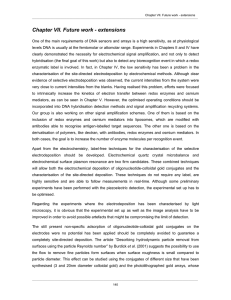

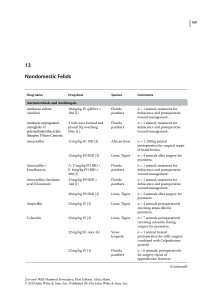

Biochemical Engineering Journal 172 (2021) 108033 Contents lists available at ScienceDirect Biochemical Engineering Journal journal homepage: www.elsevier.com/locate/bej Progress and perspective of enzyme immobilization on zeolite crystal materials Huaxin Zhang a, b, c, *, Zhengbing Jiang a, Qinghua Xia b, Dan Zhou a, b, ** a State Key Laboratory of Biocatalysis and Enzyme Engineering, School of Life Sciences, Hubei University, Wuhan, 430062, PR China Ministry-of-Education Key Laboratory for the Synthesis and Application of Organic Functional Molecules, Hubei University, Wuhan, 430062, PR China c Hubei Key Laboratory of Drug Synthesis and Optimization, Jingchu University of Technology, Jingmen, Hubei, 448000, PR China b A R T I C L E I N F O A B S T R A C T Keywords: Enzyme catalysis Covalent bonding Crosslinking Hierarchical pores Cascade reaction Zeolites play irreplaceable roles in the industrial catalysis field due to their diverse pore structures and special physical and chemical properties, which are also one type of the most attractive inorganic materials for the immobilization of enzymes. In this review, the research progress of enzyme immobilization on molecular sieve crystal materials, including the immobilization methods and applications in chemistry, biomedicine, energy and environment areas, are reviewed. Strategies for constructing delaminated zeolites, hierarchical zeolites and hollow-structured zeolites to effectively immobilize enzymes are summarized. Meanwhile, primary perspectives on future zeolite-enzyme composites are proposed. 1. Introduction Enzymes are a kind of biological macromolecules with catalytic ac­ tivity, which are essentially proteins with the exception of a few ribo­ zymes. Some enzymes require additional inorganic or organic cofactors to realize full activity, such as urease, laccase, carbonic anhydrase, peroxidase, etc. Owing to high catalytic activity (usually more than 107 times of inorganic catalyst), high specificity, and mild action conditions, enzymes are by far the most ideal selective catalysts for more than 5000 types of reactions and play an important role in chemical, pharmaceu­ tical, food and other industrial processes [1]. However, this kind of catalysts from living cells bear poor stability and reusability, which are unacceptable in large-scale industrial applications. As a result, scientists began to overcome these limitations by immobilizing enzymes on the surfaces of various support materials [2]. Some key factors such as the effectiveness of immobilization methods, the mass transfer efficiency of the materials, the operational stability, and the activity retention rate, need to be taken into account when selecting materials used to immobilize the enzyme [3]. So far, a variety of materials have been employed for enzyme immobilization [4], including polymer nanofibers [5], carbon nanotubes (CNTs) [6], mes­ oporous silica [7,8], graphene and graphene oxide [9], magnetic nanoparticles [10–12], metal organic framework compounds (MOFs) [13–17], natural biopolymers [18,19], metal nanoparticles [20], metal oxides [21,22], metal hydroxides [23,24], biochar [25], zeolites [26, 27], etc. Among them, zeolites, as a kind of traditional inorganic ma­ terials, have become ideal carrier materials for enzyme immobilization owing to their diverse pore structures, adjustable surface properties, excellent thermal stability, relatively low cost and good environmental compatibility. Though only the external surface of zeolites can be exploited to immobilize enzymes, researchers still do a great deal of attempts on this subject. The immobilization of enzyme on zeolite has involved many fields, such as chemistry, biomedicine, energy and environment, as shown in Fig. 1. As support materials, zeolites can maintain the activity of enzymes to achieve their recycle in industrial reactors, can improve the stability (including thermal stability, pH stability, storage stability) of enzymes [28,29], and in some circumstances can even enhance the catalytic ac­ tivity of enzymes [30,31]. In addition, as zeolites themselves are excellent chemical catalytic materials, their combination with biocata­ lyst enzymes may sometimes give rise to promoting effects, or achieve chemo-enzymatic cascade reactions [32]. For example, Vennestrøm et al. [33] anchored glucose oxidase (GOx) on the surface of TS-1 by glutaraldehyde (GA) coupling, a titanium silicalite molecular sieve with chemical catalytic activity, composing a bifunctional catalyst. The byproduct of the oxidation of β-D-glucopyranosyl catalyzed by GOx, * Corresponding author at: Hubei Key Laboratory of Drug Synthesis and Optimization, Jingchu University of Technology, Jingmen, Hubei, 448000, PR China. ** Corresponding author at: State Key Laboratory of Biocatalysis and Enzyme Engineering, School of Life Sciences, Hubei University, Wuhan, 430062, PR China. E-mail addresses: [email protected] (H. Zhang), [email protected] (D. Zhou). https://doi.org/10.1016/j.bej.2021.108033 Received 2 February 2021; Received in revised form 8 April 2021; Accepted 15 April 2021 Available online 21 April 2021 1369-703X/© 2021 Elsevier B.V. All rights reserved. H. Zhang et al. Biochemical Engineering Journal 172 (2021) 108033 H2O2, was in situ used for the epoxidation of allyl alcohol which was the substrate of TS-1. Smeets et al. [34] entrapped the cross-linked enzyme aggregates (CLEAs) of GOx into hollow microspheres composed of TS-1 nano-crystals, realizing similar in situ tandem reaction. In recent years, literature concerning the immobilization of enzymes on molecular sieves has begun to increase. In this paper, the progress of immobiliza­ tion of different kinds of enzymes on molecular crystal sieves with different topological structures in recent 30 years is summarized, as shown in Table 1. The immobilization methods and potential applica­ tions in biomedicine, chemistry, energy and environment are reviewed. The strategies for building immobilized enzymes on zeolites with special properties such as delaminated zeolites, hierarchical zeolites and hollow-structured zeolites are introduced. The research prospect of zeolite-enzyme composite materials is also discussed. For example, Zhang et al. [74] proposed that the recognition between the iron atoms in the Fe-ZSM-5 skeleton and the phosphates in the phospho-phytase promoted immobilization. Equilibrium cations often affect the immobilization yield and cata­ lytic activity of the immobilized enzyme [30]. de Vasoncellos et al. [61] demonstrated that gismondine (NaP) exchanged by Cu2+, Zn2+ and Ni2+ was more effective in the immobilization of Rhizomucor miehei lipase, showing a promoting effect for catalyzing transesterification reactions. A flavin oxidoreductase immobilized on Ni2+ impregnated X-type zeolite derived from coal fly ash exhibited good activity for the biochemical decomposition of 4-chlorophenol (4-CP) [27]. Li et al. [88] investigated the effects of nine equilibrium cations (Ca2+, Sr2+, Mg2+, Na+, K+, NH4+, Fe3+, Cu2+ and Zn2+) on the procoagulant activity of zeolite Y, and found that Ca2+, Sr2+ and Mg2+ had significant promoting effects, while Cu2+ and Zn2+ showed anticoagulant activities, indicating that the interaction between thrombin and different equilibrium cations was quite different. Organosilane modification of zeolites is also a common strategy to regulate enzyme adsorption and enzyme activity [62]. Mitchell et al. [53,54] grafted 3-aminopropyl and 3-mercaptopropyl onto mesoporous ZSM-5 and found that silanization was conducive to improving the retention rate of lipase in catalytic application. It is worth noting that some enzymes can hardly retain their activity after being adsorbed by zeolites. For example, Yagiz et al. [89] found that the catalytic activity of lipase lipozyme-TLIM for transesterification of waste edible oil with methanol to methyl ester was almost completely lost after being adsorbed on 13-X, 5A, FM-8 and AW-300. Therefore, prior to enzyme adsorption, it is often necessary to design the structure and surface properties of zeolites to regulate their interaction with enzyme, so as to ensure that enzymes will not be inactivated after adsorption. 2. Immobilization methods for enzymes on zeolites 2.1. Adsorption/Deposition Adsorption method to fix enzyme on the surface of zeolites bears the advantages of simplicity, rapidity, good reproducibility and no toxic compounds incorporation. It is especially suitable for constructing bio­ sensors based on zeolite-enzyme composites, because these advantages are particularly important for the standardization and further largescale production of biosensors [85]. In essence, the strength of adsorp­ tion depends on the affinity between enzyme protein and molecular sieve surface [86], which can be adjusted by changing the composition or surface properties of zeolite [87]. The ratio of Si/Al or SiO2/Al2O3 is one of the important factors that affect the surface properties of mo­ lecular sieves. In general, the lower the Si/Al ratio (the higher the aluminum content), the stronger the hydrophilicity and ion exchange performance of the zeolites [36]. Kirdeciler et al. [81] found that the enhancement of hydrophobicity and B-Acidity leading by the increase of Si/Al ratio resulted in enhanced response of conductivity biosensor modified by zeolite Beta and urease to urea. Calgaroto et al. [60] determined the adsorption of porcine pancreatic lipase on MCM-22 with Si/Al ratios of 15, 25 and 50, respectively. It was found that immobilized enzyme on MCM-22 with Si/Al ratios of 25 showed the highest immo­ bilization yield and better catalytic activity, which was attributed to the proper acidity and porosity of the material. In addition, heteroatoms in the skeleton may also contribute to the adsorption of enzyme proteins. 2.2. Covalent bonding In order to prevent enzymes from leaching from the surface of zeo­ lites and impairing their reusability, various protein linking techniques are used to anchor enzymes on the surface of material through covalent bonds, namely covalent bonding method, or crosslinking method. The free amino group, carboxyl group, hydroxyl, sulfydryl, phenolic hy­ droxyl and imidazole group in the enzyme proteins are all active groups that can be used for crosslinking. Corresponding reactive groups can also Fig. 1. Research and application of immobilization of enzymes on zeolites. 2 H. Zhang et al. Biochemical Engineering Journal 172 (2021) 108033 Table 1 Summary of published results on enzymes immobilized by zeolite crystalline materials. Enzyme Zeolite Structure code Immobilization method (Activity retention) Application Ref. α-amylase α-chymotrypsin, thermolysin A Y A, X, Y, M, ZSM-5 GA coupling (58.44 %) Adsorption (>100 %) Deposition Starch hydrolysis Peptide syntheses in organic solvents Butyl acetate alcoholysis [35] [30] [36] NaY LTA FAU LTA, FAU, FAU, MOR, MFI FAU Adsorption Butyl acetate alcoholysis NaA, NaY NaY A, X, Y NaY X LTA, FAU FAU LTA, FAU, FAU FAU FAU Butyl acetate alcoholysis Triglycerydes hydrolysis Tricaprylin hydrolysis p-nitrophenyl butyrate hydrolysis 4-chlorophenol degradation NaY TS-1 FAU MFI Adsorption/deposition (80 %) Deposition Deposition Adsorption Nickel ions-assisted adsorption (64 %) Adsorption GA coupling [37, 38] [39] [40] [41] [28] [27] DAY NaY FAU FAU TS-1 CBV-100 MFI FAU NaY Sodalite FAU SOD X FAU Heulandite NaY, DSY, DAY [Si, B]-MFI HEU FAU MFI Beta *BEA ZSM-5 ZSM-5 Silicalite-1 Silicalite 1, ITQ-2 Silicalite 1, ITQ-6 Silicalite 1, ITQ-2, ITQ-6, FAU Faujasite, Modernite MFI MFI MFI MFI, MWW MFI, FER MFI, MWW, FER, FAU FAU, MOR MCM-22 Gismondine TS-1, GIS, LTA, BEA, X Y NaY NaY Pure-silica MFI RUB-15 NaY ZSM-5 NaY ITQ-2, ITQ-6 CBV-100 MWW GIS MFI, GIS, LTA, *BEA, FAU FAU FAU FAU MFI RUB FAU MFI FAU MWW, FER FAU 13X FAU Phospho-phytase ZSM-5 MFI Ribonuclease Binase Clinoptilolite, chabazite, natrolite Silicalite-1 NaA, CaA NaX W HEU, CHA, NAT Adsorption (35 %) Adsorption (>100 %) Extrudate-shape NaY in a RPBR Adsorption Adsorption (9.8 %) Nano-Au tethering (>100 %) Adsorption (79.77 %) Nano-Au tethering (>100 %) GA coupling Solid-binding peptide linker (0 %–105.2 %) Fixed bed columns of zeolites (25.6 %) Heteroatom (Fe)-phytase coordination Adsorption MFI LTA FAU MER Silica sol–gel tethering GA coupling (82 %, 85 %) GA coupling (2.76 times) Adsorption Clinoptilolite Silicalite, Beta Beta, A Silicalite Beta, L, silicate-1, HEU MFI, *BEA *BEA, LTA MFI *BEA, LTL, MFI Deposition Deposition Deposition Adsorption Adsorption Cutinase Flavin oxidoreductase Glucose oxidase Glucose oxidase, HRP β-glucosidase, β-annanase, β-xylanase HRP Laccase Lipase Lysozyme Pepsin Protease Penicillin G Acylase PGM1, IPS, IMP, MIOX, Udh, Nox Phosphatase Trypsin Tyrosinase Urease Adsorption Rhodium-dispersed GOx carbon paste CLEAs entrapped (50 %) Solid-binding peptide linker + CLEAs Gelatin entrapment (59 %) GA crosslinking (145 %) Adsorption (83 %) GA coupling Adsorption GA coupling (146 %) Coating in stainless steel porous discs Adsorption, GA coupling Adsorption (95 %) Adsorption (>100 %) Adsorption Adsorption Adsorption (>74 %) Adsorption Adsorption (51.2 %) Adsorption (>100 %) GA coupling 3 Glucose biosensor Glucose oxidation + allyl alcohol epoxidation Glucose biosensor Glucose biosensor [42] [33] Glucose oxidation + olefin epoxidation Biomass polysaccharides hydrolysis [34] [45] Phenol electro-oxidation Pollutant (Direct Red 23) bio-degradation Dyes (RB19; AB225) decolorization [46] [47, 48] [29] Dyes (Reactive Red 120) degradation Bisphenol A biodegradation Vinyl propionate and 1-butanol transesterification Vinyl propionate and 1-butanol transesterification p-nitrophenyl esters hydrolysis p-nitrophenyl butyrate hydrolysis Alkyl esters hydrolysis Fatty acids transesterification Biodiesel production (transesterification) Triglycerides hydrolysis [49] [50] [51] Triolein hydrolysis; Oleic acid esterification Oleic acid and ethanol esterification Soybean oil to biodiesel Microalgae oil ethanolysis transesterification to FAEEs Palm oil hydrolysis M. lysodeikticus cells hydrolysis Micrococcus lysodeikticus cells disruption Coatings for implantable devices Micrococcus lysodeikticus cells disruption Casein digestion Milk coagulation/cheese production Hb digestion Hydrolysis of penicillin G Glucose-1-phosphate to glucaric acid [59] p-nitrophenyl phosphate salt (pNPP) dephosphorylation Phytate-phosphorus utilization [73] Carrying therapeutically active enzyme [75] Protein digestion (BSA and Cyt-C) L-DOPA production L-DOPA production Oral sorbent for the removal of urea in uremia Urea Biosensor Urea Biosensor Urea Biosensor Urea Biosensor Urea Biosensor [76] [77] [78] [79] [43] [44] [52] [53] [54] [55] [56] [57] [58] [60] [61] [62] [63] [64] [65] [66] [67] [68] [69] [70] [71] [72] [74] [80] [81] [82] [83] [84] H. Zhang et al. Biochemical Engineering Journal 172 (2021) 108033 be introduced onto zeolites through the silanization reaction with the surface hydroxyl groups, which provides the possibility for crosslinking of enzymes and zeolites. The selection of crosslinking method needs to consider the effectiveness of crosslinking reaction, the crosslinking yield, the retention rate of enzyme activity and the simplicity of oper­ ation. At present, the most commonly used method for covalent connection between enzymes and zeolites is the glutaraldehyde cross­ linking method [48]. Its major procedures involves (1) the introduction of active amino groups on the surface of zeolites through the silane re­ agent (aminopropyl-3-ethoxysilane, aminopropyl-3-methoxysilane, etc.), (2) the transformation of amino groups into aldehyde groups by reaction with glutaraldehyde, (3) the anchoring of enzymes through reaction of aldehyde groups with the free amino group in enzyme pro­ tein (mainly ε-ammonia of lysine), and (4) the reduction reaction with sodium borohydride or sodium cyanoborohydride to stable the linking bonds, as shown in Fig. 2a. It must be pointed out that the 4th step (reduction of the imine to the amine) is not always needed and even sometimes strongly deleterious [90]. At present, the above-mentioned glutaraldehyde coupling method has successfully achieved the immobilization of a variety of enzymes on the surface of zeolites with different topological structures, including glucose oxidase@MFI [33], amylase@LTA [35], laccase@SOD [47,48], lipase@MFI [51,62], lipase@GIS/LTA/BEA/FAU [62], penicillin acy­ lase@MWW/FER [71], etc. The enzymes in all these examples maintain certain catalytic activity after immobilization. In addition to the glutaraldehyde crosslinking method, there are also some other successful crosslinking agents, such as glymo [91] and eth­ ylenediamine [49]. For example, Celikbicak et al. [49] introduced amino groups via ethylenediamine to poly (2-chloroethyl acrylate) generated on the surface of heulandite by surface initiated atom transfer radical polymerization (SI-ATRP), followed by tethering Trametes ver­ sicolor laccase through glutaraldehyde crosslinking to catalyze dye degradation. Metal ions or metal nanoparticles are sometimes used as bridges to anchor enzymes to zeolites, as they have special affinity with both en­ zymes and carriers or functionalized carriers [92]. Mukhopadhyay et al. successively anchored pepsin [68] and fungal protease [70] onto amino-functionalized zeolite NaY using Au nanoparticles as bridges, forming the enzyme-nanogold-zeolite biocatalysts, which were applied to catalyze the digestion of casein and hemoglobin. Recently, molecular biology techniques have also been reported as covalent attachment strategies to construct enzyme-zeolite composite biocatalysts. Care and Petroll et al. [45,72] reported a special amino acid sequence which can firmly bind to silicon-based materials. They fused this sequence to the C-terminal or N-terminal of enzymes using genetic engineering techniques to produce bifunctional fusion proteins, achieving immobilization of a variety of industrially-significant en­ zymes. In their practice of converting glucose-1-phosphate (G1P) into glucaric acid, six enzymes including phosphoglucomutase (PGM), myo-inositol-3-phosphate synthase (IPS), inositol-1-monophosphatase (IMP), myo-inositol oxygenase (MmMIOX), uronate dehydrogenase (Udh) and NADH oxidase (Nox), were immobilized on CBV-100 to catalyze the two-batch reaction of upper and the lower pathway, as shown in Fig. 3. The major problem for zeolite’s functionalization is that zeolites intrinsically have few surface defects (e.g. silanols) on their surface, which limits the maximum degree of functionalization. In view of this limitation, Zhang et al. found that piranha solution treatment can effi­ ciently increase the amount of silanol on zeolite [93]. 2.3. Entrapment The entrapment method used for immobilization of enzyme on zeolite can be divided into three situations. The first one is to use additional materials to encapsulate enzymes onto zeolites. For example, gelatin was used by Carvalho et al. [46] to encapsulate horseradish peroxidase on the surface of NaY to prepare composite electrode for electrocatalytic oxidation of phenol. Many biosensors based on zeolite-enzyme complexes have also used similar encapsulation methods. The second type is to seal enzymes in other materials by mo­ lecular sieve. For example, Marthala et al. [52] fixed lipase in the gradient pores of stainless steel cakes by suction filtration, and sealed with a layer of zeolite Beta on the surface of the steel cake to prevent the leakage of the enzyme. The experimental results showed that the mac­ ropores of stainless steel cakes maintained the natural state of the enzyme, and the Beta coating effectively prevented the leakage of Fig. 2. Schematic diagram of enzyme immobilization on zeolite through chemical methods. a) Typical steps of glutaraldehyde coupling method for covalently anchoring enzyme on zeolite surface. b) Entrapment of CLEAs in the constructed additional mesopores or macropores in conventional microporous zeolites. 4 H. Zhang et al. Biochemical Engineering Journal 172 (2021) 108033 Fig. 3. Schematic illustration of the production of glucaric acid (GlucA) from glucose-1-phosphate (G1P) through a two-batch reaction of the upper and lower pathway. Respective enzyme concentration in U/mL, MIOX pre-activation with Fe and Cys, the immobilised NAD+ regeneration system (Nox-L) and conversion of glucaro-1,4-lactone to glucaric acid (GlucA) are shown. Enzymes PGM-L, IPS-L, IMP-L, LUdh and Nox-L were used either as free enzymes or immobilised onto zeolite while MmMIOX was used as free enzyme. RT, room temperature [72]. Reprinted with permission from ref [72]. Copyright 2020 Elsevier. enzymes. The third strategy is to form cross-linked enzyme aggregates (CLEAs) through enzymes themselves, which makes their swollen ag­ gregates entrapped the mesopores or macropores of zeolite [53], or in their hollow structure [34], similar to the idea of "ship in a bottle", as shown in Fig. 2b. synthesized 3,4-dihydroxyphenyl-L-alanine (L-DOPA) from L-tyrosine under the catalysis of tyrosinase on zeolite A and X, respectively. Xing et al. [30] employed α-chymotrypsin and thermophilic bacterial pro­ teinase on various Y zeolites, realizing peptide syntheses in organic solvent. In chemical synthesis area, lipases (including keratinase) are one type of the most frequently used enzymes, which have a wide range of sources and varieties. It can catalyze the hydrolysis, alcoholysis, ester­ ification, transesterification and reverse synthesis of tricaprylin and other esters. For example, Serralha et al. [36–39] successfully catalyzed the alcoholysis of butyl acetate and n-hexanol with cutinase or recom­ binant cutinase immobilized on zeolite Y, A, X, M, ZSM-5, etc., respec­ tively. Gonçalves et al. [40,41] deposited cutinase from Fusarium solani pisi on zeolite A, X, Y and catalyzed the hydrolysis of tricaprylin. Mitchell et al. [53,54] reported the hydrolysis of p-nitrophenyl ester catalyzed by lipase immobilized on porous ZSM-5. Macario et al. [55,56, 58] demonstrated the catalytic activity of the lipase immobilized on silicalite-1, ITQ-2, ITQ-6 and other zeolites in hydrolysis of triglycerides, the transesterification of olive oil and the hydrolysis of alkyl esters. In addition, the lipases immobilized on the molecular sieve crystal have been successfully used to catalyze the transesterification of vinyl propionate and n-butanol [51], the esterification of oleic acid and glycerol [59], the esterification of oleic acid and ethanol [60], the hy­ drolysis of palm oil [63], and the transesterification of microalgae oil to ethyl fatty acids (FAEEs) [62], etc. Zeolite-enzyme composites have also been applied in the field of drug synthesis [71] and enantiomeric 3. Application of immobilized enzymes on zeolites 3.1. Chemical field Heterogeneous enzyme catalysis based on molecular sieves is an important branch of catalysis, which has been divided into biomolecule conversion and chemical synthesis. In the aspect of biomolecular transformation, the reactions are mainly catalyzed by various proteases, amylases, lysozymes, etc. For example, a pepsin [68] and a fungal pro­ tease [70] were respectively fastened to zeolite NaY by Mukhopadhyaya et al. to catalyze the hydrolysis of casein and hemoglobin. Kumari et al. [69] used a brinjal leaf protease adsorbed on mesoporous ZSM-5 to promote milk coagulation in cheese production. Huang et al. [76] tethered trypsin on silicalite-1 to effectively catalyze the transformation of bovine serum protein and cytochrome C. Chang et al. [64] and Lee et al. [65] immobilized lysozyme on NaY to successfully disrupt Micro­ coccus lysodeikticus cells. α–amylase covalently attached on zeolite A by Talebi et al. [35] exhibited higher stability than free state in catalysis for the hydrolysis of water-soluble starch. In the aspect of biomolecule synthesis, Seetharam et al. [77] and Donato et al. [78] successfully 5 H. Zhang et al. Biochemical Engineering Journal 172 (2021) 108033 resolution [94]. It is worth mentioning that research about enzyme immobilization on zeolite has achieved good results, many of which have been applied in industrial flow reactors [35,95]. Zeolites are found to be superior to many other carriers such as PA6 [38,39], which is mainly related to the possibility of generating and regulating the acid-base, electrostatic and hydrophobic-hydrophilic character. Meanwhile, the versatile pore structures on zeolite surface can provide appropriate grasp power for different sidechains of enzymes, which facilitates the immobilization and activity retention. Furthermore, compared to other supports, the stability, biocompatibility and economy of zeolites are also competitive, some of which can even be directly obtained from natural environment. All the advantages abovementioned determine the broad prospects of zeolite-enzyme biocatalysts in industrial application. 3.4. Environmental field Research on the degradation of toxic substances in the environment by zeolite immobilized enzyme has attracted increasing attention in recent years. Laccase, catalase, flavoenzyme and some other oxidore­ ductase have frequently been immobilized on zeolites and used for dyes decolorization and phenols biodegradation. For example, Celikbicak et al. [49] reported a Trametes versicolor laccase on the Heulandite connected by the hairy polymer, which continuously catalyzed the degradation of Reactive Red 120. RB 19 and AB 225 were degraded under the catalysis of laccase on zeolite X [29]. Mahmood et al. [47,48] successively immobilized laccase on sodalite combined with carbon nanotubes (CNTs) and graphite oxide (GO) to degrade dye DR23, and the results implied the addition of CNTs and GO promoted the electron transfer of catalytic sites. Different zeolite Y were employed by Taghi­ zadeh et al. [50] to fix laccase for degradation of bisphenol A. The degradation of 4-chlorophenol was effectively catalyzed by flavinase immobilized on zeolite X [27]. Carvalho et al. [46,100] found that NaY had a positive effect on the activity of HRP in the oxidation of phenols, based on which, gelatin/HRP/NaY/graphite composite electrode was prepared to realize the electrocatalytic oxidation of phenols. Besides, lipase immobilized on zeolite has also been reported to catalyze the degradation of waste cooking oil [89]. 3.2. Biomedical field Many zeolites have good biocompatibility and thus have many po­ tential or practical applications in the fields of biotechnology and medicine [96,97]. Many enzymes with medicinal value can be fixed by zeolites to prepare enzyme-zeolite composites, which can improve the stability of enzyme and realize the delivery or slow release of medicinal enzymes. A stable urease-zeolite oral sorbent microcapsule prepared by Cattaneo et al. [79] removed up to 80 % of urea in less than one hour. Khojaewa et al. [75] found that the complexes of a ribonuclease binase with clinoptilolite and chabazite showed enhanced antitumor activity in comparison with enzymes and supports separately, revealing the application potential of binase-zeolite complexes in treating colorectal cancer or malignant skin neoplasms. Biosensors based on zeolite-enzyme composites are widely used as biosensors for the detection of glucose [44], urea [80,81] and other metabolites. Soldatkin et al. [82,83,85,98] have performed systematic work in this field and they have constructed biosensors for the deter­ mination of urea, glucose, glutamate, acetylcholine, sucrose and other substrates by immobilization of urease, glucose oxidase, glutamate ox­ idase, acetylcholinesterase, butyrylcholinesterase, mutarotase, invertase etc. on zeolites including clinoptilolite, silicalite, beta, A, L etc. In addition, lysozyme on pure-silica MFI was proved to possess antibacterial and anti-infection activity and was thought to be an applicable coating for implantable devices, which could improve the success rate of transplantation [66]. The hemostasis function of zeolites also has also been proved to be related to enzyme adsorption. Li et al. [88] noticed that the procoagulant performance of zeolite A, Y, X, Beta and MOR was significantly improved when their cations were exchanged into Ca2+, which was found to be the result of promoting effect of Ca2+ on the adsorption of plasma proteins. 4. Enzyme immobilization by zeolites with special structures The micropores of traditional microporous zeolites are too small to accommodate enzyme molecules, so enzymes can only be fixed on the outer surface of the zeolites. However, the external specific surface of general microporous zeolites is very limited, which restricts their application in enzyme immobilization to a certain extent. Therefore, to increase the ratio of external surface area to internal surface area, and to improve the efficiency of enzyme immobilization, researchers prepared many special zeolite materials, such as delaminated zeolites, hierarchi­ cal zeolites and hollow zeolites. Compared to conventional microporous zeolites, these zeolites with special structure or morphology can provide either larger external surface to load more enzyme molecules or addi­ tional hollow space to accommodate enzymes or their aggregates. Consequently, they are gaining increasing attention. 4.1. Delaminated zeolites Delaminated zeolites, usually refer to two-dimensional molecular sieve materials with nano lamellar structure. Compared with the threedimensional structure of traditional zeolites, the two-dimensional nano lamellar materials release more surface area, especially the outer surface area, which effectively increases the ratio of external surface area to internal surface area and is conducive to improve their loading capa­ bility to enzyme. Roth et al. [101] made a detailed summary on the progress of synthesis methods for two-dimensional zeolites, in which they classified the preparation methods of two-dimensional zeolites into three categories: hydrothermal synthesis, surfactant-templated synthe­ sis and zeolite partial hydrolysis method. Among the 237 types of skeleton structure included in the international zeolite structure data­ base at present, more than 10 types of molecular sieves, such as AFO, CAS, CDO, FER, HEU, MFI, MWW, NSI, OKO, PCR, RRO, RWR, SOD, can form layered structure. In theory, these delaminated molecular sieves can be synthesized directly, or post-synthesized through swelling, pil­ laring, stripping, ultrasound and other appropriate chemical or physical treatment. Among them, the preparation technology of delaminated zeolites with FER, MFI and MWW framework are relatively mature, and some of them have been used to fix enzyme molecules [56–58]. Corma et al. [71] first proposed the strategy of enzyme immobili­ zation by delaminated zeolites. They treated the layered precursor Ferrierite with surfactant and prepared delaminated zeolite ITQ–6. After the introduction of amino group by alkylation, β - galactosidase and 3.3. Energy field In the energy field, immobilization of enzyme on zeolites is mainly used in the production of biodiesel. Macario et al. [57] prepared bio­ diesel through transesterification reaction catalyzed by Rhizomucor miehei lipase fixed by silicalite-1 and ITQ-6. Vasoncellos et al. [61] synthesized methyl ester by transesterification of soybean oil catalyzed by Rhizomucor miehei lipase immobilized on different ion exchanged gismondine, Na-P, Cu-P, Zn-P and Ni-P. It was found that the enzyme activity of Ni-P-enzyme complex was better than that of other com­ plexes, and the promoting effect of Ni-P/200-ENZ complex on soybean oil transesterification was observed. Considering the outstanding per­ formance of zeolite-enzyme modified electrode in the field of biosensor, it is speculated that zeolite-enzyme composites may have development potential in the field of biofuel cell [99]. Zeolites in these applications not only serve as supports for enzymes to improve their thermal sta­ bility, pH stability, storage stability and reusability, but also in some circumstances enhance the catalytic activity of enzymes, playing increasingly significant roles. 6 H. Zhang et al. Biochemical Engineering Journal 172 (2021) 108033 penicillin acylase (PGA) were fixed on the surface of ITQ-6 by electro­ static adsorption and glutaraldehyde crosslinking, respectively, achieving high immobilization yield and enzyme activity retention rate. Furthermore, the stability of enzyme immobilized on ITQ was found to be higher than that on amorphous silica or in free state. Kawai et al. [67] compared the immobilization of lysozyme by RUB-15 zeolite and its delamination form, RUB-15-nano, proving that lysozyme adsorbed on RUB-15-nano retained higher activity. lipase immobilization yield and efficiency. The correlation between mesoporous specific surface area, adsorption capacity to lipase and corresponding activity of biocatalyst proved that the mesopore played an important role in immobilization processes. The surface modification of mesoporous ZSM-5 resulted in improved enzyme immobilization ef­ ficiency, catalytic activity and reusability of enzyme compared with unmodified counterparts, and lipase immibilized on mercaptan func­ tionalized mesoporous ZSM-5 is the most effective biocatalyst. Mean­ while, the functionalized MCM-41 exhibited lower enzyme uptake than functionalized mesoporous ZSM-5 despite its higher specific surface area of mesoporous, which could be attributed to the limited accessibility of its one-dimensional mesopores, inferior to the interconnected meso­ pores of mesoporous ZSM-5. In 2009, Choi et al. [103] first reported a bottom-up strategy for one-pot synthesis of hierarchical ZSM-5 microspheres assembled by MFI ultra-thin nanosheets using tumbling crystallization method in the presence of a dual functional surfactant (C22-6-6). After that, Marthala et al. [51,104] successfully synthesized similar pure silicon, aluminum-containing and boron-containing MFI structure by static crystallization method, and the synthesized boron-containing hierar­ chical MFI nanosheet microspheres was used for enzyme immobiliza­ tion. The results suggested that lipase, covalently linked to MFI microspheres by glutaraldehyde crosslinking method, showed high ac­ tivity in the transesterification of vinyl propionate with butanol. Zhou et al. [105] first synthesized a type of hierarchical zeolite microsphere constructed by MWW nano-sheet through a one-step method. It was found that the surface roughness and groove angles be­ tween the lamellae were favorable for protein loading, which suggested these hierarchical crystalline materials might be ideal supports for enzyme immobilization [93]. 4.2. Hierarchical zeolite Introducing mesopores and macropores into the traditional micro­ porous zeolites to conventional microporous zeolites, can not only reserve the inherent size, shape and transition state selectivity of zeo­ lites, but also increase the external surface which can be utilized to load enzymes. More importantly, the introduced mesopores and macropores can reduce the diffusion resistance of substrates, and promote their mass transfer. This will increase the contact opportunity between substrates and enzymes, and subsequently improve the catalytic efficiency of immobilized enzymes. So. More and more attention has been paid to the synthesis of hierarchical zeolites and their application in enzyme immobilization [54,74]. Jia et al. [102] reviewed the top-down and bottom-up synthesis strategies of introducing mesopores/macropores into microporous zeolites, in which the top-down strategy is mainly achieved by desilication or dealumination, and the bottom-up strategy is mainly synthesized under template (soft or hard) or template-free conditions. Taghizadeh et al. [50] adopted the top-down strategy to prepare two hierarchical zeolites, the desilicated and dealuminated forms of NaY, named DSY and DAY, respectively. The products were successfully used to adsorb laccase and then applied for degradation of bisphenol A, as shown in Fig. 4. The results showed that the immobilization yield and efficiency of DSY and DAY for laccase were significantly improved in comparison to microporous NaY as a portion of laccase have entered the constructed mesopores. The immobilization yield and efficiency of DAY to laccase were the highest, reaching 81.12 ± 1.32 % and 98.56 ± 2.93 %, respectively. Moreover, the hierarchical carrier also improved the pH stability, catalytic stability and reusability of laccase. Desilicated and dealuminated mesoporous ZSM-5 was prepared by Mitchell and Pérez-Ramírez [53] using the top-down strategy and used to immobilize lipase after surface treatment by organosilanes and glutaraldehyde, as shown in Fig. 5. The results indicated that meso­ porous ZSM-5 was obviously superior to pure microporous ZSM-5 in 4.3. Hollow zeolites Hollow zeolites are a kind of special inorganic materials. On one hand, the microporous crystal structure ensures their good hydrother­ mal stability, chemical stability, acidity and shape selectivity. On the other hand, the hollow structure provides a unique space for encapsu­ lation of other materials. Moreover, the overall size of the particles is usually large, the thickness of shell wall can be adjusted by controlling the synthesis conditions [106], which is convenient for design and operation. Therefore, hollow zeolites have great research and applica­ tion potential, especially in the fields of encapsulated metal catalyst [107] and drug delivery [108]. Pagis et al. [109] reviewed the synthesis Fig. 4. Desilicated Y (DSY) and dealuminated Y (DAY) was prepared from NaY by top-down strategy and the products were used to immobilize laccase for bisphenol A degradation [50]. 7 H. Zhang et al. Biochemical Engineering Journal 172 (2021) 108033 Fig. 5. Immobilization of lipase enzymes on ZSM-5 zeolites with varying surface and textural properties [53]. Reprinted with permission from ref [53]. Copyright 2011 Elsevier. strategies of hollow zeolites, which are mainly divided into three cate­ gories. In the first category, inorganic or organic inert templates (carbon powder, polymer, liquid drop, etc.) are used as crystallization supports which are removed after core-shell structure forms; In the second cate­ gory, template materials (amorphous SiO2 ball, zeolite crystal, etc.) are not only the supports but also the species participating in the secondary crystallization to constitute shell; In the third category, the heteroge­ neous nuclei of zeolite are dissolved to generate hollow structures. However, enzyme molecules can hardly cross through the shell of conventional hollow zeolites. Then how to enter into the cavity to make use of their hollow structures becomes a key issue. Spray drying tech­ nology was employed by Smeets et al. [34] to construct hollow zeolite Fig. 6. Schematic representation of the synthesis strategy used for (a) the preparation of hollow zeolite microspheres formed by the aggregation of TS-1 crystals using the aerosol method, (b) the immobilization of glucose oxidase on the aerosol-made material by the formation of entrapped cross-linked enzyme aggregates (CLEAs) [34]. Reprinted with permission from ref [34]. Copyright 2020 RSC. 8 H. Zhang et al. Biochemical Engineering Journal 172 (2021) 108033 microspheres through aerosol-assisted assembly of TS-1 nanocrystals. Glucose oxidase (GOx) passed through the porous silica shell with embedded TS-1 nanocrystals to get into the hollow space and then was precipitated and cross-linked after the treatment of ethyl lactate and glutaraldehyde. The formation of cross-linked enzyme aggregates (CLEAs) made GOx entrapped in the cavities of as-synthesized hollow zeolite microspheres, forming a bifunctional catalyst with both chemical and enzymatic catalytic activity, as shown in Fig. 6. The cavity of zeolite was not only the nest for enzymes, but also an effective inorganic catalyst. H2O2 generated in glucose oxidation reaction catalyzed by GOx directly participated in the epoxidation of olefin catalyzed by TS-1. The immobilization of the combined CLEAs of GOx and horseradish perox­ idase (HRP) was also discussed. Obviously, this enzyme immobilization strategy may also be applicable to other zeolite nanocrystals, or even other types of catalytic materials. Recently, Debecker’s group developed their spray drying strategy and prepared the combination of TS-1 nanocrystals and GOx in only one step [110]. Declaration of Competing Interest 5. Conclusion and perspective References The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. Acknowledgements The authors thank the financial supports by Open Funding Project of the State Key Laboratory of Biocatalysis and Enzyme Engineering (SKLBEE2020019), National Natural Science Foundation of China (U20A20122, 22072038, 21571055), Scientific Research Project of Hubei Education Department (T2020023, Q20184305), Fund of Jing­ men Science and Technology Project (ZDCX2017004, 2020ZDYF002), Wuhan Science and Technology Bureau (2019010701011415), Key Program (ZD201902) and Porous Materials Preparation & Application Innovation Team Project in Jingchu University of Technology. [1] A. Basso, S. Serban, Industrial applications of immobilized enzymes—A review, Mol. Catal. 479 (2019), 110607. [2] D.-M. Liu, J. Chen, Y.-P. Shi, Advances on methods and easy separated support materials for enzymes immobilization, TrAC, Trends Anal. Chem. 102 (2018) 332–342. [3] J. Boudrant, J.M. Woodley, R. Fernandez-Lafuente, Parameters necessary to define an immobilized enzyme preparation, Process Biochem. 90 (2020) 66–80. [4] C. geor malar, M. Seenuvasan, K.S. Kumar, A. Kumar, R. Parthiban, Review on surface modification of nanocarriers to overcome diffusion limitations: an enzyme immobilization aspect, Biochem. Eng. J. 158 (2020), 107574. [5] Z.-G. Wang, L.-S. Wan, Z.-M. Liu, X.-J. Huang, Z.-K. Xu, Enzyme immobilization on electrospun polymer nanofibers: an overview, J. Mol. Catal., B Enzym. 56 (2009) 189–195. [6] W. Feng, P. Ji, Enzymes immobilized on carbon nanotubes, Biotechnol. Adv. 29 (2011) 889–895. [7] N. Carlsson, H. Gustafsson, C. Thörn, L. Olsson, K. Holmberg, B. Åkerman, Enzymes immobilized in mesoporous silica: a physical–chemical perspective, Adv. Colloid Interface Sci. 205 (2014) 339–360. [8] L. Zhang, Y. Sun, Poly(carboxybetaine methacrylate)-grafted silica nanoparticle: a novel carrier for enzyme immobilization, Biochem. Eng. J. 132 (2018) 122–129. [9] M. Adeel, M. Bilal, T. Rasheed, A. Sharma, H.M.N. Iqbal, Graphene and graphene oxide: functionalization and nano-bio-catalytic system for enzyme immobilization and biotechnological perspective, Int. J. Biol. Macromol. 120 (2018) 1430–1440. [10] M. Bilal, Y. Zhao, T. Rasheed, H.M.N. Iqbal, Magnetic nanoparticles as versatile carriers for enzymes immobilization: a review, Int. J. Biol. Macromol. 120 (2018) 2530–2544. [11] X. Liu, L. Lei, Y. Li, H. Zhu, Y. Cui, H. Hu, Preparation of carriers based on magnetic nanoparticles grafted polymer and immobilization for lipase, Biochem. Eng. J. 56 (2011) 142–149. [12] J. Zhang, H. Mao, M. Li, E. Su, Cyclodextrin glucosyltransferase immobilization on polydopamine-coated Fe3O4 nanoparticles in the presence of polyethyleneimine for efficient β-cyclodextrin production, Biochem. Eng. J. 150 (2019), 107264. [13] J. Cui, S. Ren, B. Sun, S. Jia, Optimization protocols and improved strategies for metal-organic frameworks for immobilizing enzymes: current development and future challenges, Coord. Chem. Rev. 370 (2018) 22–41. [14] S. Liang, X.-L. Wu, J. Xiong, M.-H. Zong, W.-Y. Lou, Metal-organic frameworks as novel matrices for efficient enzyme immobilization: an update review, Coord. Chem. Rev. 406 (2020), 213149. [15] Y. Hu, L. Dai, D. Liu, W. Du, Y. Wang, Progress & prospect of metal-organic frameworks (MOFs) for enzyme immobilization (enzyme/MOFs), Renew. Sustain. Energy Rev. 91 (2018) 793–801. [16] X. Liu, W. Chen, M. Lian, X. Chen, Y. Lu, W. Yang, Enzyme immobilization on ZIF67/MWCNT composite engenders high sensitivity electrochemical sensing, J. Electroanal. Chem. 833 (2019) 505–511. [17] S. Rafiei, S. Tangestaninejad, P. Horcajada, M. Moghadam, V. Mirkhani, I. Mohammadpoor-Baltork, R. Kardanpour, F. Zadehahmadi, Efficient biodiesel production using a lipase@ZIF-67 nanobioreactor, Chem. Eng. J. 334 (2018) 1233–1241. [18] M. Bilal, H.M.N. Iqbal, Naturally-derived biopolymers: potential platforms for enzyme immobilization, Int. J. Biol. Macromol. 130 (2019) 462–482. [19] H. Cao, J. Xiao, H. Liu, Enhanced oxidase-like activity of selenium nanoparticles stabilized by chitosan and application in a facile colorimetric assay for mercury (II), Biochem. Eng. J. 152 (2019), 107384. [20] A.A. Saei, J.E.N. Dolatabadi, P. Najafi-Marandi, A. Abhari, M. de la Guardia, Electrochemical biosensors for glucose based on metal nanoparticles, TrAC, Trends Anal. Chem. 42 (2013) 216–227. Immobilization of enzymes on zeolites can improve the stability of enzymes (including pH, heat, storage, etc.), reduce the cost by recovery and reuse of biocatalyst, and sometimes enhance their activity, which consequently exhibits broad industrial application prospects. Zeolites will continue to be important supports for enzymes, in both industry and academia. However, high enzyme loading does not necessarily mean high activity in practical application. Many enzymes become inactivated due to the conformational change or the inaccessibility of the active sites after immobilization. Therefore, in addition to the yield and stability of immobilized enzyme, many other issues such as the possible confor­ mational changes of enzymes, the exposure of active sites, the diffusion and mass transfer performance of composite materials, should also be considered. In the aspect of material design,aforementioned zeolites with special structures are still the focus in future. The Si/Al ratio, morphology, texture and surface property of zeolites have significant influence on their affinity to enzyme, immobilization yield and enzymatic activity retention. For example, different pore structures on the external surface of zeolites may prefer different sidechains of enzymes, which results in different conformational impact and thus different activity retention. In addition, introducing additional functional components into composites can enhance the property of biocatalysts to a certain extent. For example, carbon nanotubes, graphene, conductive polymers can pro­ mote electron transfer and enhance the catalytic activity of materials; sol-gel and organic polymers can improve the immobilization efficiency of enzymes and prevent the enzyme from leaching and deactivation. In the aspect of immobilization strategy, one of the key problems that need further study is to make the immobilized enzyme as close to its natural conformation as possible because the enzyme molecule with natural conformation in general has the best activity. New immobili­ zation strategies that cause little damage to enzyme’s structure, like the spray drying technology proposed by Debecker’s group, are the impor­ tant directions for future efforts. In the aspect of application of composite catalyst, cascade catalytic reaction is one of the main directions in future. Combining zeolite ma­ terials with chemical catalytic activity with enzymes, or fixing multiple enzymes on zeolites, can achieve cascade reactions by utilizing the product of one catalytic reaction as the reactant for another, which is of great significance in improving catalytic reaction efficiency, simplifying industrial process and reducing production costs. The key point lies in how to reserve certain porosity and expose the chemical catalytic sites in zeolite after enzyme immobilization. One potential solution is to control the coverage rate of enzyme on zeolite by regulating the dosage ratio of enzyme and zeolite, which can be estimated by analyzing the size of enzyme molecule and the external surface of zeolite support. 9 H. Zhang et al. Biochemical Engineering Journal 172 (2021) 108033 [21] L. Wu, S. Wu, Z. Xu, Y. Qiu, S. Li, H. Xu, Modified nanoporous titanium dioxide as a novel carrier for enzyme immobilization, Biosens. Bioelectron. 80 (2016) 59–66. [22] M.F. Khan, D. Kundu, C. Hazra, S. Patra, A strategic approach of enzyme engineering by attribute ranking and enzyme immobilization on zinc oxide nanoparticles to attain thermostability in mesophilic Bacillus subtilis lipase for detergent formulation, Int. J. Biol. Macromol. 136 (2019) 66–82. [23] N. Zou, J. Plank, Intercalation of cellulase enzyme into a hydrotalcite layer structure, J. Phys. Chem. Solids 76 (2015) 34–39. [24] G. Silva Dias, P.T. Bandeira, S. Jaerger, L. Piovan, D.A. Mitchell, F. Wypych, N. Krieger, Immobilization of Pseudomonas cepacia lipase on layered double hydroxide of Zn/Al-Cl for kinetic resolution of rac-1-phenylethanol, Enzyme Microb. Technol. 130 (2019), 109365. [25] D. Pandey, A. Daverey, K. Arunachalam, Biochar: production, properties and emerging role as a support for enzyme immobilization, J. Clean. Prod. 255 (2020), 120267. [26] A.-X. Yan, X.-W. Li, Y.-H. Ye, Recent progress on immobilization of enzymes on molecular sieves for reactions in organic solvents, Appl. Biochem. Biotechnol. 101 (2002) 113–129. [27] Y. Lim, J. Yu, S. Park, M. Kim, S. Chen, N.A.B. Bakri, N.I.A.B.M. Sabri, S. Bae, H. S. Kim, Development of biocatalysts immobilized on coal ash-derived Ni-zeolite for facilitating 4-chlorophenol degradation, Bioresour. Technol. 307 (2020), 123201. [28] L. Costa, V. Brissos, F. Lemos, F. Ramôa Ribeiro, J.M.S. Cabral, Enhancing the thermal stability of lipases through mutagenesis and immobilization on zeolites, Bioprocess Biosyst. Eng. 32 (2009) 53–61. [29] H.R. Wehaidy, M.A. Abdel-Naby, H.M. El-Hennawi, H.F. Youssef, Nanoporous Zeolite-X as a new carrier for laccase immobilization and its application in dyes decolorization, Biocatal. Agric. Biotechnol. 19 (2019), 101135. [30] G.-W. Xing, X.-W. Li, G.-L. Tian, Y.-H. Ye, Enzymatic peptide synthesis in organic solvent with different zeolites as immobilization matrixes, Tetrahedron 56 (2000) 3517–3522. [31] A. de Vasconcellos, J. Bergamasco Laurenti, A.H. Miller, D.A. da Silva, F. Rogério de Moraes, D.A.G. Aranda, J.G. Nery, Potential new biocatalysts for biofuel production: the fungal lipases of Thermomyces lanuginosus and Rhizomucor miehei immobilized on zeolitic supports ion exchanged with transition metals, Microporous Mesoporous Mater. 214 (2015) 166–180. [32] D.P. Debecker, V. Smeets, M. Van der Verren, H. Meersseman Arango, M. Kinnaer, F. Devred, Hybrid chemoenzymatic heterogeneous catalysts, Curr. Opin. Green Sust. Chem. 28 (2021), 100437. [33] P.N.R. Vennestrøm, E. Taarning, C.H. Christensen, S. Pedersen, J.-D. Grunwaldt, J.M. Woodley, Chemoenzymatic combination of glucose oxidase with titanium silicalite-1, ChemCatChem 2 (2010) 943–945. [34] V. Smeets, W. Baaziz, O. Ersen, E.M. Gaigneaux, C. Boissière, C. Sanchez, D. Debecker, Hollow zeolite microspheres as a nest for enzymes: a new route to hybrid heterogeneous catalysts for chemo-enzymatic cascade reactions, Chem. Sci. 11 (2020) 954–961. [35] M. Talebi, S. Vaezifar, F. Jafary, M. Fazilati, S. Motamedi, Stability improvement of immobilized α-amylase using nano pore zeolite, Iran. J. Biotechnol. 14 (2016) 33–38. [36] F.N. Serralha, J.M. Lopes, F. Lemos, D.M.F. Prazeres, M.R. Aires-Barros, J.M. S. Cabral, F. Ramôa Ribeiro, Zeolites as supports for an enzymatic alcoholysis reaction, J. Mol. Catal., B Enzym. 4 (1998) 303–311. [37] F.N. Serralha, J.M. Lopes, F. Lemos, D.M.F. Prazeres, M.R. Aires-Barros, J.M. S. Cabral, F. Ramôa Ribeiro, Kinetics and modelling of an alcoholysis reaction catalyzed by cutinase immobilized on NaY zeolite, J. Mol. Catal., B Enzym. 11 (2001) 713–718. [38] F.N. Serralha, J.M. Lopes, F. Lemos, F. Ramôa Ribeiro, D.M.F. Prazeres, M. R. Aires-Barros, J.M.S. Cabral, Application of factorial design to the study of an alcoholysis transformation promoted by cutinase immobilized on NaY zeolite and Accurel PA6, J. Mol. Catal., B Enzym. 27 (2004) 19–27. [39] F.N. Serralha, J.M. Lopes, M.R. Aires-Barros, D.M.F. Prazeres, J.M.S. Cabral, F. Lemos, F. Ramôa Ribeiro, Stability of a recombinant cutinase immobilized on zeolites, Enzyme Microb. Technol. 31 (2002) 29–34. [40] A.P.V. Gonçalves, J.M. Lopes, F. Lemos, F. Ramôa Ribeiro, D.M.F. Prazeres, J.M. S. Cabral, M.R. Aires-Barros, Effect of the immobilization support on the hydrolytic activity of a cutinase from Fusarium solani pisi, Enzyme Microb. Technol. 20 (1997) 93–101. [41] A.P.V. Gonçalves, J.M. Lopes, F. Lemos, F. Ramôa Ribeiro, D.M.F. Prazeres, J.M. S. Cabral, M.R. Aires-Barros, Zeolites as supports for enzymatic hydrolysis reactions. Comparative study of several zeolites, J. Mol. Catal., B Enzym. 1 (1996) 53–60. [42] J. Dong, X. Zhou, H. Zhao, J. Xu, Y. Sun, Reagentless amperometric glucose biosensor based on the immobilization of glucose oxidase on a ferrocene@NaY zeolite composite, Microchimica Acta 174 (2011) 281–288. [43] B. Liu, R. Hu, J. Deng, Characterization of immobilization of an enzyme in a modified Y zeolite matrix and its application to an amperometric glucose biosensor, Anal. Chem. 69 (1997) 2343–2348. [44] J. Wang, A. Walcarius, Zeolite containing oxidase-based carbon paste biosensors, J. Electroanal. Chem. 404 (1996) 237–242. [45] A. Care, K. Petroll, E.S.Y. Gibson, P.L. Bergquist, A. Sunna, Solid-binding peptides for immobilisation of thermostable enzymes to hydrolyse biomass polysaccharides, Biotechnol. Biofuels 10 (2017) 29. [46] R.H. Carvalho, F. Lemos, M.A.N.D.A. Lemos, J.M.S. Cabral, F. Ramôa Ribeiro, Electro-oxidation of phenol on a new type of zeolite/graphite biocomposite electrode with horseradish peroxidase, J. Mol. Catal. A Chem. 278 (2007) 47–52. [47] N.M. Mahmoodi, M.H. Saffar-Dastgerdi, B. Hayati, Environmentally friendly novel covalently immobilized enzyme bionanocomposite: from synthesis to the destruction of pollutant, Composites Part B 184 (2020), 107666. [48] N.M. Mahmoodi, M.H. Saffar-Dastgerdi, Clean Laccase immobilized nanobiocatalysts (graphene oxide - zeolite nanocomposites): from production to detailed biocatalytic degradation of organic pollutant, Appl. Catal. B 268 (2020), 118443. [49] O. Celikbicak, G. Bayramoglu, M. Yılmaz, G. Ersoy, N. Bicak, B. Salih, M.Y. Arica, Immobilization of laccase on hairy polymer grafted zeolite particles: degradation of a model dye and product analysis with MALDI–ToF-MS, Microporous Mesoporous Mater. 199 (2014) 57–65. [50] T. Taghizadeh, A. Talebian-Kiakalaieh, H. Jahandar, M. Amin, S. Tarighi, M. A. Faramarzi, Biodegradation of bisphenol A by the immobilized laccase on some synthesized and modified forms of zeolite Y, J. Hazard. Mater. 386 (2020), 121950. [51] V.R.R. Marthala, L. Urmoneit, Z. Zhou, A.G.F. Machoke, M. Schmiele, T. Unruh, W. Schwieger, M. Hartmann, Boron-containing MFI-type zeolites with a hierarchical nanosheet assembly for lipase immobilization, Dalton Trans. 46 (2017) 4165–4169. [52] V.R.R. Marthala, M. Friedrich, Z. Zhou, M. Distaso, S. Reuss, S.A. Al-Thabaiti, W. Peukert, W. Schwieger, M. Hartmann, Zeolite-coated porous arrays: a novel strategy for enzyme encapsulation, Adv. Funct. Mater. 25 (2015) 1832–1836. [53] S. Mitchell, J. Pérez-Ramírez, Mesoporous zeolites as enzyme carriers: synthesis, characterization, and application in biocatalysis, Catal. Today 168 (2011) 28–37. [54] S. Mitchell, A. Bonilla, J. Pérez-Ramírez, Preparation of organic-functionalized mesoporous ZSM-5 zeolites by consecutive desilication and silanization, Mater. Chem. Phys. 127 (2011) 278–284. [55] A. Macario, G. Giordano, P. Frontera, F. Crea, L. Setti, Hydrolysis of alkyl ester on lipase/silicalite-1 catalyst, Catal. Lett. 122 (2008) 43–52. [56] A. MacArio, G. Giordano, L. Setti, A. Parise, J.M. Campelo, J.M. Marinas, D. Luna, Study of lipase immobilization on zeolitic support and transesterification reaction in a solvent free-system, Biocatal. Biotransform. 25 (2007) 328–335. [57] A. Macario, M. Moliner, U. Diaz, J.L. Jorda, A. Corma, G. Giordano, Biodiesel production by immobilized lipase on zeolites and related materials, in: a. Gédéon, in: P. Massiani, F. Babonneau (Eds.), Stud. Surf. Sci. Catal., Elsevier, 2008, pp. 1011–1016. [58] A. Macario, A. Katovic, G. Giordano, L. Forni, F. Carloni, A. Filippini, L. Setti, Immobilization of lipase on microporous and mesoporous materials: studies of the support surfaces, in: A. Gamba, C. Colella, S. Coluccia (Eds.), Stud. Surf. Sci. Catal., Elsevier, 2005, pp. 381–394. [59] E. Lie, G. Molin, Hydrolysis and esterification with immobilized lipase on hydrophobic and hydrophilic zeolites, J. Chem. Technol. Biotechnol. 50 (1991) 549–553. [60] C. Calgaroto, R.P. Scherer, S. Calgaroto, J.V. Oliveira, D. de Oliveira, S.B. C. Pergher, Immobilization of porcine pancreatic lipase in zeolite MCM 22 with different Si/Al ratios, Appl. Catal. A 394 (2011) 101–104. [61] A. de Vasconcellos, A.S. Paula, R.A. Luizon Filho, L.A. Farias, E. Gomes, D.A. G. Aranda, J.G. Nery, Synergistic effect in the catalytic activity of lipase Rhizomucor miehei immobilized on zeolites for the production of biodiesel, Microporous Mesoporous Mater. 163 (2012) 343–355. [62] A. de Vasconcellos, A.H. Miller, D.A.G. Aranda, J.G. Nery, Biocatalysts based on nanozeolite-enzyme complexes: effects of alkoxysilane surface functionalization and biofuel production using microalgae lipids feedstock, Colloids Surf. B Biointerfaces 165 (2018) 150–157. [63] Z. Knezevic, L. Mojovic, B. Adnadjevic, Palm oil hydrolysis by lipase from Candida cylindracea immobilized on zeolite type Y, Enzyme Microb. Technol. 22 (1998) 275–280. [64] Y.K. Chang, L. Chu, A simple method for cell disruption by immobilization of lysozyme on the extrudate-shaped NaY zeolite, Biochem. Eng. J. 35 (2007) 37–47. [65] S.Y. Lee, P.L. Show, C.-M. Ko, Y.-K. Chang, A simple method for cell disruption by immobilization of lysozyme on the extrudate-shaped Na-Y zeolite: recirculating packed bed disruption process, Biochem. Eng. J. 141 (2019) 210–216. [66] K.L. Avery, C. Peixoto, M. Barcellona, M.T. Bernards, H.K. Hunt, Lysozyme sorption by pure-silica zeolite MFI films, Mater. Today Commun. 19 (2019) 352–359. [67] A. Kawai, Y. Urabe, T. Itoh, F. Mizukami, Immobilization of lysozyme on the layered silicate RUB-15, Mater. Chem. Phys. 122 (2010) 269–272. [68] K. Mukhopadhyay, S. Phadtare, V.P. Vinod, A. Kumar, M. Rao, R.V. Chaudhari, M. Sastry, Gold nanoparticles assembled on amine-functionalized Na− Y zeolite: a biocompatible surface for enzyme immobilization, Langmuir 19 (2003) 3858–3863. [69] A. Kumari, B. Kaur, R. Srivastava, R.S. Sangwan, Isolation and immobilization of alkaline protease on mesoporous silica and mesoporous ZSM-5 zeolite materials for improved catalytic properties, Biochem. Biophys. Rep. 2 (2015) 108–114. [70] S. Phadtare, V.P. Vinod, K. Mukhopadhyay, A. Kumar, M. Rao, R.V. Chaudhari, M. Sastry, Immobilization and biocatalytic activity of fungal protease on gold nanoparticle-loaded zeolite microspheres, Biotechnol. Bioeng. 85 (2004) 629–637. [71] A. Corma, V. Fornes, F. Rey, Delaminated zeolites: an efficient support for enzymes, Adv. Mater. 14 (2002) 71–74. [72] K. Petroll, A. Care, P.L. Bergquist, A. Sunna, A novel framework for the cell-free enzymatic production of glucaric acid, Metab. Eng. 57 (2020) 162–173. [73] F. Alfani, L. Cantarella, M. Cantarella, A. Gallifuoco, C. Colella, Synthetic zeolites as carrier for enzyme immobilization in laboratory-scale fixedbed columns, in: 10 H. Zhang et al. [74] [75] [76] [77] [78] [79] [80] [81] [82] [83] [84] [85] [86] [87] [88] [89] [90] [91] [92] Biochemical Engineering Journal 172 (2021) 108033 J. Weitkamp, H.G. Karge, H. Pfeifer, W. Hölderich (Eds.), Stud. Surf. Sci. Catal., Elsevier, 1994, pp. 1115–1122. W. Zhang, F. Xu, D. Wang, Fabrication of phospho-phytase/heteroatomic hierarchical Fe-ZSM-5 zeolite (HHFeZ) bio-conjugates for eco-sustainable utilization of phytate-phosphorus, RSC Adv. 4 (2014) 16528–16536. V. Khojaewa, O. Lopatin, P. Zelenikhin, O. Ilinskaya, Zeolites as carriers of antitumor ribonuclease binase, Front. Pharmacol. 10 (2019), 442–442. Y. Huang, W. Shan, B. Liu, Y. Liu, Y. Zhang, Y. Zhao, H. Lu, Y. Tang, P. Yang, Zeolite nanoparticle modified microchip reactor for efficient protein digestion, Lab Chip 6 (2006) 534–539. G. Seetharam, B.A. Saville, l-DOPA production from tyrosinase immobilized on zeolite, Enzyme Microb. Technol. 31 (2002) 747–753. L. Donato, C. Algieri, V. Miriello, R. Mazzei, G. Clarizia, L. Giorno, Biocatalytic zeolite membrane for the production of l-DOPA, J. Membr. Sci. 407–408 (2012) 86–92. M.V. Cattaneo, T.M. Chang, The potential of a microencapsulated urease-zeolite oral sorbent for the removal of urea in uremia, ASAIO Trans. 37 (1991) 80–87. O.Y. Saiapina, V.M. Pyeshkova, O.O. Soldatkin, V.G. Melnik, B.A. Kurç, A. Walcarius, S.V. Dzyadevych, N. Jaffrezic-Renault, Conductometric enzyme biosensors based on natural zeolite clinoptilolite for urea determination, Mater. Sci. Eng., C 31 (2011) 1490–1497. S.K. Kirdeciler, E. Soy, S. Öztürk, I. Kucherenko, O. Soldatkin, S. Dzyadevych, B. Akata, A novel urea conductometric biosensor based on zeolite immobilized urease, Talanta 85 (2011) 1435–1441. O.O. Soldatkin, E. Soy, A. Errachid, N. Jaffrezic-Renault, B. Akata, A.P. Soldatkin, S.V. Dzyadevych, Influence of composition of zeolite/enzyme nanobiocomposites on analytical characteristics of urea biosensor based on ion-selective field-effect transistors, Sensor Lett. 9 (2011) 2320–2326. O.O. Soldatkin, I.S. Kucherenko, S.V. Marchenko, B. Ozansoy Kasap, B. Akata, A. P. Soldatkin, S.V. Dzyadevych, Application of enzyme/zeolite sensor for urea analysis in serum, Mater. Sci. Eng. C 42 (2014) 155–160. I. Kucherenko, O. Soldatkin, B.O. Kasap, S.K. Kirdeciler, B.A. Kurc, N. JaffrezicRenault, A. Soldatkin, F. Lagarde, S. Dzyadevych, Nanosized zeolites as a perspective material for conductometric biosensors creation, Nanoscale Res. Lett. 10 (2015) 209. O.V. Soldatkina, I.S. Kucherenko, O.O. Soldatkin, V.M. Pyeshkova, O. Y. Dudchenko, B. Akata Kurç, S.V. Dzyadevych, Development of electrochemical biosensors with various types of zeolites, Appl. Nanosci. 9 (2019) 737–747. L.F. Atyaksheva, I.A. Kasyanov, I.I. Ivanova, Adsorptive immobilization of proteins on mesoporous molecular sieves and zeolites, Petrol. Chem. 59 (2019) 327–337. M. Matsui, Y. Kiyozumi, Y. Mizushina, K. Sakaguchi, F. Mizukami, Adsorption and desorption behavior of basic proteins on zeolites, Sep. Purif. Technol. 149 (2015) 103–109. Y. Li, X. Liao, X. Zhang, G. Ma, S. Zuo, L. Xiao, G.D. Stucky, Z. Wang, X. Chen, X. Shang, J. Fan, In situ generated thrombin in the protein corona of zeolites: relevance of the functional proteins to its biological impact, Nano Res. 7 (2014) 1457–1465. F. Yagiz, D. Kazan, A.N. Akin, Biodiesel production from waste oils by using lipase immobilized on hydrotalcite and zeolites, Chem. Eng. J. 134 (2007) 262–267. L. van den Biggelaar, P. Soumillion, D.P. Debecker, Biocatalytic transamination in a monolithic flow reactor: improving enzyme grafting for enhanced performance, RSC Adv. 9 (2019) 18538–18546. N. Brun, A. Babeau Garcia, H. Deleuze, M.F. Achard, C. Sanchez, F. Durand, V. Oestreicher, R. Backov, Enzyme-based hybrid macroporous foams as highly efficient biocatalysts obtained through integrative chemistry, Chem. Mater. 22 (2010) 4555–4562. M. Planchestainer, M.L. Contente, J. Cassidy, F. Molinari, L. Tamborini, F. Paradisi, Continuous flow biocatalysis: production and in-line purification of [93] [94] [95] [96] [97] [98] [99] [100] [101] [102] [103] [104] [105] [106] [107] [108] [109] [110] 11 amines by immobilised transaminase from Halomonas elongata, Green Chem. 19 (2017) 372–375. H. Zhang, H. Li, K. Wang, Q. Xia, D. Zhou, Efficient protein delivery systems based on hierarchical zeolite microspheres constructed by MWW-nanosheets, Microporous Mesoporous Mater. 298 (2020), 110098. D.-Z. Dai, L.-M. Xia, Enzymatic resolution of (R, S) -2-Octanol by Ultrastable-Y molecular sieve immobilized-lipase in microaqueous media, Chem. J. Chin. U. 28 (2007) 2307–2310. R.A. Sheldon, S. van Pelt, Enzyme immobilisation in biocatalysis: why, what and how, Chem. Soc. Rev. 42 (2013) 6223–6235. L. Bacakova, M. Vandrovcova, I. Kopova, I. Jirka, Applications of zeolites in biotechnology and medicine – a review, Biomater. Sci. 6 (2018) 974–989. N. Vilaça, A.F. Machado, F. Morais-Santos, R. Amorim, A. Patrícia Neto, E. Logodin, M.F.R. Pereira, M. Sardo, J. Rocha, P. Parpot, A.M. Fonseca, F. Baltazar, I.C. Neves, Comparison of different silica microporous structures as drug delivery systems for in vitro models of solid tumors, RSC Adv. 7 (2017) 13104–13111. O.O. Soldatkin, M.K. Shelyakina, V.N. Arkhypova, E. Soy, S.K. Kirdeciler, B. Ozansoy Kasap, F. Lagarde, N. Jaffrezic-Renault, B. Akata Kurç, A.P. Soldatkin, S.V. Dzyadevych, Nano- and microsized zeolites as a perspective material for potentiometric biosensors creation, Nanoscale Res. Lett. 10 (2015) 59. P. Pinyou, V. Blay, L.M. Muresan, T. Noguer, Enzyme-modified electrodes for biosensors and biofuel cells, Mater. Horiz. 6 (2019) 1336–1358. R.H. Carvalho, F. Lemos, J.M.S. Cabral, F.R. Ribeiro, Influence of the presence of NaY zeolite on the activity of horseradish peroxidase in the oxidation of phenol, J. Mol. Catal., B Enzym. 44 (2007) 39–47. W.J. Roth, P. Nachtigall, R.E. Morris, J. Čejka, Two-dimensional zeolites: current status and perspectives, Chem. Rev. 114 (2014) 4807–4837. X. Jia, W. Khan, Z. Wu, J. Choi, A.C.K. Yip, Modern synthesis strategies for hierarchical zeolites: bottom-up versus top-down strategies, Adv. Powder Technol. 30 (2019) 467–484. M. Choi, K. Na, J. Kim, Y. Sakamoto, O. Terasaki, R. Ryoo, Stable single-unit-cell nanosheets of zeolite MFI as active and long-lived catalysts, Nature 461 (2009) 246–249. A.G. Machoke, I.Y. Knoke, S. Lopez-Orozco, M. Schmiele, T. Selvam, V.R. R. Marthala, E. Spiecker, T. Unruh, M. Hartmann, W. Schwieger, Synthesis of multilamellar MFI-type zeolites under static conditions: the role of gel composition on their properties, Microporous Mesoporous Mater. 190 (2014) 324–333. D. Zhou, T. Zhang, Q. Xia, Y. Zhao, K. Lv, X. Lu, R. Nie, One-pot rota-crystallized hollownest-structured Ti–zeolite: a calcination-free and recyclable catalytic material, Chem. Sci. 7 (2016) 4966–4972. D. Deepika, J. PonnanEttiyappan, Synthesis and characterization of microporous hollow core-shell silica nanoparticles (HCSNs) of tunable thickness for controlled release of doxorubicin, J. Nanopart. Res. 20 (2018). C. Dai, A. Zhang, C. Song, X. Guo, Chapter Two - Advances in the synthesis and catalysis of solid and hollow zeolite-encapsulated metal catalysts, in: C. Song (Ed.), Adv. Catal., Academic Press, 2018, pp. 75–115. M.W. Zhao, Y.A. Gao, L.Q. Zheng, W.P. Kang, X.T. Bai, B. Dong, Microporous silica hollow microspheres and hollow worm-like materials: a simple method for their synthesis and their application in controlled release, Eur. J. Inorg. Chem. (2010) 975–982. C. Pagis, A.R.M. Prates, D. Farrusseng, N. Bats, A. Tuel, Hollow zeolite structures: an overview of synthesis methods, Chem. Mater. 28 (2016) 5205–5223. M. Van der Verren, V. Smeets, A. vander Straeten, C. Dupont-Gillain, D. P. Debecker, Hybrid chemoenzymatic heterogeneous catalyst prepared in one step from zeolite nanocrystals and enzyme–polyelectrolyte complexes, Nanoscale Adv. 3 (2021) 1646–1655.