish. 7. Where our contractual obligations also include assembly of the items to be delivered, an acceptance certificate must be produced once assembly has been completed to be signed by the Customer. This must record any defects the Customer has become aware of or that have become apparent by this time. Where these defects are not recorded our services shall be deemed accepted free from defects in this respect. 8. Services rendered in lieu and remedied defects shall be subject to the same warranty provisions governing the item originally delivered. 9. Claims for defects shall become statute-barred 1 year after the passing of the risk unless we are found to have caused the defect due to gross negligence or with pre-meditation or to have concealed the defect with an intent to deceive. This shall apply for any guarantees issued by us or binding to us in the absence of other agreements to the contrary. The statutory time-limits for claims lodged under the right of recourse pursuant to § 478 of the German Civil Code (BGB) shall remain unaffected by this. The same shall apply for longer statutory time limitations, for the construction of buildings or for the delivery of goods used for a building in accordance with their normal purpose that have caused the building’s defectiveness. These time limitations shall also apply for consequential damage where the claims are not asserted here based upon an illegal act. Where a defective delivery shall make defect remediation necessary, the time limitation shall only be suspended for such time as defects have been remedied and shall not be reinstated again. 10. Before the Customer can assert any further claims or rights (cancellation, price reductions, compensation or reimbursement of expenses) we shall have the opportunity to be set an appropriate deadline in which to remedy the defect where we have not issued any guarantee worded to the contrary. Where we fail to remedy the defect despite at least two attempts, where we refuse to remedy the defect or where this remediation is not possible or not reasonable to the Customer, the Customer shall be entitled to cancel the Contract or to lower (reduce) remuneration. § 13 of these terms shall apply for the assertion of claims for compensation or reimbursement of expenses. 11. The following shall also apply in the event of claims based upon deficiencies in title: In the absence of provisions to the contrary we shall merely be obliged to effect delivery in the country of the delivery address unaffected by third party rights. In the event of us being responsible for violating third party copyrights we shall be entitled to either acquire at our own expense a right of exploitation sufficient for the agreed or precluded use and make this over to the Customer, to change the delivered goods in such a way as to ensure the copyright is not violated or to exchange the delivered goods insofar as the agreed and precluded use is not compromised. Where we are unable to do this, where we refuse to remedy the defect or where this fails, the Customer shall be entitled to lodge legal claims and assert his rights. § 13 of these terms shall apply for the assertion of claims for compensation or reimbursement of expenses. 12. Where the Customer chooses to cancel the Contract on the basis of deficiencies in title or a quality defect subsequent to a failure to remedy these, he shall also forfeit his right to claim for compensation for the defect. Where the Customer chooses to claim damages subsequent to a failure to remedy defects, the goods shall remain at the Customer’s premises insofar as this is reasonable to him. Compensation shall be limited to the difference between the price to the Customer and the value of the defective goods. This shall not apply where we have caused the contractual violation with an intent to deceive. 13. Where a selection of samples is sent out to the Customer for inspection, we shall only be responsible for ensuring the delivery is effected in accordance with the sample selection taking any adjustments into account. 14. Where the Customer receives erroneous assembly instructions, we shall merely be obliged to deliver assembly instructions free from errors and indeed only at all when the error in the assembly instructions is at variance with proper assembly. § 13 Compensation/Reimbursement of Expenses 1. The assertion of claims for compensation or reimbursement of expenses (hereinafter referred to as “compensation”) based upon defects in the delivered goods (warranty claims) shall be ruled out where we are unable to remedy the defect for reasons for which we are not responsible. The assertion of claims for compensation for consequential harm caused by a defect or consequential damages based upon a consignment of goods found defective shall – as a rule - depend on our being at fault with intent, gross negligence or negligent neglect of duty of legal significance in the absence of another provision to the contrary. The same shall apply for the assertion of claims for compensation for a violation of a service life warranty granted by or on behalf of us (§ 443, Section 2 of the German Civil Code - BGB). 2. Otherwise, claims for compensation and claims for reimbursement of expenses (“claims for compensation”) on the Customer’s part shall be ruled out irrespective of the legal grounds for this - in particular those lodged on the basis of neglect of duty arising from and in connection with the obligatory relation, those arising from culpa in contrahendo and those arising from offences. This shall not apply for claims pursuant to § 1 and § 4 of the Product Liability Law, in the case of premeditation or gross negligence, injury to life, body or health, due to the taking over of a guarantee on the existence of a property (guarantee on the nature of the goods) or in the case of our neglect of duty that is negligent and legally significant. Under no condition shall we be liable beyond the legal claims. Where we are liable for negligence our liability shall be limited to foreseeable and typical damage. Changes to the burden of proof shall not be connected to these provisions in Sections 1 and 2. 3. Where our liability is ruled out or limited this shall also apply for the personal liability of our salaried employees, blue-collar staff, contract staff, representatives and vicarious agents. 4. Statutory limitation of claims between the Supplier and the Customer shall be governed by § 12, Section 9 insofar as claims relating to product liability pursuant to § 823 et seq. of the German Civil Code (BGB) or the Product Liability Law are not affected by this. This statutory limitation shall also particularly apply in the case of consequential damage. 5. We shall assume no liability for damage caused by unsuitable or improper use, defective commissioning or assembly carried out by the Customer himself, natural wear and tear, defective or negligent treatment – in particular through excessive use, unsuitable operating resources, replacement materials, defective construction work, unsuitable ground for building, chemical, electrochemical or electrical influences and improper modifications or maintenance performed without our approval. 6. We shall not be responsible for issuing any special public permits required or for the observance of any pollution protection laws. This shall not apply where the observance of these laws or the provision of special public permits have been agreed upon by us on an individual contractual basis. § 14 Court of Jurisdiction and Place of Fulfilment 1. The place of fulfilment for all contractual obligations shall be 87772 Pfaffenhausen. 2. Where the Customer is a merchant, a legal entity under public law or a special public fund, we shall be entitled to make the court of jurisdiction for all litigation arising from this contractual relationship alternatively Memmingen, the Customer’s place of business or – in the case of foreign deliveries – the capital of the country where the Customer has his place of business. The same shall apply where the domicile or place of habitual residence of the Customer at the time the action commences is not known. This shall also apply for litigation arising from bills of exchange and cheques. 3. Legal relationships between the Customer and ourselves shall be subject only to the law of the Federal Republic of Germany excluding the UN convention on the international sale of goods. § 15 Others 1. We process your personal data for the execution of your order and to provide you with the latest news about our range of products. You may object to the processing and use of your data for advertising purposes at any time (e-mail to [email protected]). Notes 2016 541 Pictures and diagrams, measurements, and technical data in this catalogue have been used for illustrating purposes, and are thus not binding. We reserve the right to make changes to reflect technical advancements. We accept no responsibility for mistakes regarding contents, typographical errors nor misprints which might have occured during producing this catalogue. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form without our prior permission in writing. All deliveries are subject to our Terms of Sales and Supply. No. 002400, Release 2016-03 542 2016 RAICO Austria Zentrale Telefon +49 8265 911 0 Telefax +49 8265 911 100 E-Mail [email protected] www.raico.at RAICO Swiss GmbH Delfterstrasse 10 5000 Aarau Telefon +41 62 738 66 00 Telefax +41 62 738 66 01 E-Mail [email protected] www.raico.ch RAICO France S.à.r.l. 8a rue Icare 67960 Entzheim RAICO UK Unit 63 Gosport Business Centre Aerodrome Road Gosport, PO13 0FQ Phone +44 1329 848 175 Fax +44 1329 848 701 E-Mail [email protected] www.raico.eu RAICO East GmbH ul. Bolschaia Spasskaya 12 Offi ce 8 129090 Moscow Phone +7 495 9951159 Fax +7 495 9951159 E-Mail [email protected] www.raico.ru Téléphone +33 3 88784894 Téléfax +33 3 88782107 E-Mail [email protected] www.raico.fr No. 002400 – Release 03/2016; Cover photo: Haus der Bauern – Freiburg, DE RAICO Bautechnik GmbH Gewerbegebiet Nord 2 87772 Pfaffenhausen Telefon +49 8265 911 0 Telefax +49 8265 911 100 E-Mail [email protected] www.raico.de